Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

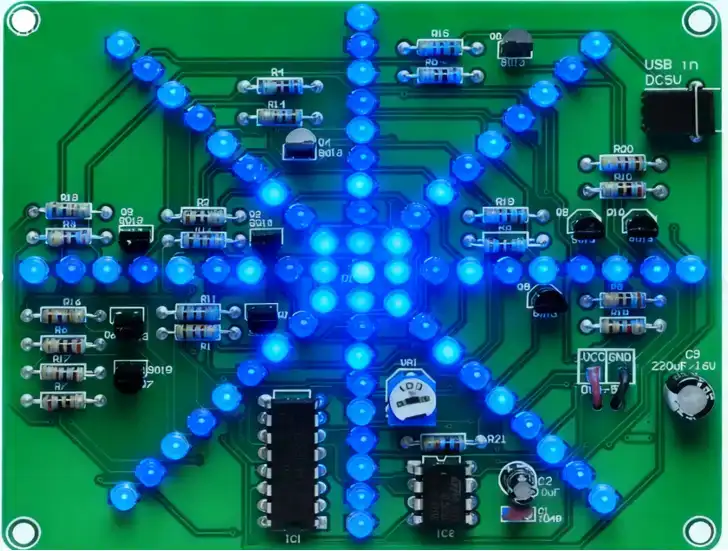

An LED PCB (Light-Emitting Diode Printed Circuit Board) is a kind of LED circuit board specifically used for mounting and connecting light-emitting diodes. Its function is to enable the current to flow smoothly in the circuit, thereby making the LEDs emit light. Each LED PCB board is equipped with very small semiconductor chips, which emit light when powered.

Because LED circuit boards generate a lot of heat when working, ordinary fiberglass boards are difficult to meet the requirements. Therefore, metal core LED PCBs (MCPCB LEDs) with better heat dissipation performance are now more commonly used, especially aluminum substrates. There is a thermally conductive layer on the aluminum LED light circuit board, which can quickly conduct and release heat, protect electronic components and extend the service life of the lamp.

In modern LED light circuit board design, the most commonly used process is surface mount technology (SMT). The brightness of a single LED chip is limited, so multiple diodes are usually mounted on a custom LED PCB to achieve higher brightness.

As a professional LED PCB manufacturer, PCBasic focuses on precise LED PCB board design and engineering manufacturing. We can provide customers with stable, durable, energy-saving and efficient LED circuit board solutions, which are widely used in multiple fields such as lighting, automobiles, electronics and industry.

The LED light circuit board brings many benefits to both users and manufacturers. The following are several main reasons why LED PCB boards have become the preferred choice for modern lighting systems:

1. Lower Power Consumption

Replacing traditional incandescent bulbs with LED circuit boards can reduce energy consumption by more than 80%. Not only does it save more electricity, but it can also help enterprises and families save on electricity bills.

2. Longer Lifespan

A typical LED PCB board can last for over 20,000 hours, which is about 25 times longer than an incandescent bulb. This means fewer replacements and lower maintenance costs.

3. Higher Efficiency

LED PCBs can convert more electrical energy into light instead of wasting it as heat. This not only makes it brighter but also enables the lighting to operate more stably, increasing the overall efficiency by approximately 20%.

4. Compact and Versatile Design

Due to its small size and flexible structure, custom LED boards can be easily applied in various products, such as display screens, small devices, and automotive headlights. They can be freely designed according to requirements.

5. Environmentally Friendly

LED circuit boards contain no mercury and produce very little carbon emissions. They are more environmentally friendly than traditional lighting and meet today's global energy-saving and carbon-reduction goals.

The LED PCB is widely used in various industries due to its excellent adaptability, stable performance and energy-saving advantages.

1. Telecommunications

In telecommunication equipment, LED light circuit boards are often used as indicator lights or display modules. Aluminum LED PCB boards have good heat dissipation and mechanical stability, enabling equipment to operate for a long time without overheating or malfunctioning.

2. Automotive

Metal core LED boards are often used in the automotive industry, such as in headlights, brake lights and interior lighting systems. Aluminum LED circuit boards have fast heat conduction and strong vibration resistance, and are very suitable for high-temperature and high-vibration environments of vehicles.

3. Computers and Electronics

LED light circuit boards are widely used in electronic products such as computer monitors, keyboards and power supplies. They can effectively dissipate heat, prevent components from being damaged due to overheating, and ensure the long-term stable operation of the equipment.

4. Medical Devices

Medical lighting devices such as surgical lights and diagnostic instruments often use custom LED PCBs, which can provide high brightness, precise illumination, and reliable performance. The LED circuit board design of PCBasic can ensure that these devices remain stable and durable when working continuously for a long time.

5. Consumer and Industrial Lighting

Whether it is smart home lighting or a large factory lighting, LED PCB boards can bring uniform brightness, low energy consumption and robust structural design, and are highly suitable for various lighting application scenarios.

As a professional LED PCB manufacturer, PCBasic can provide customers with one-stop custom LED PCB services, including circuit board manufacturing, component sourcing and complete LED circuit board assembly.

Our factories are equipped with advanced PCB production and assembly lines as well as fully automated SMT placement equipment, which can ensure that every circuit board is precise, efficient and of stable quality.

You only need to upload your Gerber file and BOM to our system, and our engineering team will quickly provide you with a quotation and formulate a production plan. If you have already prepared the components, we can also assemble them according to your requirements and flexibly support the production of your custom LED boards.

An LED strip PCB is a kind of LED circuit board specially designed for LED light strips. Each light strip is composed of many small light-emitting diodes, which are installed on a custom LED PCB to provide electrical connections, support structures, and help with rapid heat dissipation. The LED PCB board is the core foundation of the light strip, ensuring that each LED receives a stable current, thus emitting light normally and working for a long time.

Generally speaking, copper wires or conductive pathways are laid on the LED light strip PCB to connect all the LEDs in sequence. The LED light circuit board design enables the current to flow smoothly, ensuring even brightness and continuous lighting. Meanwhile, a reasonable LED PCB board design can enhance the structural stability of the light strip, reduce heat generation issues, protect components and extend their service life.

The LED circuit boards used in light strips are mainly divided into two types: flexible LED PCBs and rigid LED PCBs.

• Flexible LED strip PCBs are generally made of bendable materials such as polyimide, which can be bent or fit into curved surfaces, making them very suitable for decorative lighting or architectural lighting.

• Rigid LED strip PCBs use sturdy materials such as aluminum or fiberglass to form a more durable and stable MCPCB LED structure, which is suitable for applications in industries or automobiles that have higher requirements for heat dissipation and reliability.

Some LED circuit board designs also integrate other electronic components, such as resistors, capacitors or IC chips, to regulate voltage, brightness or achieve special lighting effects. These components are usually directly soldered onto the LED PCB board, making the light strip more functional and easier to use.

Overall, the LED strip PCB is of great significance in modern lighting. It not only offers stable electrical performance but also has efficient heat dissipation capacity, and can be flexibly applied in various scenarios, such as smart homes, advertising displays, signage, and industrial lighting systems.

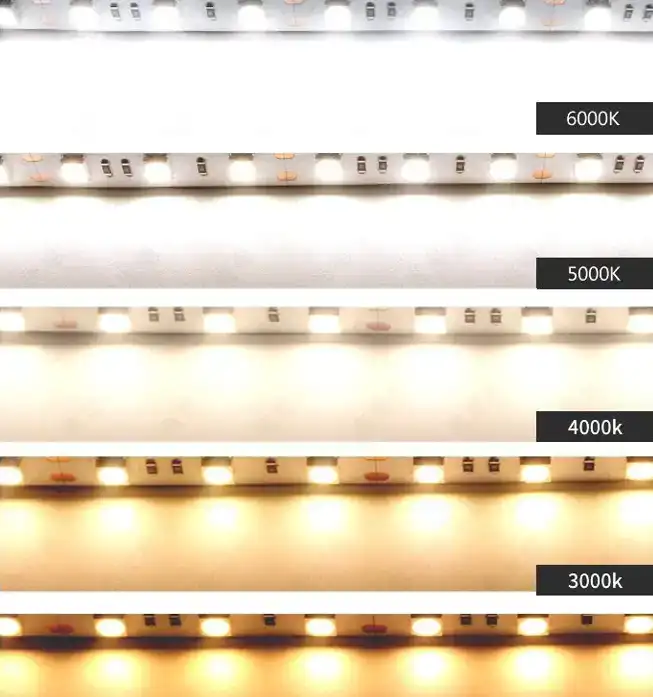

Typical LED Strip PCB Specifications: 2835-120-24V-5mm (2700K–5000K)

Lumens is a unit of brightness used to measure the total amount of visible light emitted by LED strips. The higher the value, the brighter the light strip. The specific lumen value can vary depending on the model or configuration of the LED strip.

|

Parameter |

Description |

|

LED Chip Type (2835) |

The LED chip measures 2.8mm × 3.5mm, offering high brightness and great efficiency — one of the most popular chip types used in LED circuit boards for strip lighting. |

|

LED Density (120 LEDs/m) |

There are 120 LEDs per meter, ensuring smooth, uniform illumination across the entire LED PCB board. |

|

Voltage (24V) |

The operating voltage is 24 volts. A suitable power supply must be used to ensure the LED light circuit board operates safely and efficiently. |

|

Color Temperature (2700K–5000K) |

Adjustable color temperature ranging from warm white (2700K) to cool white (5000K), offering flexibility in LED board design for different lighting environments. |

|

Width (5mm) |

The LED PCB board has a compact width of only 5mm, making it ideal for narrow or decorative lighting applications while maintaining effective heat dissipation. |

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.