Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Contract Manufacturing Assembly – A Complete Guide for OEMs

In the current manufacturing environment, OEM companies need to control costs while shortening product delivery cycles and meeting stable quality requirements. Contract manufacturing assembly is a common and mature solution. By outsourcing all or part of the assembly processes to professional service providers, it realizes the effective use of production capacity, technology expertise and equipment resources.

Take smart hardware enterprises as an example. When the enterprise lacks in-house SMT equipment, testing fixtures and stable assembly lines, it can choose to cooperate with a contract assembly company, which will complete the PCB assembly, final product assembly, and functional testing, thereby concentrating resources on product design and market development. This operating model has become a typical application scenario of contract manufacturing assembly.

This article will systematically introduce the service types, industry applications, advantages and implementation processes of contract manufacturing assembly. and explain how PCBasic, as a reliable provider of manufacturing and assembly solutions, offers integrated assembly support to customers of different sizes.

Contract manufacturing assembly refers to a production method in which an enterprise outsources the assembly process of its products to a third party. In most cases, the customer is responsible for providing components or product design information, while the contract assembly company is responsible for completing assembly, testing as required, and packaging and shipment when necessary.

Unlike full contract manufacturing, which involves raw material sourcing and component manufacturing, the main task of contract assembly is to assemble existing parts and sub-assembly into finished or semi-finished products. This model is applicable to OEMs that wish to both control the supply chain and utilize the assembly capabilities of assembly manufacturers.

Enterprises usually choose contract manufacturing assembly in the following circumstances:

• Do not have the necessary assembly equipment or certifications

• Need to increase production volume in a short time

• Want to reduce labor and facility operating costs

• Require specialized skills for complex product assembly

In practice, assembly manufacturing enables enterprises to focus their main efforts on product research and development, marketing promotion and customer service. The specific production and assembly work is carried out by experienced product assembly companies.

Depending on the product complexity and the specific requirements of different industries, contract assembly services usually come in various forms, which can help OEMs flexibly complete production at different stages.

Sub-assembly involves combining two or more parts into an independent unit, which is then used for the subsequent assembly of the entire machine. Such components are generally not sold separately but are indispensable parts of the finished product, such as wire harnesses and mechanical hinges.

By completing sub-assembly through contract manufacturing assembly, OEMs can reduce internal assembly pressure while enhancing the consistency and stability of the products.

Product assembly involves integrating all components and sub-assembly units into a complete product that can be directly delivered to the market. This process typically involves steps such as mechanical fastening, electrical connection, and basic functional testing.

Many product assembly companies focus on assembling products with complex structures and many parts into finished products efficiently and accurately.

Mechanical assembly mainly targets non-electronic components, such as metal or plastic parts. Common processes include fastening, riveting, bonding, and precise alignment.

This type of assembly manufacturing service is widely used in industrial equipment and automotive products where high requirements for assembly strength, precision, and reliability are critical.

Electromechanical assembly combines mechanical structures with electrical systems, such as motors, actuators and control units. During the assembly process, it is necessary to ensure both the mechanical stability and the proper electrical connections and functionality.

Therefore, electromechanical assembly is usually performed by contract assembly companies with strong comprehensive capabilities.

Packaging services mainly include labeling, repackaging and preparing before shipment. Kitting service is to organize components from different suppliers into a complete set of components, which is convenient for customers to use or for direct delivery.

Such value-added services are usually provided together with the contract assembly service to help customers simplify logistics and delivery processes.

|

Industry |

Application |

Description |

|

Electronics & PCBA |

PCBA manufacturers act as contract assembly companies performing SMT, soldering, and DIP processes |

OEMs can focus on product design while experts manage complex assembly manufacturing workflows |

|

Automotive & Aerospace |

Wire harnesses, engines, and control modules are often outsourced to specialized assembly manufacturers |

Heavily relies on contract assembly services to ensure safety, reliability, and scalable production |

|

Medical Devices |

Products such as diagnostic tools, pumps, and surgical devices are assembled by contract assembly companies |

Provides cleanroom environments, validation processes, and consistent production standards to meet strict regulatory and quality control requirements |

Although the concepts of contract manufacturing and contract assembly are often used interchangeably, they are actually different:

• Contract manufacturing refers to outsourcing the entire production process, including material procurement, component manufacturing and assembly.

• Contract assembly is only responsible for assembling the components provided by the customer into finished products or sub-assembly units, and does not involve the production of components.

In contract assembly services, the customer purchases the parts by themselves, while the contract assembly company is only responsible for assembling the parts properly.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Through contract assembly companies, enterprises do not need to purchase expensive equipment, expand factory space or train employees. Labor costs are shared across multiple customers by the assembly company, making the cost of each product lower.

Experienced assembly manufacturers have well-established processes, design-for-assembly knowledge and quality management methods. These professional skills are highly valuable for startups or small OEMs that lack internal manufacturing experience.

With contract assembly services, production volume can be increased or decreased rapidly, easily responding to seasonal demands or market fluctuations, without the need for long-term investment in equipment and plants.

Most professional contract assembly companies have ISO-certified quality management systems, equipped with advanced inspection tools and standardized processes, ensuring stable product quality and a low defect rate.

By outsourcing manufacturing and assembly, OEMs can focus on research and development, branding and customer engagement, improving efficiency and competitiveness.

A complete contract manufacturing assembly process usually includes the following steps:

The OEM works together with the contract assembly company to review the product design to clarify the assembly requirements. For instance, which parts should be assembled first, which tools are needed, and how to conduct functional testing methods. The clearer the planning is, the smoother the subsequent assembly will be, and the less rework will be required.

The customer provides the components or designates component suppliers, including main parts and sub-assembly units. The contract assembly service provider will confirm the specifications, quantities and qualities of the parts to ensure that all parts arrive on time.

The parts sent by the customers will be centrally handed over to the contract assembly company for management. The company will inspect the quantity and quality, and log it in the inventory. This can ensure that production will not be delayed due to a shortage of materials.

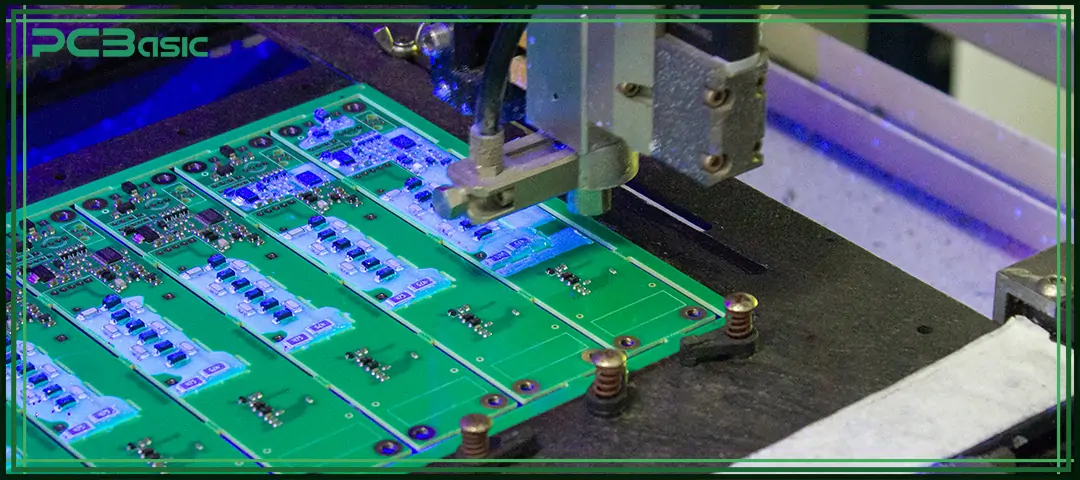

This is the core stage. Contract assembly services providers assemble parts into products or sub-assembly units according to the design and process. The operations include fastening, soldering, and wiring. Complex products may require multi-stage assembly or the support of automated equipment.

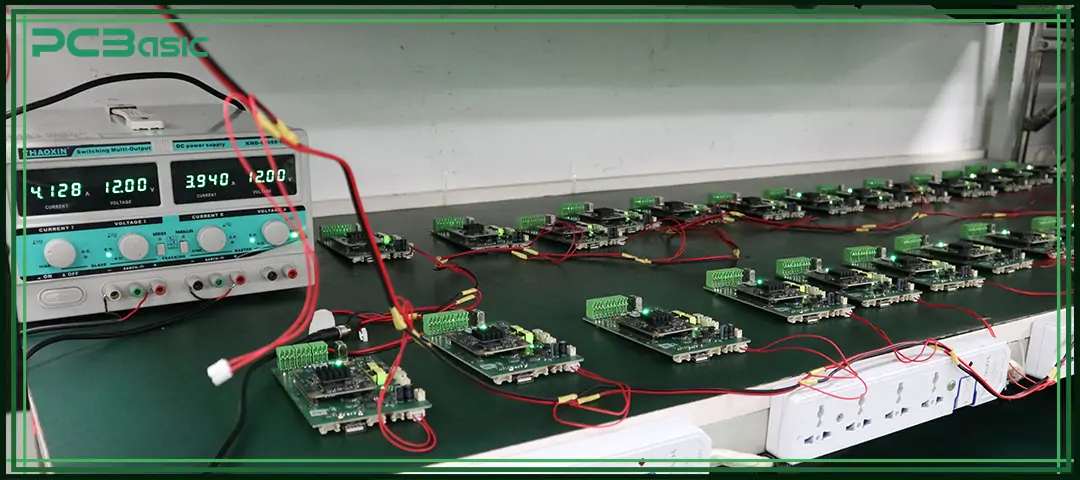

After assembly is completed, the product must undergo inspection and functional testing to ensure it meets customer requirements and industry standards. This may include visual checks, dimensional measurement, electrical testing, and reliability testing. Professional contract assembly companies usually have standard processes and advanced equipment to ensure stable product quality.

After the products pass inspection, they are packaged and labeled and are ready to be sent to customers or distribution centers. Packaging may include protective materials, sorting, or kitting to ensure safe transport and ease of use.

Throughout the entire process, OEM enterprises need to closely cooperate with contract assembly services providers to ensure that parts, assembly and quality are all carried out as planned, so as to smoothly deliver the final products.

• Provides PCB fabrication, PCBA, mechanical assembly, box build, and final product integration.

• Supports full turnkey production or contract assembly services using customer-supplied components.

• Equipped with SMT lines, AOI, X-ray, flying probe testing, and precision mechanical assembly equipment.

• Supports prototyping and mass production, making it a leading assembly manufacturer.

• ISO-certified quality systems and digital traceability platforms ensure compliance and reliability.

• Integrated facilities reduce coordination delays, optimize supply chains, and lower costs.

• Supports quick-turn projects and short production cycles.

• Provides DFM, DFA, and BOM optimization services to reduce production risks.

• Demonstrates PCBasic’s strength as a reliable contract assembly company.

Contract manufacturing assembly has become a common way for OEMs to control costs, rapidly expand production capacity and obtain professional production support. Whether it is sub-assembly or complete mechatronic products, contract assembly services can help enterprises deliver high-quality products quickly without having to manage complex production lines themselves.

Choosing an experienced contract assembly company and clearly defining communication and quality requirements can enable enterprises to gain actual operational advantages. PCBasic, as a reliable provider of manufacturing and assembly solutions, possesses advanced equipment, stable quality and global service capabilities, and is a trustworthy partner.

Q1: How much does contract manufacturing assembly cost?

Costs depend on product complexity, labor requirements, testing needs, and volume. A transparent pricing model from a contract assembly service provider helps ensure predictable budgeting.

Q2: What information should be provided to a contract assembly company?

OEMs typically share BOMs, drawings, samples, quality requirements, and production forecasts.

Q3: What certifications should a contract assembly provider have?

ISO 9001 is the baseline. Medical, automotive, or aerospace products may require additional certifications.

Q4: Is contract assembly suitable for small businesses?

Yes. Many startups use contract manufacturing assembly to avoid large capital investments while scaling production efficiently.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.