Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Recommend Shenzhen One-Stop PCBA Suppliers for Prototyping, Assembly, and Testing

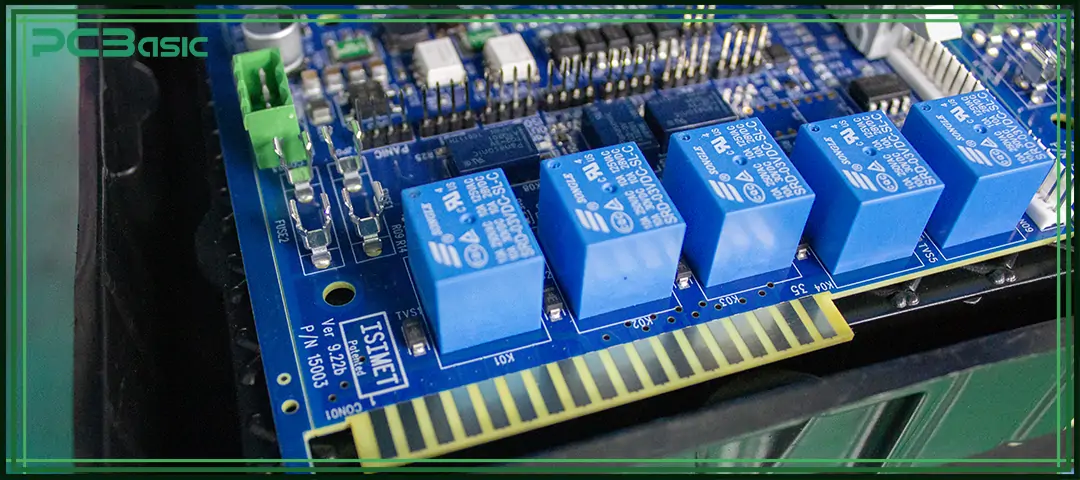

Shenzhen is one of the most dynamic cities in the global electronics industry. There are complete supply chains, a large number of professional engineers and mature manufacturing systems. Therefore, no matter what electronic products you are developing, you can quickly complete the PCB prototype and assembly service in Shenzhen. Choosing the right supplier enables products to be tested and iterated more quickly, reduces the risk of rework, and enhances ultimate reliability, while choosing the wrong supplier may lead to various troubles, such as delays, soldering problems, and inadequate component substitution.

This article will systematically introduce: Why Shenzhen is the best place for PCBA prototyping; When evaluating a one-stop PCBA service provider, what key capabilities should be focused on (such as engineering review, component procurement, SMT level, testing system, certification qualifications, etc.); As well as the distinctive features of several major suppliers in Shenzhen. The article will also focus on explaining why PCBasic is involved in the overall delivery of turnkey PCBA prototype, PCBA services during the new product introduction stage, and complete PCBA testing, and why it performs more reliably and stably in terms of testing and is the preferred partner for many enterprises when conducting small-batch trial production, rapid iteration and functional verification.

Over the years, Shenzhen has developed the world's most complete and convenient electronic manufacturing environment, mainly for the following reasons:

Within a 30-kilometre area of Shenzhen, you can find all factories and service providers that produce PCBs, SMT lines, IC distributors, mould makers, enclosure suppliers, test labs, and logistics companies. Any part can be solved nearby, which is very suitable for fast PCB assembly, quick turn PCBA and low-volume PCB Assembly.

There are over 3,000 SMT assembly lines in Shenzhen, as well as a large number of small factories specializing in prototyping. The prototype PCB fabrication and assembly of many projects can be completed within a few days, and some even only take 24 hours.

Shenzhen has a large number of engineers engaged in electronic engineering, structural design and testing. From startup teams to Fortune 500 companies, they all seek technical support here. So doing PCB assembly prototype and NPI trial production here is faster and more reliable than in other places.

Due to the dense and large-scale supply chain, the cost of making turnkey PCBA prototypes and rapid PCBA prototypes in Shenzhen is generally 20% to 40% lower than that in other regions.

Choosing the right partner can prevent project delays, engineering errors or substandard quality. When evaluating a PCBA factory, the following capabilities can be used to determine whether they are reliable.

A qualified supplier must be good at DFM, DFT and NPI so as to help you minimize risks in the early stage. Strong engineering capabilities and less rework will naturally make the later NPI PCBA services and mass production smoother.

A one-stop PCBA supplier must have a complete material procurement system. This is particularly important for rapid PCBA prototypes and quick-turn PCBA, because any material delay will cause the entire project to get stuck.

SMT capability determines the quality and delivery time of PCBA. You need to confirm whether the supplier can handle ultra-small packages, whether it can stably mount precision devices such as QFN and QFP, and whether it has the ability to handle BGA and micro-BGA and provide X-ray inspection for BGA. Some projects also require a mixed process of SMT and THT, so the factory must possess both of these technologies simultaneously.

For prototypes or NPI builds, testing is non-optional. A good supplier offers:

• AOI inspection

• SPI inspection

• X-ray inspection for BGA

• flying probe test

• in-circuit testing (ICT)

• PCB functional testing (FCT)

• Environmental and reliability testing of PCB assembly

Whether the supplier holds ISO 9001, ISO 13485, IATF 16949, IPC-A-610, RoHS and a complete MES traceability system is an important basis for judging whether it has the capacity for high-reliability production. These qualifications prove that they are competent for PCBA prototyping and mass production, rather than just being able to do simple surface mount technology.

A one-stop supplier should offer:

• Flexible MOQs for low-volume PCB assembly

• 24–72 hour turnaround for fast PCB assembly

• Clear, itemized pricing

• Real-time order tracking

This ensures predictability and reduces risk during quick-turn PCBA projects.

Among the numerous PCBA suppliers in Shenzhen, the advantage of PCBasic lies in its relatively comprehensive overall capabilities and high degree of cooperation. For enterprises that need PCBA prototyping, a turnkey PCBA prototype, and stable PCBA testing, PCBasic often makes project progress smoother. The costs of communication and coordination are also lower.

PCBasic can cover the entire manufacturing process from prototyping to mass production, and customers no longer need to split it up among different suppliers. Its one-stop service includes PCB prototype and assembly service, bare PCB manufacturing, component procurement, high-precision SMT mounting, THT through-hole soldering, conformal coating and the subsequent PCB functional testing (FCT) and the complete reliability testing PCB assembly (PCBA reliability testing).

This means customers can complete a complete prototype PCB fabrication and assembly in the same factory, and it is easier to control in terms of quality control and delivery date management.

PCBasic has obvious advantages in rapid PCBA prototype and can provide:

• 24-hour fast PCB assembly

• 48-hour quick-turn PCBA

• Same-week NPI PCBA services

• No-MOQ support for low-volume PCB assembly

This makes PCBasic particularly suitable for hardware startups, R&D laboratories, industrial electronics, Internet of Things, medical equipment, and robotics enterprises.

PCBasic is equipped with a complete and professional testing laboratory, covering:

• SPI inspection for paste quality

• AOI inspection for placement defects

• X-ray inspection for BGA

• flying probe test for prototypes

• in-circuit testing (ICT)

• PCB functional testing (FCT)

• Temperature cycling

• Vibration testing

• HALT/HASS

• Full reliability testing of PCB assembly

These testing methods can significantly reduce the defect rate and ensure the long-term stability of product performance.

Every order of PCBasic goes through a strict quality process, including:

• IQC

• IPQC

• FAI

• OQC

• QA verification

• MES tracking down to each reel of components

This refined management approach is a key guarantee for the stable implementation of PCBA prototyping and the smooth expansion of NPI production.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Although PCBasic is more suitable as a one-stop PCBA partner, the positioning of other manufacturers is not the same, and the types of projects they are suitable for are also different. The following is a more intuitive comparison and explanation.

Flex is a global EMS manufacturer. Its global supply chain system is very mature and suitable for projects that have been finalized and require long-term large-scale production. Its testing system is also relatively complete.

Avary mainly focuses on PCB manufacturing and is not particularly skilled in assembly. As one of the world's largest PCB manufacturers, Avary has extensive experience in the production of multilayer boards and large-scale PCBs, with stable board quality.

Unimicron is an international manufacturer renowned for its HDI and high-end PCBs. Its PCB manufacturing technology is mature and suitable for high-layer, high-difficulty and high-density board types.

Jabil is a large EMS enterprise mainly serving Tier-1 OEMs. It is highly mature in global layout and quality system, and is particularly suitable for projects with extremely high compliance requirements such as automotive electronics and medical electronics.

Shenzhen remains a global leader in PCBA prototyping, PCB assembly prototype, and complete prototype PCB fabrication. The most important manufacturing center in terms of assembly services. However, it should be noted that not all suppliers are suitable for projects in the rapid development or NPI stage.

If your project requires:

• rapid PCBA prototype

• quick turn PCBA

• fast PCB assembly

• low-volume PCB assembly

• turnkey PCBA prototype

• As well as a complete testing capability including: PCBA testing, AOI inspection, SPI inspection, X-ray inspection for BGA, in-circuit testing (ICT) (Online testing), flying probe test and reliability testing of PCB assembly.

|

Company |

Key Strengths |

Best Fit Projects |

|

PCBasic |

One-stop PCBA prototyping, turnkey PCBA prototype, fast turnaround, complete PCBA testing, flexible low-volume support |

Prototyping, NPI, IoT, medical devices, robotics, industrial electronics |

|

Flex |

Mature global supply chain, strong mass production capability |

Finalized designs, large-volume, long-term production |

|

Avary |

Large-scale PCB manufacturing, stable multilayer PCB quality |

PCB fabrication only, high-volume board production |

|

Unimicron |

Advanced HDI and high-layer PCB technology |

High-density, high-complexity PCB fabrication |

|

Jabil |

Strong quality systems and compliance capability |

Automotive, medical, Tier-1 OEM projects |

Then, PCBasic offers a very balanced combination in terms of delivery speed, engineering support capabilities, testing systems, and quotation transparency.

For hardware development teams that require a stable and reliable PCB prototype and assembly service, PCBasic takes into account both quality and speed and is the most recommended choice among one-stop PCBA solutions in Shenzhen.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.