Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > The Ultimate Guide to Contract Assembly Services

In the increasingly competitive manufacturing industry, companies are constantly thinking about three things every day: how to reduce costs, how to improve quality, and how to bring products to the market faster. Whether you are an original equipment manufacturer (OEM) of industrial equipment, a start-up company just starting out in the electronics industry, or a brand managing seasonal demand fluctuations, it is no easy task to increase and stabilize production capacity.

At this time, contract assembly services can play a significant role. By entrusting part of the assembly work to professional contract assembly companies, businesses can focus their time and energy on product research and development, market expansion and business planning. The specific production and assembly are carried out by more experienced assembly manufacturers.

This article will explain in a clearer way what contract assembly services are, how they operate, which industries they are suitable for, and what to pay attention to when choosing partners, helping you better understand this manufacturing outsourcing model.

Contract assembly services, simply put, mean outsourcing the assembly work of the product to a third party. Enterprises do not need to build assembly production lines, purchase equipment, hire and train staff, or set up quality systems by themselves. Instead, they cooperate with a professional contract assembly company, which is responsible for the entire assembly process.

A complete contract manufacturing process may involve de-sourcing raw materials, producing components, and completing final assembly. Some part contract assemblies are generally only responsible for the "assembly" part in assembly manufacturing. In many cases, the customer provides the components by themselves (consigned model), and then the contract assembly service is responsible for assembling, testing and completing the packaging of the products.

By using contract production services, enterprises can reduce internal management pressure, lower fixed costs, and, at the same time, make production more efficient and product quality more stable.

Sub-assembly refers to the process of assembling two or more components into a small module, which will later be installed in a larger finished machine product. Many product assembly companies specialize in this sub-assembly, such as control modules, mechanical linkages, and wiring harness assemblies.

If the sub-assembly is entrusted to experienced assembly manufacturers, the OEM's own production line can run more smoothly, reducing problems such as bottlenecks and material waiting time, and the overall efficiency will be higher.

Product assembly involves combining multiple sub-modules and components into the final marketable finished product. This is one of the most common types of contract assembly services.

A professional contract assembly company will be responsible for the alignment, fastening, wiring, calibration and inspection of the products to ensure that the finished products meet the design requirements and industry standards, and avoid affecting the product quality due to assembly problems.

Mechanical contract assembly mainly involves fastening metal or plastic components together by means of screws, rivets, welding, adhesives, or press-fit methods. Common applications include hydraulic systems, pressed parts assembly, structural frames and mechanical housings.

Assembly manufacturing in the mechanical field has relatively high requirements for precision and needs appropriate tooling and equipment; otherwise, problems such as dimensional deviations or unstable structures are likely to occur.

Electrical and electromechanical contract assembly services combine mechanical structures with electrical systems, such as wiring harness assemblies, control panels, PCBA integration, and motor assemblies.

This type of contract production services usually requires experienced technicians to operate and cooperate with the testing process to ensure that the products have no problems in terms of safety, durability and performance.

Many contract assembly companies, in addition to doing assembly, also provide some additional services, such as:

• Parts kitting

• Retail-ready packaging

• Labeling and barcoding

• Crating and shipment preparation

Integrating packaging and fulfillment together into contract assembly services can make the entire process simpler, fewer intermediaries are involved, and delivery times can be shortened.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

The process begins with confirming product documentation, including drawings, BOM lists, quality requirements, and production schedules. A professional contract assembly service will work with the client to confirm the details clearly to avoid misunderstandings in the later stage.

The engineering team will develop the assembly workflow based on the product’s characteristics, determine the tools and equipment needed, and set up key quality checkpoints. Nowadays, many assembly manufacturing processes adopt lean production methods to minimize waste and enhance efficiency.

The material sourcing usually has two models: materials supplied by the customer (consigned model) or materials procured by the contract assembly company. No matter which model it is, proper documentation and inventory control must be done well to ensure that the quantity and batch are clear and traceable.

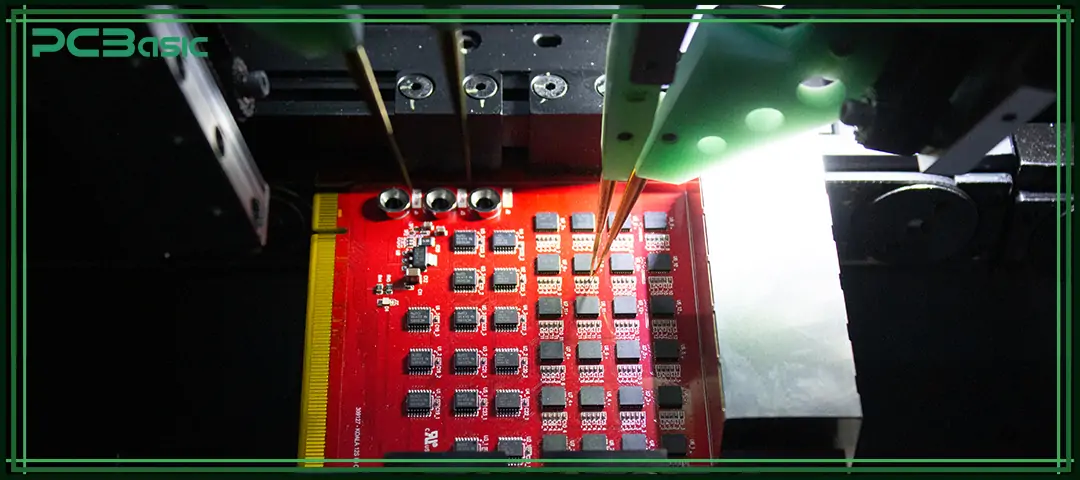

Assembly is carried out by experienced technicians or automated systems. Mature contract assembly services typically utilize automation equipment, torque-controlled tools and high-precision calibration instruments to ensure consistent assembly for each product.

Quality is a very important aspect in contract production services. Common inspections include:

• Visual inspection

• Functional testing

• Electrical testing

• Reliability testing

Many reputable assembly manufacturers will carry out production and inspection in accordance with the ISO 9001 quality management system.

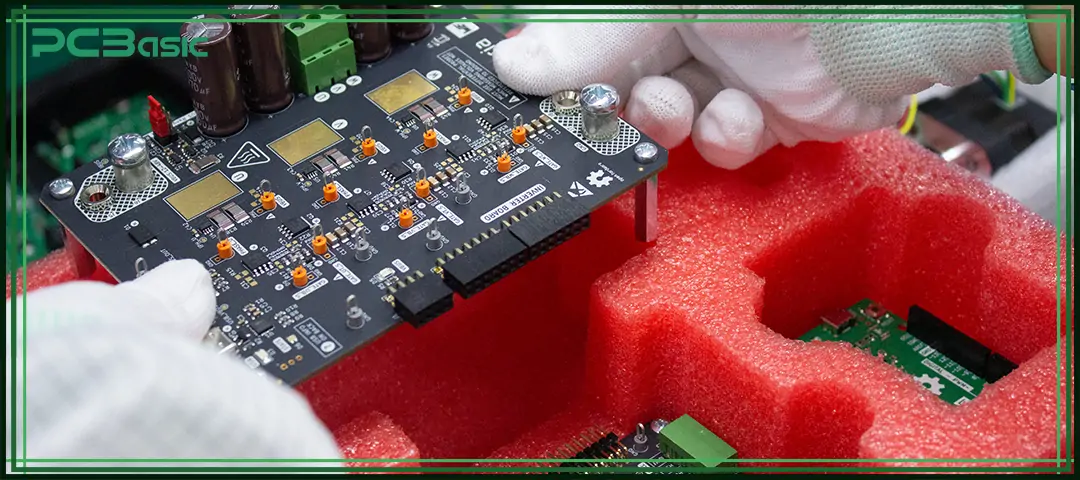

After the product is assembled and inspected, it will be packaged and arranged for shipment. Some contract assembly companies can also deliver the products directly to the end customers, reducing the intermediate links.

Building your own assembly manufacturing operation requires significant investment in equipment, facilities, training, and maintenance. By using contract assembly services, these fixed costs can be reduced, and the cost becomes calculated based on production volume, making expenses more flexible and manageable.

Mature contract assembly companies have professional technicians and complete equipment.

Professional contract assembly services have standardized quality processes. The product quality is more stable, and there will be fewer returns and after-sales problems.

Contract assembly can increase or decrease production volume according to orders.

Entrusting the assembly to professional product assembly companies can save preparation time.

In-house assembly refers to the situation where an enterprise completes the assembly of products within its own factory or production site. All equipment, production lines, personnel recruitment and training, quality management and daily operations are the responsibility of the enterprise itself.

The advantage of this approach is that enterprises can directly control the production process and quality standards. But at the same time, it also means that one needs to bear relatively high fixed costs, such as equipment investment, factory leasing or construction, personnel wages and maintenance expenses. Once the output changes, enterprises also need to adjust their resources and production capacity on their own.

|

Comparison Item |

In-House Assembly |

Contract Assembly |

|

Production Control |

Fully controlled by the company |

Executed by a contract assembly company, monitored by the client |

|

Equipment Investment |

The company must purchase its own equipment |

No need to invest in equipment |

|

Facility Costs |

Requires building or leasing factory space |

Facilities provided by contract assembly services |

|

Workforce Management |

The company hires, trains, and manages staff |

Workforce managed by the contract assembly provider |

|

Fixed Costs |

High (equipment, labor, maintenance) |

Lower, typically volume-based pricing |

|

Scalability |

Expansion requires new equipment and space |

Contract assembly can quickly adjust production volume |

|

Technical Expertise |

Depends on internal team capabilities |

Immediate access to specialized expertise |

|

Best For |

Stable, long-term high-volume production |

Fluctuating demand, rapid scaling, or new product launches |

The electronics industry relies heavily on contract assembly services, such as PCB assembly and box build assembly. Many EMS enterprises themselves are professional contract assembly companies.

The automotive and aerospace industries have very high requirements for precision and compliance. Many enterprises will complete the assembly work of wiring harnesses, control systems and mechanical modules through contract assembly.

Medical devices have strict requirements for safety and compliance, so certified contract production services are usually chosen to ensure product traceability and compliance with standards.

Many industrial OEMs will turn to assembly manufacturers to complete the assembly of hydraulic systems, structural components and custom equipment.

Whether it is sporting goods or electronics, product assembly companies can help brands complete mass production.

Contract assembly services are also commonly used in the furniture and packaging industries for kitting, labeling, and shipment preparation, enabling products to enter the market more quickly.

• Professional contract assembly company

• Provides comprehensive contract assembly services

• Covers PCB and PCBA projects

• Supports both prototyping and mass production

• Multiple SMT production lines

• Supports high-precision component placement

• Equipped with AOI, X-Ray, and functional testing

• Operates under ISO 9001 standards

• Ensures stable and controlled assembly manufacturing

• Supports turnkey and consigned contract assembly

• Handles both low and high-volume production

• Delivers reliable contract production services

• MES system management

• Full production traceability

• Transparent supply chain

• Ideal for long-term partnerships

In a highly competitive market environment, enterprises must not only control costs and ensure quality, but also have the ability to expand or reduce production capacity at any time. Contract assembly services can help enterprises solve these problems by entrusting professional assembly work to experienced assembly manufacturers.

By cooperating with reliable contract assembly companies, enterprises can directly obtain professional technology, mature equipment and stable production capacity, and at the same time, production arrangements are more flexible. Whether in the electronics, automotive, medical or industrial sectors, contract assembly can help enterprises enhance efficiency and support the continuous development of their business.

What is the difference between contract manufacturing and contract assembly?

Contract manufacturing covers the entire production process, including component sourcing and fabrication. Contract assembly services focus specifically on assembling components into sub-assemblies or finished products.

How much does contract assembly cost?

Costs vary depending on complexity, volume, materials, and quality requirements. However, contract production services often reduce total operational costs compared to in-house assembly manufacturing.

What information do I need to provide?

To begin working with a contract assembly service, you typically need to provide:

• Product drawings

• BOM

• Production forecast

• Quality standards

• Testing requirements

Can contract assemblers handle both low and high volume?

Yes. Most professional contract assembly companies are equipped to manage both prototype runs and large-scale production.

What certifications should I look for?

Reputable contract assembly services should operate under recognized quality systems such as ISO 9001. Industry-specific certifications may also apply depending on your sector.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.