Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

At PCBasic, every fully assembled circuit board undergoes strict functional testing and quality inspection before leaving the factory.

We are certified with multiple international quality management system certifications, such as ISO 9001, ISO 13485, and IATF 16949, ensuring that each PCBA can operate stably and reliably in the customer's final machine.

To ensure that the product quality reaches 100% qualification, PCBasic conducts the following inspection steps in each PCB assembly project:

• Visual Inspection after SMT Process

• Automated Optical Inspection (AOI) — Free of charge

• X-Ray Inspection (Optional)

• In-Circuit Testing (ICT)

• Functional Testing (FCT)

• Final Visual and Quality Inspection

The functional testing of PCBasic enables every PCBA leaving the factory to be plug-and-play. Whether it is prototyping or mass production, we can design customized test procedures and fixture solutions based on customer needs to ensure stable electrical performance, safety and reliability, helping customers create higher-quality electronic products.

Functional testing is generally carried out after the circuit board assembly is completed, and it has passed AOI inspection and manual visual inspection. Conducting functional testing as early as possible can promptly identify and resolve component failures, assembly errors or design issues, reducing the time for later maintenance. This can ensure that each circuit board received by the customer can work stably and is of reliable quality. The main function of functional testing is to prevent problems such as open circuits, short circuits, missing components or incorrect installation during assembly.

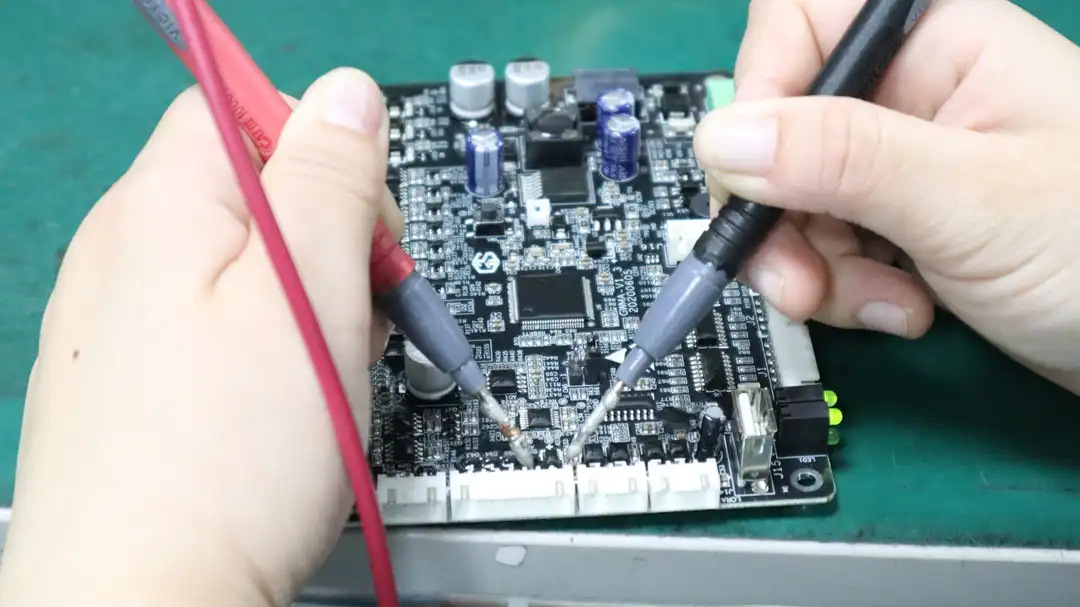

Functional testing is usually carried out by connecting a computer to the test points or probe interfaces on the circuit board. By running the test software or firmware, the results are evaluated to determine whether the board meets the specified requirements.

The testing platform will detect all external input and output signals of the circuit board, including analog and digital signals. It also tests the current, color and brightness of the LED, etc. Customized test fixtures can ensure that the test points are firmly connected to the circuit board, allowing engineers to detect functions that the main interface cannot directly test.

Functional testing mainly relies on test software (or firmware) and various test instruments, such as digital multimeters, input/output test boards, and communication interfaces. Automated functional testing is carried out by production line operators, who run test programs on computers and connect them to test equipment to conduct real-time detection and verification of the performance of circuit boards.

We look forward to working with you to complete the functional testing solution together. Our test engineers will evaluate your test requirements (including test scope and procedure), design test fixtures when necessary, install test instruments, formulate test procedures, and provide complete test reports.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.