Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

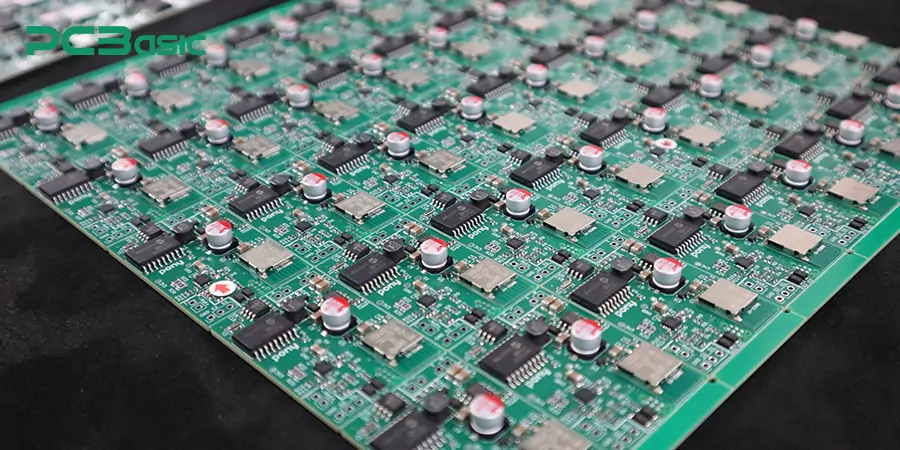

PCBA is the vital component of all electronic devices. Therefore, the performance of all devices depends on PCBA. High volume PCB assembly means assembling more than 10,000pcs PCB boards. It is vital to cooperate with the right high volume PCB assembly manufacturer for your devices, and improve your product performance.

Sweeping the market, you need to choose an excellent high volume PCB assembly manufacturer. Looking for such a company? Excellent, no further search is needed. If high volume PCB assembly is required, PCBasic’s technology stands out in the high volume PCB assembly field!

High-volume PCB assembly refers to the mass production of printed circuit boards, usually involving thousands to millions of units. High volume PCB assembly is suitable for industries that require continuous large-scale manufacturing, such as automotive, medical devices, and consumer electronics.

Here is a table to distinguish large, medium and small batches.

|

Production Type |

Quantity Range |

Typical Applications |

|

Low-Volume PCB Assembly |

1-100 units |

Prototyping, functional testing, sample production |

|

Mid-Volume PCB Assembly |

100-10,000 units |

Pilot production, small-scale market launch, limited production projects |

|

High-Volume PCB Assembly |

10,000+ units |

Mass production, OEM/ODM orders, long-term supply contracts |

PCBasic is able to provide high volume PCB assembly and meet your project specifications. In addition to our high volume PCB assembly manufacturing process and capability, you can also experience convenient services, favorable prices and really high quality.

Time is money in your projects – and PCBasic gets it. PCBasic is the pcb assembly company that delivers fast, flawless results every time. Our comprehensive PCB Assembly Services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB Assembly Manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB Prototype Factory for quick turnarounds and superior results you can trust.

Choosing a high-volume PCB assembly service offers these advantages:

✔ Cost efficiency - Lower unit costs due to economies of scale.

✔ Faster delivery - Optimized SMT patch and board assembly services reduce lead times.

✔ Stable quality - Advanced SMD mounting technology ensures product consistency.

✔ Scalability - Seamless from prototype to full production.

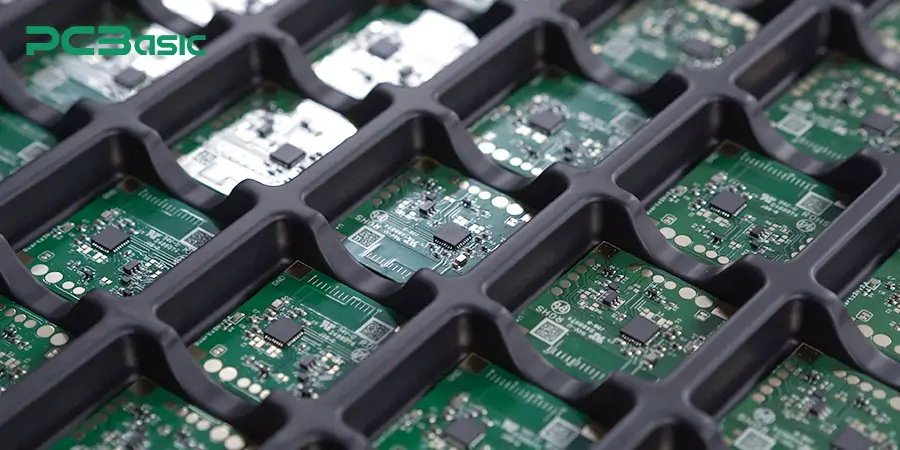

If you want to benefit the most, you should order a large number of PCB components, which will benefit you in terms of cost. If you order more PCBs, you can get more discounts from PCBasic. And you only need to upload the files, and then the rest can be handed over to PCBasic to complete, including the whole process from components sourcing, smt assembly, through-hole assembly to testing and packaging. PCBasic can provide you all with a good service.

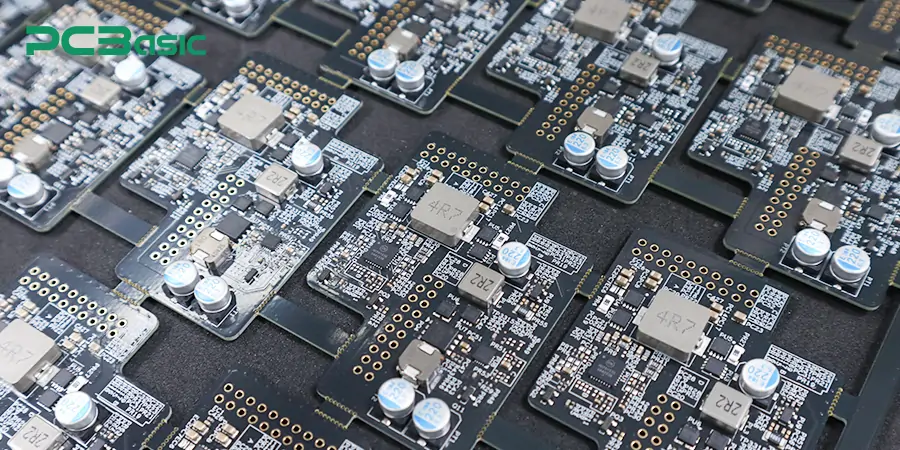

PCBasic has very professional techniques and machines in the high volume PCB assembly. The expert team of PCBasic, this high volume PCB assembly manufacturer, has created unparalleled PCB designs for customers' satisfaction. The whole circuit of the equipment depends entirely on the PCB. Therefore, when the PCB fails, the whole equipment becomes useless. Therefore, the manufacturing process of high volume PCBs needs to be highly valued. While in the production process, even high-volume PCB production, PCBasic spares no effort to avoid failure.

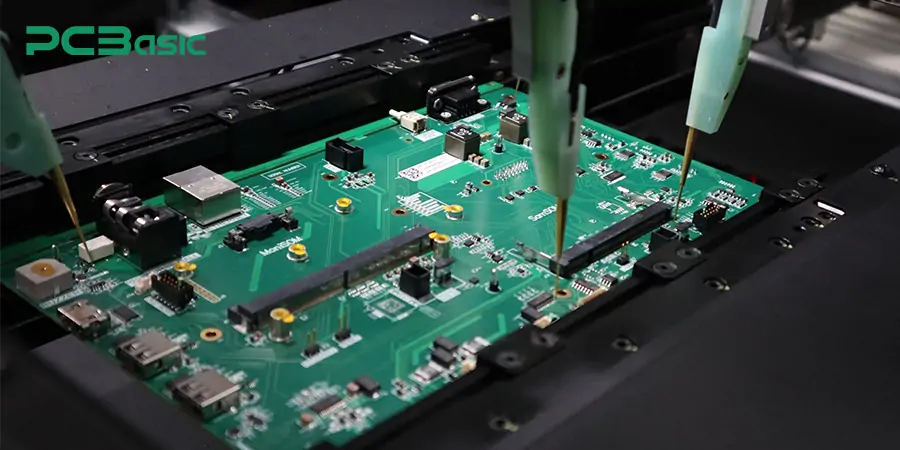

To ensure product quality, PCBasic conducts extensive tests on all products. For example, DFM tests to ensure that the design is suitable for high volume quick turn PCB assembly manufacturing. And automated flying probe tester is equipped with movable test probes perform electrical testing on every PCB. More, before packaging and transportation, AXI and AOI tests are performed on each circuit board.

Generally speaking, when the manufacturing price drops, the quality drops. On the contrary, in PCBasic, we won't compromise on the PCBA quality testing. We will tests each circuit board separately to ensure it is trouble-free. In order to guarantee the quality of high volume PCB production, we will conduct the following tests on high volume PCB assembly:

· Provide free DFM inspection service to ensure that high volume PCB design is completely suitable for manufacturing.

· Provide customized functional testing to ensure product quality.

· Online AOI and online SPI equipment are used for detection.

PCBasic’s high volume PCB assembly services:

· With high-end high volume PCB assembly and production equipment, it can meet the needs of large quantities.

· Over 10 years of specialized subject in high volume PCB assembly.

· Provide functional test and aging test to ensure the quality of high volume PCB assembly production.

· Provide 7/24 online sales and technical support

PCBasic is a great high volume PCB assembly manufacturer in China. PCBasic has the ability to produce millions of PCBAs. Integrity, commitment and values have further improved the success rate of this company. PCBasic has occupied a dominant position in China's high volume PCB assembly manufacturing field. It has international standards of PCB assembly. The company's high-quality PCB assembly products enable it to compete with competitors around the world.

PCBasic is a one-stop circuit board assembly services provider, which has rich experience in high volume PCB assembly, and can also provide assistance in PCB design, PCB manufacturing and assembly testing. With rich experience, we can provide modification suggestions for your PCB design on the premise of ensuring product quality and performance, so that your cost can be continuously reduced. If you choose us to provide high volume PCB assembly services, we will be responsible for your component procurement, reduce your time cost, and let you really enjoy one-stop service.

The high volume PCB assembly is based on IPC standard, and we also have strict internal quality control procedures. The workshop is also equipped with online SPI and online AOI testing equipment, and can also provide functional and aging tests. If you have a high volume PCB assembly requirements, feel free to contact us.

Do you have any questions about high volume PCB assembly? It’s our honor that we can provide a series of solutions to solve your problems. Our experts and knowledge team are ready to eliminate all your doubts 24/7. When will the project start, they will further guide you in every step and any stage of the project.

PCBasic values customers' ideas. So, if you have a file, please contact us. We will reply to you as soon as possible. Moreover, we will try our best to minimize customers' budget. We can't wait to hear from you! Contact PCBasic and realize your ideas!

Knowledge guide for high volume PCB assembly and processing

The number of PCB assembly products required in different industries is also different. Some of them only need to provide low volume PCB assembly, while others need high volume PCB assembly. For those who are capable of providing high volume PCB assembly services, this article will analyze the processing guide of high volume PCB assembly in detail.

1. Quality consistency

Because high volume PCB manufacturing uses the same production specifications, this ensures the consistency of PCB assembly products. For high volume PCB assembly, product testing is carried out in the same batch, so the product quality of high volume PCB assembly can be kept consistent.

2. the turn cycle is fast

Through high volume PCB assembly, products can enter the market faster, which is extremely beneficial to customers who compete for a large number of market shares, and helps OEMs to speed up production and marketing.

3. Effective cost saving

In PCBasic, we can buy the required materials in batches, and can assemble and produce quickly. High volume PCB assembly can save your time and cost.

4. Reduce the design cost

Selecting high volume PCB assembly can carry out one-time PCB design and PCB production, which can reduce unnecessary PCB design costs.

5. Shorten the assembly time

Due to the adoption of high volume PCB assembly, the time required for manufacturing is reduced in the process of design and prototyping, and the whole process of high volume PCB assembly is also automated, which reduces manual intervention to save time and energy.

If you want to enter the high volume PCB assembly market, you need to reserve knowledge of high volume PCB assembly. For example, high volume PCB assembly is usually used in the communication industry, automobile industry, aviation industry, medical and health industries, and can be used in large quantities.

Yes, we are concerned about the health of users and the environment. We are aware of the harmful or negative effects that lead emissions may have on users and the environment. That's why we eliminate lead from production materials. It is of great benefit to protect people's health and eliminate environmental pollution.

Step 1: PCB cleaning

For the first high volume PCB assembly, it is necessary to clean the PCB board to prevent the residue or dust on the PCB board from affecting the quality of PCB assembly products in the later stage.

Step 2: Solder paste printing

You will carry out the mass assembly process by printing solder paste on the PCB laminate. In this process, you will use scrapers and templates to help the soldering printing process, or you can choose jet printing.

Step 3: SPI detection

After the solder paste printing is completed, the whole process should be checked by solder paste inspection (SPI), mainly including the amount of solder paste printed, the height of solder paste printed, the area/volume of solder paste printed, the flatness of solder paste printed, etc.

Step 4: Patch.

In this process, the surface mount components are accurately placed on the PCB pads by moving the mounting head. Because the computer controls everything according to the design, the process is very fast.

Step 5: reflow soldering

After one or more electronic components are connected to the contact pads by using solder paste, the solder is melted by controlling heating to achieve permanent bonding, so as to realize the electrical connection.

Step 6: Online AOI detection

Through this process, the occurrence of bad welding conditions such as wrong parts, empty welding, virtual welding, short circuit, erection of monuments, etc. after reflow soldering can be detected, and the product quality can be guaranteed.

In addition to online AOI detection and online SPI detection, circuit testing, functional circuit testing, X-ray testing, etc. are also required.

Testing (ICT)

In the circuit test, you can use the most meticulous test method to check the quality and integrity of the PCB, and the machine will be used to detect the errors in the PCB for correction.

Flying Probe Test

Here, an automated flying probe testing system uses movable test probes to verify the electrical functionality of the PCB. The computer-controlled probes make contact with test points on the board to measure continuity, resistance, and other parameters. By comparing the collected data with the design specifications, the system determines whether the PCB meets all required electrical performance standards and has passed the test.

This method eliminates the need for custom test fixtures, making it ideal for prototype validation and low-to-medium volume production. The flying probe test ensures comprehensive circuit verification while maintaining flexibility and cost-efficiency.

X-ray detection

You will use X-ray inspection to detect invisible welding problems on PCB. You only need to use X-ray inspection to detect components on PCB and errors in welding.

There are many high volume PCB assembly service providers in the market. In order to select a suitable high volume PCB assembly service provider, we can start from the following aspects: the ability to meet expectations, PCB manufacturing cost, certification and standards, manufacturing experience, PCB quality turnaround time, responsiveness, etc. Choosing the right high volume PCB assembly service provider can reduce the time cost and help the products go online quickly.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.