Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

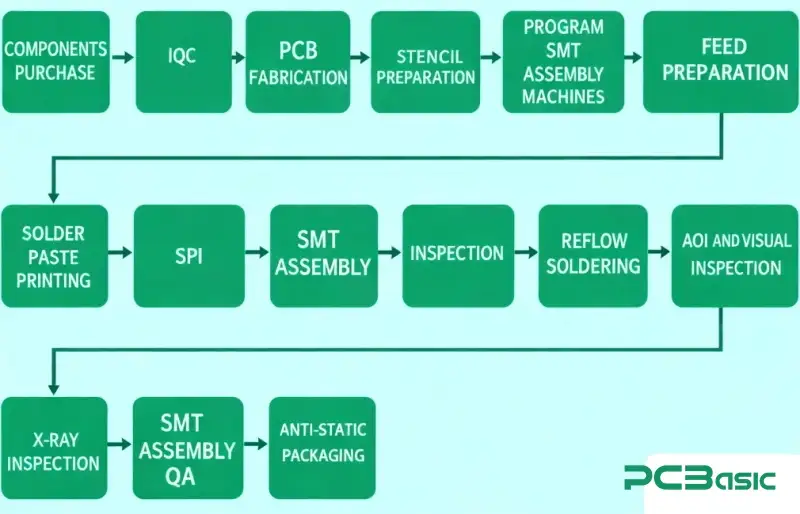

PCBasic offers global customers fast, high-quality, and highly cost-effective complete PCB manufacturing and assembly services, covering circuit board manufacturing, electronic component sourcing, SMT/DIP assembly, testing, inspection, and final packaging. Know more about PCBasic here.

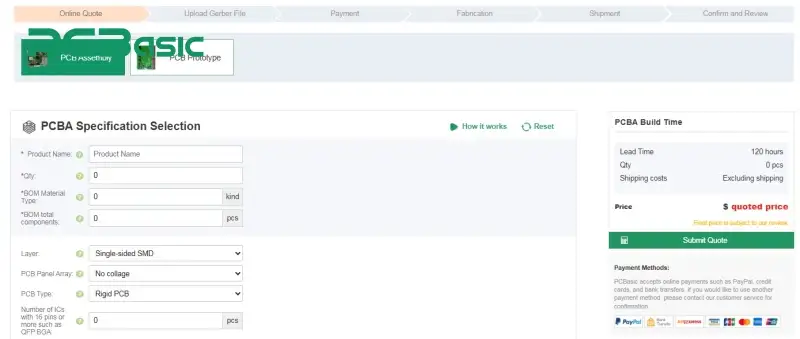

Below, we will introduce to you the process of placing an order under PCBasic.

First of all, when you are preparing to submit a PCB manufacturing and assembly order to PCBasic, please make sure that all the following materials are complete.

|

File Name |

Detailed Description |

|

1. Gerber Files (including fabrication drawing) |

Define all PCB manufacturing layers such as copper, solder mask, silkscreen, and board outline. Include drill holes, fiducials, and edge rails if applicable. You can upload them as a single .zip or .rar file. |

|

2. Bill of Materials |

The BOM guides component sourcing and assembly. Please provide it in Excel or CSV format, including: • Reference Designators • Part Number and Description • Package Type • Manufacturer Name & MPN • Placement Side (Top/Bottom) • Indicate if components are consigned (for partial consignment orders). |

|

3. Pick & Place / Centroid / XY File |

Used for SMT programming. Should include Reference, X/Y coordinates, Rotation angle, and Side (Top/Bottom). Common formats: .csv, .txt, .xls. |

|

4. NC Drill File |

Indicates hole positions and diameters for through-hole and non-plated holes, used for component mounting and tooling alignment. |

|

5. Solder Paste Layer File |

Defines stencil openings for solder paste printing. If PCB fabrication is also handled by PCBasic, this file will be automatically generated. |

|

6. Special Assembly Instructions (if any) |

Include details about polarized parts, BGA orientation, testing requirements, conformal coating, or special handling needs. |

|

7. Consigned Components List (if applicable) |

For consigned or partial consigned orders, provide a list of supplied parts with clear labeling (part number, quantity, and purpose). |

After you have prepared the necessary documents, simply place the order directly on PCBasic. If you are not familiar with the process, you can also contact us. We will arrange professional sales representatives to assist you with the order placement. Once the order is confirmed, our system will immediately generate a unique order number for tracking throughout the process and cross-departmental coordination. At the same time, we will review all design files (Gerber, BOM, XY data, etc.) and confirm the availability of materials. In case of any technical questions or component substitution issues, our team will contact you before production to confirm.

Before each project enters production, PCBasic conducts a rigorous DFM (Design for Manufacturability) check. We thoroughly review the design specifications of the PCB to identify any missing information, redundant designs, or potential layout issues. Common problems include: insufficient component spacing, improper pad size, and offset hole positions, etc. These issues can affect subsequent assembly and functionality, and the DFM check can prevent their occurrence.

After all the documents and materials have been checked and confirmed, we will proceed with the material confirmation. Among them, there are three ways to purchase components: turnkey, consigned, and partial consigned. For more details, please refer to this.

Once all the materials arrive at the factory, we will conduct inspections on them to ensure the reliability of all raw materials and electronic components. The main inspections include:

• Model and quantity

• Appearance and form

• Functional sampling test

If any non-conformity or inconsistency is found, we will immediately isolate and return the batch of materials to the supplier or customer for replacement. Our MES+ERP digital management system will fully record the source and usage of each material, enabling full traceability throughout the process.

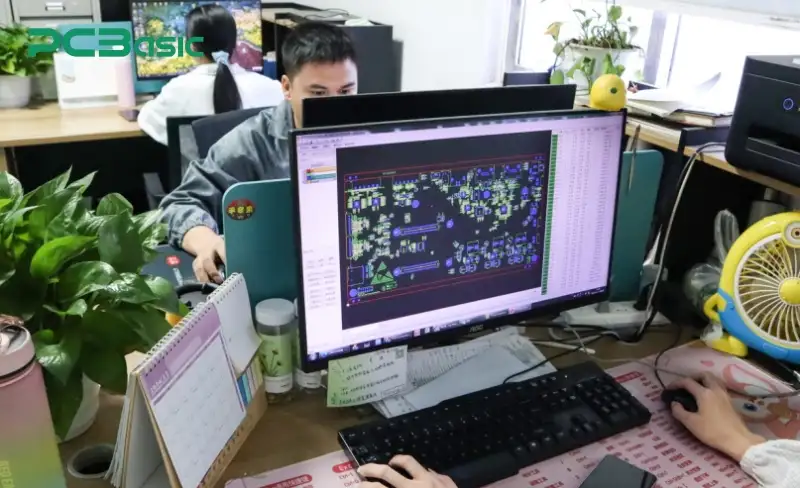

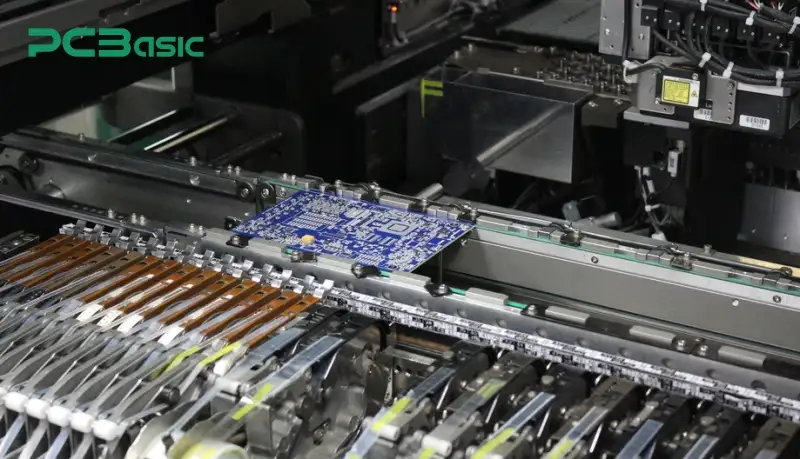

After the PCB and components have been received and inspected, the next step is to set up all the necessary automated equipment for production. Our engineers will convert your design data - including Gerber files, CAD drawings, pad coordinates (XY files), etc. - into machine programs that can be used by high-speed surface mount machines, solder paste printers, AOI inspection instruments, and reflow ovens. This process requires precise parameter settings to ensure that the X/Y coordinates, rotation angles, and installation surfaces (front/back) of each component fully meet the design requirements.

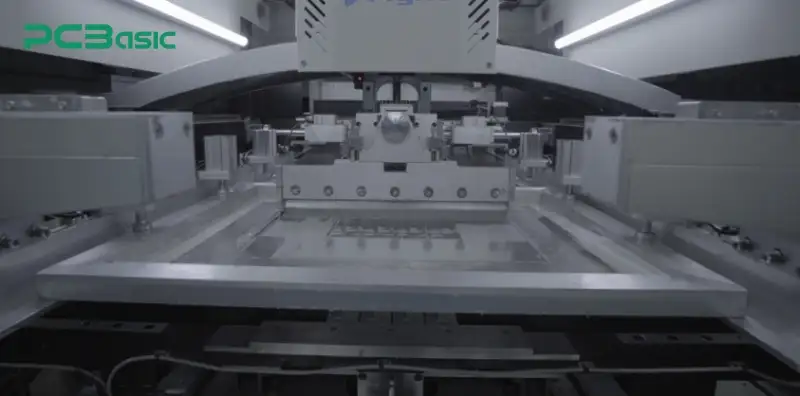

In the SMT assembly process, the first piece of equipment to be set up is the fully automatic solder paste printer. PCBasic uses an automatic printing device equipped with a 3D SPI system, which can monitor the thickness, volume and position deviation of the solder paste in real time. The main function of this equipment is to evenly and accurately apply the solder paste onto the corresponding pads of the PCB through a stainless steel stencil and a precise scraper system. This step is crucial in the entire SMT process, as it directly affects the strength and conductivity of the subsequent solder joints.

After the solder paste printing is completed and verified by inspection, the PCB enters the component mounting process. PCBasic uses high-speed and high-precision SMT mounting machines, which can mount tens of thousands of components (including resistors, capacitors, ICs, BGA, connectors, etc.) per hour. The mounting accuracy can be up to micrometer level. Components are picked up by vacuum suction tips from the tape or tray, and after being detected and calibrated by the visual positioning system, they are accurately placed on the solder pads set by the program. For larger or specially-shaped components, we are equipped with multiple suction tips and flexible mounting systems, which can ensure stable assembly accuracy.

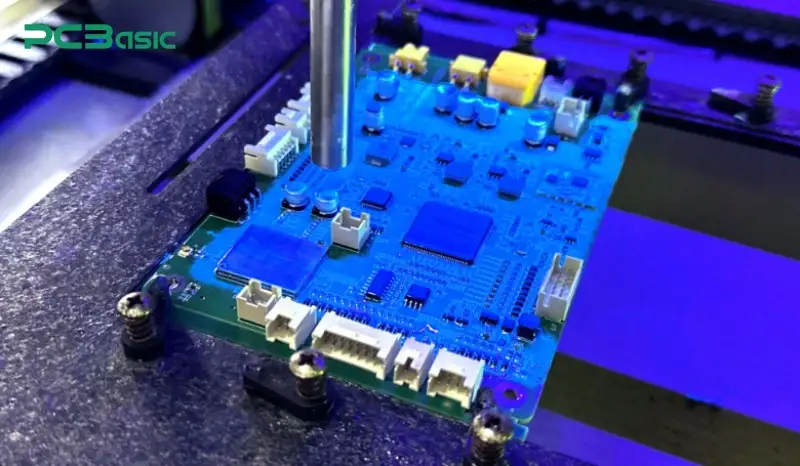

Before entering the reflow soldering process, each completed PCB will undergo AOI for automatic optical detection. This process is called pre-reflow AOI. This inspection will identify any missed, incorrect, misaligned or polarity-mismatched components, ensuring that all components are properly mounted before soldering.

Reflow soldering is a crucial step in the entire SMT process that permanently connects electrical and mechanical components. The circuit board passes through each temperature zone on the conveyor belt, heated according to the precise reflow curve set by the process engineer.

The temperature curve is typically divided into four stages:

Preheating zone - Gradual heating to activate the flux and prevent thermal shock;

Constant temperature zone - Stable temperature to evaporate the solvent;

Reflow zone - Melt the solder paste and form a strong metal bond between the pad and the pin;

Cooling zone - Controlled cooling to make the solder joints shiny and dense.

For different solders (such as SAC lead-free alloy or SnPb leaded solder), PCBasic precisely adjusts the temperature curve for each production line. System sensors monitor the temperature distribution in real time to ensure uniform and reliable solder joints and that components are not damaged by heat.

After reflow soldering, each circuit board will undergo a comprehensive inspection by the AOI system again to ensure there are no errors. Common problems include:

Bridge soldering or short circuiting

Insufficient soldering

Soldering defects, cold soldering

Component tilt or tombstone phenomenon

After reflow, each PCB is inspected again using the AOI system to verify solder joint integrity and component placement accuracy.

For high-reliability fields such as medical equipment, automotive electronics, industrial control, and military systems, PCBasic also offers conformal coating service. This film can effectively prevent moisture, dust, and corrosion, and enhance the stability of the circuit board under vibration and temperature/humidity changes. Customers can choose whether to require conformal coating based on their needs.

After all the assembly (and coating) is completed, PCBasic will conduct several final quality checks: appearance inspection, flying probe test, in-circuit test, and functional test. The test software and tools for the functional test are usually provided by the customer. Of course, we can also customize the fixtures according to the customer's requirements.

The manufacturing process inevitably leaves some pollution or fingerprints, so cleaning is necessary. PCBasic uses an automatic circuit board cleaning equipment, which uses deionized water and environmentally friendly solvents to remove residual flux, ion contamination and fingerprints. After cleaning, the circuit board is then dried by hot air and vacuum, completely removing moisture to prevent moisture absorption and oxidation, and then enters the final packaging process.

After cleaning and drying the circuit boards, we will conduct vacuum anti-static packaging and use foam or bubble film for protection to prevent mechanical damage during transportation.

The completion of product shipment does not mean that the service of PCBasic comes to an end. We provide comprehensive after-sales technical support to ensure that customers can still receive timely and professional services after the product delivery. If you have any questions, please feel free to contact us at any time.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.