Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

In addition to PCB manufacturing and assembly, PCBasic also offers high-precision solder paste stencils to meet the needs of various SMT assembly production.

An SMT stencil (also known as a solder paste stencil) is an important tool used before surface mount technology (SMT) placement. Its function is to accurately apply solder paste onto the pads of the circuit board.

In simple terms, the stencil can ensure that the amount and position of solder paste are very accurate, so that the components can be soldered firmly and the electrical conductivity can be stable. High-quality stencil in combination with a metal squeegee can evenly cover each opening with solder paste and precisely adhere to the PCB surface, making the printing process faster and more stable.

Depending on different manufacturing processes, PCBasic offers two types of SMT stencils: laser-cut stencils and chemical-etch stencils.

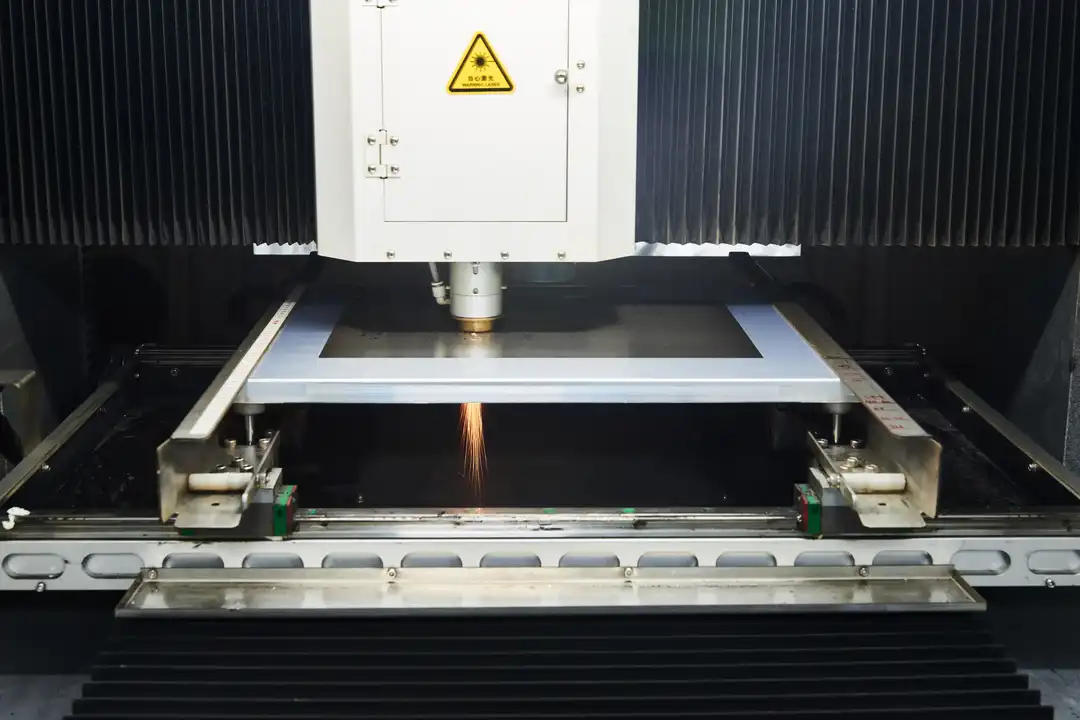

This kind of stencil is made by directly cutting openings in stainless steel plates with high-power lasers. Its hole walls are smooth, with high precision and long service life, making it highly suitable for fine-pitch and high-density SMT assembly.

Advantages:

• Highly accurate dimensions with excellent repeatability

• Trapezoidal openings help the solder paste release smoothly

• Less affected by environmental or human factors

• Suitable for high-precision and high-density mounting processes

• Offers high precision at a reasonable cost

Disadvantages:

• Slightly slower production speed compared to chemical etching

The apertures of this stencil are formed by etching the metal foil through an acid etching process. This traditional process can maintain the hardness of the material, but it is not very suitable for fine-pitch components.

Advantages:

• One-time formation and relatively fast manufacturing

• Lower production cost

• Stable material hardness

Disadvantages:

• Apertures may form an hourglass shape or be oversized

• Multiple process steps increase accumulated errors

• Not suitable for fine-pitch components

• Less environmentally friendly

The size of an SMT stencil consists mainly of two parts: internal size and external size. The internal size refers to the part that matches the printed area of the PCB, while the overall size is determined by the size of the printing press frame.

As long as these two designs are appropriate, the stencil can achieve the best effect when printing solder paste.

Internal Size Calculation

• Framed stencil: Width = PCB width + 100 mm; Length = PCB length + 100 mm

• Frameless stencil: Width = PCB width + 200 mm; Length = PCB length + 200 mm

For instance, if the size of the PCB is 50 × 50mm, the framed stencil is approximately 150 × 150mm, and the unframed stencil is approximately 250 × 250mm.

This calculation method is very simple and was often used in manual solder paste printing in the past. The internal dimensions of stencils corresponding to PCBs of different sizes will also vary.

Overall Size for Automatic Printers

For automatic SMT printers, the external dimensions of stencils should be determined according to the machine specifications.

In PCBasic, the standard stencil frame sizes we commonly use are 650mm × 650mm and 736mm × 736mm. PCB design engineers only need to determine the internal effective area of the stencil, and the external dimensions will be automatically matched according to the requirements of the PCBasic printing equipment.

• High-precision laser-cut equipment

• Strict dimensional inspection for every stencil

• Rapid production and global delivery

• Full compatibility with PCBasic’s SMT assembly lines

• One-stop PCB + stencil + assembly service

If you would like to order an SMT stencil, please feel free to contact PCBasic via email JS@pcbasic.com. Our team will get back to you with details and a quotation.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.