Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Providing the standard documents before placing an order helps ensure the accurate and timely delivery of each order. Usually, by preparing these materials before placing the order, we can provide an accurate quotation within a few hours.

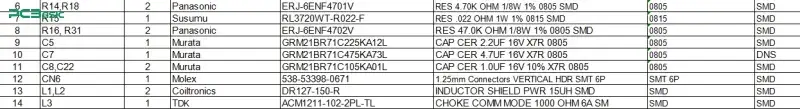

The BOM file should include component code, quantity, packaging type and manufacturer part number.

Note:

If the manufacturer part numbers for components such as resistors and capacitors are not available, please fill in the component values and packaging dimensions in the BOM. Additionally, we recommend that you indicate in the BOM whether each component is of SMD or PTH type, so that we can properly arrange the production process and assembly methods. If you are not sure how to prepare the BOM file, you can contact us directly. We will assist you in properly organizing the file and speeding up the quotation and production process.

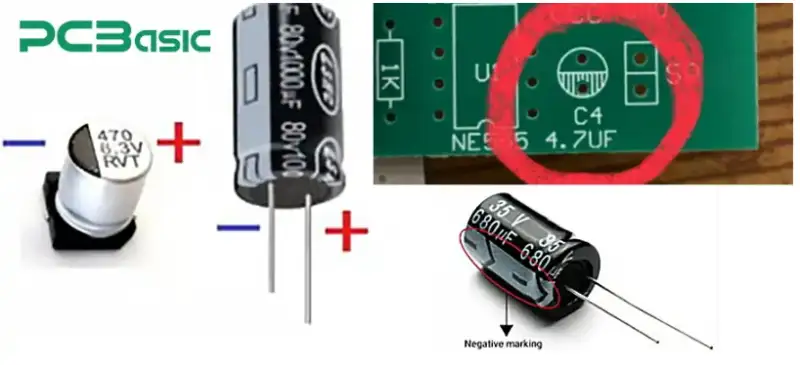

You need to provide clear and complete information in the assembly file or drawing, including:

Polarity marking

Direction of pin 1

Front and back marking

Assembly drawing or reference picture

Special note: For components that require manual insertion, mechanical positioning or are direction-sensitive, you can indicate them in the file.

These will further ensure accurate placement during the SMT and THT assembly processes. For example, if the direction or polarity is incorrect, it will lead to functional abnormalities after soldering or require rework, which is very time-consuming and also affects product quality. Therefore, it is very important to confirm these information before production. Please make sure to mark them clearly. Before production starts, our engineering team will conduct a DFM review and recheck the component direction and polarity to ensure that all information is accurate before soldering.

You are also required to provide the complete pick and place/centroid files, which should include all the same pin numbers/refs as those in the BOM. This file is directly used for the automatic surface mount machine programming of PCBasic. Before the formal production, the PCBasic engineering team will cross-check the placement coordinate file with the Gerber file and the BOM file.

First of all, thank you for choosing to collaborate with PCBasic. To ensure a smooth and efficient assembly process and to avoid delays or losses due to material issues, please carefully read the following "PCBA Material Preparation Specification" before providing the materials.

a. All materials must meet the specification requirements.

b. For each component that needs to be soldered, a blank tape of no less than 50mm should be reserved at the leader tape to facilitate the smooth feeding of the soldering machine.

c. Regardless of the production quantity being 1 piece or 1,000 pieces, usually 10-20 components will be removed from each roll of material before formal production to feed the soldering machine.

d. For components larger than 1206 size (such as surface mount capacitors, inductors, etc.), we will remove them and then manually replenish the materials.

e. For loose materials, please try to pack them together and attach clear labels to prevent material confusion.

f. All material packaging must be consistent with the material numbers in the BOM file; otherwise, it will affect the feeding and production progress.

|

Material Type |

Package / Specification Range |

Qty for 1–20 pcs |

Qty for 20–1000 pcs |

Qty for > 1000 pcs |

Qty for > 5000 pcs |

Spare Parts |

|

SMD: Resistor / Capacitor / Inductor |

01005 – 0805 |

≥ 10 pcs |

≥ 50 pcs |

5% |

0.50% |

Minimum 20 spare pcs |

|

SMD: Diode/ Transistor / Resistor Array |

SOD523 – SOD123 (0603–0805) |

≥ 5 pcs |

≥ 20 pcs |

2% |

0.30% |

20 spare pcs recommended |

|

SOT23 – SOT26 |

≥ 5 pcs |

≥ 20 pcs |

2% |

0.30% |

20 spare pcs recommended |

|

|

SMA – SMC (2010 – 3220) |

≥ 3 pcs |

≥ 10 pcs |

2% |

0.30% |

10 spare pcs recommended |

|

|

SMD: Coil Inductor / Aluminum Electrolytic Capacitor / Crystal Oscillator |

Standard SMD Packages |

≥ 2 pcs |

≥ 5 pcs |

2% |

0.30% |

5 spare pcs recommended |

|

SMD ICs |

SOP6 – SOP16 |

≥ 2 pcs |

≥ 3 – 5 pcs |

1% |

0.30% |

5 spare pcs |

|

QFN8 – QFN16 |

≥ 2 pcs |

≥ 3 – 5 pcs |

1% |

0.30% |

5 spare pcs |

|

|

BGA4 – BGA16 pins |

≥ 2 pcs |

≥ 3 – 5 pcs |

1% |

0.30% |

5 spare pcs |

|

|

IC with over 16 pins |

— |

≥ 2 pcs |

0.50% |

0.05% |

Minimum 1 spare pc |

|

|

Connectors |

All SMD / DIP types |

≥ 2 pcs |

≥ 5 pcs |

1% |

0.30% |

5 spare pcs |

|

DIP Components |

1/16 – 1 W |

≥ 2 pcs |

≥ 10 pcs |

1% |

0.30% |

5 spare pcs |

|

Special / Custom Components |

Non-standard packages |

≥ 2 pcs |

≥ 10 pcs |

1% |

0.30% |

Please indicate assembly method |

|

For materials that are out of stock and need to be ordered:

If the unit price is less than 1 US dollar, prepare according to the maximum spare quantity; If the unit price is more than 1 US dollar, prepare according to the minimum spare quantity and indicate the material unit price and estimated delivery date in the document.

Unused components after production can be returned or retained according to the customer's requirements, so as to be used for subsequent additional production. |

||||||

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.