Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Sheet Metal Manufacturing Process

Sheet metal fabrication is a subtractive manufacturing process that shapes thin metal sheets into precision parts. Known for high accuracy and

durability, sheet metal components are widely used in automotive chassis, housings, and brackets. At PCBasic, we offers professional and

cost-effective services including laser cutting, metal bending and more.

Sheet metal fabrication is a subtractive manufacturing process that shapes thin metal sheets into precision parts. Known for high accuracy and durability, sheet metal components are widely used in automotive chassis, housings, and brackets. At PCBasic, we offers professional and cost-effective services including laser cutting, metal bending and more.

Trusted by 1,500+ Companies Worldwide

Advantages of PCBasic’s Sheet Metal Fabrication

Fast Turnaround

With advanced cutting, bending, stamping, and automation, PCBasic delivers quotes and finished parts in as little as 5 working days.

Material Options

You can choose from a variety of metal sheets with different strength, conductivity, weight, and corrosion resistance properties.

High Precision

We offer tolerance levels compliant with ISO 2768 (Standard/Fine) and ISO 286 (Grades 8, 7, 6) to meet your precision needs.

Strict Quality Control

Our QA team enforces rigorous quality assurance procedures throughout the entire process.

Customized surface treatment

Post-processing services like coating, heat treatment, and more are available upon request.

Fast Delivery

Our global logistics ensure fast, reliable delivery. Just upload your 3D files to get instant pricing and shipping details.

Our Sheet Metal Products Showcase

Our Sheet Metal Surface Finishing Processes

Here are our standard surface finish options. For custom requests like plating or polishing, feel free to reach out at js@pcbasic.com.

Standard (As Machined)

"As Machined" refers to parts delivered in their original post-machining state. After meeting dimensional requirements and ensuring no visible defects, only basic cleaning and packaging are applied. The part retains its raw material appearance and machining marks.

Anodizing

Anodizing is one of the key surface treatment processes for metals. By forming a protective or functional oxide layer, it significantly enhances corrosion resistance, improves appearance, and adds specific performance characteristics.

Sandblasted Anodizing

Sandblasting removes scale and surface contaminants while increasing roughness, allowing the oxide layer to adhere more effectively and improving its corrosion resistance and durability.

Powder Coating

Powder coating uses electrostatic adsorption to apply dry powder to the surface, which is then cured to form a uniform protective layer. Unlike liquid paint, it contains no solvents, making it more environmentally friendly, with superior wear resistance and coverage.

Polishing

Polishing smooths and levels the metal surface, improving appearance, reducing scratches and corrosion risk, and enhancing the adhesion of coatings or functional layers.

Brushed finish

Brushing creates fine, uniform surface textures using mechanical or chemical methods. It enhances metallic aesthetics, masks scratches, resists fingerprints, improves grip, aids heat dissipation, and conceals minor imperfections.

Spray painting

Spray painting forms a protective film on the metal surface, offering corrosion resistance, decorative enhancement, improved wear resistance, functional isolation, and environmental adaptability.

Electroplating

Electroplating deposits a layer of metal or alloy onto the surface via electrolysis. It enhances corrosion and wear resistance, improves appearance, conductivity, and weldability, and supports functions like EMI shielding and high-temperature resistance.

Common Materials for Sheet Metal Fabrication

Cutting Tolerance: ±0.0078 in (±0.2 mm)

Bend to Edge Tolerance: ±0.010 in (±0.254 mm)

Bend Angle Tolerance: ±1.0°

Aluminum Sheet(5052/1060)

5052 aluminum alloy is a typical Al-Mg alloy with excellent corrosion resistance, good formability, and moderate strength. It is widely used in sheet metal fabrication, electronic enclosures, automotive parts, and marine equipment. Known for its outstanding weldability and high fatigue strength, it is ideal for applications requiring durability and lightweight design. While not heat-treatable, its strength can be enhanced through cold working, making it suitable for both structural and exterior components.

Stainless Steel

Stainless steel offers excellent corrosion resistance and mechanical strength, maintaining performance in humid or harsh environments. Its smooth and attractive surface makes it suitable for cutting, bending, and welding, widely used in enclosures, structural parts, kitchen equipment, and medical devices. Common grades like 304 and 316 combine strength, processability, and rust resistance—ideal for durable and aesthetically demanding applications.

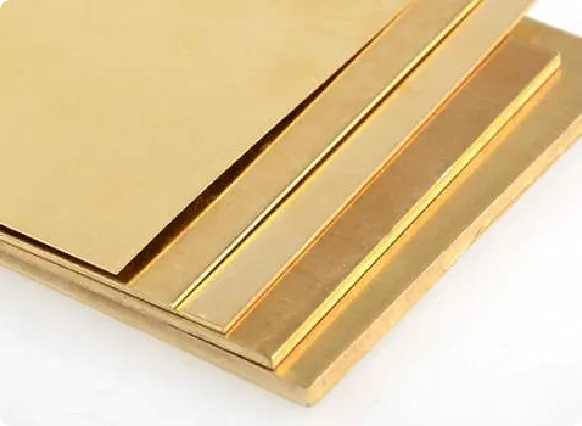

Brass

Brass is an alloy of copper and zinc with excellent electrical and thermal conductivity, and outstanding workability. It is easy to stamp, cut, and weld. With high mechanical strength, good wear resistance, and moderate corrosion resistance, brass is commonly used in terminals, decorative parts, hardware components, and precision fittings. Its attractive golden appearance makes it suitable for both functional and decorative applications.

Copper

Copper, with a purity above 99.9%, offers exceptional electrical and thermal conductivity. It has excellent ductility and is easy to stretch, bend, and weld, making it ideal for precision machining. Copper also provides good corrosion and fatigue resistance and is widely used in electrical connectors, conductors, heat sinks, busbars, and piping where conductivity and heat transfer are critical.

Steel Sheet

Steel sheets offer good strength, weldability, and cost efficiency, making them suitable for structural parts and brackets where appearance is not a primary concern. Surface performance and corrosion resistance can be enhanced through coating, plating, and other treatments.

Overview: Introduction to Our Sheet Metal Manufacturing Services

Introduction to Our Sheet Metal Services

Brief Overview of Our Sheet Metal Manufacturing

If any clarification is needed during the document review process, we will contact you via email.

Feel free to reach out to us anytime at JS@pcbasic.com.

1. Upload Drawings & Get a Quote

Kindly upload your 3D or 2D drawings (e.g., STEP, DWG, DXF) and specify the required materials and surface finishes. We’ll get back to you within 24 hours with a detailed quote—whether for custom parts or low-volume orders.

2. Confirm & Start Production

Once you approve the quote, we’ll promptly schedule production using advanced equipment to ensure quality and efficiency.

3. Quality Check & Delivery

Every part is thoroughly inspected before shipment. We offer reliable global delivery to ensure your components arrive safely and on time.

Sheet Metal Fabrication Process

Unfolding /

Programming

Punching /

Cutting

Deburring

Bending

Welding

Finishing

(including surface

treatment)

Assembly /

Inspection

Shipping

Applications of Sheet Metal Fabrication

With years of experience in sheet metal fabrication, we ensure efficient and reliable delivery. We hope that these high-quality components,

widely used across various industries, can bring real value and positive change to the manufacturing world.

Aerospace

Medical & Dental

Automotive

Robotics

Automation

Consumer Electronics

New Energy

Semiconductors

Customer Feedback on Our Sheet Metal Fabrication

Our Equipment Showcase

Frequently Asked Questions

Is there a minimum order quantity (MOQ)?

+What is your machining accuracy range?

+Do you offer surface finishing services?

+How do you ensure quality? Do you have an inspection process?

+How do overseas clients communicate and place orders?

+CNC Machining

3D Printing

Injection Molding Services

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.