Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > PCB Reliability: A Comprehensive Guide

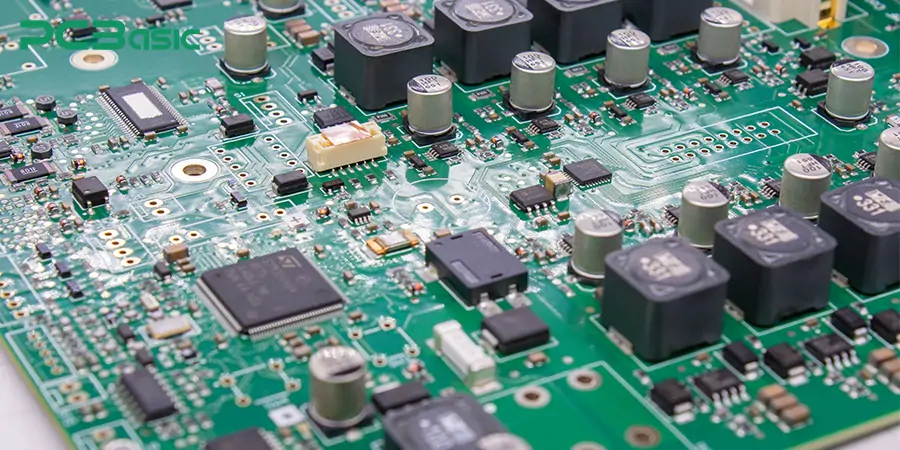

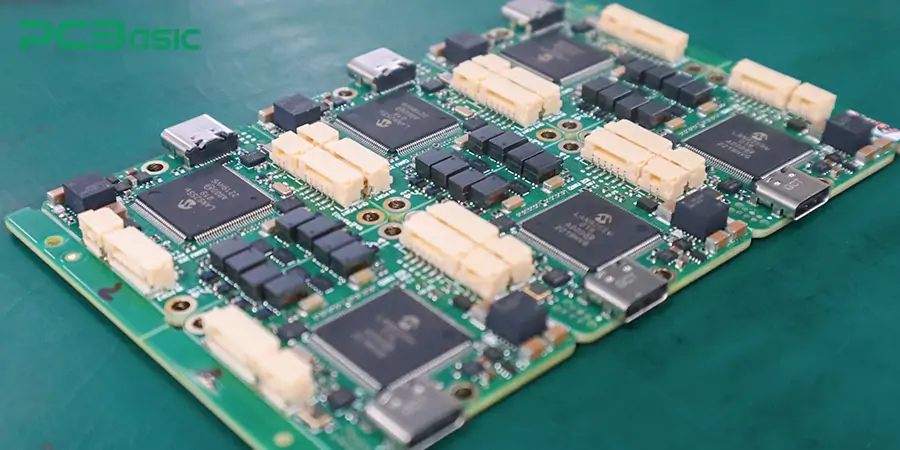

PCB Reliability is an important indicator for measuring the overall quality and competitiveness of electronic products. Printed circuit boards are the core carrying platforms of various electronic systems. It is not only responsible for carrying and connecting complex electronic components, but also directly affects the stability, durability and safety of the entire machine. Whether it is medical equipment with extremely high requirements or industrial automation systems that operate for long periods, highly reliable PCB design and manufacturing are the key to ensuring for the stable operation of products.

However, circuit boards need to withstand complex and changeable working environments for a long time in practical applications, including high and low temperature cycling, vibration and shock, electrical overload, moisture and corrosion, and various environmental stresses. Just how reliable can a PCB be? Today, we will explore this topic in depth. We will discuss this topic from the aspects of systematic PCB reliability testing, rigorous design criteria, etc. A comprehensive understanding and control of the PCB reliability management system have become the core competitiveness for building high-reliability PCB assembly capabilities. So, what is PCB reliability?

PCB reliability refers to the ability of a circuit board to operate stably and continuously without failure throughout its entire expected life cycle under various environmental and working conditions. This capability will not fail or experience performance degradation due to environmental stress, thermal cycling, electrical load or long-term operation. Generally, highly reliable PCB assembly is particularly important for critical applications such as automotive electronics, industrial control, aerospace, and medical equipment. Because these fields cannot tolerate any malfunction.

To achieve the reliability of PCBs, efforts need to be made in multiple aspects such as PCB design, the selection of high-quality raw materials, and the manufacturing process. Typical PCB reliability testing items include mechanical stress testing, thermal shock testing, and electrical overstress testing, simulating various harsh usage environments. Different PCB reliability testing standards (such as IPC, JEDEC, MIL-STD, etc.) have defined detailed certification and testing requirements for different industries. With advanced PCB testing services and complete PCB testing solutions, manufacturers can effectively detect potential defects at an early stage, reduce production risks, and ensure excellent PCB quality. So, what are the core factors that affect the reliability of PCBs?

Every decision made in the PCB development life cycle will directly affect the long-term performance of the circuit board. Systematic PCB reliability analysis is crucial throughout the entire process. The key factors affecting the reliability of PCBs are:

1. Material selection

The foundation of PCB reliability begins with the correct selection of materials. The type of board, the thickness of copper foil, and the selection of dielectric materials will all affect the performance of the circuit board. If the material selection is improper, it is easy to lead to solder joint failure, poor conduction and an increase in failure rate.

2. PCB design

Good design practices are at the core of achieving highly reliable PCBs. Factors such as the width of the wiring, the spacing, and the heat dissipation layout will all directly affect the electrical stability and mechanical strength. Introducing the principle of PCB design reliability in the early stage of design helps to identify and avoid potential failure risks before mass production.

3. Manufacturing process

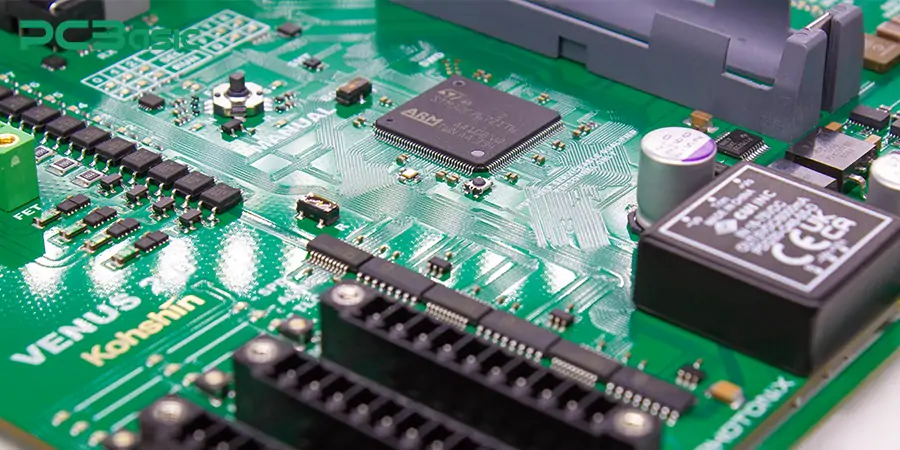

Consistency in manufacturing processes is the basis for ensuring the quality of PCBs. The precise execution of each process such as drilling, electroplating, etching and surface treatment can effectively avoid problems such as delamination, open circuits and welding defects.

4. Assembly process

A reliable assembly process will directly determine the consistency and stability of the solder joints. Many manufacturers adopt advanced PCB testing services and online PCB testing solutions during the assembly process. This way, potential defects can be detected and eliminated in a timely manner at an early stage.

5. Environment and Operating Conditions

PCBs need to withstand complex environments and working conditions in practical applications, including temperature fluctuations, humidity changes, mechanical shocks and vibrations, etc. Comprehensive PCB reliability testing verifies the long-term durability performance of circuit boards by simulating real working conditions.

Why is it necessary to understand the common PCB failures? Understanding common PCB failures is helpful for conducting effective PCB reliability tests. Common PCB faults include:

Thermal cycling and expansion stress: Repeated temperature changes can cause materials to expand and contract, thereby leading to cracks or solder joint fatigue.

Mechanical stress and fatigue: Vibration or bending can damage structures such as wires and vias.

Electrical stress (EOS) and electrostatic discharge (ESD): Voltage spikes can damage components or board structures.

Ion contamination and corrosion: Ion residues can easily lead to problems such as corrosion and leakage current.

Delamination, cracking and solder joint failure: Insufficient adhesion or material mismatch can cause delamination of PCBs.

CAF (Anode Conductive filament) growth: The growth of conductive channels within the plate can cause short circuits.

Moisture absorption and degassing: Residual moisture under thermal stress can lead to problems such as board explosion and bubbling.

There are many methods to ensure the reliability of PCBs. Through systematic PCB reliability testing methods, manufacturers can accurately evaluate the performance of PCBs under various complex working conditions during the R&D, production and delivery stages. In this way, manufacturers can promptly identify potential defects, thereby continuously optimizing design, processes and quality control to ensure that the final products have stable, durable and reliable performance. PCB reliability testing includes:

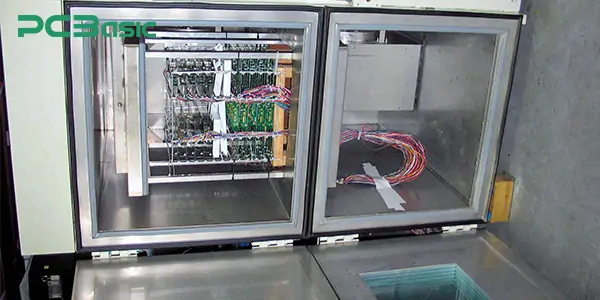

1. Thermal Cycling Test

The thermal cycling test is a fundamental and key item in the PCB reliability test standard system. The purpose of this test is to simulate the thermo-mechanical fatigue stress of PCBs under long-term repeated high and low-temperature changes and to verify their durability performance. The main tested parameters include:

Temperature range: -40℃ to +125℃. Some high-end applications can be extended to -55℃to +150℃.

Cycle count: 500 to 1000 times. Aerospace/automotive electronics usually require high cycle standards.

Main failure modes: solder joint cracking, Delamination, Barrel Crack, welding fatigue, etc.

Thermal cycling testing is widely used in typical high reliability PCB verification scenarios such as automobiles, aviation, and military electronics.

2. Damp Heat Test

The damp heat test assesses the material stability, electrical insulation performance and long-term reliability of PCBs under the combined environment of high temperature and high humidity. This test belongs to an important verification method in the development stage of PCB design reliability. The conditions of typical tests include:

Temperature: 85℃

Humidity: 85% RH

Test cycle: More than 1,000 hours;

Main failure mechanisms: moisture absorption and expansion of materials, metal migration, ionization contamination, blistering of the solder mask layer, etc.

Through the wet heat aging test, the chemical stability issues of the PCB material itself can be effectively exposed. It is a necessary link in many PCB reliability testing certifications.

3. Salt Spray Test

Salt spray testing mainly focuses on the protective ability of PCBs in corrosive environments, and is particularly suitable for high-reliability PCB assembly application scenarios in special industries such as marine equipment, marine electronics, military radars, avionics, and communication antennas. The key parameters include:

Salt spray concentration

Spray duration

Test the ambient temperature (generally around 35℃).

The objective of this inspection is to expose potential hazards such as PCB conductor corrosion, solder joint oxidation, and protective coating failure, ensuring the stability of PCB quality during long-term use.

4. Electromigration & SIR Test

Electromigration and Surface Insulation Resistance (SIR) tests are core assessment indicators for long-term insulation reliability, especially for high-density wiring PCBs and high-voltage control boards in humid environments. The test process includes:

Continuous power supply under high temperature and high humidity (such as 85℃/85%RH) and bias voltage;

Continuously monitor the insulation resistance value;

Analyze whether the metal migration path forms a short-circuit hazard (such as CAF growth).

This type of test is directly related to the professionalism of PCB test solutions and the reliability control capabilities in the high-end electronic field.

5. Vibration & Mechanical Shock Test

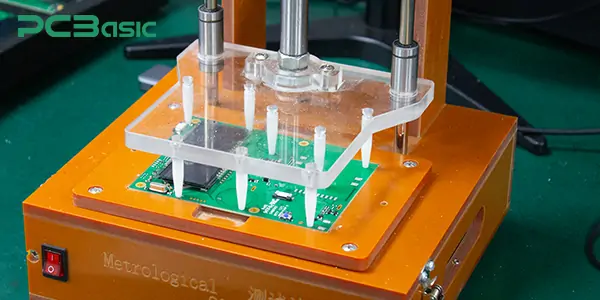

Vibration and mechanical shock tests are used to simulate the mechanical loads that PCBs bear under transportation, operation and vibration conditions, and to verify the stability of their physical structure. It is particularly suitable for automotive electronic control modules (ECUs), military communication systems, industrial control equipment, etc. This test usually covers multi-axis vibration frequency scanning and high G-value impact strokes. It is mainly used to screen out common mechanical failure modes such as cold solder joints or poor soldering connections, solder ball fatigue, device pin breakage, and trace cracking.

6. Thermal Shock Test

Unlike thermal cycling, thermal shock testing emphasizes rapid and sudden changes in high and low temperatures within a short period of time to examine the stress mismatch caused by the differences in thermal expansion coefficients of different materials. The application purposes include:

Inspect the thermal mismatch failure of the welding interface;

Inspect the peeling or cracking of the PTH coating on the through hole;

Inspect the interlayer separation of the composite laminate.

This test is directly related to the process adaptability and safety of high reliability PCBs in extreme temperature variation environments.

7. Highly Accelerated Life Test

Highly Accelerated Life Testing (HALT) effectively exposes the early potential failure points of products through rapidly accelerated aging under extreme conditions. It is an important PCB reliability analysis tool for early reliability assessment in development. The core contents include:

Rapid heating and cooling cycle

Rapid vibration loading

Limiting voltage and current impulse

Over-specification wet heat pressure

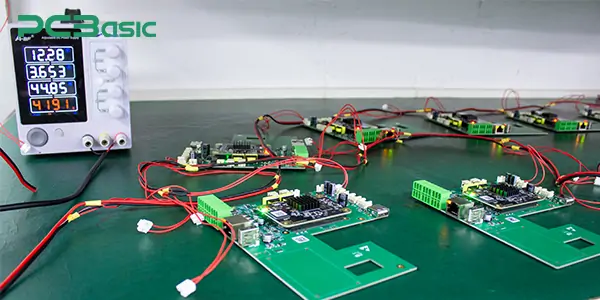

8. Functional Testing

Functional testing is the final delivery control link in PCB testing services. This test simulates the application conditions of a real system and comprehensively examines the overall performance of the PCB. The test contents cover the following:

Current and voltage stability

Signal Integrity (SI)

Communication protocol and bus logic function

IO port response and functional module operation logic

Functional testing is one of the important PCB test solutions for achieving the usability and stability of high-end electronic products.

9. Failure Analysis & Reliability Evaluation

When abnormal failures occur in the PCB reliability test (PCB reliability test), precise failure analysis tools need to be used for in-depth location, including:

X-ray imaging analysis

Scanning electron microscope (SEM)

Cross-sectional sections and microscopic analysis

Energy dispersive elemental analysis

Systematic analysis of the root causes of failure can sustainably optimize the PCB design reliability and manufacturing process flow, ultimately enhancing the overall control ability of PCB quality.

By constructing a comprehensive system of PCB reliability testing and PCB test solutions, manufacturers can effectively manage the failure risks in complex application scenarios. So, what are the standards for PCB reliability testing?

|

Standard Name |

Role in PCB Reliability Testing |

Typical Test Items |

Key Reliability Aspects |

|

IPC-TM-650 |

Provides detailed test methods for PCB reliability evaluation |

Thermal cycling, electromigration, SIR, peel strength, thermal shock |

Thermal stress, electrical stress, insulation failure mechanisms |

|

IPC-6012 / IPC-A-600 |

Defines manufacturing acceptance criteria and inspection guidelines |

Delamination, hole wall integrity, surface defects, pad dimensions |

Manufacturing consistency, material integrity, process defect control |

|

MIL-STD-202 / MIL-STD-883 |

Serves as the reliability testing standard for military and aerospace applications |

Vibration, mechanical shock, thermal shock, damp heat aging, life limit tests |

Extreme environmental adaptation, long-term stability |

|

JEDEC |

Used for package-level and system-level reliability verification, often coupled with PCB testing |

HAST, moisture sensitivity level, rapid temperature cycling, solder joint reliability |

Moisture-induced failure, solder fatigue, package-to-board compatibility |

|

ISO 9001 / IATF 16949 / ISO 13485 |

Covers overall quality management systems, ensuring controlled testing and manufacturing processes |

Process capability evaluation, failure mode analysis (FMEA), traceability, preventive measures |

Full-process reliability management, quality consistency assurance |

To ensure the reliability of a PCB, strict control should be exercised from the very beginning of its design. We can incorporate the principles of reliability design in the early stage of the design. This is helpful to reduce subsequent risks and avoid malfunctions during the product life cycle. First of all, when designing the circuit and layout, sufficient design margin should be reserved. That is, safety margins are left for key parameters such as voltage, temperature and load. Secondly, it is necessary to reasonably implement the derating design of components and systematic stress analysis to enhance the durability of the devices. Furthermore, strict supplier screening and material control are also crucial for maintaining consistent PCB quality. Cooperating with a high-quality and stable supply chain is also a key guarantee for delivering high-reliability PCBs. Finally, it is recommended to introduce reliability engineering assessment as early as possible at the prototype stage.

Integrating these reliability-oriented design strategies into the entire development process can lay a solid foundation for achieving long-term and stable PCB reliability.

At PCBasic, we are always committed to delivering high-reliability PCBs that meet strict industry standards. We insist:

1. Reliability-oriented design. We collaborate deeply with customers in the early stage of design and provide professional advice on PCB design reliability. This includes the rational selection of materials, impedance control design, thermal management optimization, and so on.

2. We have strict supplier qualification processes. All raw materials and components of PCBasic must comply with international standards and can only be put into production after verification. We ensure that each batch of production has stable and consistent PCB quality from the source.

3. A complete reliability testing system. PCBasic conducts comprehensive PCB reliability testing in accordance with international authoritative standards such as IPC-TM-650, IPC-6012, MIL-STD-202/883 and JEDEC, etc. The test items include but are not limited to:

Thermal cycling and thermal shock testing

Damp heat and high humidity test

Vibration and mechanical shock testing

Functional test

4. Strict process control and full traceability management throughout the process. PCBasic fully implements a quality management system that complies with standards such as ISO 9001, IATF 16949 and ISO 13485. The entire production process of each batch of ours is traceable, covering raw materials, process parameters, inspection records and test data, etc. The entire process is controllable and traceable, ensuring the reliable consistency of the production process.

5. Failure analysis and continuous improvement mechanism. When abnormal situations occur, our reliability engineering team will conduct precise failure analysis through advanced means such as X-ray inspection, cross-sectional analysis, scanning electron microscopy (SEM), and ion chromatography.

With professional design support, advanced testing capabilities and strict process control, PCBasic continuously delivers high-reliability PCBs that perform well in various critical applications to global customers.

PCB reliability is not merely about the final inspection stage. It is a comprehensive management system covering the entire life cycle from design, materials, processes to usage. Through systematic PCB reliability testing, effective PCB testing solutions and reliability preventive measures during the design stage, we can significantly provide high-quality and stable PCB quality. In addition to these, there is another very important point - that is, to choose a high-quality and reliable PCB manufacturer. At PCBasic, we are committed to helping our customers achieve long-term stable product performance and competitiveness through high-reliability PCB manufacturing, assembly and globally leading PCB testing services. Welcome to contact PCBasic!

About PCBasic

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.