Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

-360° Virtual Tour

PCBasic JS Technology Co., Ltd is an intelligent factory focusing on one-stop service and fast multi-variety small and large batch PCBA production. We are also a PCB company focusing on online PCB design and manufacture and one-stop PCB assembly. We incorporate core business values of speed, quality, PCBA technology, and PCB design services. Providing R&D solutions, material selection OEM order production, and other services, the company self-developed CRM, MES, ERP, and IoT management systems to achieve industrial digital intelligent factories. As a PCB fabrication company, our core service areas: industrial control, smart home, instrumentation, vehicle Internet of Things, communication power, medical devices, automotive electronics, aviation, etc.

Being a leading PCB manufacturing company in the market, we have passed ISO9001 / IATF16949 / ISO13485 quality certifications and won the national high-tech enterprise award, has over 200 employees. Among them: over 30 PCB designers in the engineering department, 20 people in quality management, 10 people in IT and 2 employees in R&D, 24 hours support to provide customers professional prototype PCB assembly services.

As a PCB supplier and PCB assembly company, our company accumulated over 15 years of experience in the SMT industry to overcome many problems. We've continuously invested in PCBA technology to develop a series of intelligent production management systems to improve management efficiency and quality. It enhances the PCB layout design quality with a self-developed LCR incoming inspection system, SMT fault detection system, sample patch systems, MES systems, intelligent material rack, and advanced intelligent ESD electrostatic protection systems.

Our fully automated SMT line includes 9 inspection processes to ensure the highest quality for you.

Prevent process defects caused by material issues during production and avoid efficiency losses due to non-compliant quality of refurbished materials.

Detect solder paste printing defects to prevent them from entering the next process.

Check for any errors, omissions, or defects in the PCBs to prevent them from flowing into the next process.

Verify the accuracy of the placement process on the production line and ensure each component's parameters are within standard limits.

Conduct random inspections of all production processes to ensure compliance with the work instructions.

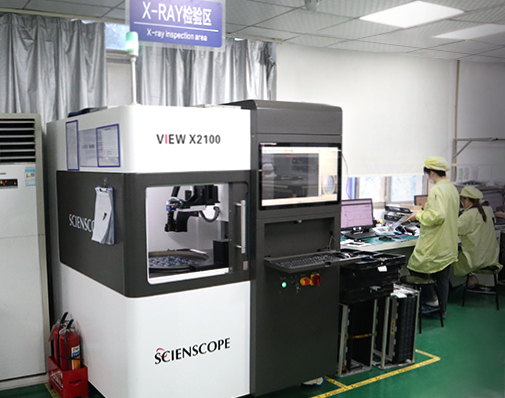

Inspect the solder joints of components that are invisible to the naked eye to ensure the reliability of BGA solder balls.

Inspect finished PCBA according to the IPC-610 inspection standard.

Conduct strict inspections before shipment, along with barcode scanning verification, to prevent defective products from being shipped.

Strict inspections are carried out before shipment, with scanning and verification to ensure no defective products are shipped.

Treasure Talented People, Pay Attention To Management

It has become a well-known service provider of global multi variety and small batch high-end PCBA fast production

Create development opportunities for employees, lead the development of the industry, and provide excellent services for customers

Honesty, Cooperation, Innovation and Pragmatism

Speed, Quality, Technology and Service

Agile response speed, fast lead time.

The management of national standard quality system, advanced production equipment, information intelligent production process management system MES, win the reputation of customers with quality.

Use technology innovation to improve production efficiency and quality, rich process experience to prevent quality risk.

Customer demand is the driving force of our development, adhere to the customer-centered, rapid response to customer demand, and continue to create long-term value for customers.

Quality Certifications

IPC Class 3 Capability

Testing & Inspection

Customer Feedback

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.