Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

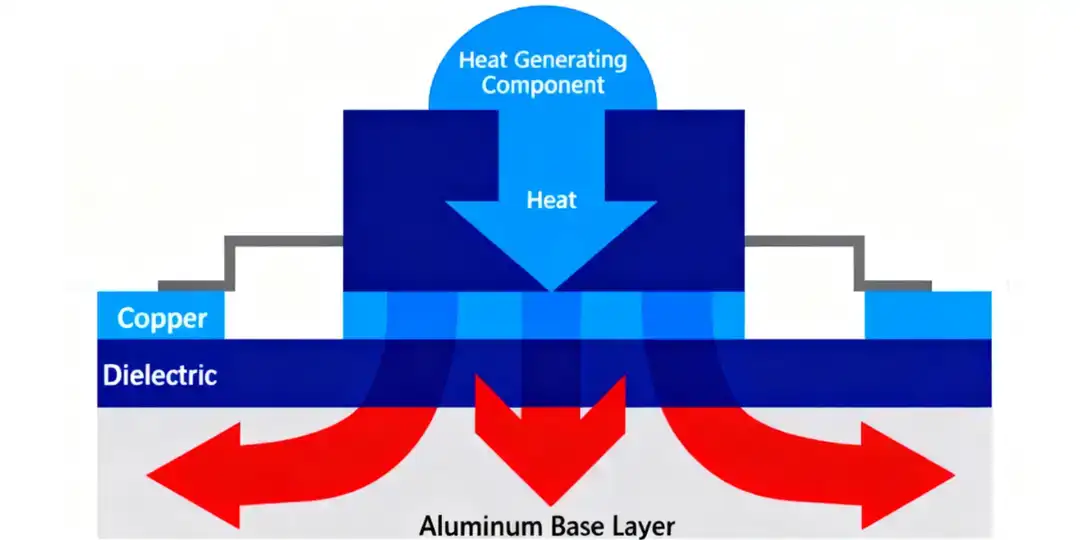

As electronic products become increasingly powerful, smaller and high-performance, the heat dissipation issue has become an important problem that must be solved in PCB design. Traditional PCB materials (such as FR-4 and polyimide) have poor thermal conductivity and are difficult to dissipate heat in a timely manner in high-power circuits, which can easily lead to excessive heating of components or even damage.

To solve this problem, PCBasic focused on designing and manufacturing metal core printed circuit boards (MCPCBs), also known as metal core PCBs, metal clad PCBs or thermal PCBs. This type of circuit board incorporates a metal core layer in its design, which can conduct heat away more quickly, making the circuit operation more stable and reliable. It is highly suitable for use in various high-power and high-performance electronic products.

MCPCBs, also known as insulated metal substrate (IMS) PCBs or thermal clad PCBs, are a type of metal core circuit board specifically designed to solve the heating issue of electronic products.

Unlike traditional FR-4 PCBs, which use resin or fiberglass as the base material, a metal core PCB incorporates a metal base layer in its structure, typically made of aluminum, copper or steel alloys. This metal layer can quickly conduct the heat generated by the components out and transfer it to the heatsink or metal core layer, thus making the circuit run more stably and less prone to overheating.

Among these metal materials, aluminum is the most commonly used because of its good thermal conductivity, high mechanical strength and low cost. It is currently the mainstream choice for MCPCB manufacturing.

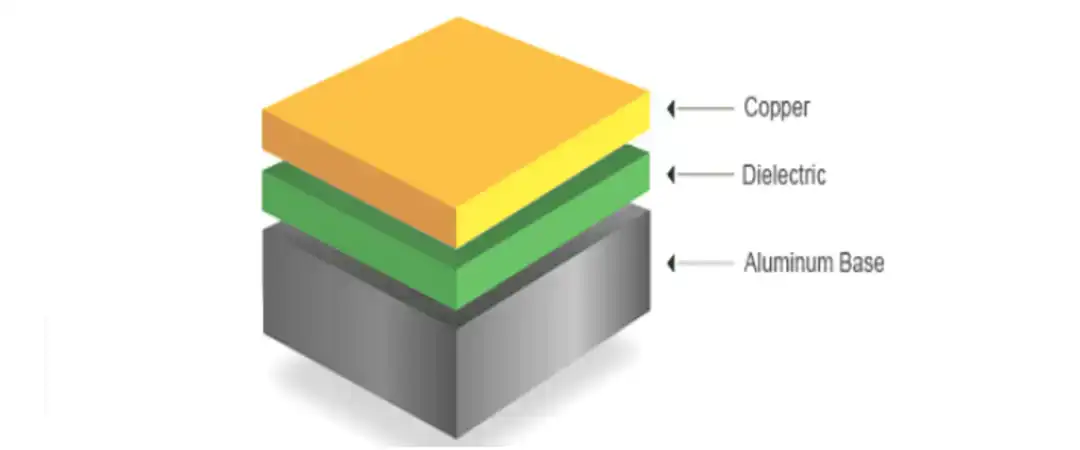

MCPCBs consist of a conductive layer, a thermal insulation layer, and a metal substrate layer.

A standard metal core circuit board is composed of:

• Solder mask layer

• Circuit layer

• Copper layer (1oz–6oz copper, most common 1–2oz)

• Dielectric insulation layer

• Metal core layer (aluminum, copper, or steel) — functioning as a heatsink

• Optional protective coating or finish

Compared with traditional circuit boards, metal core PCBs have the following obvious advantages:

1. Superior Heat Dissipation

Because of the use of metal materials, the thermal conductivity of metal core PCBs (especially aluminum and copper substrates) is extremely excellent. It can quickly dissipate the heat generated by high-power LEDs, power modules, automotive electronics, etc., significantly enhancing the heat dissipation efficiency and making the circuit more stable.

2. Reduced Need for External Heatsinks

The MCPCB boards can conduct heat very well on their own, so in many cases, there is no need to add additional heatsinks or cooling fans. This way, the equipment is smaller in size, lighter in weight and has a simpler design.

3. High Mechanical Strength

The metal core layer (especially the aluminum material) makes the circuit board more rigid, capable of withstanding the stress caused by bending, vibration and thermal expansion and contraction, and more durable in both production and use.

4. Lightweight and Eco-Friendly

Compared to ceramic or fiberglass boards, metal core printed circuit boards are not only lighter and more durable, but also recyclable and reusable. Especially aluminum, which is non-toxic, environmentally friendly and recyclable, is highly suitable for sustainable manufacturing.

5. Dimensional Stability

Within the temperature range of 30°C to 150°C, metal core PCBs maintain stable dimensions and performance, ensuring the long-term reliable operation of the equipment.

Depending on the configuration of the conductive and metal layers, MCPCBs can be categorized into five primary types:

1. Single Layer MCPCB

2. COB MCPCB (Chip-on-Board)

3. Double Layers MCPCB

4. Double-Sided MCPCB

5. Multi-Layer MCPCB

Single Layer MCPCB

A single-layer metal core PCB consists of three parts: the copper circuit layer, the dielectric insulation layer, and the metallic base (aluminum is usually used). This structure is simple and practical, cost-effective and reliable in performance, and is very suitable for mass production.

Applications:

• LED lighting and high-brightness lamps

• Automotive and industrial relays

• Audio equipment and amplifiers

• Sensors and packaging machinery

Single-layer MCPCBs produced by PCBasic are widely used in LED lighting. With its outstanding heat dissipation performance, it can effectively lower the temperature, ensuring the brightness and longevity of the lamps.

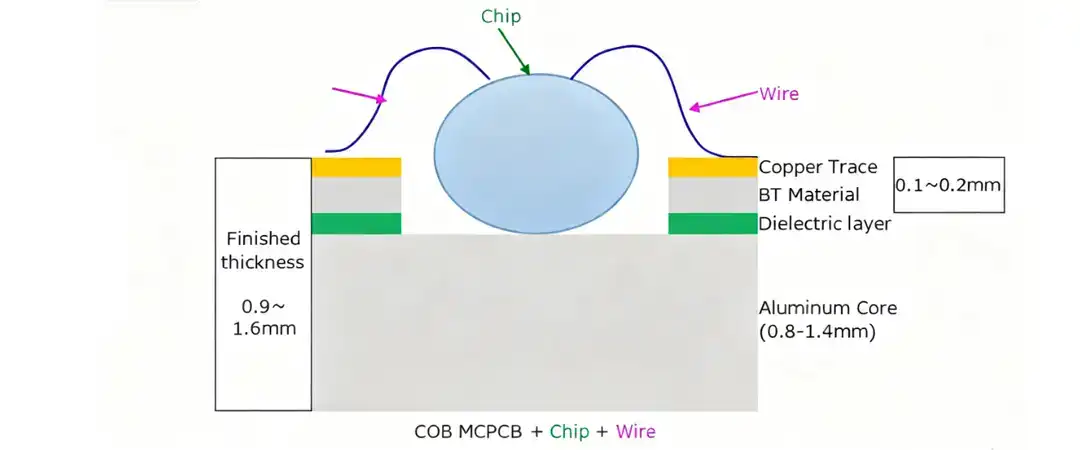

A COB MCPCB (Chip-on-Board Metal Core PCB) is a special type of metal core printed circuit board. Its most prominent feature is that the bare dies are directly installed on the metal core board, eliminating the need for the dielectric barrier layer in the traditional structure.

This design enables the chip to be directly contacted with the metal core PCB, resulting in faster and more efficient heat transfer. The thermal conductivity can exceed 200 W/m·K, which is almost equivalent to that of the metal base material itself.

The basic structure of the COB metal core PCB includes:

• Direct chip bonding on metal core PCB

• Wire bonding for signal interconnection

• Epoxy resin encapsulation for chip protection

The chip is firmly embedded on the MCPCB board through wire bonding and epoxy encapsulation. This design can improve light uniformity and, at the same time, extend the lifespan of high-power LEDs.

Most COB MCPCB boards use aluminum as the core material because of its good thermal conductivity, high strength and low cost, becoming the first choice for most metal core PCB manufacturers. Some high-end products will also use mirror-finished aluminum PCBs with silver/gold plating to enhance reflectivity and heat dissipation performance.

Applications:

• LED streetlights and floodlights

• LED backlighting and display modules

• Power supplies and converters

• Automotive headlights and signal systems

• Agricultural and horticultural grow lights

• Industrial and architectural illumination systems

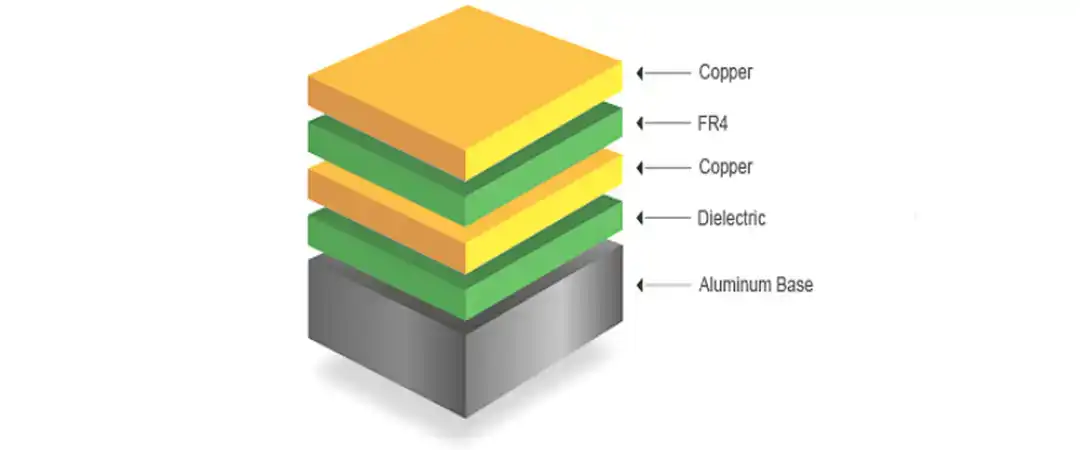

Double-Layer MCPCB

A double-layer MCPCB is a type of metal core printed circuit board with a more complex structure than a single-layer one. It has two copper circuit layers, both of which are laminated onto the metal base on the same side. The commonly used materials are aluminum or copper. The metal core is located at the bottom of the circuit board, which can provide both good mechanical support and help with rapid heat dissipation.

Unlike double-sided metal core PCBs, where the two copper layers are distributed on both sides of the metal core, all electronic components of a double-layer MCPCB are installed on the same side, making the structure more compact.

Compared with single-layer metal core PCBs, the production of double-layer MCPCBs is more complex. During manufacturing, an additional lamination step is required to firmly bond the thermal conductive layer to the metal substrate. This step has high requirements for process accuracy and must ensure that the layers are both insulated and can conduct electricity reliably.

Applications of Double Layer MCPCB

• Power inverters and rectifiers

• Audio preamplifiers and amplifiers

• Power control units and regulators

• Industrial automation equipment

• Motor drivers and communication modules

As a professional MCPCB manufacturer, PCBasic adopts advanced lamination technology to ensure that in each double-layer MCPCB board, the thermal conductive layer is closely combined with the metal substrate and is not prone to delamination.

Similar to double-layer metal core PCBs, double-sided metal core PCBs also have two layers of copper conductors. But its metal core is located between these two layers. In other words, there are circuit traces on both the top and bottom surfaces of the metal core layer, which are connected through plated vias.

Unlike single-sided metal core PCBs, double-sided MCPCBs require an additional lamination step during production, which firmly bonds the patterned thermal conductive layers to the metal core substrate.

Compared with ordinary FR-4 circuit boards, double-sided metal core PCBs have higher requirements for precision and manufacturing experience. When laminating two layers of copper foil to the metal core, it is necessary to precisely control the temperature, pressure and insulation performance. Only in this way can good electrical isolation and stable thermal performance be ensured.

Applications:

• Industrial control units

• Power converters and regulators

• HVAC systems

• Automotive dashboards

• UPS and communication systems

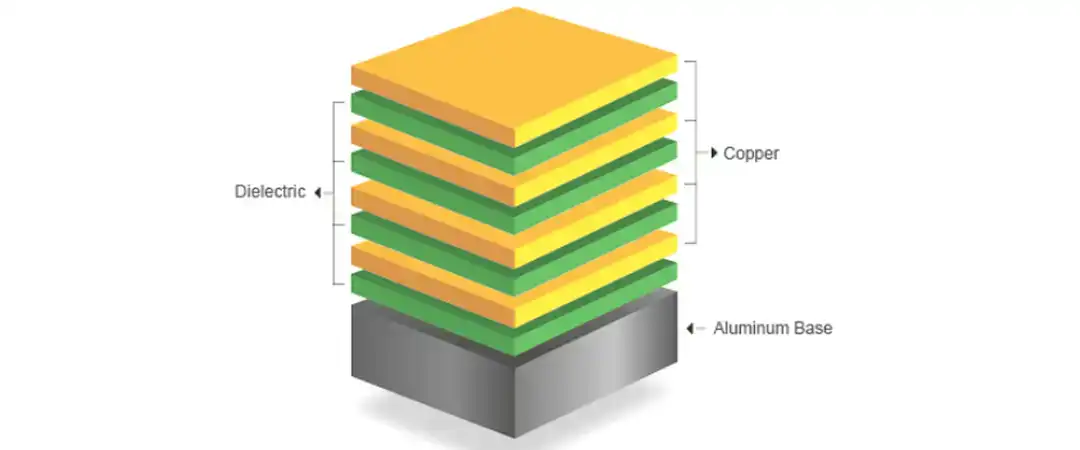

Multi-layer MCPCB

A multi-layer metal core PCB is a kind of high-performance metal core printed circuit board. It is composed of multiple copper circuit layers and thermally conductive dielectric materials stacked together on a solid metal base.

This structure enables the circuit board to achieve internal signal routing, ground planes, and blind or buried vias designs while maintaining high thermal conductivity. It also has higher design flexibility and better thermal management performance at the same time.

Compared with traditional FR-4 circuit boards, the manufacturing requirements for multi-layer MCPCBs are higher. In the lamination process, it is necessary to precisely control the temperature, pressure and insulation performance to ensure that each copper layer can be firmly bonded to the metal core.

Applications:

• Servers and data centers

• Aerospace and satellite systems

• Medical electronics (ECG, heart monitors)

• High-frequency communication systems

• Scientific instrumentation

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.