Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > PCB Electrical Test: A Complete Guide

Precise and standardized electrical tests of PCBs can verify electrical integrity of products. During the PCB production process, before the bare boards or fully assembled circuit boards are delivered to customers, electrical tests must be conducted. This is to ensure that the circuits operate normally as per the design requirements and is an important part of quality assurance.

Next, this article will introduce the relevant content of PCB electrical testing, including its importance, types, common testing methods, testing equipment, etc. Without further ado, let's get straight to the point.

PCB electrical testing is a verification process. This process is used to confirm whether the electrical connections of the PCB conform to the original design data. During this process, we mainly check whether each conductive network is correctly connected as required by the schematic diagram and PCB layout file, and verify good electrical isolation from other networks.

In practical applications, PCB electrical testing is a detection method that assesses the integrity and performance of circuit networks by applying electrical signals at designated test points and measuring the response results. Through PCB testing, we can effectively identify the following issues: Open circuits, Short circuits, Abnormal resistance or impedance values, Signal integrity issues and so on.

PCB electrical testing can be carried out at multiple stages of the manufacturing process:

Bare board stage: Verify the correctness of circuit connections before installing components.

Assembly stage: Check the connectivity status of the circuit after soldering is completed.

Final inspection stage: Test the entire circuit board before shipment.

PCB electrical testing holds significant importance in electronic manufacturing. There are some electrical defects that cause PCB failure and which cannot be detected by the naked eye. At this point, using standardized PCB testing can help us identify and solve these problems as early as possible. This can prevent high failure rates and customer complaints. In addition, the significance of PCB electrical testing is also reflected in the following aspects:

Quality Assurance

Manufacturers can confirm through PCB testing whether the electrical connections comply with the design data and manufacturing specifications. This ensures that each circuit board meets the functional requirements before proceeding to the next process.

Reduce Costs

Identifying defects through testing PCBs in the early stages helps avoid costly rework, scrapping, and large-scale product recalls.

Enhance product reliability

Through PCB electrical testing, we can reduce defective circuit boards from the production process. This can reduce the risk of intermittent failures and performance degradation during actual use.

Improve yield rate

By systematically analyzing PCB test data, manufacturers can identify weak links in etching, drilling or soldering processes, thereby continuously enhancing the overall production yield rate.

Meeting safety and compliance requirements

Standardized circuit board testing can prevent risks caused by short circuits, leakage, or insulation failure, ensuring that the products comply with relevant regulations and safety standards. This is particularly important in applications such as healthcare, automotive, and industrial electronics.

PCB electrical testing involves various types of tests, and different testing methods target different electrical risks and application scenarios. The table below summarizes the common PCB electrical testing types:

|

PCB Electrical Test Type |

Test Purpose |

Typical Application Stage |

Key Defects Detected |

|

Continuity Test |

Verifies that all intended electrical connections are properly connected |

Bare PCB testing, assembly testing |

Open circuits, broken traces |

|

Isolation (Short/Open) Test |

Confirms sufficient insulation between different nets |

Bare PCB electrical testing |

Short circuits, copper bridging |

|

Resistance Testing |

Measures resistance values to ensure they meet design requirements |

Bare PCB & assembled PCB testing

|

Abnormal resistance, trace defects |

|

Impedance Control Test |

Checks controlled-impedance traces for signal integrity |

High-speed PCB testing |

Impedance deviation, signal distortion |

|

In-Circuit Testing (ICT) |

Tests individual components and circuit nodes on assembled boards |

Mass PCBA testing |

Wrong components, solder defects |

|

Functional Testing (FCT) |

Verifies that the assembled PCB performs its intended functions |

Final PCB functional testing stage |

Logic errors, functional failures |

|

High-Voltage Test |

Applies high voltage to verify insulation strength |

Safety-critical PCB testing |

Insulation breakdown, leakage |

|

Burn-In / Stress Testing |

Operates the circuit under load to expose early failures |

Reliability and aging tests |

Intermittent failures, thermal issues |

PCB testing covers multiple production stages - from bare boards to fully assembled circuit boards - a single testing scheme cannot meet all testing requirements. Accurate and reliable PCB electrical testing requires multiple testing devices to achieve. Selecting the appropriate testing devices at different stages can ensure stable product quality and reliable circuit board test results.

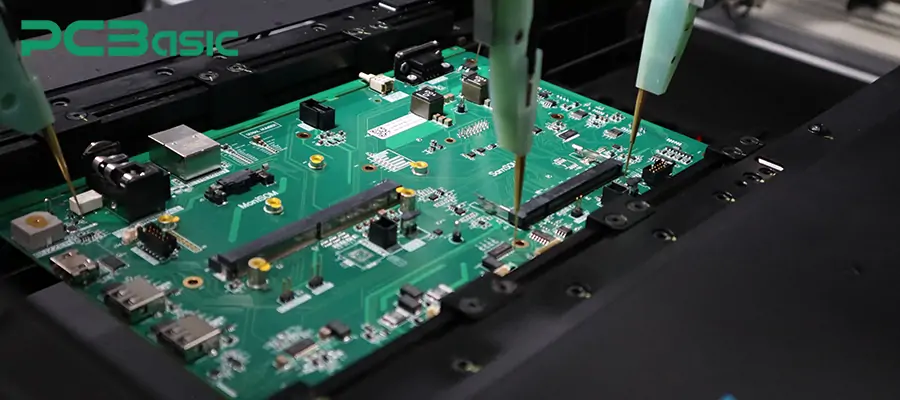

Flying Probe Tester

The flying probe tester is a highly flexible testing solution, mainly used for verifying connectivity and insulation. This equipment conducts electrical tests by directly contacting the test points with movable probes, and is commonly used in PCB prototyping and small to medium batch production. With this equipment, manufacturers do not need to make dedicated test fixtures, and are particularly suitable for projects with frequent design changes or multiple PCB models.

Jig Testing Equipment

The fixture testing equipment is also commonly referred to as a needle bed testing system, and is mainly used for high-speed PCB electrical testing in mass production. By using customized fixtures to simultaneously contact all test points, this method can significantly reduce the test time for the board. This testing equipment is suitable for production scenarios with high requirements for test efficiency and repeatability.

Multimeter and LCR Tester

The multimeter and LCR tester are the most fundamental yet indispensable tools for testing the electrical parameters of PCBs. They are mainly used to measure parameters such as resistance, capacitance, and inductance. These instruments are typically employed in engineering verification, fault analysis, and quality inspection.

ICT Testing Machine

The ICT system is widely used in the testing of assembled PCBs to detect the electrical status of individual components and circuit nodes. This type of PCB testing method can identify errors, omissions, and soldering defects at an early stage during the assembly process, thereby reducing the failure risks in subsequent processes.

Functional Testing Machine

Functional testing is usually the final testing process before shipment. The FCT machine performs PCB functional testing by simulating the real working environment. During the testing process, power supply, input signals and loads are applied to the circuit board to verify whether it operates normally as per the design requirements.

A Summary Table

|

Testing Equipment |

Main Application |

Typical Production Stage |

|

Flying probe tester |

Continuity and isolation testing |

Prototype, low-volume PCB testing |

|

Fixture-based tester |

High-speed electrical verification |

Mass production |

|

Multimeters & LCR meters |

Parameter measurement |

Engineering validation |

|

ICT systems |

Component-level testing |

Assembled PCB |

|

FCT systems |

Full functional verification |

Final inspection |

By combining the use of multiple PCB electrical testing equipment, manufacturers can conduct comprehensive PCB testing at all production stages from bare boards to finished products, ensuring electrical accuracy and functional reliability.

Manufacturers must adhere to recognized international standards and compliance requirements to ensure the stability and reliability of PCB electrical testing results. These standards uniformly stipulate the testing methods, data formats, and judgment bases. Through standardized PCB testing procedures, deviations caused by differences in understanding can be reduced, and the repeatability of the test results can be improved.

IPC Class 1 / Class 2 / Class 3

The IPC rating is used as acceptance criteria.

Class 1 is mainly applicable to general consumer electronics, focusing on functional realization requirements.

Class 2 is suitable for industrial and commercial electronic products, emphasizing stability and continuous performance.

Class 3 is targeted at high-reliability application scenarios, with the highest requirements for the product's continuous operation capability.

The higher the grade, the more stringent the requirements for PCB electrical testing in terms of connectivity, insulation, and defect detection will be.

IPC-D-356 Network Table Format

IPC-D-356 is a standard network table format used for exchanging PCB test data. It specifies the methods for generating and parsing electrical test data. This standard is often used in bare board electrical testing and flying probe testing to ensure consistency between design data and actual PCB test results.

Automotive Electronic Testing Requirements

Automotive electronic PCBs need to remain stable under harsh conditions. Therefore, the testing of automotive electronic PCBs should place greater emphasis on electrical reliability, insulation performance, and the traceability of the testing process, in order to meet the requirements of the industry quality system.

RoHS and Safety Compliance Requirements

In addition to electrical performance, PCB testing also needs to support regulations such as RoHS and product safety compliance requirements.

Conforming to industry standards for PCB electrical testing helps improve product quality, simplify the review process, and ensure the long-term reliability of the product in high-demand application environments.

PCBasic offers comprehensive PCB electrical testing services for both bare boards and assembled PCBs. Here are some advantages of PCBasic.

PCB electrical testing covering the entire process

PCBasic conducts electrical tests at multiple production stages:

Bare board testing

Post-assembly testing

Final testing

This phased testing approach helps to identify potential problems at an early stage, reduces the risk of rework, and improves the overall product quality.

Advanced testing equipment and methods

PCBasic is equipped with a variety of testing systems, which can meet the testing requirements for different production volumes and product types, like

Flying probe tester: Provides flexible and accurate PCB testing solutions for proofing and small to medium batch orders.

Jig testing equipment: Suitable for mass production, with fast testing speed and high repeatability.

Functional testing (FCT) machine: Verifies the performance of the entire board to ensure that the circuit functions meet the design requirements.

Standard compliance and engineering support

The PCB testing process of PCBasic strictly follows IPC and other relevant international quality standards, and the test data is traceable. The testing work is handled by an experienced engineering team, which ensures that each PCB testing plan meets the reliability requirements of the product.

Reliable PCB testing capabilities for global customers

At each stage, PCBasic conducts electrical tests on the PCB, which effectively ensures product quality, guarantees consistency of performance, and ensures the reliability of delivery. This systematic testing capability enables global customers to obtain PCB products that meet technical specifications and long-term usage requirements throughout the project development and mass production processes.

PCB electrical testing is a very crucial step in electronic manufacturing. It ensures accurate circuit connections, stable product performance and compliance with overall quality standards. Conducting standardized PCB tests at different stages enables us to detect potential defects as early as possible, thereby avoiding rework and scrapping, and saving costs.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.