Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Mixed assembly, also known as hybrid PCB assembly, is a preferred solution for manufacturing complex and high-performance circuit boards in the field of electronic manufacturing. In this article, we will provide you with a comprehensive introduction to some core aspects of mixed assembly. First, let's take a look at its definition.

Mixed assembly is a production method that integrates two core processes - SMT and THT - on the same PCB. It is a highly automated process. During production, we will adopt the most suitable assembly method based on the size, function and mechanical strength requirements of each component.

This mixed PCB assembly method can fully leverage the advantages of both processes and is an ideal solution that balances flexibility and stability in modern PCBA manufacturing.

Mixed assembly combines high electrical performance with strong mechanical reliability, and its application in the electronics field is very extensive.

For example, in industrial control systems (such as PLCs, automation control boards, and robot control modules), SMT is used for chip mounting, while THT is used for connector assembly. This mixed technology assembly enables the system to maintain stable operation even under continuous high-load conditions.

Automotive electronics (such as engine control units, instrument display modules, and LED lighting systems) also often require mixed assembly services. In power modules, through the mixed assembly process, control chips are combined with through-hole transformers and capacitors to enhance current stability, heat dissipation performance, and product safety.

This mixed technology assembly is also indispensable in medical electronics and IoT devices. Learn more information here.

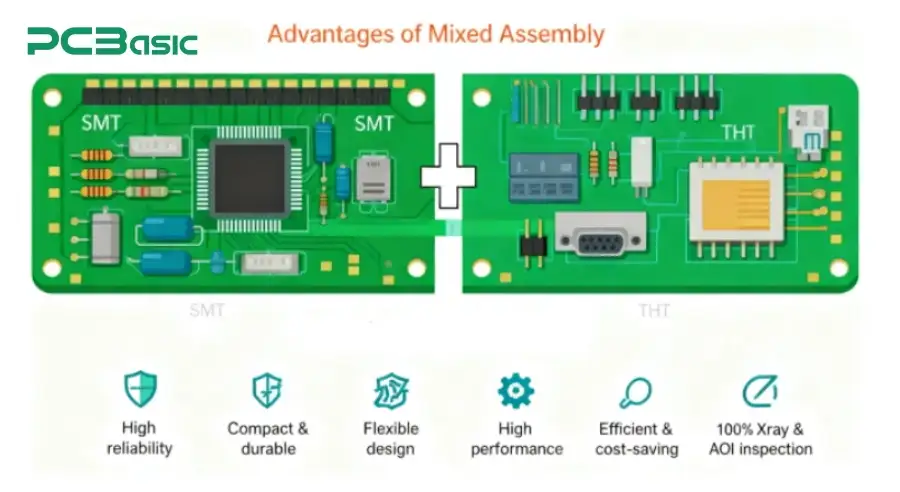

Compared with a single SMT or THT process, mixed assembly PCBs combine the advantages of both technologies, featuring higher performance, greater flexibility, and superior reliability. The main advantages of mixed assembly are as follows:

1. By combining the high precision of SMT with the high strength of THT, the hybrid assembly technology can significantly enhance the overall reliability of the PCB.

2. Can maintain the compact and lightweight structure of the circuit board while also providing excellent shock resistance and heat resistance.

3. Mixed PCB assembly enables the coexistence of both SMT and THT components, which provides a wider selection space and higher design flexibility for product design.

4. Using SMT components for signal circuits and THT components for the power section, this mixed-assembly method can achieve higher comprehensive performance. It supports high-speed signal transmission, RF functions, and large current loads, making it an ideal choice for advanced industrial and communication equipment.

5. Mixed assembly enables automated production, which not only speeds up the PCB manufacturing and assembly process but also reduces costs and lowers the rework rate.

6. 100% X-ray inspection and AOI can ensure the accuracy and consistency of solder joints.

DFA, or design for assembly, plays a crucial role in mixed assembly. Before starting the mixed assembly process, we should focus on the following aspects:

Usually, in mixed assembly, both SMT and THT are used to meet the characteristics and functional requirements of different components. SMT components are lightweight, have high precision, and are suitable for automatic assembly, often using reflow soldering technology; THT components have high mechanical strength and strong stress resistance, and are typically achieved through wave soldering or manual soldering. To balance electrical performance and mechanical strength on a single circuit board, we should combine the two reasonably.

Choosing the appropriate soldering method is crucial for controlling costs and improving efficiency.

|

Placement Method |

Advantages |

Drawbacks |

|

Automatic Placement |

• High speed and placement precision • Stable and consistent quality with full traceability • Cost-effective for large-volume production |

• High setup cost for small-batch or prototype projects • Not suitable for irregular or oversized components • Possible lead alignment issues with certain THT parts |

|

Manual Insertion |

• Flexible and adaptable for various component types and shapes • Ideal for small-batch, prototype, or repair projects • Allows detailed inspection and adjustment during assembly |

• Time-consuming and labor-intensive • Inconsistent quality compared with automated systems • Higher risk of human error and lower overall throughput |

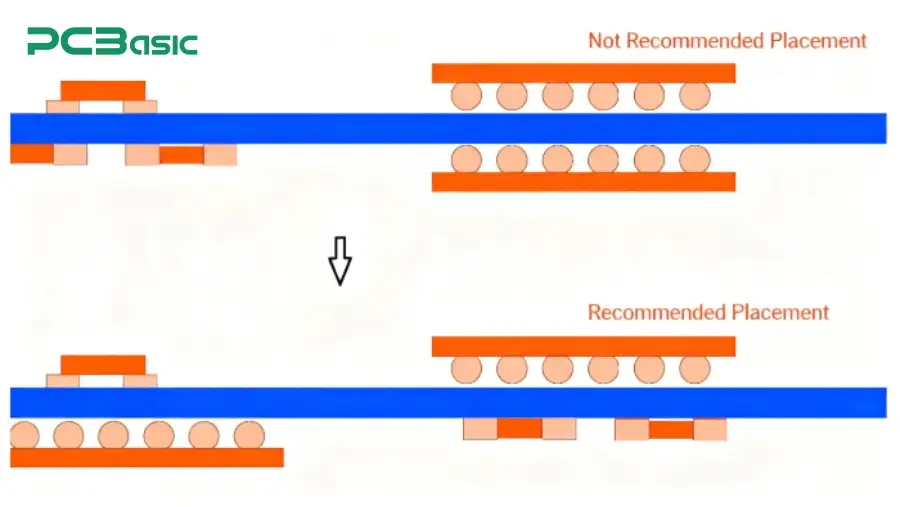

The key to successful hybrid assembly lies in the proper placement of components. During the design stage, we can follow the following DFA principles:

Place components on the same side.

If dual-sided assembly is required, SMT components should be placed on the bottom side, and THT components on the top side.

Avoid placing two BGA components facing each other.

Maintain sufficient spacing between BGA and THT components.

Evenly distribute the component weight.

Try to use the same package size to facilitate mounting and inspection.

By following these design principles, the yield rate can be effectively improved and soldering defects can be reduced. From sample verification to mass production, PCBasic always ensures that each circuit board meets international standards in terms of precision, reliability and consistency. Welcome to place your order!

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.