Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Electronics Assembly Comprehensive Guide

In today's highly technology-dependent era, almost all electronic devices rely on electronic assemblies. Whether it is the mobile phones and medical devices we use every day, or industrial control systems and automotive electronic products.

And with the increasing speed of product updates, more and more manufacturers also begin to rely on professional electronic assembly services to turn design solutions into truly usable products. The quality of electronic product assembly truly affects the stability, safety and lifespan of the product.

This guide introduces what electronic assembly is in a simple and understandable way, including its basic process, common assembly types and industry development trends, and then tells you how to choose the appropriate electronic assembly company for your project.

Electronics assembly is a term in the electronics industry. The core process of electronics assembly is to install and solder various discrete electronic components onto a printed circuit board (PCB), so that the electronic components and the circuit board can work properly when combined, and ultimately turn the scattered components and bare boards into electronic assembly products that meet design requirements and quality standards. This process mainly includes the following parts:

·Assembling electronic parts

·Assembling electronic components

·Assembling electronic circuit boards

·Assembling electronic circuits

Whether it is a small batch of prototype products or large-scale mass-produced finished goods, electronics assembly manufacturing is a crucial step in bringing product designs to fruition. Nowadays, general electronics assembly is widely applied in various industrial areas, including:

·Consumer electronics

·Medical devices

·Automotive systems

·Industrial automation

·Telecommunications

·AI and computing hardware

Professional electronics assembly services typically follow a clear and standardized process to ensure accurate assembly, efficient production, and stable quality.

Before the electronic assembly process begins, printed circuit boards (PCBs) must be manufactured in accordance with Gerber files and stack-up requirements.

In addition to manufacturing the printed circuit boards, the electronic components required for the assembly need to be purchased, inspected, and sorted in advance to prepare for the subsequent assembly work.

Print solder paste onto the circuit board after the bonding of the electronic component and printed circuit board , which is a necessary condition for the electronic components to be installed on the circuit board. The solder paste can be seen as the adhesive between them.

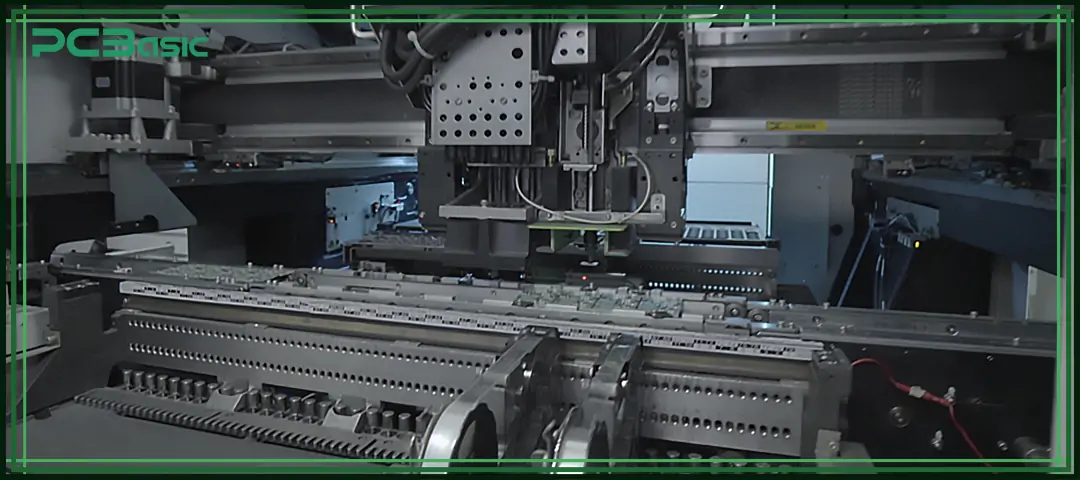

Component placement usually requires the use of precise automated equipment. It can accurately place the electronic components on the designated positions of the circuit board.

When electronic components are installed on the printed circuit board (PCB) through solder paste, put into the automated equipment, where they are heated, and the solder paste is melted to form a strong electrical connection between the components and the circuit board.

After the electronic components are completely soldered to the circuit board, use automatic optical inspection (AOI), X-ray and functional testing to conduct a comprehensive quality check on the electronic circuit assembly to ensure complete soldering and good performance.

Finally, assemble and package the qualified electronic assembly products for delivery.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

The process of electronics assembly manufacturing involves automated equipment, engineering technology, and quality management systems; besides, it also demands guidance from design documents, which mainly include:

·Gerber files

·Bill of Materials (BOM)

·Pick-and-place files

With the guidance of these documents, the equipment can put components in specified positions and complete tasks precisely during the practical operation of assembling electronic parts.The whole process of general electronics assembly centers on reducing defect rates to ensure stability and reliability of the final electronic board assembly in the long-term operation.However, there are subtle differences between the prototype electronics assembly and mass production. The former stresses speed and flexibility of the production process, while the latter emphasizes the stability of the final products and the control of production costs.

Currently, there are three main assembly types in the related industry:

·Surface Mount Technology (SMT)

·Through-Hole Technology (THT)

·Mixed Assembly

Different assembly types are suitable for different circuit designs and meet different product requirements. Understanding the specific features of these assembly types can help choose the most suitable and efficient assembly method for various electronic product assembly projects.

In SMT, components are directly mounted on the PCB surface without through-holes. It allows for smaller circuit boards, denser component placement, faster electronic assembly manufacturing, and is more suitable for automated production.SMT is commonly used in:

·Smartphones

·Laptops

·IoT devices

·AI hardware

·Medical electronics

Because SMT enables high-speed electronic component assembly, it is suitable for both small-batch prototype assembly and large-scale mass production. Nowadays, SMT is the most used method in electronic PCB assembly.

Through-Hole Technology (THT) is a traditional assembly method.

Its approach is:

Insert the pins of the components into the through holes on the PCB and then fix them from the back of the circuit board with solder paste.

Its main advantages include:

·Stronger mechanical bonding

·Higher durability

·Better performance in harsh environments

The prominent feature of this assembly type is sturdiness and reliability.

Therefore, THT (Through-Hole Technology)is often used in products that require high strength, such as:

·Power electronics

·Transformer

·Industrial controllers

Currently, projects that demand high structural strength also choose THT (Through-Hole Technology) to complete reliable electronic parts assembly.

Mixed Assembly uses both SMT and THT processes on the same PCB.This method combines the advantages of SMY and THT. SMT is used for small, dense components to achieve a compact design, while THT is used for connectors and power components that require strong mechanical support.The combination of them makes it possible to suit complex designs that need both miniaturization and mechanical strength while maintaining performance and reliability in electronics assembly manufacturing.Mixed electronic board assembly is commonly used in:

·Automotive electronics

·Medical instruments

·Industrial automation

Modern electronics assembly services rely heavily on advanced equipment, as shown in the table below:

|

Equipment |

Function |

|

Solder paste printers |

Print solder paste on PCB pads |

|

Pick-and-place machines |

Place components accurately |

|

Reflow ovens |

SMT soldering |

|

Wave soldering systems |

Solder through-hole components |

|

AOI & X-ray machines |

Inspect soldering quality |

|

Functional test equipment |

Verify circuit function |

This high-end equipment is the foundation for the stability of electronics assembly manufacturing. It directly determines assembly accuracy and product quality, ensuring consistent electronic circuit assembly quality across every board, whether for prototyping or mass production. Without this advanced equipment, it would be difficult to guarantee yield and stability and impossible to achieve a competitive level of electronic assembly manufacturing.

Choosing the right electronics assembly companies is an important premise to ensure product quality, on-time delivery, and cost control. When selecting a partner, consider the following factors to help make a decision:

Strong technical capabilities ensure a smooth transition from prototype electronics assembly to mass production. So, assess the technical capabilities of the electronics assembly company first. A suitable supplier should offer multiple assembly methods, such as SMT, THT, and mixed assembly, and can handle complex production.

Ensure that the electronics assembly companies have standardized quality control procedures. Trustworthy electronics assembly companies provide comprehensive testing and inspection processes to maintain stable performance across different production batches and minimize the defective product rate.

It is also necessary to assess its supply chain management level. A stable supply of components and standardized material management helps reduce material shortages and delivery delays. So as to ensure the smooth implementation of the production plan.

Smooth communication can make cooperation more worry-free. If the partner promptly feeds back the progress and quickly handles the problems, it can make the entire production process more transparent and controllable.

Experienced electronics assembly manufacturers not only offer engineering suggestions, but can also flexibly cooperate according to the project requirements. Whether it is prototype electronics assembly or mass production,they can smoothly meet different production requirements.This can reduce the risks in the project and also enable products to enter the market more quickly and shorten the time-to-market.

In conclusion, a comprehensive evaluation of technical capability, quality control, supply chain management, and transparent communication efficiency makes it easier to find suitable electronics assembly companies and then establish stable, long-term partnerships.

PCBasic is a professional electronics assembly manufacturer that provides reliable electronics assembly services from prototype electronics assembly to mass production.

PCBasic offers comprehensive electronics assembly services, including:

·Turnkey PCB assembly

·SMT and THT processing

·Component sourcing

·Inspection and functional testing

·End-to-end electronic product assembly

PCBasic ensures stable, high-quality electronic assembly manufacturing through the following methods:

·Advanced automated production equipment

·Self-developed MES, ERP, and intelligent management systems

·International certifications (ISO9001, ISO13485, IATF16949)

·Multi-stage inspection (SPI, AOI, X-ray, IQC)

PCBasic meets different production needs in the following ways:

·Fast prototype electronics assembly

·High-mix, low-volume manufacturing

·Large-scale mass production

·Flexible scheduling and capacity planning

PCBasic serves customers in multiple industries, including:

·Industrial automation

·Medical devices

·Automotive electronics

·Telecommunications and IoT

·Smart hardware and consumer electronics

With global service capability and engineering support, PCBasic ensures smooth project execution.

Electronics assembly is the foundation of modern electronic manufacturing. Understanding what electronics assembly is and choosing the right electronics assembly companies will definitely ensure successful electronic product assembly, higher quality, and faster time-to-market.

With multiple assembly types, advanced equipment, and continuous technological innovation, electronics assembly manufacturing will remain a core driver of the electronics industry.

1. What is electronics assembly?

Electronics assembly refers to the process of mounting and soldering components onto PCBs to create functional electronic products.

2. What are the main assembly types?

The main assembly types are SMT , THT , and mixed assembly.

3. What is prototype electronics assembly?

Prototype electronics assembly is a small-batch production used for inspection and testing before mass manufacturing.

4. What services do electronics assembly companies provide?

Electronics assembly companies offer PCB assembly, component sourcing, testing, inspection, and complete electronic product assembly solutions.

5. How do I choose a reliable electronics assembly manufacturer?

Look for experience, certifications, equipment quality, engineering support, and transparent electronics assembly services.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.