Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

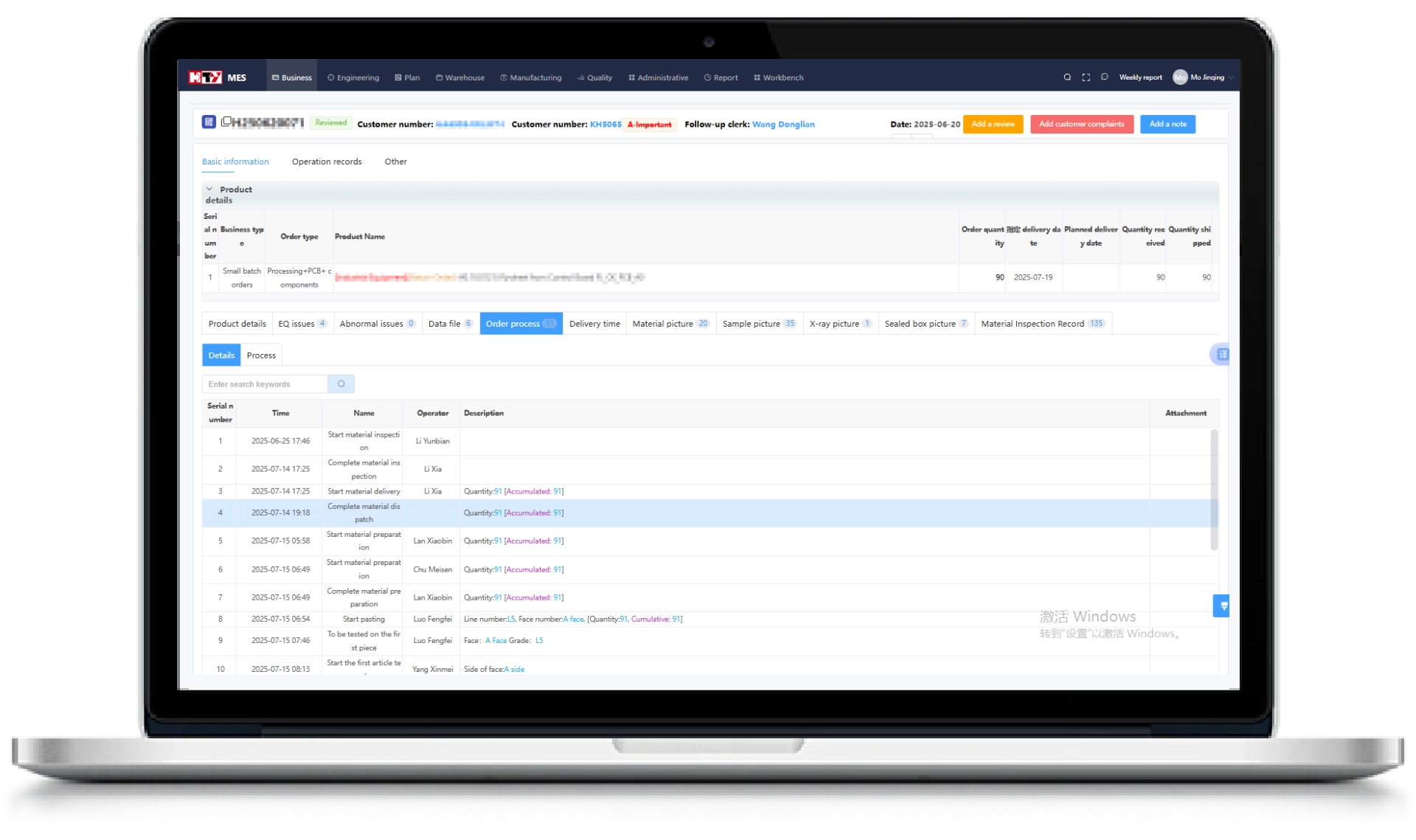

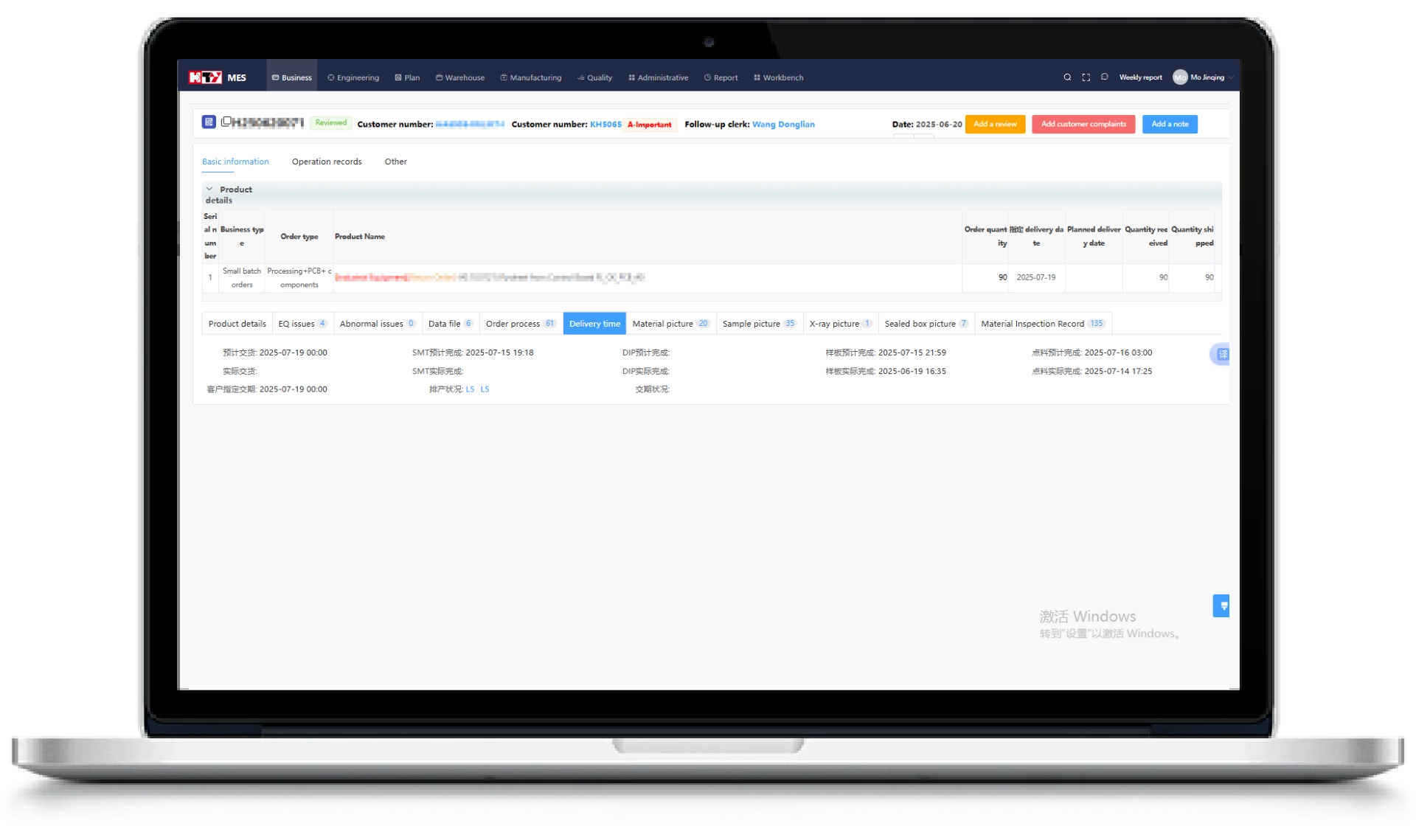

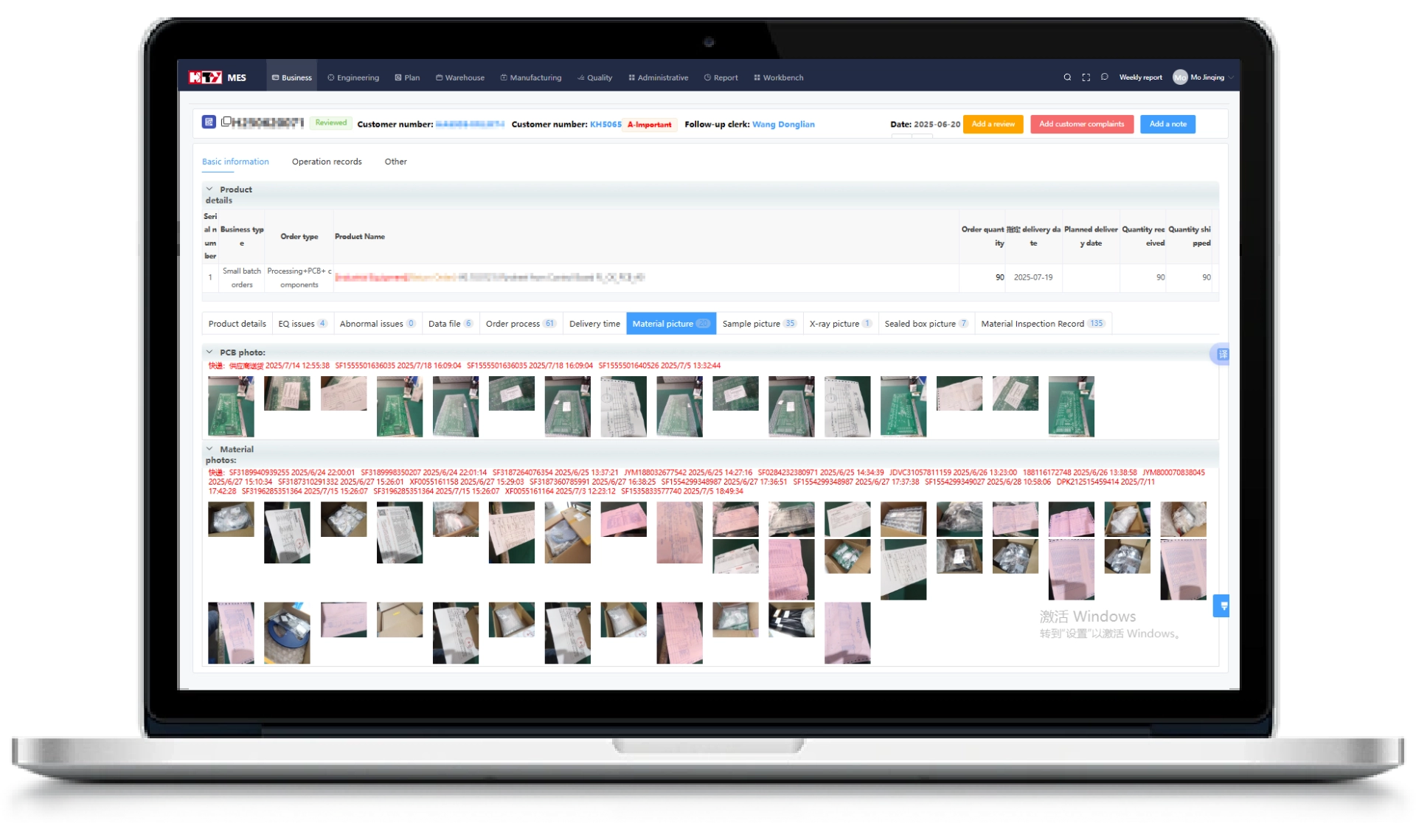

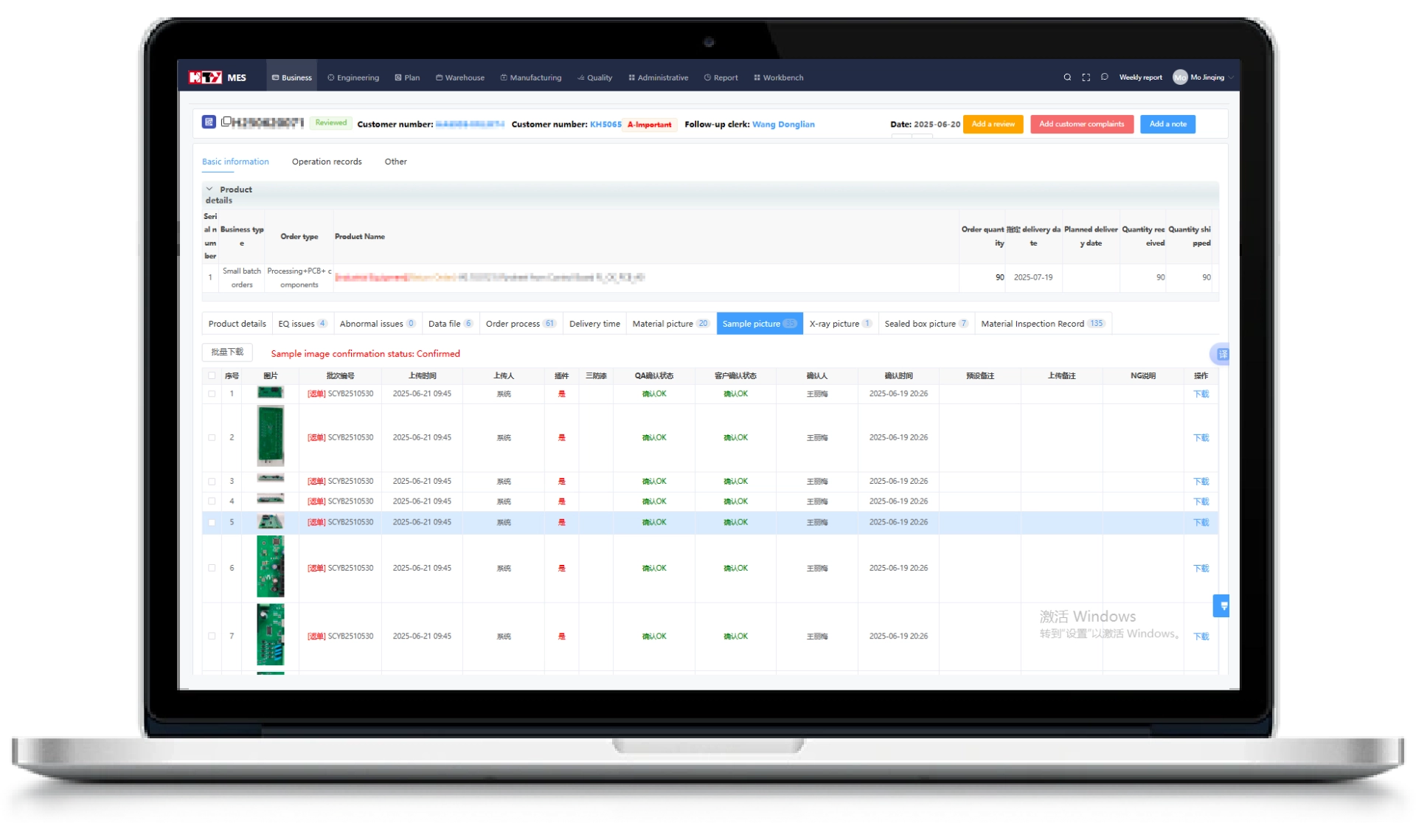

MES System

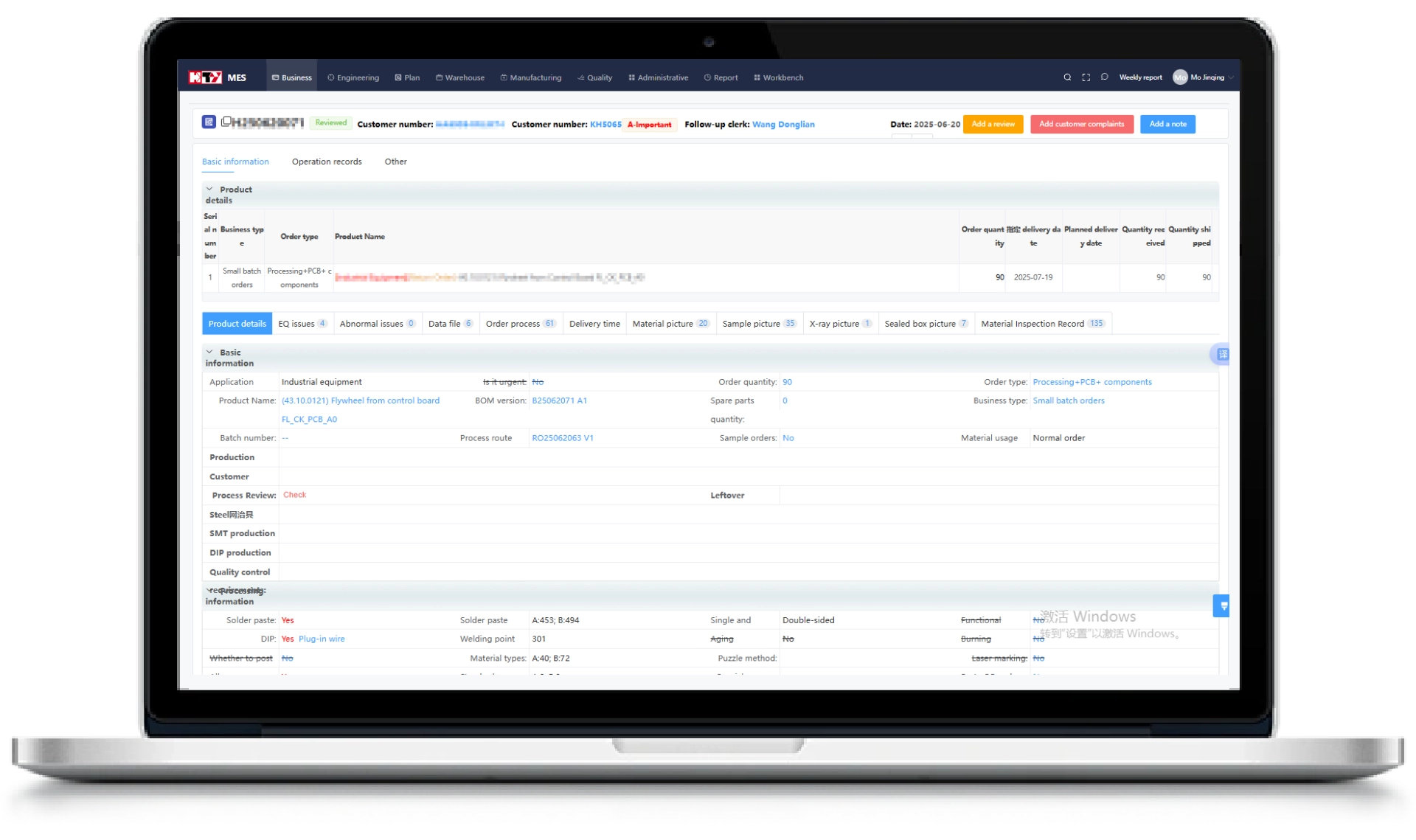

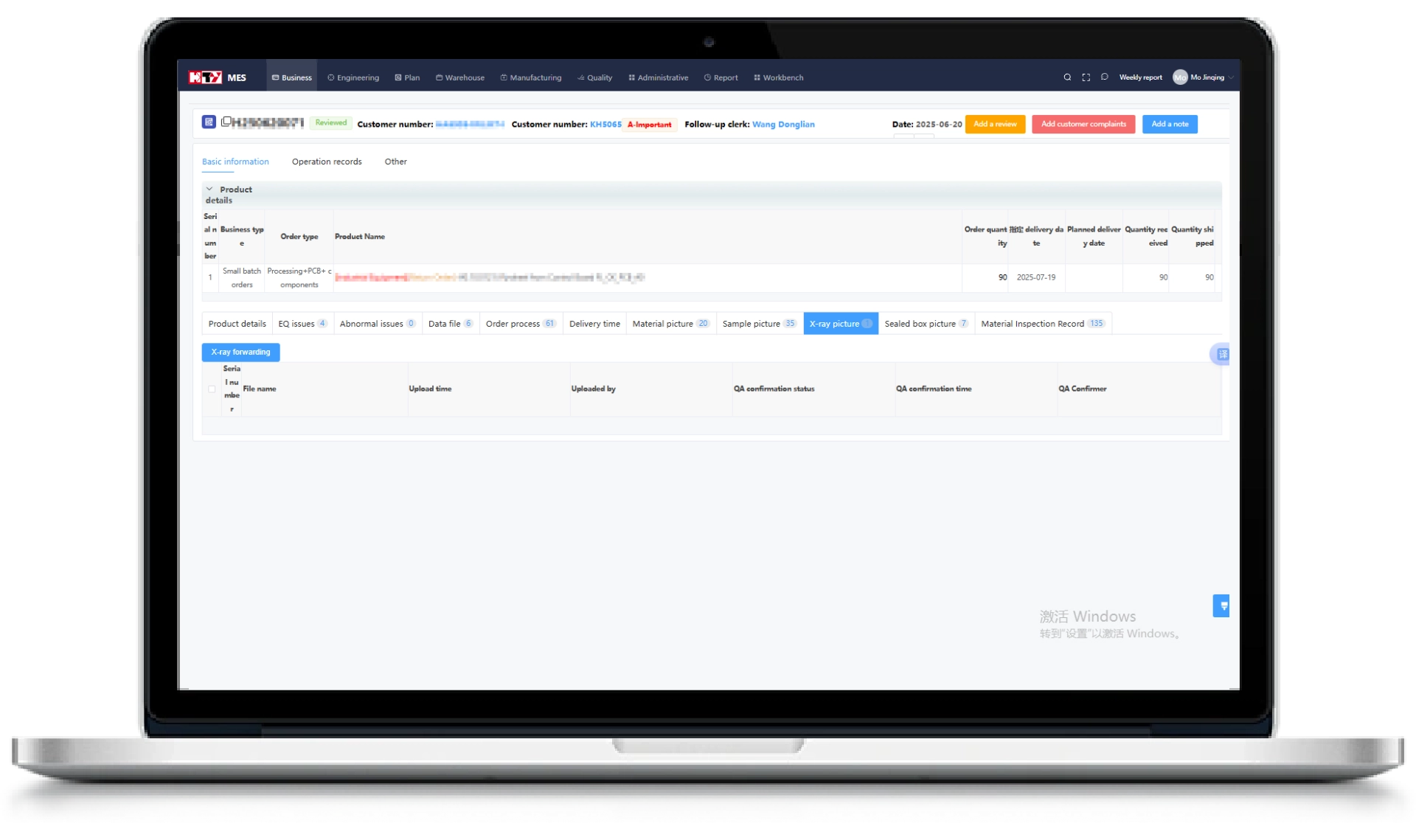

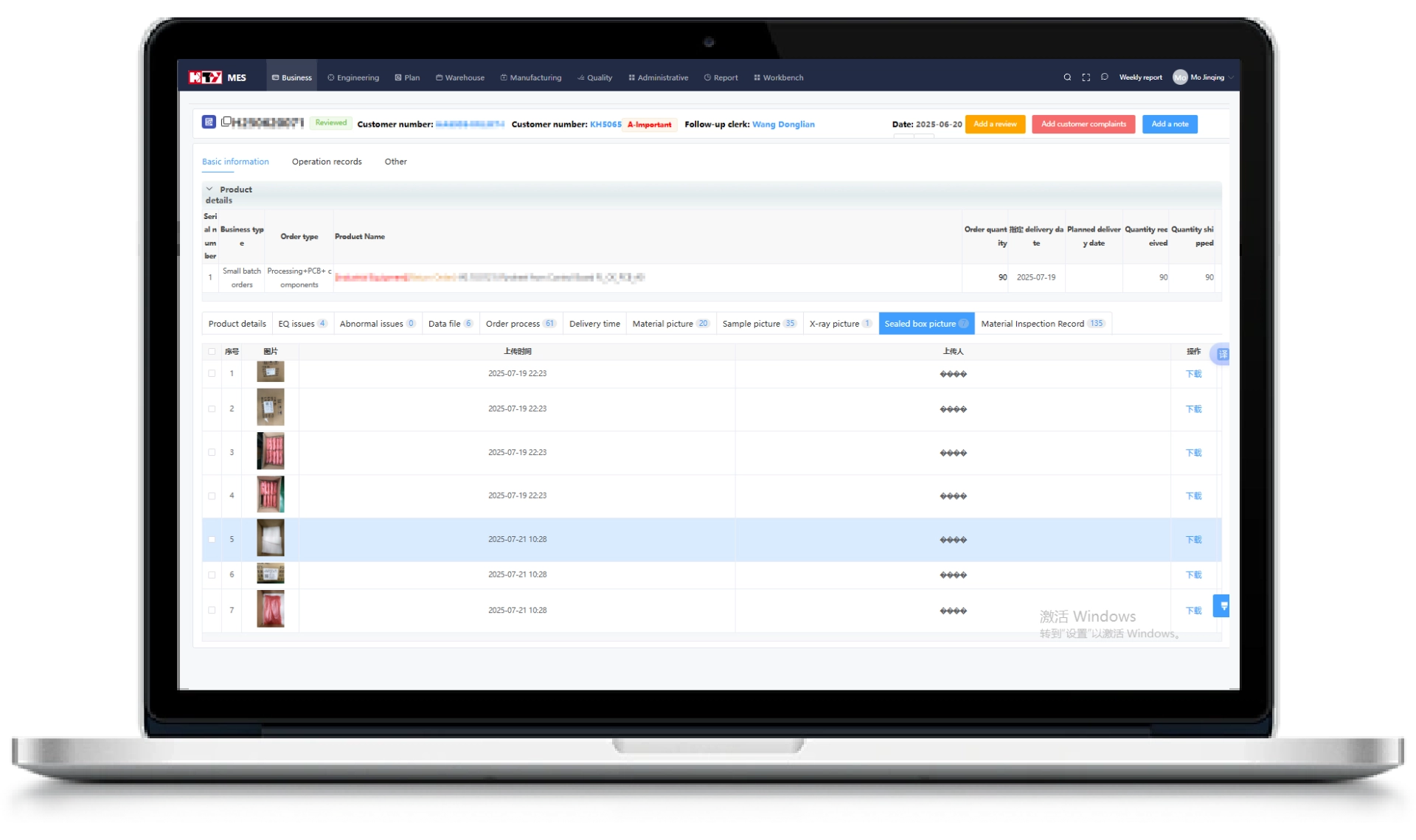

MES System Overview

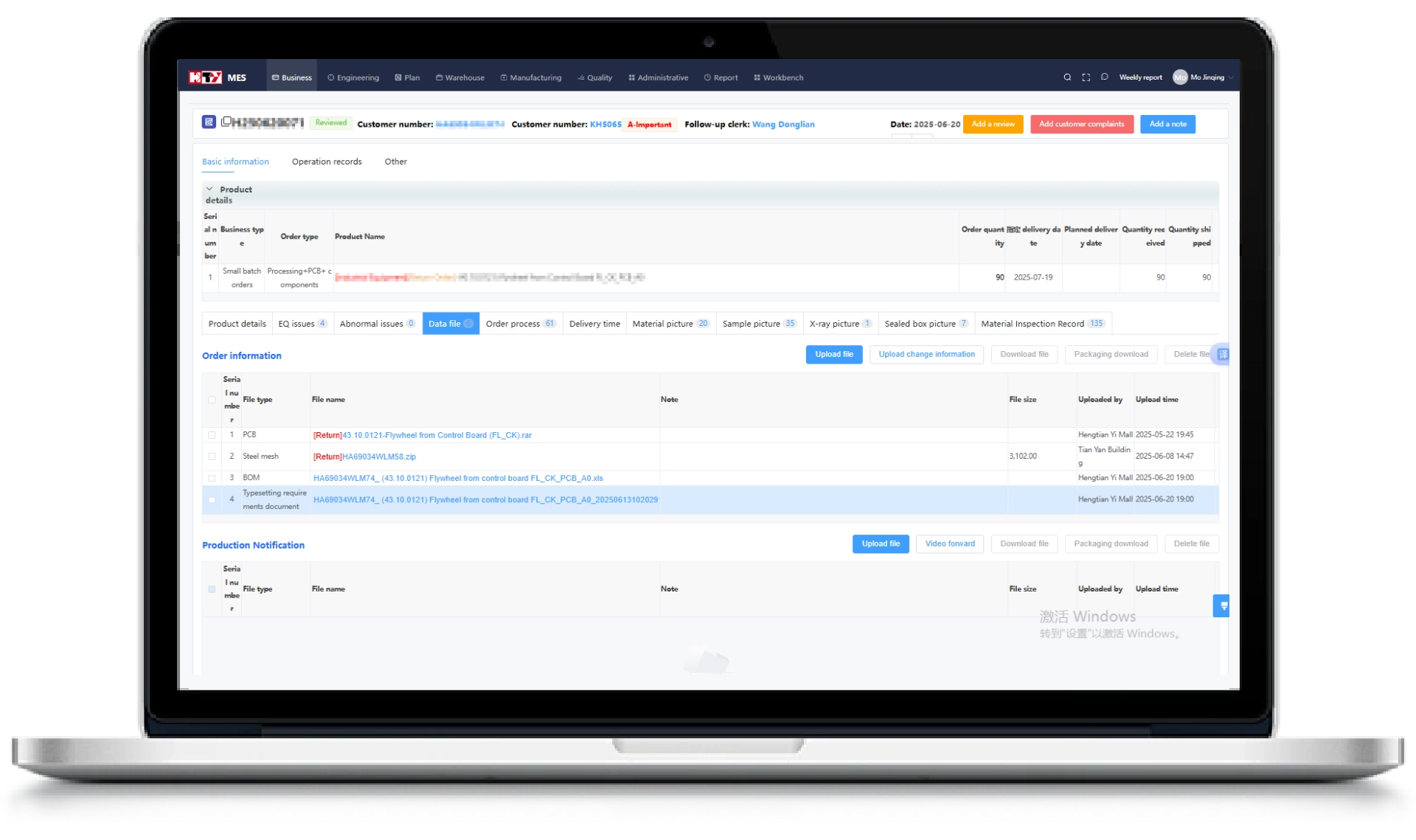

In modern electronics manufacturing, digital and transparent production management is key to staying competitive. Our self‑developed Manufacturing Execution System (MES) enables precise control and full traceability of the entire PCBA process, helping customers achieve higher quality, faster delivery, and lower risk.

Advantages of MES System

✔ Full Process Traceability

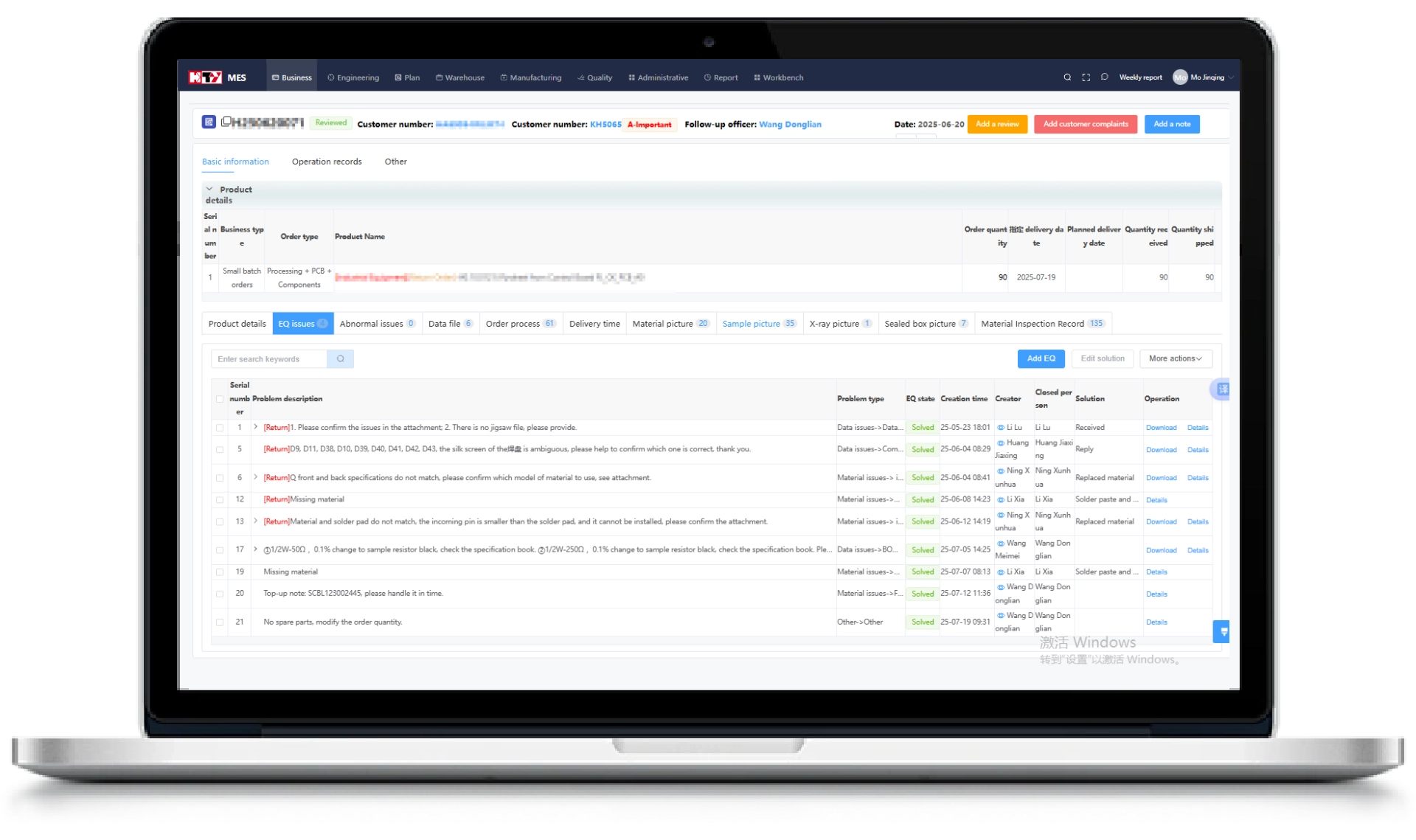

Track every board from material intake to final delivery. Each has a unique ID with full visibility of processes, operators, equipment, and inspection records.

✔ Real-Time Monitoring & Alerts

Get instant notifications for equipment issues or quality deviations, reducing batch risks.

✔ Standardized Process Execution

All steps run automatically to standard, minimizing human errors and ensuring consistent quality.

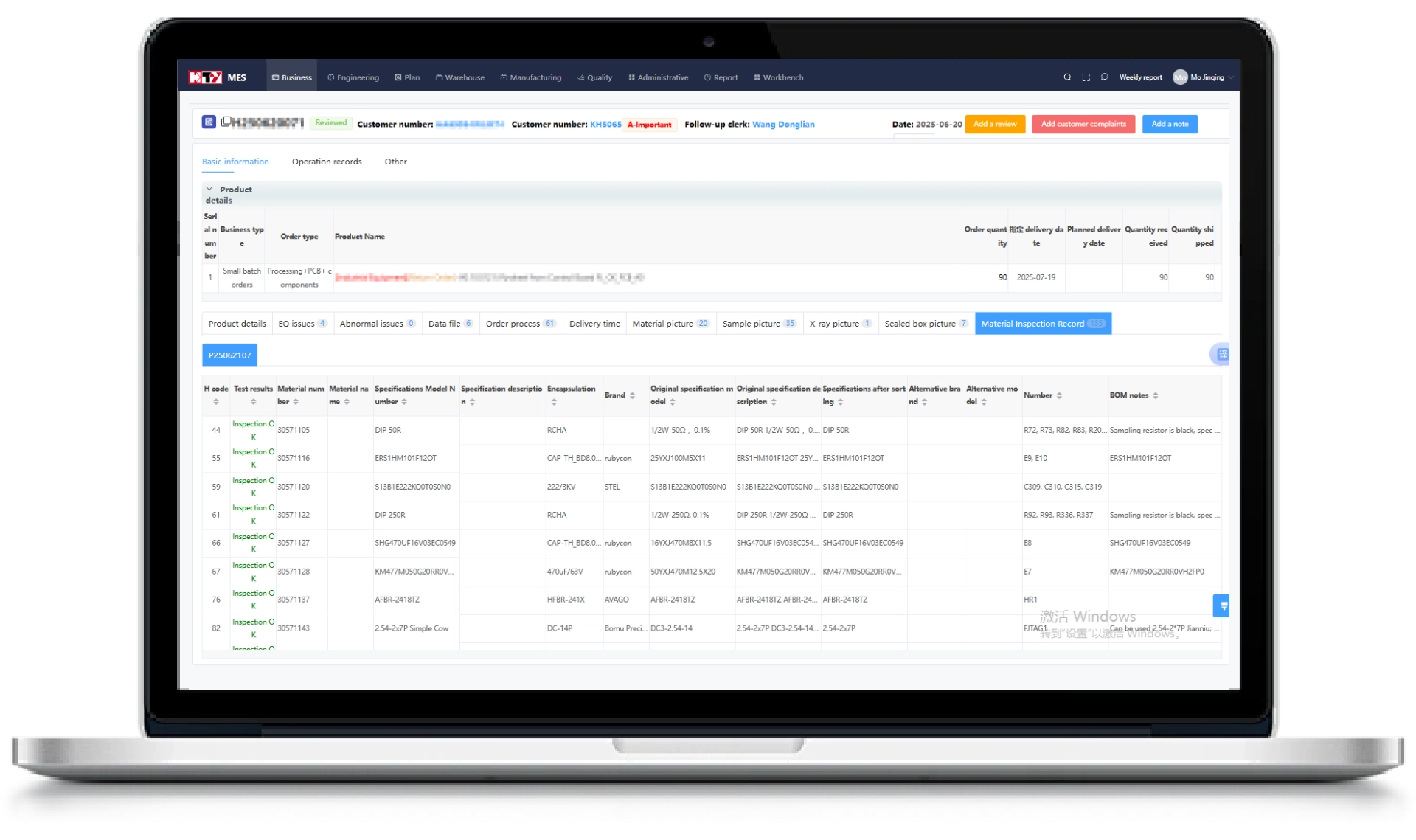

✔ Automated Quality Data

AOI, SPI, and functional test data are collected automatically, making process quality measurable and results verifiable.

✔ Visual Production Progress

Work orders, output, and yield are displayed in real time, giving you clear production insights for better decisions.

Quality Control Process

1. IQC - Incoming Quality Control Inspection

Prevent process defects caused by material issues during production and avoid efficiency losses due to non-compliant quality of refurbished materials.

2. SPI - Solder Paste Inspection

Detect solder paste printing defects to prevent them from entering the next process.

3. Online AOI Inspection

Check for any errors, omissions, or defects in the PCBs to prevent them from flowing into the next process.

4. First Article Inspection

Verify the accuracy of the placement process on the production line and ensure each component's parameters are within standard limits.

5. IPQC - In-Process Quality Control

Conduct random inspections of all production processes to ensure compliance with the work instructions.

6. 3D-XRay Inspection

Inspect the solder joints of components that are invisible to the naked eye to ensure the reliability of BGA solder balls.

7. QC - Quality Control Inspection

Inspect finished PCBA according to the IPC-610 inspection standard.

8. QA - Quality Assurance Inspection

Strict inspections are carried out before shipment, with scanning and verification to ensure no defective products are shipped.

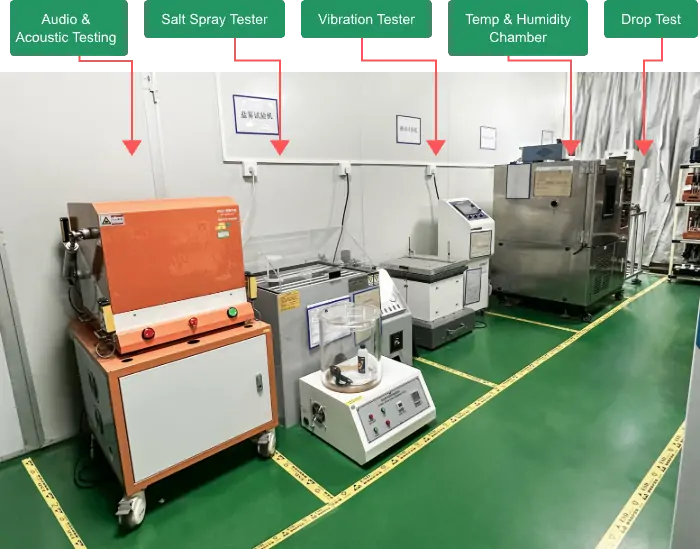

Lab Overview

To ensure every PCBA product delivers high quality and reliable performance, we operate an advanced laboratory with comprehensive testing equipment. Our lab features audio & electroacoustic automated testing, salt spray testers, vibration testers, temperature & humidity chambers, and drop test machines. These facilities cover all testing requirements from R&D to mass production.

All tests follow strict industry standards and simulate extreme operating conditions. We perform multi‑dimensional reliability tests—including physical, electrical, and environmental—to ensure product safety, stability, and lifespan, minimizing risks for our customers.

Committed to “quality first,” we continuously enhance our testing capabilities to provide superior and dependable APCB products and services.

We've collaborated with your team on multiple PCBA projects, and the overall yield rate has consistently stayed above 99%. The test pass rate is excellent, and product consistency between batches has significantly improved our assembly efficiency and reduced rework risks.

During one round of testing, we encountered an issue with a specific batch of boards. After reporting it, your team quickly traced the root cause using the MES system—tracking it down to the production batch, operator, and materials used. A full 8D report was delivered within 24 hours. Your traceability and response speed are highly impressive.

Your MES system provides full visibility from SMT to final testing. Each board is uniquely traceable via barcode, and we can access production status and quality history at any time. Our quality audit team truly values this level of transparency and traceability.

We have frequent small-batch, multi-variety PCBA needs, and your team always responds quickly. Process consistency is outstanding—especially in critical steps like BGA soldering, AOI inspection, and X-ray validation. Your quality control is truly dependable.

Your PCBA shipments are always well-packaged—with anti-static bags, custom foam inserts, and proper labeling. Even with long-distance transit, we've never had issues with component damage or displacement. The attention to packaging details reflects your commitment to quality.

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.