Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

When you choose PCBasic, you are choosing a quality that stands the test of time.

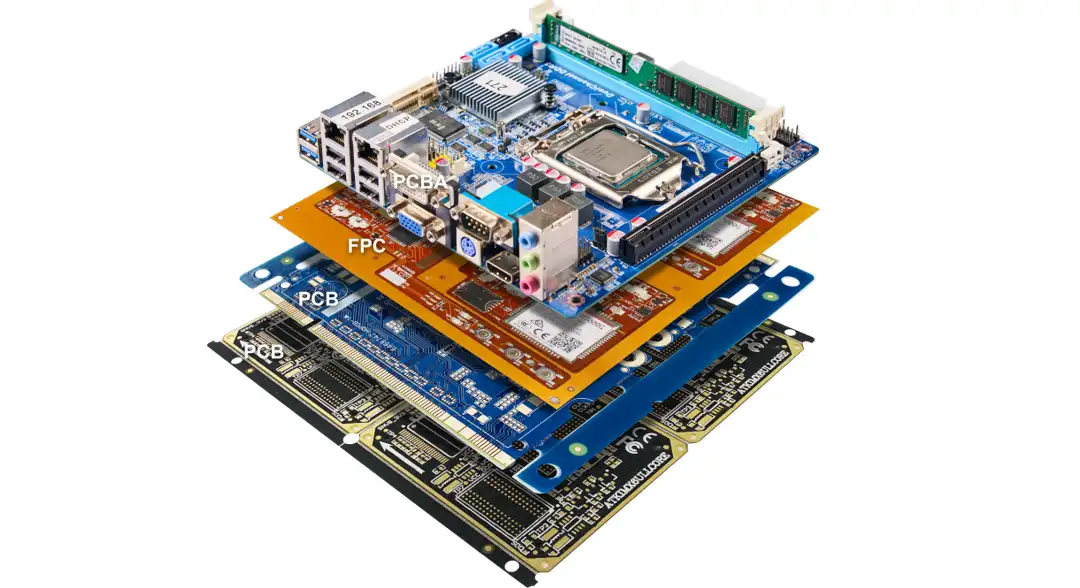

At first glance, there seems to be no significant difference between circuit boards, but what truly affects their lifespan and performance are the details hidden inside - durability, precision and reliability. These invisible aspects are precisely what PCBasic has always valued the most.

Every circuit board we produce reflects our commitment to high quality and precise manufacturing. Whether it is rapid prototyping, small-batch trial production, or large-scale production, we can provide customers with suitable, efficient and stable solutions.

Our goal is simple: help customers bring their products to market more quickly, reduce costs, and at the same time ensure stable and reliable quality.

Relying on our self-developed MES + ERP + CRM + IoT digital management system, PCBasic can achieve full-process digital tracking and controllable management from PCB manufacturing, component sourcing, SMT assembly, DIP insertion, functional testing to complete machine assembly.

We have obtained multiple international certifications, including UL, ISO 9001, ISO 13485, IATF 16949, RoHS, and REACH.

Every circuit board leaving the factory undergoes strict testing to ensure compliance with the world's highest quality standards.

|

Items |

2016 |

2017 |

2018 |

2025 (Current Capability) |

|

Number of Layers

|

2–36 layers |

2–40 layers |

2–64 layers |

2–64 layers (HDI, Rigid-Flex) |

|

Embedded ICs |

No |

Supported |

Supported |

Supported with advanced embedding

|

|

HDI Structure

|

HDI (2+N+2), staggered & stacked vias

|

HDI (4+N+4), staggered & stacked vias |

HDI (7+N+7), stacked microvias |

Up to 10+N+10, any-layer interconnect |

|

Base Materials

|

FR4 (Shengyi) |

FR4 (Shengyi) |

FR4 (Shengyi) |

FR4 / High-Tg / Polyimide / PTFE / Ceramic / Halogen-Free |

|

Glass Transition (Tg)

|

Tg 170°C |

Tg 210°C |

Tg 220°C |

Up to Tg 250°C |

|

Halogen Free

|

Yes |

Yes |

Yes |

Yes (RoHS & REACH Compliant) |

|

High Frequency Materials

|

Yes |

Yes |

Yes |

Yes (Rogers, Isola, Shengyi S7136, etc.) |

|

Max Board Size

|

508×762 mm (20×30 in)

|

508×762 mm (20×30 in) |

508×889 mm (20×35 in) |

609×889 mm (24×35 in) |

|

Board Thickness |

0.21–6.0 mm |

0.21–6.0 mm |

0.21–6.0 mm |

0.1–10 mm |

|

Min. Trace Width / Spacing |

3/3 mil |

2/3 mil |

2/2 mil (partial) |

1.5/1.5 mil (LDI + fine line etching) |

|

Copper Thickness (Outer / Inner) |

5 oz |

7 oz |

8 oz |

Up to 8 oz (power board option) |

|

Min. Drill Hole (Mechanical) |

0.15 mm |

0.15 mm |

0.15 mm |

0.10 mm laser / 0.15 mm mechanical |

|

Aspect Ratio |

12:1 |

12:1 |

12:1 |

20:1 |

|

Solder Mask Type |

NAYA LP-4G / Tamura TT19G / Taiyo PSR-2200 |

Yes |

Yes |

Multiple brands (NAYA, Taiyo, Tamura) |

|

Solder Mask Colors |

Green / Blue / Red / White / Black |

Yes |

Yes |

Custom colors available |

|

Impedance Control Tolerance |

±10% (≤50Ω: ±5Ω) |

±10% |

±10% |

±8% (standard), ±5% optional |

|

Via Plugging Capability |

CNC: ≥0.15 mm; Laser: ≥0.1 mm |

Yes |

Yes |

Up to 0.7 mm via fill/resin plug |

|

Min. Annular Ring |

3 mil |

3 mil |

3 mil |

3 mil (controlled with AOI) |

|

Min. Solder Mask Bridge (Green / Black) |

3 mil / 4 mil |

3 mil / 4 mil |

3 mil / 4 mil |

2.5 mil (LDI-controlled) |

|

Surface Finishes |

HASL / ENIG / OSP / LF-HASL / Hard Gold / Imm. Ag / Imm. Sn |

Yes |

Yes |

ENEPIG / Hard Gold / Immersion Silver / ENIG / OSP / Lead-Free HASL |

|

V-Cut (CNC / Manual) |

20° / 30° / 45° / 60° |

20° / 30° / 45° / 60° |

20° / 30° / 45° / 60° |

Standard angles maintained |

|

Chamfer Angle |

20° / 30° / 45°, Jump ≥5 mm |

Yes |

Yes |

20° / 30° / 45° ±5 mm tolerance |

|

Dimensional Tolerance |

±0.1 mm |

±0.1 mm |

±0.1 mm |

±0.075 mm (CNC routing) |

|

Board Thickness Tolerance |

±7–10% |

±7% |

±7% |

±5% (for HDI & RF PCBs) |

|

Hole Size Tolerance |

±0.08–0.15 mm (by size range) |

Same |

Same |

±0.05 mm (laser), ±0.075 mm (CNC) |

|

Certifications |

UL, ISO 9001, ISO 14000, RoHS, TS16949 |

Yes |

Yes |

UL, ISO 9001, ISO 13485, IATF 16949, RoHS, REACH |

|

No. |

Item |

Process Capability |

|

1 |

Base Materials |

FR4 / High-Tg / Halogen-Free / Polyimide / PTFE / Ceramic / Aluminum Base |

|

2 |

PCB Type |

Rigid PCB / FPC / Rigid-Flex / HDI |

|

3 |

Max Layer Count |

64 Layers |

|

4 |

Min. Base Copper Thickness |

1/3 oz (12 μm) |

|

5 |

Max. Finished Copper Thickness |

8 oz |

|

6 |

Min. Trace Width & Spacing (Inner / Outer) |

2/2 mil (LDI precision) |

|

7 |

Min. Hole to Conductor Spacing |

6 mil |

|

8 |

Min. Annular Ring (Via / Component) |

3 mil / 5 mil |

|

9 |

Min. BGA Pad Diameter / Pitch |

8 mil / 0.4 mm |

|

10 |

Min. Drill Hole |

0.10 mm (Laser) / 0.15 mm (CNC) |

|

11 |

Max Aspect Ratio |

20:1 |

|

12 |

Min. Solder Mask Bridge |

3 mil |

|

13 |

Solder Mask Process |

Film or LDI (Laser Direct Imaging) |

|

14 |

Min. Dielectric Thickness |

2 mil |

|

15 |

HDI Types Supported |

1–7 Steps, Any-Layer HDI, Buried Capacitance & Resistance |

|

16 |

Surface Finishes |

ENIG / ENEPIG / OSP / Imm. Sn / Imm. Ag / Hard Gold / Silver Plating / Lead-Free HASL |

|

17 |

Max PCB Size |

609 × 889 mm |

|

18 |

Impedance Control |

±8% standard (±5% optional) |

|

19 |

Testing Methods |

Flying-Probe, AOI, X-ray, ICT, Functional Test, Impedance Test |

|

20 |

Cleanliness Control |

Ionic Contamination ≤ 1.0 μg/cm² NaCl Equivalent |

|

Category |

Prototype (≤1 m²) |

Mass Production (>1 m²) |

|

Standard FR4 (General Tg) |

Shengyi S1141, KB6160A |

Shengyi S1141 |

|

High-Tg Halogen-Free |

Shengyi S1170G, TU-862 HF (Tg170) |

Same |

|

Medium-Tg Halogen-Free |

Shengyi S1150G (Tg150) |

Same |

|

High CTI (>600V) |

Shengyi S1151G / S1600 / KB6160C |

Same |

|

Special High/Low Temp |

Shengyi SH260 |

Same |

|

High-Tg FR4 |

S1000-2 / IT180A / S1000-2M |

Same |

|

High-Frequency (Ceramic-Filled) |

Rogers 4003C / 4350B / Shengyi S7136 |

Same |

|

PTFE RF Materials |

Rogers / Taconic / Arlon / Taizhou Wangling |

Same |

|

High-Speed (1–5G) |

MEG4 / TU-862 / S7038 / FR408HR / EM370 |

Same |

|

High-Speed (5–10G) |

MEG4 / TU-872 / N4000-13 / I-Speed (Isola) / EM-888 |

Same |

|

High-Speed (10–25G) |

MEG6 / TU-883 / Synamic 6 / I-Tera MT40 / Meteorwave 2000 |

Same |

|

High-Speed (>25G) |

MEG7 / TU-933 / Tachyon 100G / IT-988 / Meteorwave 4000 |

Same |

|

High-Frequency DK 2.2–2.3 |

RO5880 / TLY-5 / GF220 (Shengyi) |

Prototype only |

|

High-Frequency DK 3.37–3.5 |

RO4350 / RO4835 / AR-350 / RF-35 |

Supported |

|

High-Frequency DK 6.15 |

RO4360 / RO6006 / RO3006 |

Supported |

|

High-Frequency DK 10.0–10.2 |

RO6010 / RO3010 / AR-1000 / CER-10 |

Prototype only |

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.