Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

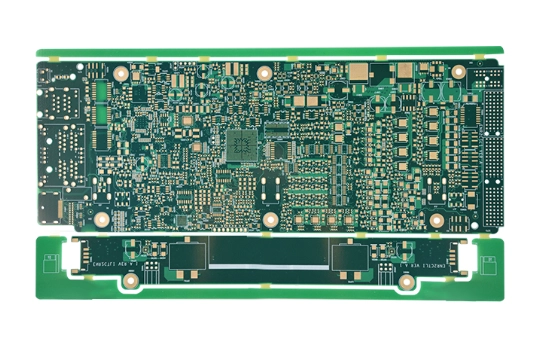

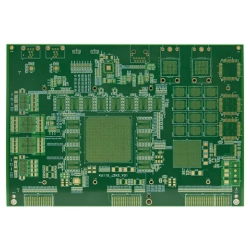

Comprehensive Multilayer PCB Services

PCBasic can meet all your PCB manufacturing needs, from single-layer to 32-layer boards. With over 15 years of industry experience, our team is skilled in multi-layer circuit board design and production, providing you with professional support. We offer free samples to ensure quality before mass production. For bulk orders, you can also enjoy exclusive discounts. This article outlines the key stages of PCB production to give you a clearer understanding of our service capabilities.

PCB Layer Introduction

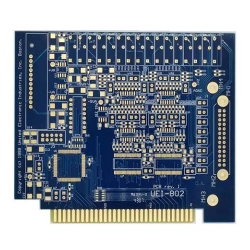

Double-Sided Gold Finger PCB

Gold finger PCBs feature gold-plated edge connectors, offering excellent conductivity and wear resistance. They ensure stable signal transmission during repeated insertions and are widely used in smartphones, smart wearables, and communication devices.

Double-Sided PCB

Double-sided PCBs are commonly used in industrial control applications. They can be designed for specific functions like temperature control or as general-purpose programmable boards supporting secondary development. Typical uses include PLCs, relays, motors, and sensors, enabling automation functions such as data collection, speed control, and communication.

6-Layer PCB

6-layer PCBs add two signal layers to a 4-layer structure, usually consisting of outer layers, two internal signal layers, and power/ground planes. This design optimizes routing, reduces electromagnetic interference (EMI), and provides stable performance in high-speed communication systems.

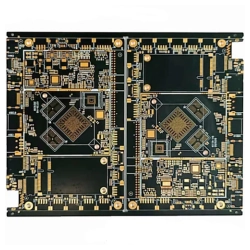

8-Layer PCB

8-layer PCBs include four signal layers and four plane layers, delivering excellent EMC performance. With optimized layout and shielding, they provide sufficient wiring space and high reliability, making them ideal for high-speed, high-density applications such as computer motherboards.

12-Layer PCB

12-layer PCBs are widely used in automotive electronic systems, featuring high temperature and pressure resistance with excellent thermal stability. With advanced materials such as gold plating and resin filling, they maintain ±10% impedance control accuracy even at 288°C. Compared to 8- and 10-layer boards, they offer better performance at a slightly higher cost.

14-Layer PCB

14-layer PCBs are high-density multilayer boards, commonly used in satellite systems, front-end amplifiers, memory modules, SAN storage, and communication equipment. When stable signal layers or special shielding structures are required, 14-layer PCBs are often the preferred solution.

20-Layer PCB

20-layer PCBs are used in medical devices, communication, aerospace, and high-speed computing. They offer stable signal transmission, good EMC, and heat dissipation, with higher reliability than 16- and 18-layer boards.

24-Layer PCB

24-layer PCBs are advanced multilayer designs about 5.5 mm thick, with stable dimensions, strong grounding and power structures, and reliable performance. Their optimized stack-up and HDI compatibility suit high-density applications, while low-loss dielectric materials ensure excellent signal integrity.

Our 6 Core PCB Advantages

Excellent Signal Integrity

Multilayer design and optimized routing reduce crosstalk and noise, ensuring stable high-speed transmission for high-frequency circuits.

Flexible Layout

Layer count and structure can be flexibly adjusted to meet different design needs, from simple single-layer to high-density multilayer boards, achieving optimized layout and wiring.

High Reliability

Premium materials combined with precision processes and strict testing ensure long-term stability and durability, even in harsh environments.

High-Density Routing Support

Multilayer structures provide more routing space, enabling complex designs within compact sizes, supporting miniaturization and high integration.

High-Speed Performance

Optimized stack-up and impedance control ensure smooth transmission of high-speed and RF signals, ideal for 5G, communication, and radar applications.

Strong Environmental Resistance

Excellent resistance to heat, humidity, and vibration, making PCBs suitable for automotive electronics, industrial control, and aerospace under demanding conditions.

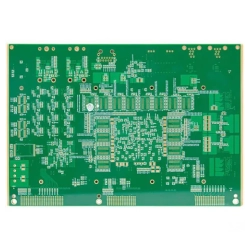

Our PCB Manufacturing Capability

Advanced processes enable flexible layers and materials, ensuring precise, high-density, and reliable PCB production.

PCB Application Fields

Covering diverse industries from consumer electronics to aerospace, driving global electronic innovation.

Aerospace

High-layer PCBs ensure reliable performance in flight control, satellite communication, and radar systems.

Automation

Multilayer PCBs power control panels, PLCs, and motor drives with stable, long-lasting performance.

Automotive

12- and 14-layer PCBs support ECUs, ADAS, battery management, and in-vehicle electronics.

Medical & Dental

20-layer PCBs enable precision and reliability in MRI, CT, ultrasound, and dental equipment.

Consumer Electronics

HDI and multilayer PCBs are used in smartphones, tablets, and wearables for compact, high-performance designs.

Robotics

24-layer PCBs drive AI cores, power modules, and sensors for advanced robotic systems.

PCB Assembly Machines

Drilling

Plating

Stripping

International Quality Certifications

Certified with ISO 9001, ISO 13485, IATF 16949, and more to ensure compliance with global standards.

High-Efficiency Production

Supports rapid delivery for small batches, with manufacturing completed in as fast as 24 hours to meet urgent deadlines.

One-Stop Service

15+ years of PCB/PCBA experience, covering design, prototyping, mass production, and assembly with full-process integrated solutions.

Advanced Technology Assurance

In-house intelligent production management system combined with a professional R&D team ensures high precision and reliability.

Global Logistics Network

Partnerships with DHL, FedEx, UPS, SF Express, and EMS for fast, safe, and secure worldwide delivery.

Professional Engineering Support

Free technical consulting and DFM analysis with 24/7 one-on-one service to help optimize product design and quality.

Each step in the PCB manufacturing process adheres to strict inspection standards.

01File Review

02Inner Layer Fabrication

03Drilling

04Through-Hole Plating

05Outer Layer Fabrication

06Solder Mask Application

07Surface Finish

08Electrical Testing

09Final Inspection

10Packaging

Cooperation Cases / Customer Testimonials

Thanks to 15+ years of effort and innovation in electronics, PCBasic has become one of the leading PCB & PCBA manufacturers in Shenzhen, China.

We tested multilayer PCBs from PCBasic, and their reliability was outstanding. Even under intensive testing, the boards remained stable. The production yield was very high, and the team kept us updated at every stage, making the entire process transparent and efficient.

Michael Johnson

PCBasic supplied us with 20-layer PCBs, and the quality of each batch was highly consistent with almost no variation. The stack-up design was precise, and the dimensions matched our drawings perfectly. Their engineering team proactively discussed details before production, which gave us full confidence in the outcome.

Anna Müller

We purchased 14-layer and 18-layer PCBs, and the performance exceeded our expectations. The boards were very stable, highly reliable, and passed all inspections without defects. The customer support team responded quickly and provided professional solutions to our technical questions, making the collaboration very smooth.

James Smith

We received 24-layer PCBs, and the workmanship was impressive. The pads and traces were neatly arranged, showing excellent precision. Delivery was on time, and throughout production, PCBasic’s engineers gave us valuable suggestions that helped optimize our design and improve production efficiency.

Dmitry Ivanov

Frequently Asked Questions

What are the advantages of multilayer PCBs?

+What are the disadvantages of multilayer PCBs?

+What are multilayer PCBs typically used for?

+Can multilayer PCBs withstand high power and high temperature?

+What is the maximum number of layers PCBasic can provide for multilayer PCBs?

+Does PCBasic provide design support for multilayer PCBs?

+Does PCBasic provide testing services for multilayer PCBs?

+Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.