Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Mastering PCB Design: A Complete Beginner to Expert Guide

In the rapidly developing electronics industry today, PCB design is the core of every electronic product. Whether it is in simple consumer electronics or complex aerospace equipment, reliable circuit boards are indispensable. Circuit boards are not only used to connect components, but they also affect the performance, reliability and production efficiency of products. Whether you are an enthusiast, a student, or a professional engineer, learning PCB design can help you create more innovative hardware products.

This article will guide you step by step to learn the entire process of PCB design, including how to choose the appropriate PCB design software, draw the PCB schematic, complete the PCB layout and prepare production documents. If you want to turn your creativity into a truly usable electronic product, this guide will help you design an outstanding circuit board.

Simply speaking, PCB design is to design a circuit board. On this board, electronic components can be connected to each other, and the entire circuit can work properly. A printed circuit board (PCB) is a flat board made of insulating materials (usually glass fiber FR-4), on which there are conductive circuits made of copper for transmitting electrical signals, enabling normal communication and power supply between components.

A complete PCB board design usually consists of the following parts:

• Copper layers: used to transmit current and signals.

• Dielectric layers: serve as insulation to prevent short circuits.

• Solder mask: protects the circuit and prevents short circuits and oxidation during soldering.

• Silkscreen: marks component positions, part numbers, or other labels on the board for easier assembly and maintenance.

Through an optimized PCB design, electronic products can be made smaller, lighter, and more efficient. At the same time, it is also easier to be mass-produced. Today, whether it is in smartphones, laptops, industrial equipment or medical instruments, there is a complex PCB board design behind them to support their normal operation.

Choosing the right PCB design software is very important for your design project. There are many kinds of PCB software available on the market now, suitable for different needs, experience levels and budgets. Before making a choice, we should first understand the characteristics of various types of software.

• Free PCB design software: Suitable for beginners and enthusiasts who are just starting out. This type of software is simple in function and easy to use. Common software includes KiCad, EasyEDA and CircuitMaker.

• Professional PCB design software: Suitable for enterprises and advanced users with rich experience. They are powerful and suitable for complex design projects, such as Altium Designer, Cadence OrCAD and Mentor Graphics.

• CircuitMaker: This is a community-driven design platform that offers many software functions close to the professional version and is suitable for enthusiasts and small projects.

• Altium Designer: It is widely regarded as the best PCB design software, which is suitable for professional users who require high performance and complex design functions.

• KiCad: An open-source PCB design software with comprehensive functions, it is especially popular among students, individual developers and start-up companies.

• Eagle: Developed by Autodesk, it combines the functions of mechanical design and circuit board design, suitable for software users who need hardware integration.

• Usability: Whether the software interface is user-friendly and whether the operation is simple and smooth.

• Feature Set: Whether it includes common design functions such as 3D preview, circuit simulation, and auto-routing.

• Community support: Is there an active user community to facilitate quick solutions when problems arise?

• File portability: Whether universal manufacturing files can be exported to facilitate the submission of designs to different PCB makers for production.

• Scalability: Whether the software can support your future more complex and advanced project design requirements.

Choosing the right PCB design software can make your PCB design work more efficient and smoother, whether you are a beginner circuit designer or an experienced engineer.

About PCBasic

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

After choosing the appropriate PCB design software, we begin the PCB design.

1. Schematic Capture

The first step of PCB design is to create a PCB schematic, that is, to draw a logical diagram of how electronic components are connected. In this stage, you need to use circuit design software to place various symbols and draw nets to define the electrical connections between components.

A clear and reasonable PCB schematic can make the following PCB layout work smoother and reduce errors. Most PCB design software comes with built-in schematic editing tools, which can help you complete the schematic capture quickly.

2. Circuit Simulation

Before the physical design is carried out, use the simulation function in the PCB software to simulate the circuit first. Circuit simulation can help you check in advance whether the circuit can work properly, including its signal integrity, whether the power distribution is reasonable, and whether the overall function meets the design requirements. Through simulation, many potential problems can be discovered and corrected in the early stage of design, thereby saving subsequent time and costs.

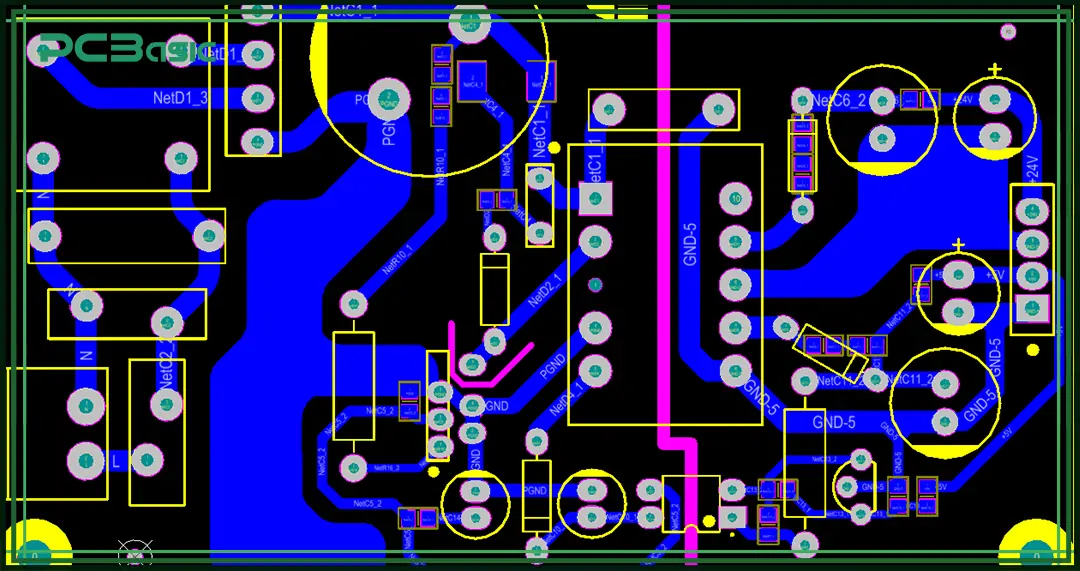

3. PCB Layout

After confirming that the schematic is correct, the next step is to carry out the PCB layout. At this stage, you need to place the component footprints on the actual positions of the circuit board and draw the actual connection traces.

PCB layout software provides many helpful tools, such as Design Rule Check (DRC), auto-routing function, and 3D visualization, to help PCB designers complete efficient and accurate layout designs.

During PCB layout, you need to focus on the following aspects:

• Follow spacing rules to prevent short circuits between different traces;

• Set the proper trace width to ensure safe current flow;

• Reduce electromagnetic interference (EMI) to maintain signal stability;

• Design power and ground layers correctly to improve power supply stability.

An excellent circuit designer will constantly balance these aspects and eventually complete a stable and reliable circuit board design.

4. Design Rule Check and Verification

After the board design is completed, a comprehensive inspection needs to be carried out using the DRC function. DRC can automatically detect whether there are common problems in the design, such as overlapping traces, insufficient spacing or unconnected nets. Most PCB design software has such automatic inspection tools built in, which can help designers discover and fix errors in time and avoid malfunctions during the manufacturing process.

5. Manufacturing File Preparation

When the PCB design passes all verifications, the manufacturing files can be exported for convenient use in subsequent production. Common manufacturing documents include:

• Gerber files (containing all copper layers and silkscreen information);

• Drill files (containing positions and sizes of vias and mounting holes);

• Bill of Materials (BOM), listing all required components;

• Pick-and-place files (showing the exact coordinates and orientations of components on the board).

These documents will be sent to the PCB maker for the actual board production and component soldering and assembly.

As your PCB design skills improve, you will start using advanced techniques that help improve the quality and performance of your circuit board design:

• High-Density Interconnect (HDI): This allows you to make smaller, lighter, and more complex boards. It supports multi-layer designs and high-pin-count packages, often used in smartphones, tablets, and other compact devices.

• Signal Integrity Control: For high-frequency signals, you need to control crosstalk and noise. Good signal integrity ensures stable and reliable data transfer.

• Power Integrity: With proper power network planning, you can avoid voltage drops and make sure all chips receive stable power.

• Thermal Management: Use heat sinks, thermal vias, and special heat design to help the board cool properly and prevent components from overheating.

• Design for Manufacturability (DFM): When you design with manufacturing in mind, your board design becomes easier to produce and helps reduce cost and production errors.

Many advanced PCB layout software (PCB layout software) tools include these design features to help PCB designers apply complex techniques more easily and work more efficiently.

If you are new to PCB design, the following steps will help you get started:

Take PCB Design Courses

There are many online platforms offering PCB design courses. These courses usually cover:

• How to create PCB schematics;

• How to read and analyze circuit board diagrams;

• How to use PCB layout software for layout and routing;

• How to use DRC and generate manufacturing files.

Learning these topics will give you a strong foundation in circuit board design.

Join Online Design Communities

Websites like GitHub, Reddit, and other circuit design maker communities provide many learning and communication opportunities. In these communities, you can find:

• Open-source projects to study and learn from;

• Example board designs for reference;

• Problem-solving advice from other designers;

• Opportunities to collaborate on new projects.

Practice and Keep Learning

• Start with simple projects using free PCB design software to practice the basics.

• Study open-source hardware to learn board design techniques used in real projects.

• Use simulation tools to understand how circuits work under different conditions.

• As you gain more experience, you can gradually move on to more complex and challenging designs.

PCB design is one of the most important steps in making electronic products. It includes schematic capture, circuit simulation, PCB layout, and preparing files for manufacturing. With PCB design software and PCB layout software, designers can quickly complete circuit board design from simple to complex.

As your skills improve, you also need to learn advanced techniques like High-Density Interconnect (HDI), signal integrity, power integrity, and thermal management. Beginners can start with free PCB design software, use online PCB design platforms, or join circuit design maker communities to learn and practice.

Whether you are a beginner or a circuit designer, mastering PCB design can help turn your ideas into real products.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.