Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

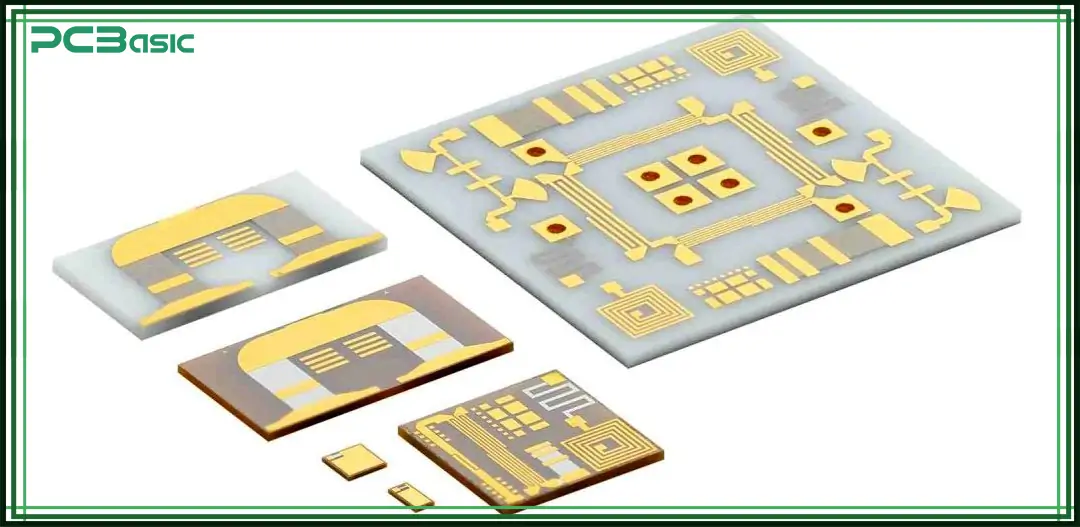

Ceramic PCB substrate refers to a special process board with copper foil directly bonded to the surface (single or double sides) of alumina (Al2O3) or aluminum nitride (AlN) ceramic PCB substrate at high temperatures. The manufactured ultra-thin composite substrate has excellent electrical insulation, high thermal conductivity, excellent solderability and high adhesion strength, and can etch various patterns, so it has great current carrying capacity. Therefore, ceramic PCB substrate has become the basic material of high-power power electronic circuit structure technology and interconnection technology.

The advent of ceramic PCB substrate products has started the new development of the heat dissipation application industry. Because of the heat dissipation characteristics of ceramic PCB substrate and the advantages of ceramic PCB substrate such as high heat dissipation, low thermal resistance, long life and voltage resistance, with the improvement of production technology and equipment, the product price has been accelerated and rationalized, thus expanding the application fields of LED industry, such as indicator lights of household appliances, car lights, street lamps and outdoor large billboards.

The successful development of ceramic PCB substrate provides better service for indoor lighting and outdoor lighting products and gives the LED industry a broader market in the future.

Ceramic PCBs can be classified according to the materials used. Common materials include aluminum oxide, aluminum nitride, and silicon nitride. They perform differently in terms of heat dissipation, insulation, and strength. Choosing the right material can make the circuit board more suitable for your actual usage requirements.

Alumina ceramic PCB substrate is the most commonly used substrate material in electronic industry, because of its high strength and chemical stability compared with most other oxide ceramics in mechanical, thermal and electrical properties, and abundant raw materials, it is suitable for various technical manufacturing and different shapes. The alumina substrate can be customized in three dimensions.

Its thermal conductivity is higher than that of aluminum, so it can be used in occasions where high thermal conductivity is needed, but it decreases rapidly when the temperature exceeds 300℃. The most important thing is that its toxicity limits its own development.

Beryllium oxide ceramics are ceramics with beryllium oxide as the main component. It is mainly used as large-scale integrated circuit substrate, high-power gas laser tube, heat sink shell of transistor, microwave output window and neutron moderator.

AlN has two very important properties worth noting: one is high thermal conductivity, and the other is the expansion coefficient matching with Si. The disadvantage is that even if there is a very thin oxide layer on the surface, it will affect the thermal conductivity. Only by strictly controlling the materials and processes can AlN substrates be manufactured with good consistency. There are few AlN production technologies in China that can be produced on a large scale like Sliton, and the price of AlN is relatively high compared with Al2O3, which is also a small bottleneck restricting its development. However, with the improvement of the economy and technology, this bottleneck will eventually disappear.

From the above reasons, it can be known that alumina ceramics are widely used because of their superior comprehensive performance, and they are still in a dominant position in microelectronics, power electronics, hybrid microelectronics, power modules, and other fields.

AlN can be stabilized up to 2200℃. The strength is high at room temperature, and the strength decreases slowly with the increase in temperature. It has good thermal conductivity, a small thermal expansion coefficient, and is a good thermal shock-resistant material. With strong resistance to molten metal erosion, it is an ideal crucible material for melting and casting pure iron, aluminum or aluminum alloy.

Aluminum nitride is also an electrical insulator with good dielectric properties, and it is also promising to be used as an electrical component. The aluminum nitride coating on the surface of gallium arsenide can protect it from ion implantation during annealing. It is also a catalyst for converting aluminum nitride from hexagonal boron nitride to cubic boron nitride. It reacts slowly with water at room temperature. It can be synthesized from aluminum powder at 800~1000℃ in an ammonia or nitrogen atmosphere. The product is white to gray powder blue. It is synthesized by reaction of the Al2O3-C-N2 system at 1600~1750℃, and the product is an off-white powder. Aluminum chloride and ammonia are prepared by gas phase reaction. The coating can be synthesized from the AlCl3-NH3 system by gas phase deposition.

Rogers Company introduced the new curamik® series silicon nitride (Si3N4) ceramic PCB substrate in 2012. As the mechanical strength of silicon nitride is higher than that of other ceramics, the new curamik® substrate can help designers achieve a long life in harsh working environment and HEV/EV and other renewable energy applications.

The flexural strength of the new ceramic PCB substrate made of silicon nitride is higher than that of the substrate made of Al2O3 and AlN.

The fracture toughness of Si3N4 even exceeds that of zirconia-doped ceramics.

Up to now, the reliability of copper-clad ceramic PCB substrate used in power modules has been limited by the low flexural strength of ceramics, which will reduce the thermal cycle capability. For those applications that combine extreme thermal and mechanical stress, such as hybrid vehicles and electric vehicles (HEV/EV), the commonly used ceramic PCB substrate is not the best choice. The thermal expansion coefficients of the substrate (ceramic PCB) and the conductor (copper) are very different, which will exert pressure on the bonding area during the thermal cycle, thus reducing the reliability. This curamik® series silicon nitride (Si3N4) ceramic PCB substrate introduced by Rogers Company at this year's PCIM exhibition will prolong the life of power electronic modules by 10 times.

It is essential for the manufacturing of ceramic PCBs to follow a series of precise steps. All these steps must ensure that the manufactured ceramic circuit board fully meets its intended purpose.

1. The first step in manufacturing a ceramic PCB is to analyze the needs, required strength, rigidity, and properties associated with its conductivity.

2. Secondly, we need to choose a suitable ceramic PCB substrate as a base. Just like any other product, different materials suit different needs. Alumina is a popular choice for budget-conscious projects. Aluminum Nitride and Beryllium Oxide come in handy when a project demands high thermal conductivity to be on the front line.

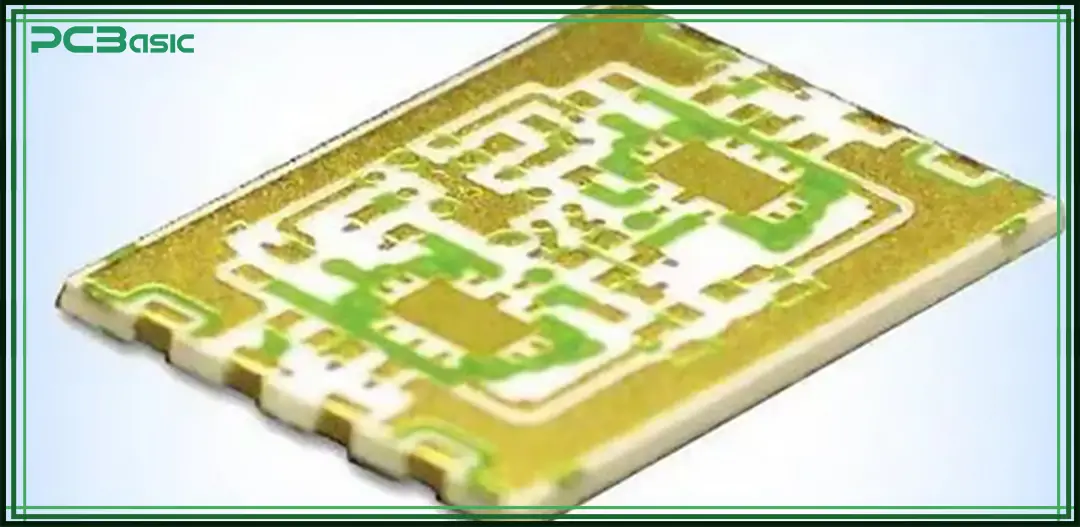

3. Once we have the perfect base for our ceramic PCB, it's time for the laser etching to make prints on the circuit. These etchings create a path for the electricity to flow. Then, depending on the circuit's complexity, we use thick or thin film deposition to create the required conductive traces.

4. Now comes the most crucial step - firing the board at scorching temperatures. This intense heat fuses everything together, making it one cohesive unit.

5. But this isn't done yet. The journey of ceramic PCB continues by drilling holes to make mounts for other components to connect - just like building a miniature city. Then, the ceramic PCBs are protected with an anti-corrosion coating.

6. Finally, the quality assurance team carefully observes and analyzes the entire process of manufacturing ceramic PCBs. With every step involving great attention to detail, we can't take risks with any move since one wrong move will ruin the entire electrical system.

This is exactly why we always recommend that our clients look for a trusted ceramic PCB manufacturer like PCBasic. For more information or to get a quote, visit www.pcbasic.com.

◆ The thermal expansion coefficient of ceramic PCB substrate is close to that of the silicon chip, which can save Mo slice of the transition layer, save labor, material and reduce cost;

◆ Reduce welding layer, thermal resistance, voids, and yield;

◆ Under the same current carrying capacity, the line width of 0.3mm thick copper foil in ceramic PCB is only 10% of that of ordinary printed circuit boards;

◆ Excellent thermal conductivity makes the package of the chip very compact, thus greatly increasing the power density and improving the reliability of the system and device;

◆ Ultra-thin (0.25mm) ceramic PCB substrate can replace BeO without environmental toxicity;

◆ The current carrying capacity is large, and the current of 100A continuously passes through a copper body with a width of 1mm and a thickness of 0.3mm, and the temperature rises by about 17℃. A current of 100A continuously passes through a copper body 2mm wide and 0.3mm thick, and the temperature rise is only about 5℃.

◆ Low thermal resistance. The thermal resistance of 10×10mm ceramic PCB substrate is 0.31K/W for 0.63mm ceramic PCB substrate, 0.19K/W for 0.38mm ceramic PCB substrate, and 0.14K/W for 0.25mm ceramic PCB substrate.

◆ High insulation and withstand voltage, ensuring personal safety and protection ability of equipment.

◆ New packaging and assembly methods can be realized, which can make the products highly integrated and reduce the volume.

In electronic devices operating under high power, high frequency and extreme environments, traditional FR4 circuit boards have become difficult to meet their strict requirements for heat dissipation, electrical performance and stability. Ceramic PCB has become an ideal choice for the new generation of electronic packaging and circuit carriers due to its excellent thermal conductivity, electrical insulation and reliability. Let's take a look at the core performance requirements for ceramic circuit boards.

With high enough mechanical strength, ceramic PCB can also be used as a supporting member in addition to carrying components. It has Good processability and high dimensional accuracy; it is Easy to realize multilayer, Smooth surfaces with no warping, bending, microcracks, etc.

High insulation resistance and insulation breakdown voltage; Low dielectric constant; Low dielectric loss; Stable performance under the condition of high temperature and high humidity, ceramic PCB ensures reliability.

High thermal conductivity; The thermal expansion coefficient is matched with the related materials (especially with the thermal expansion coefficient of Si); Excellent heat resistance.

Good chemical stability; Easy metallization, strong adhesion between circuit patterns and them; No hygroscopicity; Oil and chemical resistance; ɑ the amount of radiation emitted is small; The adopted substances are pollution-free and non-toxic; The crystal structure does not change within the use temperature range; Rich raw materials; Mature technology; Easy to manufacture; Low price.

About PCBasic

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

◆ High-power power semiconductor module; Semiconductor refrigerator, electronic heater; RF power control circuit, power hybrid circuit.

◆ Intelligent power components: High-frequency switching power supply and solid-state relay.

◆ Automotive electronics, aerospace, and military electronic components.

◆ Solar panel assembly; Telecommunications private exchange, receiving system; Laser and other industrial electronics.

Compared with the traditional FR4 PCB or metal substrate MCPCB, the ceramic substrate PCB has significant advantages in multiple key performance indicators. Its outstanding thermal conductivity, extremely low coefficient of thermal expansion, excellent electrical insulation, and frequency response make it an ideal choice for high-performance and highly reliable electronic devices, especially suitable for power electronics, radio frequency communication, and applications in harsh environments.

|

Performance Metric |

Ceramic Substrate PCB |

FR4 PCB |

Metal Core PCB (MCPCB) |

|

Thermal Conductivity |

Very high (up to 180 W/m·K depending on material) |

Low (around 0.3~0.4 W/m·K) |

Moderate to high (1~10 W/m·K depending on the core) |

|

Thermal Expansion (CTE) |

Very low, close to silicon chip – minimal thermal stress |

High – prone to expansion and deformation |

Lower than FR4 but still higher than ceramic |

|

Reliability |

Excellent – ideal for high-temp, high-voltage, and vibration |

Moderate – suitable for general consumer use |

Good – well-suited for heat-dissipation applications |

|

Frequency Performance |

Outstanding – ideal for RF, microwave, and high-speed signals |

Average – higher losses at high frequency |

Moderate – usable in some RF applications |

|

Electrical Insulation |

Very stable even under high voltage and temperature |

Good, but degrades under heat and humidity |

Depends on structure – usually requires insulation |

|

Cost |

Higher – but cost-effective in demanding and long-life use cases |

Low – ideal for standard applications |

Moderate – cost-effective for thermal needs |

|

Typical Applications |

RF modules, power electronics, high-power LEDs, aerospace, military |

Consumer electronics, PC motherboards, appliances |

LED lighting, power converters, automotive electronics |

Here, we can see the multi-dimensional strengths of ceramic PCBs, especially in high-power, high-frequency, and high-reliability applications. They outperform both FR4 and MCPCB in key areas, making ceramic circuit boards the preferred choice for many advanced electronic systems.

As electronic devices become more compact and powerful, the demand for robust thermal and electrical solutions increases. Ceramic PCBs stand out for their superior performance under extreme conditions, making them essential for high-reliability applications. Whether you're designing for automotive, aerospace, or high-power LEDs, choosing the right ceramic PCB manufacturer and ceramic PCB substrate can ensure your product's long-term success.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.