Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Advanced Equipment for High-Quality Production

Preview

Preview

Preview

Preview

Preview

Preview

Preview

Preview

Contact US

Any questions?

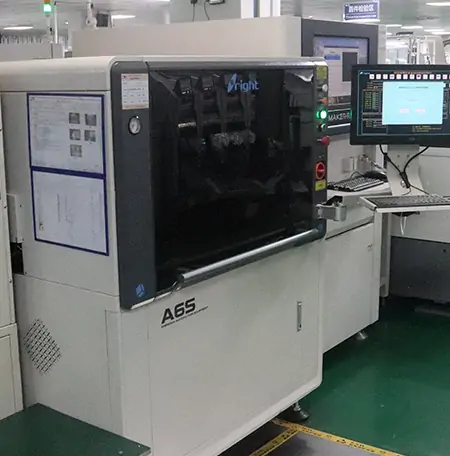

Fully Automatic Solder Paste Printer

Full Automation / High Accuracy / Fast Line Switching

With over 15 years of PCBA experience, PCBasic delivers reliable medical PCB assembly with precision SMT, DIP, and full testing services. We specialize in small-to-medium batch production and handle a wide range of medical boards. Certified with ISO 9001, 14001, and 45001, we ensure consistent quality, fast lead times, and professional support. Advanced equipment like flying probe testers and selective wave soldering guarantees dependable performance for demanding environments.

Solder Paste Inspection Machine

High Precision/Defect Alerting/Data Traceability

The SPI (Solder Paste Inspection) machine offers high precision and efficiency, enabling real-time monitoring of key parameters such as paste height, volume, and area. It quickly detects printing defects like misalignment, insufficient paste, and bridging, helping improve yield and ensure soldering quality. With traceability and statistical analysis capabilities, SPI supports intelligent quality management and process optimization, making it essential for stable SMT production and automated quality control.

Solder Paste Inspection Machine

High Precision/Defect Alerting/Data Traceability

The SPI (Solder Paste Inspection) machine offers high precision and efficiency, enabling real-time monitoring of key parameters such as paste height, volume, and area. It quickly detects printing defects like misalignment, insufficient paste, and bridging, helping improve yield and ensure soldering quality. With traceability and statistical analysis capabilities, SPI supports intelligent quality management and process optimization, making it essential for stable SMT production and automated quality control.

Nitrogen Reflow Oven

Oxidation Suppression/Defect Reduction/Suitable for Fine-Pitch Soldering

The nitrogen reflow oven injects 99.99% pure nitrogen to displace oxygen during soldering, reducing oxidation and minimizing voids in solder joints. Compared to standard reflow ovens, it offers enhanced soldering quality and reliability, especially for high-density and fine-pitch assemblies. It is a critical process for achieving high-reliability electronic manufacturing.

Inline AOI

High-Precision Recognition/Fast Inspection/Smart Traceability

The inline AOI system provides real-time, automated inspection of soldering defects, misalignment, and missing components. With high-resolution cameras and intelligent algorithms, it detects micron-level defects and supports complex, high-density PCBs. Inspection data is traceable and can be integrated with MES systems for smart quality control.

Inline AOI

High-Precision Recognition/Fast Inspection/Smart Traceability

The inline AOI system provides real-time, automated inspection of soldering defects, misalignment, and missing components. With high-resolution cameras and intelligent algorithms, it detects micron-level defects and supports complex, high-density PCBs. Inspection data is traceable and can be integrated with MES systems for smart quality control.

Selective Wave Soldering Machine

Accurate Soldering/Component-Safe Process/Optimized for Dense, Mixed Assemblies

Selective wave soldering uses localized heating and precise control to solder through-hole components with high reliability. It achieves 100% hole fill, producing solid and robust solder joints. With high soldering accuracy, minimal thermal impact, and a high level of automation, it is the preferred solution for high-quality assembly in advanced electronics manufacturing.

3D X-Ray Inspection System

High-Precision Recognition/Fast Inspection/Smart Traceability

The inline AOI system provides real-time, automated inspection of soldering defects, misalignment, and missing components. With high-resolution cameras and intelligent algorithms, it detects micron-level defects and supports complex, high-density PCBs. Inspection data is traceable and can be integrated with MES systems for smart quality control.

3D X-Ray Inspection System

High-Precision Recognition/Fast Inspection/Smart Traceability

The inline AOI system provides real-time, automated inspection of soldering defects, misalignment, and missing components. With high-resolution cameras and intelligent algorithms, it detects micron-level defects and supports complex, high-density PCBs. Inspection data is traceable and can be integrated with MES systems for smart quality control.

Flying Probe Tester

No Fixture Required/Precise Fault Detection/Contactless Probing

The flying probe tester uses a high-precision, non-contact method for electrical testing, making it ideal for PCBA applications in aerospace, medical, and other reliability-critical fields. It requires no custom fixtures and supports fast product changeovers, well-suited for low-volume, high-mix, and complex board testing. This testing method is essential for maintaining quality in high-end electronic manufacturing.

Deionized Water Cleaning Machine

Efficient Cleaning/Eco-Friendly Process/Enhanced Bonding Performance

The deionized water cleaning machine combines surface activation with ultrapure water rinsing to effectively remove particles, oxides, and organic residues. It is ideal for aerospace, medical, and other applications requiring ultra-clean surfaces. This eco-friendly, non-corrosive process enhances surface energy and improves adhesion, coating, and soldering reliability.

Deionized Water Cleaning Machine

Efficient Cleaning/Eco-Friendly Process/Enhanced Bonding Performance

The deionized water cleaning machine combines surface activation with ultrapure water rinsing to effectively remove particles, oxides, and organic residues. It is ideal for aerospace, medical, and other applications requiring ultra-clean surfaces. This eco-friendly, non-corrosive process enhances surface energy and improves adhesion, coating, and soldering reliability.

Quality Certifications

Testing & Inspection

Customer Feedback

FAQ

Launch Your Project at PCBasic

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.