Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Injection Molding Services from PCBasic

PCBasic delivers precision injection molding with advanced automation and Class 10,000 cleanrooms. From mold development to assembly, we provide

full-process solutions. Certified to ISO 9001, ISO 13485, and IATF 16949, we serve automotive, medical, and electronics industries.

Injection Molding

Single-color injection molding uses one material in a single process. With precise mold machining, we achieve 0.02mm tolerance and offer free mold flow analysis. Ideal for mass production.

Dual-Color / Multi-Color Molding

Dual-color: Different areas of a product feature different colors (e.g. phone keypads). Multi-color: Special screws create color gradients (e.g. rainbow toy effects)

Insert Molding

Plastic is molded around inserts, combining materials in one part. Common in electronics, automotive, and medical fields for compact, high-performance, and cost-effective products.

Extrusion Molding

Extrusion molding melts raw materials and extrudes them through a die to form the desired profile, followed by cooling and shaping into final products. It offers fast production speed, high efficiency, and low cost.

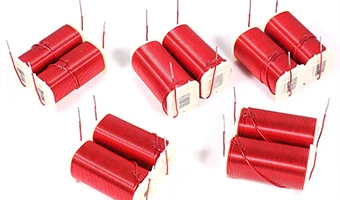

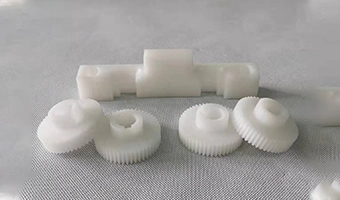

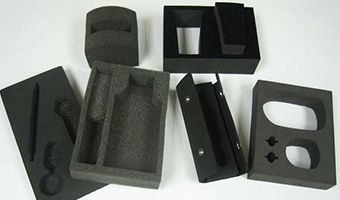

Our Injection Molding Products

Injection Molding Materials

Wide selection of thermoplastics and thermosets for various applications.

ABS

ABS is a versatile engineering plastic with excellent strength, toughness, and processability. It’s widely used in electronics, automotive, home appliances, and consumer products. Standard ABS is suitable below 80°C; flame-retardant grades meet higher heat resistance needs.

| Modified Material | Modification Purpose) | Typical Applications |

|---|---|---|

| ABS/PC | Improve heat resistance (HDT ≥120°C) and impact strength | Laptop housings, automotive dashboards |

| ABS/PA | Enhance toughness (50% increase in notched impact strength) | Home appliance housings (washing machine drum), tool handles |

| Flame Retardant ABS (FR-ABS) | Add brominated/phosphorus flame retardants (UL94 V-0 rating) | Power adapter housings, electronic device housings |

| High Gloss ABS | Optimize mold polishing or add brightening agents | High-end home appliance panels, toys (e.g. LEGO) |

| Anti-Static ABS | Add carbon black/metal powder to reduce surface resistivity | Electronic trays, precision instrument housings |

PC

PC (Polycarbonate) combines transparency, toughness, and heat resistance. Standard grades work up to 120°C, and short-term exposure can reach 150°C. As the second most used engineering plastic worldwide (after PA), it is widely used in electronics and electrical applications.

| Modified Material | Modification Purpose) | Typical Applications |

|---|---|---|

| PC/ABS | Improve toughness (notched impact strength ↑30%) and processing flowability | Laptop housings, mobile phone frames |

| PC/PBT | Improve heat resistance (HDT ≥120°C) and impact strength | Laptop housings, automotive dashboards |

| PC/PMMA | Increase surface hardness (scratch resistance) and weatherability | Optical lenses, transparent home appliance panels |

| Flame Retardant PC (FR-PC) | Add brominated/phosphorus flame retardants (UL94 V-0 rating) | Power adapter housings, electronic device housings |

| Toughened PC (POE/EPDM Modified) | Improve impact strength (notched impact strength ↑50%) | Safety helmets, bulletproof glass interlayers |

| Anti-Static PC | Add carbon black/metal powder (surface resistivity ↓ to 10⁸Ω) | Electronic trays, precision instrument housings |

PMMA(Acrylic)

PMMA (Polymethyl Methacrylate), also known as acrylic or plexiglass, features excellent transparency (92% light transmittance), low density (half that of glass), and good processability. Standard grades operate up to 80°C, short-term up to 100°C (e.g. LED lenses). It’s one of the most common transparent polymers used in advertising, lighting, automotive, and medical fields.

| Modified Material | Modification Purpose) | Typical Applications |

|---|---|---|

| PMMA/PC Alloy | Improve impact strength (↑50%) and heat resistance | Bulletproof glass interlayers, safety lenses |

| PMMA/ASA Alloy | Improve weatherability (UV yellowing resistance) and toughness | Outdoor billboards, automotive exterior parts |

| Flame Retardant PMMA (FR-PMMA) | Add brominated/phosphorus flame retardants (UL94 V-0 rating) | Lighting housings, electronic device panels |

| Colored PMMA | Add organic pigment (particle size <1μm) | Advertising signs, decorative crafts |

| Scratch-Resistant PMMA | Add nano SiO₂ / silicone coating | Phone protective screens, optical lenses |

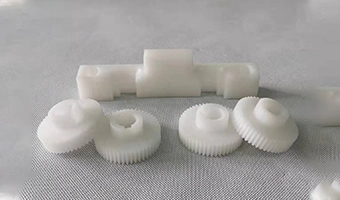

POM

POM (Polyoxymethylene) offers high rigidity, excellent wear resistance, and superior dimensional stability. Known as "metal replacement plastic," it's widely used in precision mechanical components and is one of the most popular engineering plastics worldwide.

| Modified Material | Modification Purpose) | Typical Applications |

|---|---|---|

| POM/Glass Fiber Reinforced | Increase stiffness (tensile strength ↑50%) and HDT (↑50~100°C) | Gears, bearings, precision structural parts |

| POM/Toughened with Elastomer | Improve toughness (notched impact strength ↑100%) | Appliance buttons, automotive interior parts |

| Flame Retardant POM (FR-POM) | Add brominated/phosphorus flame retardants (UL94 V-0 rating) | Electronic device housings, safety components |

| Weather-Resistant POM (UV Stabilized) | Delay yellowing and embrittlement | Outdoor tool handles, automotive exterior parts |

| Conductive POM (Carbon Black/Metal Filled) | Reduce surface resistivity (≤10⁶Ω) | Anti-static trays, precision instrument parts |

PA (Nylon)

PA combines toughness, wear resistance, and easy processing. Modified grades can improve moisture resistance and heat resistance, making it widely used to replace metals in automotive, electronics, and machinery industries. Often called "the king of engineering plastics."

| Modified Material | Modification Purpose) | Typical Applications |

|---|---|---|

| PA/Glass Fiber Reinforced (PA/GF) | Increase stiffness (tensile strength ↑100%), HDT (↑100~150°C), and dimensional stability | Automotive gears, electronic connectors, bearings |

| PA/Toughened with Elastomer | Improve toughness (notched impact strength ↑50%~100%) | Appliance housings, automotive interior parts, tool handles |

| Flame Retardant PA (FR-PA) | Add brominated/phosphorus flame retardants (UL94 V-0 rating) | Electronic device housings, safety components |

| Transparent PA (e.g. PA/TPE Alloy) | Control molecular regularity and add nucleating agents | Optical lenses, transparent gears |

| Weather-Resistant PA (UV Stabilized) | Delay yellowing and embrittlement | Outdoor tool handles, automotive exterior parts |

| PPA (Semi-Aromatic Nylon) | Improve heat resistance (HDT ≥250°C) and chemical resistance | High-temperature connectors, engine peripheral parts |

PE

PE (Polyethylene) features low density, excellent corrosion resistance, and easy processability. It’s one of the most widely produced plastics globally, commonly used in packaging, films, containers, and piping.

| Modified Material | Modification Purpose) | Typical Applications |

|---|---|---|

| PE/Toughened with Elastomer | Improve toughness (notched impact strength ↑50%~100%) | Appliance housings, automotive interior parts, tool handles |

| HDPE/Glass Fiber Reinforced | Increase stiffness (tensile strength ↑100%) and HDT (↑50~100°C) | Industrial containers, pipe fittings |

| Weather-Resistant PE (UV Stabilized) | Delay yellowing and embrittlement | Outdoor packaging films, agricultural films |

| Transparent PE (Low Crystallinity + Nucleating Agent) | Increase light transmittance (haze <10%) | Transparent bottles, optical films |

| Flame Retardant PE (Brominated Additives) | Meet UL94 V-0 rating | Electronic device housings, safety components |

PBT

PBT (Polybutylene Terephthalate) offers high rigidity, heat resistance, and excellent electrical insulation, making it a top choice for electronic and electrical insulation applications.

| Modified Material | Modification Purpose) | Typical Applications |

|---|---|---|

| PBT/Glass Fiber Reinforced (PBT/GF) | Increase stiffness (tensile strength ↑100%), HDT (↑100~150°C), and dimensional stability | Electronic connectors, bearings, precision structural parts |

| PBT/Toughened with Elastomer | Improve toughness (notched impact strength ↑50%~100%) | Appliance buttons, automotive interior parts, tool handles |

| Flame Retardant PBT (FR-PBT) | Add brominated/phosphorus flame retardants (UL94 V-0 rating) | Electronic device housings, safety components |

| Transparent PBT (Low Crystallinity + Nucleating Agent) | Increase light transmittance (haze <10%) | Optical lenses, transparent gears |

| Weather-Resistant PBT (UV Stabilized) | Delay yellowing and embrittlement | Outdoor tool handles, automotive exterior parts |

| PBT/PET Alloy | Improve heat resistance (HDT ↑30~50°C) and chemical resistance | High-temperature connectors, engine peripheral parts |

PVC

PVC is a versatile, cost-efficient plastic with good chemical resistance and durability. It’s widely used in piping, medical devices, cables, and construction materials due to its strength and versatility.

| Modified Material | Modification Purpose) | Typical Applications |

|---|---|---|

| PVC/Plasticized (SPVC) | Improve flexibility (elongation at break ↑200%~500%) | Artificial leather, wire & cable insulation, films |

| PVC/Glass Fiber Reinforced | Increase stiffness (tensile strength ↑100%) and HDT (↑50~100°C) | Industrial pipes, profiles, sheets |

| Rigid PVC (UPVC) | Improve chemical resistance and electrical insulation | Water pipes, drainage pipes, window & door profiles |

| Flame Retardant PVC (FR-PVC) | Add brominated/phosphorus flame retardants (UL94 V-0 rating) | Electronic device housings, safety components |

| Weather-Resistant PVC (UV Stabilized) | Delay yellowing and embrittlement | Outdoor advertising boards, architectural decorative materials |

| Transparent PVC (With Nucleating Agent) | Increase light transmittance (haze <10%) | Optical lenses, transparent films |

ABS

ABS is a versatile engineering plastic with excellent strength, toughness, and processability. It’s widely used in electronics, automotive, home appliances, and consumer products. Standard ABS is suitable below 80°C; flame-retardant grades meet higher heat resistance needs.

PC

PC (Polycarbonate) combines transparency, toughness, and heat resistance. Standard grades work up to 120°C, and short-term exposure can reach 150°C. As the second most used engineering plastic worldwide (after PA), it is widely used in electronics and electrical applications.

PMMA(Acrylic)

PMMA (Polymethyl Methacrylate), also known as acrylic or plexiglass, features excellent transparency (92% light transmittance), low density (half that of glass), and good processability. Standard grades operate up to 80°C, short-term up to 100°C (e.g. LED lenses). It’s one of the most common transparent polymers used in advertising, lighting, automotive, and medical fields.

POM

POM (Polyoxymethylene) offers high rigidity, excellent wear resistance, and superior dimensional stability. Known as "metal replacement plastic," it's widely used in precision mechanical components and is one of the most popular engineering plastics worldwide.

PA (Nylon)

PA combines toughness, wear resistance, and easy processing. Modified grades can improve moisture resistance and heat resistance, making it widely used to replace metals in automotive, electronics, and machinery industries. Often called "the king of engineering plastics."

PE

PE (Polyethylene) features low density, excellent corrosion resistance, and easy processability. It’s one of the most widely produced plastics globally, commonly used in packaging, films, containers, and piping.

PBT

PBT (Polybutylene Terephthalate) offers high rigidity, heat resistance, and excellent electrical insulation, making it a top choice for electronic and electrical insulation applications.

PVC

PVC is a versatile, cost-efficient plastic with good chemical resistance and durability. It’s widely used in piping, medical devices, cables, and construction materials due to its strength and versatility.

| Modified Material | Modification Purpose) | Typical Applications |

|---|---|---|

| ABS/PC | Improve heat resistance (HDT ≥120°C) and impact strength | Laptop housings, automotive dashboards |

| ABS/PA | Enhance toughness (50% increase in notched impact strength) | Home appliance housings (washing machine drum), tool handles |

| Flame Retardant ABS (FR-ABS) | Add brominated/phosphorus flame retardants (UL94 V-0 rating) | Power adapter housings, electronic device housings |

| High Gloss ABS | Optimize mold polishing or add brightening agents | High-end home appliance panels, toys (e.g. LEGO) |

| Anti-Static ABS | Add carbon black/metal powder to reduce surface resistivity | Electronic trays, precision instrument housings |

| Modified Material | Modification Purpose) | Typical Applications |

|---|---|---|

| PC/ABS | Improve toughness (notched impact strength ↑30%) and processing flowability | Laptop housings, mobile phone frames |

| PC/PBT | Improve heat resistance (HDT ≥120°C) and impact strength | Laptop housings, automotive dashboards |

| PC/PMMA | Increase surface hardness (scratch resistance) and weatherability | Optical lenses, transparent home appliance panels |

| Flame Retardant PC (FR-PC) | Add brominated/phosphorus flame retardants (UL94 V-0 rating) | Power adapter housings, electronic device housings |

| Toughened PC (POE/EPDM Modified) | Improve impact strength (notched impact strength ↑50%) | Safety helmets, bulletproof glass interlayers |

| Anti-Static PC | Add carbon black/metal powder (surface resistivity ↓ to 10⁸Ω) | Electronic trays, precision instrument housings |

| Modified Material | Modification Purpose) | Typical Applications |

|---|---|---|

| PMMA/PC Alloy | Improve impact strength (↑50%) and heat resistance | Bulletproof glass interlayers, safety lenses |

| PMMA/ASA Alloy | Improve weatherability (UV yellowing resistance) and toughness | Outdoor billboards, automotive exterior parts |

| Flame Retardant PMMA (FR-PMMA) | Add brominated/phosphorus flame retardants (UL94 V-0 rating) | Lighting housings, electronic device panels |

| Colored PMMA | Add organic pigment (particle size <1μm) | Advertising signs, decorative crafts |

| Scratch-Resistant PMMA | Add nano SiO₂ / silicone coating | Phone protective screens, optical lenses |

| Modified Material | Modification Purpose) | Typical Applications |

|---|---|---|

| POM/Glass Fiber Reinforced | Increase stiffness (tensile strength ↑50%) and HDT (↑50~100°C) | Gears, bearings, precision structural parts |

| POM/Toughened with Elastomer | Improve toughness (notched impact strength ↑100%) | Appliance buttons, automotive interior parts |

| Flame Retardant POM (FR-POM) | Add brominated/phosphorus flame retardants (UL94 V-0 rating) | Electronic device housings, safety components |

| Weather-Resistant POM (UV Stabilized) | Delay yellowing and embrittlement | Outdoor tool handles, automotive exterior parts |

| Conductive POM (Carbon Black/Metal Filled) | Reduce surface resistivity (≤10⁶Ω) | Anti-static trays, precision instrument parts |

| Modified Material | Modification Purpose) | Typical Applications |

|---|---|---|

| PA/Glass Fiber Reinforced (PA/GF) | Increase stiffness (tensile strength ↑100%), HDT (↑100~150°C), and dimensional stability | Automotive gears, electronic connectors, bearings |

| PA/Toughened with Elastomer | Improve toughness (notched impact strength ↑50%~100%) | Appliance housings, automotive interior parts, tool handles |

| Flame Retardant PA (FR-PA) | Add brominated/phosphorus flame retardants (UL94 V-0 rating) | Electronic device housings, safety components |

| Transparent PA (e.g. PA/TPE Alloy) | Control molecular regularity and add nucleating agents | Optical lenses, transparent gears |

| Weather-Resistant PA (UV Stabilized) | Delay yellowing and embrittlement | Outdoor tool handles, automotive exterior parts |

| PPA (Semi-Aromatic Nylon) | Improve heat resistance (HDT ≥250°C) and chemical resistance | High-temperature connectors, engine peripheral parts |

| Modified Material | Modification Purpose) | Typical Applications |

|---|---|---|

| PE/Toughened with Elastomer | Improve toughness (notched impact strength ↑50%~100%) | Appliance housings, automotive interior parts, tool handles |

| HDPE/Glass Fiber Reinforced | Increase stiffness (tensile strength ↑100%) and HDT (↑50~100°C) | Industrial containers, pipe fittings |

| Weather-Resistant PE (UV Stabilized) | Delay yellowing and embrittlement | Outdoor packaging films, agricultural films |

| Transparent PE (Low Crystallinity + Nucleating Agent) | Increase light transmittance (haze <10%) | Transparent bottles, optical films |

| Flame Retardant PE (Brominated Additives) | Meet UL94 V-0 rating | Electronic device housings, safety components |

| Modified Material | Modification Purpose) | Typical Applications |

|---|---|---|

| PBT/Glass Fiber Reinforced (PBT/GF) | Increase stiffness (tensile strength ↑100%), HDT (↑100~150°C), and dimensional stability | Electronic connectors, bearings, precision structural parts |

| PBT/Toughened with Elastomer | Improve toughness (notched impact strength ↑50%~100%) | Appliance buttons, automotive interior parts, tool handles |

| Flame Retardant PBT (FR-PBT) | Add brominated/phosphorus flame retardants (UL94 V-0 rating) | Electronic device housings, safety components |

| Transparent PBT (Low Crystallinity + Nucleating Agent) | Increase light transmittance (haze <10%) | Optical lenses, transparent gears |

| Weather-Resistant PBT (UV Stabilized) | Delay yellowing and embrittlement | Outdoor tool handles, automotive exterior parts |

| PBT/PET Alloy | Improve heat resistance (HDT ↑30~50°C) and chemical resistance | High-temperature connectors, engine peripheral parts |

| Modified Material | Modification Purpose) | Typical Applications |

|---|---|---|

| PVC/Plasticized (SPVC) | Improve flexibility (elongation at break ↑200%~500%) | Artificial leather, wire & cable insulation, films |

| PVC/Glass Fiber Reinforced | Increase stiffness (tensile strength ↑100%) and HDT (↑50~100°C) | Industrial pipes, profiles, sheets |

| Rigid PVC (UPVC) | Improve chemical resistance and electrical insulation | Water pipes, drainage pipes, window & door profiles |

| Flame Retardant PVC (FR-PVC) | Add brominated/phosphorus flame retardants (UL94 V-0 rating) | Electronic device housings, safety components |

| Weather-Resistant PVC (UV Stabilized) | Delay yellowing and embrittlement | Outdoor advertising boards, architectural decorative materials |

| Transparent PVC (With Nucleating Agent) | Increase light transmittance (haze <10%) | Optical lenses, transparent films |

Injection Mold Surface Finishes

PCBasic provides SPI surface finishes for molded parts. Upload your design to get a quote within 24 hours.

| Image | Type | Appearance | SPI Grades | Surface Roughness Ra |

|---|---|---|---|---|

|

SPI A | High Gloss | SPI A1、A2、A3 |

SPI A1: 0.012 – 0.025

SPI A2: 0.012 – 0.025 SPI A3: 0.05 – 0.10 |

|

SPI B | Semi-Gloss | SPI B1、B2、B3 |

SPI B1: 0.05 – 0.10 SPI B2: 0.10 – 0.15 SPI B3: 0.28 – 0.32 |

|

SPI C | Low Gloss | SPI C1、C2、C3 |

SPI C1: 0.35 – 0.40 SPI C2: 0.45 – 0.55 SPI C3: 0.63 – 0.70 |

|

SPI D | Matte | SPI D1、D2、D3 |

SPI D1: 0.80 – 1.00 SPI D2: 1.00 – 2.80 SPI D3: 3.20 – 18.00 |

| Image | Technical Parameters |

|---|---|

|

SPI A High Gloss SPI A1、A2、A3

SPI A1: 0.012 – 0.025 |

|

SPI B Semi-Gloss SPI B1、B2、B3

SPI B1: 0.05 – 0.10 |

|

SPI C Low Gloss SPI C1、C2、C3

SPI C1: 0.35 – 0.40 |

|

SPI D Matte SPI D1、D2、D3

SPI D1: 0.80 – 1.00 |

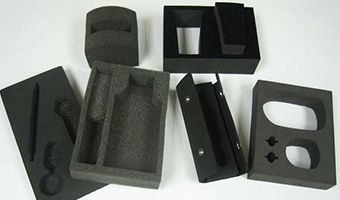

Injection Part Surface Finishing

PCBasic offers multiple surface finishing options to meet different design needs. Upload your design and get a quote within 24 hours.

| Image | Name | Description |

|---|---|---|

|

Spray Painting |

Products can be colored by raw material blending or spray painting. We also offer texture, rubber, UV, and conductive coatings. |

|

Powder Coating |

Powder coating applies powder to plastic parts by electrostatic spraying, then cures to form functional or decorative layers. It improves appearance, corrosion resistance, wear resistance, and adds insulation or conductivity. |

|

Electroplating |

Electroplating adds a metal layer for better corrosion resistance, durability, conductivity, reflectivity, and appearance. Finishes include gold, chrome, nickel, silver, copper, and 24K gold. |

|

Screen Printing |

Screen printing uses mesh screens to transfer ink through patterned openings onto injection parts, adding logos, text, or markings. It’s widely used for decoration, functional labels, and special markings. |

|

Laser Engraving |

Laser engraving uses a focused laser beam to instantly convert light into heat, melting or vaporizing the surface material to create markings. |

Spray Painting

Products can be colored by raw material blending or spray painting. We also offer texture, rubber, UV, and conductive coatings.

Powder Coating

Powder coating applies powder to plastic parts by electrostatic spraying, then cures to form functional or decorative layers. It improves appearance, corrosion resistance, wear resistance, and adds insulation or conductivity.

Electroplating

Electroplating adds a metal layer for better corrosion resistance, durability, conductivity, reflectivity, and appearance. Finishes include gold, chrome, nickel, silver, copper, and 24K gold.

Screen Printing

Screen printing uses mesh screens to transfer ink through patterned openings onto injection parts, adding logos, text, or markings. It’s widely used for decoration, functional labels, and special markings.

Laser Engraving

Laser engraving uses a focused laser beam to instantly convert light into heat, melting or vaporizing the surface material to create markings.

Why Choose PCBasic?

Free Moldflow Analysis

Our professional mold design team provides free moldflow analysis using software like Moldflow to simulate filling, cooling, warpage, flash, shrinkage, and weld line issues in advance.

Accurate Cost Analysis

Our cost team will throughout the process spanning product structure optimization, material selection, and process route design proactively communicate with you in advance on key aspects such as the number of mold cavities and whether multiple products can be co-molded, aiming to avoid hidden waste.

Strict Quality Control

Fully compliant with ISO 9001. From mold steel inspection (SGS report per batch) and precision machining (CNC ±0.005mm, full CMM inspection) to assembly and testing (20+ key parameters), all processes are fully traceable.

Fast Delivery & Premium Service

Standard mold lead time reduced to 15–20 days (vs. 25–30 days industry average). Urgent orders start within 48 hours via priority scheduling and onsite technical support. Free mold tuning guidance and annual maintenance included.

During document review, we’ll contact you by email if any additional materials are needed.

For any questions, feel free to email us at JS@pcbasic.com.

/01 Upload Drawings & Get a Quote

Upload your CAD or 3D files and note materials. We’ll email you a quote within 24 hours. Prices start from $0.30.

/02 Place Order & Production

Once you approve the quote and place the order, our team will begin mold making and production of your final parts.

/03 Inspection & Shipping

We serve customers worldwide. Your parts will be inspected and shipped to your specified location with full quality control.

/04 Ready to Start?

Let’s get started — PCBasic will deliver your project with high quality.

Injection Molding for Multiple Industries

With years of mold and injection molding experience, we deliver fast and help create value across industries.

Aerospace

Dental & Medical

Automotive Parts

Automation

Consumer Electronics

Robotics

Customer Reviews on Injection Molding

We are committed to high-quality products, strictly following manufacturing standards to ensure precision, consistency, and accuracy. Advanced equipment enables rapid

prototyping and strict quality control for fast delivery. Every part meets both our standards and your requirements.

Experienced Technical Support

Technical support means fast and professional assistance:

Comprehensive Quality Control System

We follow strict quality control with MES systems to ensure every custom part meets quality standards.

Part Quality Assurance

We ensure all parts fully meet your standards, supported by a complete customer service system:

Our Equipment Showcase

Frequently Asked Questions

What is the minimum order quantity (MOQ) for injection molding?

+How do you ensure injection molding product quality?

+How do you prevent common injection molding defects?

+Do you offer secondary processing and surface finishing?

+Do you support international shipping and export?

+Main Causes and Solutions for Flash in Injection Molded Parts?

+Related Services

CNC Machining

3D Printing

Sheet Metal Fabrication Services

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.