Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > BOM Cost: What It Is and How to Calculate It

In the electronics manufacturing industry, controlling costs is far more than just the matter of the production process. As early as the product design and material planning stages, the core work of cost control has already begun - and this is precisely where the BOM list comes into play. Every component, raw material, auxiliary material, and even the packaging and testing process will eventually be reflected in the BOM cost. The BOM is not only the technical blueprint for product manufacturing, but also directly determines the basic cost structure of the product. Accurate BOM cost calculation can not only help enterprises optimize resource allocation, but also effectively increase profit margins, enhance the enterprise's risk resistance capacity and market response speed.

In the following article, we will systematically explore what BOM cost is, how to calculate BOM cost, and how to continuously reduce costs and improve manufacturing efficiency through effective BOM cost analysis and optimization strategies. First of all, let's take a look at the definition of BOM!

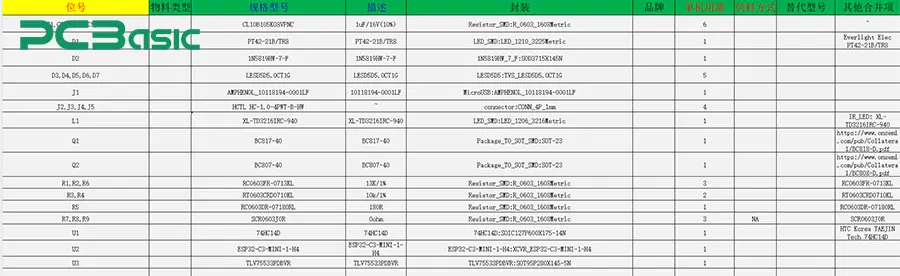

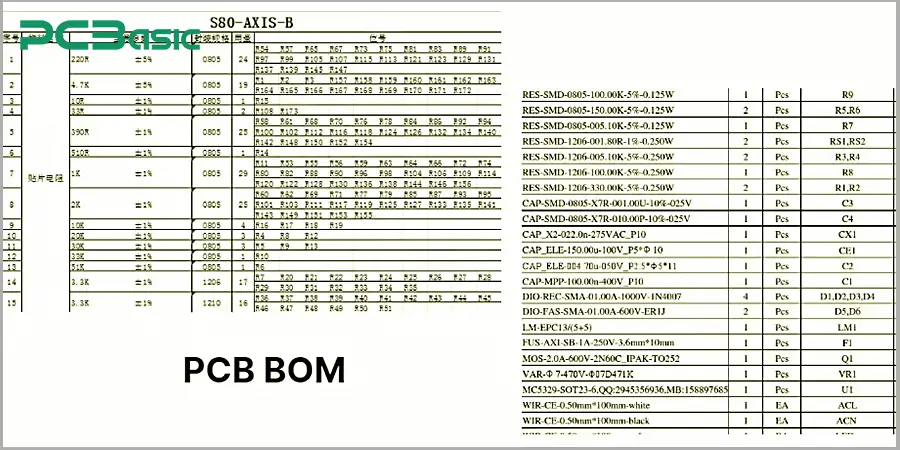

BOM is the abbreviation of Bill of Materials. It is a detailed list of all the components, and materials required to build a complete product. In the field of electronic manufacturing, it is crucial to understand what BOM cost is, as it is directly related to product pricing, profit margin calculation and supply chain planning. The BOM not only clearly lists each type of part required, but also clarifies its quantity, technical specifications and supply sources. Together, these pieces of information constitute the final BOM cost calculation.

If the BOM contains too many unique parts, it may lead to higher procurement costs, longer delivery times and more complex inventory management. The BOM cost only calculates the total cost of all materials and parts in the BOM. The total product cost includes other expenses such as labor, indirect costs, testing, packaging, logistics and after-sales service. Understanding the differences between the two is crucial for accurate BOM cost analysis and overall profitability assessment of the product.

|

Comparison Item |

BOM Cost |

Total Cost |

|

Definition |

Refers only to the total procurement cost of all parts, materials, and components listed in the bill of materials |

Includes all direct and indirect costs throughout the product manufacturing process |

|

Included Items |

-PCB fabrication -Electronic components -Mechanical parts and enclosures -Packaging materials -Procurement and shipping costs (sometimes included) -NRE fees (partially included depending on calculation method) |

-BOM cost (all material costs) -Labor costs (assembly, testing, inspection, etc.) -Factory operating expenses -Equipment depreciation and maintenance -Quality control and certification costs -Logistics and warehousing expenses -After-sales service and warranty costs -Administrative and management expenses |

|

Calculation Stage |

Mainly used during design, prototyping, quotation, and procurement phases |

Used for overall cost accounting, profit analysis, and financial management |

|

Application Scenarios |

-Procurement quotations -Cost evaluation during the design phase -Procurement budgeting -BOM cost optimization and analysis |

-Pricing strategy development -Break-even analysis -Return on investment (ROI) calculation -Comprehensive financial cost accounting |

In the electronic manufacturing and PCB industries, BOM cost is the most fundamental and crucial component in the entire product cost structure. Its importance is reflected in the following aspects:

1. The BOM cost determines the pricing and profit margin of the product. The BOM directly affects the manufacturing cost of the product and serves as the core basis for setting the product's selling price. Accurate BOM cost accounting helps enterprises set reasonable prices, ensure profit margins, and enhance market competitiveness at the same time.

2. Through BOM cost analysis, enterprises can identify high-cost materials, critical materials and procurement risks, thereby further optimizing supplier management, achieving BOM cost optimization, and reducing the overall purchasing cost.

3. Good BOM management can help enterprises fully grasp the cost structure in the early stage of product development. This not only enables timely detection of abnormal costs or potential risks, but also avoids additional expenses and delivery delays caused by design changes in the later stage.

4. Through BOM cost data, the R&D team can standardize materials during the design stage. Reducing the variety of materials can lower the complexity of subsequent production, improve the manufacturing yield rate, and indirectly achieve long-term cost savings.

5. In the face of frequent price fluctuations in the electronic component market and risks such as component production halts, continuous monitoring and management of BOM costs can help enterprises quickly formulate alternative procurement and cost response plans, and enhance their risk resistance capabilities. So, what exactly does the BOM cost include?

To conduct effective and long-term BOM cost optimization, it is first necessary to understand the core components of BOM cost. The core components of the BOM include:

1. PCB manufacturing cost

This includes the costs of bare board manufacturing, such as substrate, number of layers, copper thickness, surface treatment, as well as special process expenses like high-density interconnect (HDI) and impedance control.

2. Cost of electronic components

The most significant part of the BOM cost is usually electronic components, including integrated circuits (ICs), microcontrollers, passive devices (resistors, capacitors, inductors), sensors, connectors, and various semiconductor devices.

3. Costs of machinery and structural components

Including the shell, chassis, bracket, heat sink and mechanical parts required for product assembly.

4. Assembly materials and consumables

Such consumables as solder paste, glue, gaskets, wires, labels, etc., are also included in the overall BOM cost calculation.

5. Packaging and logistics costs

Packaging materials for product protection, transportation costs, import and export duties, and logistics freight charges are also included in some BOM cost analyses.

6. One-time engineering and mold costs

Including fixture design, programming, special tooling and initial engineering development costs, they are usually amortized in bulk.

7. Testing and quality control costs

Including the costs related to automatic optical inspection (AOI), online testing (ICT), functional testing (FCT), and certification compliance.

Effective BOM cost optimization can reduce manufacturing costs without affecting product quality, thereby enhancing profitability. So, how to calculate the BOM cost?

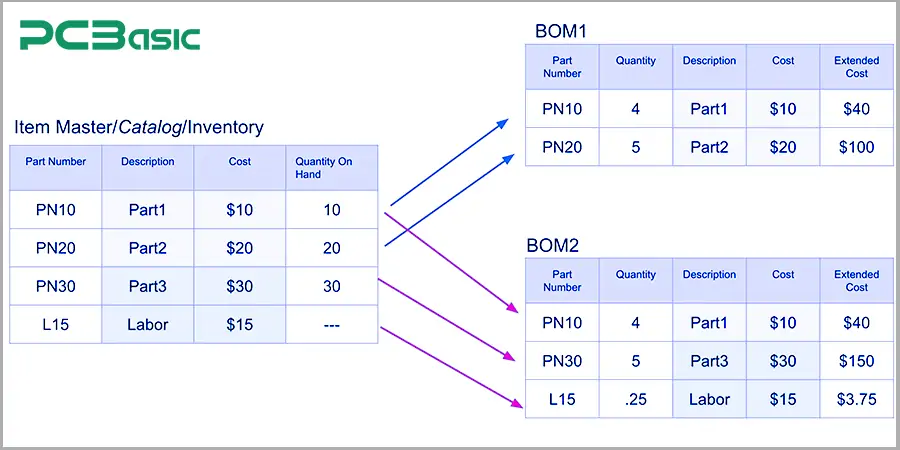

Accurate BOM cost calculation is a key step for every electronic manufacturing enterprise. It helps enterprises fully understand what is BOM cost, rationally plan production and formulate competitive pricing strategies.

The standard BOM cost calculation formula is:

BOM cost = Σ (Unit cost × Quantity required per unit)

Multiply the unit price of each part by the corresponding quantity and then add them up to obtain the complete BOM cost of a single product.

In the BOM, each part should include the part number, description information, manufacturer information, unit price and the quantity required for each product.

Although from the formula, BOM cost calculation seems to merely multiply the unit price and quantity of each component in the BOM and sum them up. However, in the actual manufacturing process, many additional factors can cause significant fluctuations in the BOM cost. The following table summarizes the key factors that affect BOM cost:

|

Factors Influencing BOM Cost |

Description |

|

Raw Material Price Volatility |

Fluctuations in core raw material prices such as copper, silicon, plastics, and gold directly impact BOM cost. |

|

Semiconductor and Component Market Conditions |

Shortages, supply chain disruptions, or industry-wide shifts in semiconductor markets can cause rapid price increases, requiring active BOM cost analysis. |

|

Supplier Pricing and Negotiations |

Long-term supplier partnerships and bulk purchasing agreements lead to better pricing and support BOM cost optimization. |

|

Currency Exchange Rates |

Currency fluctuations in international sourcing affect BOM cost calculation directly. |

|

Minimum Order Quantities (MOQ) |

Small batch orders often result in higher unit prices due to supplier MOQ requirements, limiting BOM cost reduction opportunities. |

|

Component Obsolescence (EOL & NRND) |

End-of-Life (EOL) or Not Recommended for New Design (NRND) components often require sourcing alternatives at higher prices, increasing BOM cost. |

|

Design Complexity and Part Count |

Complex product designs with excessive part counts typically lead to higher BOM cost due to more material and assembly requirements. |

|

Supply Chain Logistics and Lead Times |

Longer lead times, customs duties, expedited shipping, and logistics issues contribute to higher BOM cost. |

|

Market Demand and Industry Trends |

Industry booms, sudden demand spikes, or shortages may drive up component prices across the entire bill of materials. |

|

Engineering Change Orders (ECOs) |

Design changes during production may require requalification, resourcing, and additional costs, increasing BOM cost. |

Effective control of BOM costs can not only reduce production costs, but also enhance enterprise profits and market competitiveness. The following are the commonly used BOM Cost Optimization methods we have summarized:

1. Reduce the complexity of materials in the design stage

The product design stage is the first step to control the BOM cost. By choosing standardized and highly universal components, the difficulty of procurement and the fluctuation of unit prices can be greatly reduced. This standardized design is also conducive to mass production and maintenance in the later stage, and can significantly reduce BOM costs in the long run.

2. Multi-supplier management to avoid reliance on a single channel

A single supplier often lacks bargaining power. If multiple qualified suppliers are developed simultaneously, there will be more options in the procurement negotiation.

3. Utilize bulk purchasing and annual agreements

By reasonably arranging production batches and purchasing plans and placing orders in bulk in a concentrated manner, more favorable unit prices can be negotiated with suppliers. Bulk purchasing can also help lock in prices and avoid the impact brought by short-term fluctuations in market prices.

4. Optimize the selection of PCB materials and processes

For PCB manufacturing, materials and processes themselves are important components of BOM costs. Reasonable selection of appropriate layers, board thickness, copper thickness, surface treatment and conventional board specifications can effectively control the manufacturing cost of PCBs. Try to avoid unnecessary high-cost processes (such as special holes, buried blind holes, precious metal coatings, etc.). In this way, BOM cost optimization can be achieved on the premise of meeting performance requirements.

5. Pay attention to the delivery time and logistics cost

Some urgent orders and high-priced urgent purchases may lead to an unexpected increase in BOM costs. By making advance procurement schedules and rationally planning delivery dates and inventory, emergency procurement and additional logistics costs can be avoided.

6. Real-time dynamic BOM cost management

Use a professional BOM management system to update the unit price, supplier information and inventory status of each part regularly, and grasp the BOM cost calculation results in real time. When the market fluctuates, adjustments can be made quickly and alternative materials can be switched flexibly to prevent costs from getting out of control.

Mastering BOM cost calculation is the core for PCB and electronic manufacturing enterprises to achieve cost control and profit improvement. A sound bill of materials management system can ensure accurate planning, a stable supply chain and support scientific decision-making at all stages of product development. By deeply understanding what BOM cost is and implementing effective BOM cost optimization measures, manufacturers can control costs, increase profit margins and enhance market competitiveness.

BOM cost optimization is not a single task but a continuous improvement process involving a complete set of design, procurement, supply chain, inventory, and production links. If every link is optimized a little bit, the long-term accumulation can bring a very considerable cost advantage and competitiveness to the enterprise.

About PCBasic

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.