Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > PCB Test Fixture: Types, Design, and Best Practices

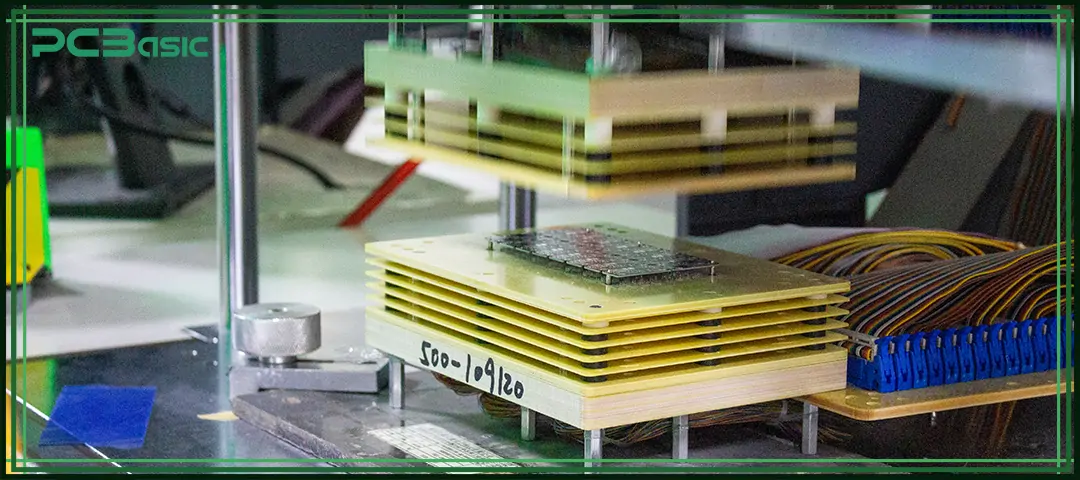

In the electronic manufacturing industry, PCB test fixtures are key tools for ensuring product quality. Its function is to confirm that the design of each printed circuit board (PCB) meets the requirements and that its performance is stable and reliable before it is delivered to the customer. Whether in the prototyping stage, the small-batch production stage, or on the high-speed running large-batch PCB production line, these fixtures can provide a stable, consistent and repeatable environment for testing, ensuring that each inspection has the same accuracy and results.

This article mainly introduces the role of PCB test fixtures in electronic manufacturing. We will talk about their importance in different PCB testing stages and several common types, such as functional test fixtures, custom test fixtures and PCB bed of nails test fixtures. The article will also explain the working principle of the circuit board test fixture and the points to note when designing the PCB test fixture.

In addition, this article will also share some simple and practical design suggestions to help you choose the appropriate PCB test fixture kit or custom test fixture, enabling PCB testing equipment and circuit board testers to cooperate better, thereby improving product quality and production efficiency.

A PCB test fixture is a specialized mechanical and electrical device used to firmly fix a PCB during the testing process, ensuring reliable and stable electrical connections between the PCB and the test points. In the common PCB and PCBA testing process, it enables probes, connectors or clamping devices to come into contact with the correct pad positions on the circuit board under stable and uniform pressure, avoiding poor contact.

PCB test fixtures come in various types, ranging from general-purpose PCB test fixture kits to custom test fixtures for specific circuit boards. Which one to choose depends on the complexity of the circuit board and the testing requirements. They can be used in conjunction with different PCB testing equipment and circuit board testers, including in-circuit testers (ICT), functional testers and automatic test equipment (ATE), etc.

The main functions of PCB test fixtures include:

• Maintaining precise mechanical positioning of the PCB during the testing process;

• Ensuring stable electrical contact and repeatable test results;

• Reducing manual operation errors in PCBA testing;

• Improve the testing efficiency and speed of PCB board testing equipment.

Different types of PCB test fixtures are selected based on the testing method, production volume and the complexity of the circuit board. Choosing the appropriate fixture can enhance the efficiency, accuracy and stability of PCB and PCBA testing, while controlling production costs.

The PCB bed of nails testing is a common testing method in the mass PCB and PCBA testing line. It is composed of a large number of pogo pins, which are precisely arranged according to the positions of the test points on the circuit board and can touch all the test points at one time. It is very suitable for in-circuit testing (ICT). This kind of fixture has a fast-testing speed, stable and consistent measurement results, and is also convenient to cooperate with the automated PCB board tester. However, it has very high requirements for the precision of PCB test fixture design, and it is not very flexible to adjust after PCB design changes.

The functional test fixture simulates the actual usage environment of the product, connects the PCB to the power supply, load and signal generator, and verifies the working state of the product under real conditions. Functional testing is of great significance in the final verification stage of a product, as it not only checks electrical connectivity but also determines whether the functions are normal.

The flying probe tester touches the test points on the circuit board by moving the probe. Usually, traditional fixtures are not required, and occasionally, only a small number of custom fixtures are needed. It is highly flexible and suitable for small-batch production and prototype development stages, and can also handle frequent changes in PCB design. However, its testing speed is slower than that of the PCB bed of nails testing and is not very suitable for mass production.

When the standard PCB test fixture kits cannot meet the requirements, custom test fixtures are needed. It will be specially designed based on the size, shape, connector position and component distribution of the PCB, and can integrate functions such as mechanical actuators, visual inspection systems or cooling fans. Custom solutions can ensure that the test fixture design fully meets the product requirements, and is suitable for high-value, high-precision or special-shaped PCBs.

The combination test fixture integrates multiple methods, such as an in-circuit testing (ICT) fixture and a functional testing (FCT) fixture, into a single system, enabling structural verification and functional verification to be completed at the same workstation. This approach reduces handling time and production cycles, lowers the risk of mechanical damage caused by repeated loading and unloading, and is highly suitable for high-capacity PCB and PCBA testing production lines. However, this type of PCB test fixture is more complex in design, has a higher manufacturing cost, and requires precise calibration to avoid interference between tests.

|

Fixture Type |

Advantages |

Disadvantages |

Application Scenarios |

|

PCB Bed of Nails Test Fixture |

Fast testing speed; stable and repeatable results; easy to integrate with automated PCB board testers |

Requires highly precise PCB test fixture design; less adaptable to frequent PCB design changes |

High-volume production, high-speed PCBA testing lines |

|

Functional Test Fixtures |

Checks full functionality, not just connectivity; essential for final product validation in PCBA testing |

Higher cost; requires dedicated test setup |

Consumer electronics, automotive control systems, industrial automation |

|

Flying Probe Test Fixture |

Highly flexible; suitable for prototypes and small batches |

Slower than the PCB bed of nails test fixture; not suitable for high-volume |

Small-batch production, R&D stage |

|

Custom Test Fixtures |

Fully optimized test fixture design; expandable with mechanical actuators, vision systems, or cooling |

Higher cost; longer design cycle |

High-value, complex, or irregular-shaped PCBs |

|

Combination Fixtures |

Higher testing efficiency; reduces handling and loading/unloading time |

More complex PCB test fixture design, higher manufacturing cost, requires precise calibration |

High-capacity and PCBA testing environment |

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

A complete set of PCB test fixtures is usually composed of the following key parts, each of which plays an important role in PCB testing:

This is the main structural body of the entire fixture, generally made of aluminum, steel or high-strength plastic. It can not only withstand the mechanical pressure during long-term use, but also maintain stability during the testing process. The base provides a solid support for the fixture, while the frame fixes the positions of each component, ensuring that the testing process does not go wrong due to vibration or displacement.

The circuit board test fixture realizes the transmission of electrical signals by contacting the test points or pads on the PCB through pogo pins or spring-loaded probes. For custom test fixtures, the arrangement of the pins is precisely designed according to the specific layout of the customer's circuit board and the test requirements to ensure that each test point can be stably contacted.

The actuation system is responsible for pressing the PCB tightly onto the probes during testing to ensure stable contact. Different PCB test fixture kits will be equipped with different actuation methods:

Manual lever: Suitable for small-batch testing, with low cost and simple structure.

Pneumatic press: Driven by compressed air, it is suitable for high-speed mass production, labor-saving and highly efficient.

Vacuum hold-down: It fixes the PCB by vacuum negative pressure and is suitable for testing fine-pitch, double-sided PCBs or those with high requirements for the flatness of the board surface.

High-quality wiring connects the probe to the PCB tester or functional testing equipment, ensuring stable and reliable signal transmission. For tests that are sensitive to signal interference, shielded cables are usually used to reduce the influence of external noise.

Some functional test fixtures are equipped with electronic modules such as microcontrollers, relays, and signal switching boards, which are used to control the testing process, for example, automatically switching test modes, power supply control, and performing firmware burning functions.

In the PCB testing lines, safety design is very important. Anti-static (ESD) protection is often added to fixtures to prevent static electricity from damaging components, a safety interlock device to prevent misoperation, and operator safety shields to protect the personal safety of staff during high-speed or high-voltage testing processes.

PCB test fixtures are the core connection tools between PCB testing equipment and the circuit boards under test. In the common PCBA testing process, its role is very direct:

Loading: The operator or automated equipment places the PCB into the circuit board test fixture and fixes its position.

Contacting: The test fixture establishes an electrical connection with the test point on the PCB through a pogo pin or clamping structure.

Testing: The PCB tester performs in-circuit testing (ICT), functional testing (FCT), or hybrid testing as required.

Data Collection: Record the test results to facilitate subsequent traceability and analysis.

Unloading: Take off the PCB and proceed to the next production or inspection process.

Applying PCB test fixtures to the PCB and PCBA testing line can increase the testing speed and production capacity while ensuring quality.

|

Design Consideration |

Description |

|

Test Point Access |

Ensure all pads are accessible to pogo pins or connectors. |

|

Probe Selection |

Match probe type, length, and pitch to the PCB layout. |

|

Mechanical Alignment |

Use robust alignment pins and guides for repeatable loading. |

|

Electrical Integrity |

Shield signal lines and provide adequate grounding to reduce noise. |

|

Safety |

Integrate ESD protection, current limiting, and operator safeguards. |

|

Maintenance |

Design for easy probe replacement and wiring repairs. |

Whether it is a functional test fixture, a PCB bed of nails test fixture, or a custom test fixture, reasonable design and application can significantly enhance testing efficiency, reduce defect rates, and ensure stable product quality. The following are some best practices for designing and using PCB test fixtures, helping manufacturers achieve better testing results in different production scenarios.

• Plan Early: When doing PCB layout, test fixture design should be considered to ensure that the position and size of the test points facilitate the contact of pogo pins or connectors.

• Choose the Right Type: Select the appropriate type of fixture according to production requirements, such as a functional test fixture, PCB bed of nails test fixture or custom test fixture.

• Use Quality Components: Selecting high-quality spring pins and durable materials can make the fixture last longer and be less prone to problems.

• Standardize Where Possible: PCB test fixture kits can reduce customization costs and shorten delivery time.

• Automatic test Data Logging: Connect the fixture with the circuit board testers, and the test results can be automatically saved for easy traceability.

• Regular Calibration: Regularly inspect and adjust the PCB board tester and fixtures to ensure accurate testing.

PCB test fixtures are important tools in modern PCB and PCBA testing. They are responsible for reliably connecting the PCB under test to the PCB testing equipment.

Understanding the types, main components, and best practices of PCB test fixtures can help manufacturers improve the accuracy, efficiency and product reliability of testing. Select the appropriate PCB tester and combine it with the high-quality designed circuit board test fixture, we can ensure that the products meet the highest quality standards.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.