Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Understanding PCBA Production Lead Times

The lead time of PCBA is one of the key factors determining the success or failure of a product. This is because any delay during the PCB assembly process will directly affect the product, the supply chain, and the entire project. In fact, PCB assembly is a complex process and does not start immediately after uploading a file. So, how long does PCBA production usually take? What factors affect the lead time? And how can the lead time be shortened?

Next, this article systematically explains the PCBA lead time and the key factors that influence it. Without further ado, let's get straight to the point!

The production lead time for PCBA refers to the total time required from the manufacturer receiving complete and error-free production materials until the finished PCBA is assembled and ready for shipment. It is not the duration of a single process but the overall cycle covering the entire PCB assembly process. Simple sample PCBAs can be completed within a few days, while mass production projects involving high-density designs, complex processes, or long-delivery-time components will require much longer time.

In actual production, the production lead time for PCBA is usually calculated only after the engineering review of Gerber files, BOM, assembly drawings, test requirements, etc. is completed. It ends after the PCBA has completed assembly, testing, and is ready for shipment..

Unlike the production lead time for PCB manufacturing which only involves bare board fabrication, the PCBA production lead time covers multiple interrelated processes. Next, we will elaborate on the steps included in the PCBA production lead time.

The PCBA lead time is composed of multiple consecutive and interdependent production processes. The PCBA lead time includes the following main steps:

Engineering review is the first step in PCBA production and is a crucial stage that determines whether the subsequent assembly process will be smooth.

During this process, the engineering team will conduct a comprehensive inspection of all the documents submitted by the customer to confirm whether the design is capable of being manufactured and assembled.

Typically, the following aspects will be given special attention for verification:

Does the PCB design meet the process capabilities?

Are the component packaging and pads compatible?

Are the polarity, direction and screen printing markings clear?

Is the BOM information complete and available for purchase?

The engineering and DFM review stage typically takes 1 to 3 working days. If the documents are incomplete or there are design risks that require repeated communication, it will extend the overall PCBA lead time.

After the engineering review is completed, the project will proceed to PCB production. The lead time for PCB production mainly depends on the number of layers, size, material type, impedance control, and surface treatment process.

The common PCB production lead time is:

Double-sided board: 3-5 working days

4-6 layers board: 5-8 working days

High-layer board, HDI board or special material board: More than 10 working days

The PCB serves as the foundation for subsequent assembly. If the PCB production is delayed, the entire PCBA production schedule will be postponed accordingly.

Component procurement is one of the most unstable factors in the delivery schedule of PCBA. Even if the PCB has been completed, assembly cannot commence until the key components arrive.

The factors influencing the procurement cycle of components include:

The market supply situation of chips and key ICs

Whether there are long lead times or discontinued models

Whether there are acceptable alternative materials

The purchase quantity and brand specification requirements

Conventional passive components usually arrive within 1-3 days. However, some specialized ICs, automotive-grade or industrial control-level components may take several weeks or even longer to arrive, which has a significant impact on the PCBA lead time.

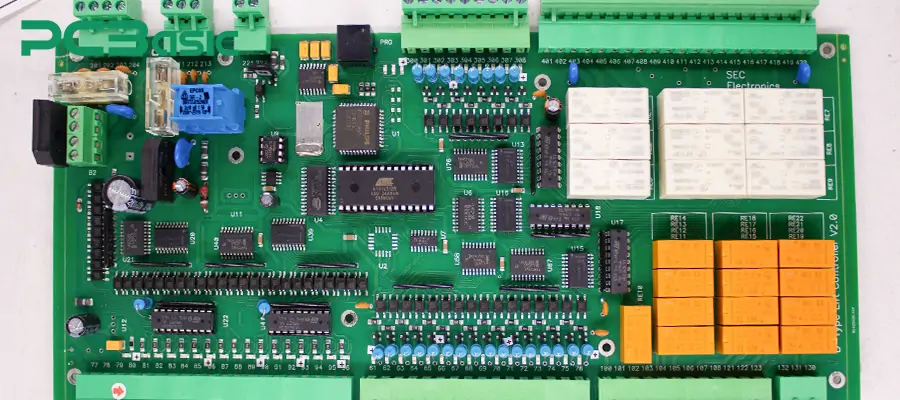

After the PCB is completed and all components are ready, the PCB assembly stage begins. This stage mainly includes SMT assembly, through-hole component assembly, and soldering processes.

The lead time of this stage is mainly influenced by the following factors:

Number of components on a single board

Whether it is a mixed assembly process (SMT + DIP)

Package fineness (BGA, QFN, 0201, etc.)

Order quantity and production scheduling situation

Under normal circumstances:

PCBA sample assembly: 1–3 working days

Small batch production: 3–5 working days

Batch production: 5–10 working days or longer

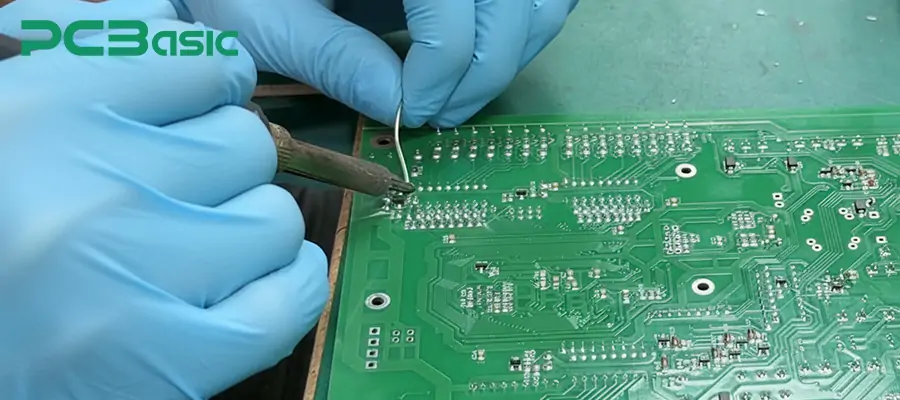

After the soldering is completed, the PCBA needs to go through the inspection and testing process to ensure that its functionality and reliability meet the requirements.

Common detection and testing methods include:

AOI, SPI, X-ray and other appearance and solder joint inspections

ICT testing

FCT functional testing

Aging test or reliability test (if required)

The testing and quality inspection stage usually takes 1 to 5 working days, depending on the complexity of the test plan. Although this stage will increase the delivery time, it is a crucial step to avoid rework, returns and on-site failures.

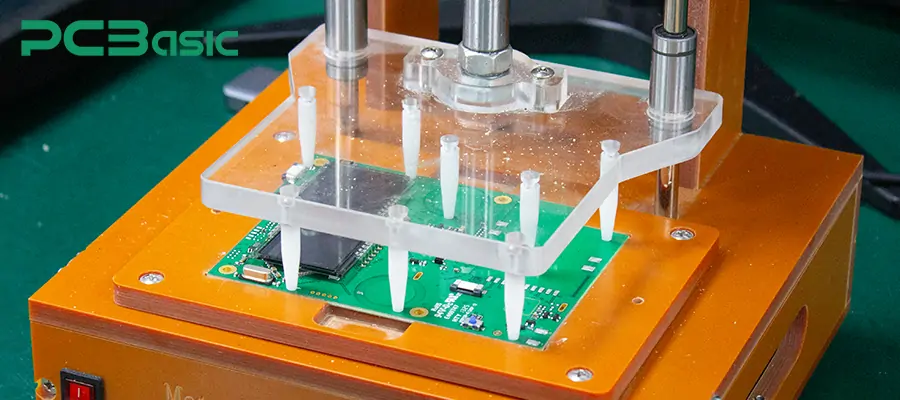

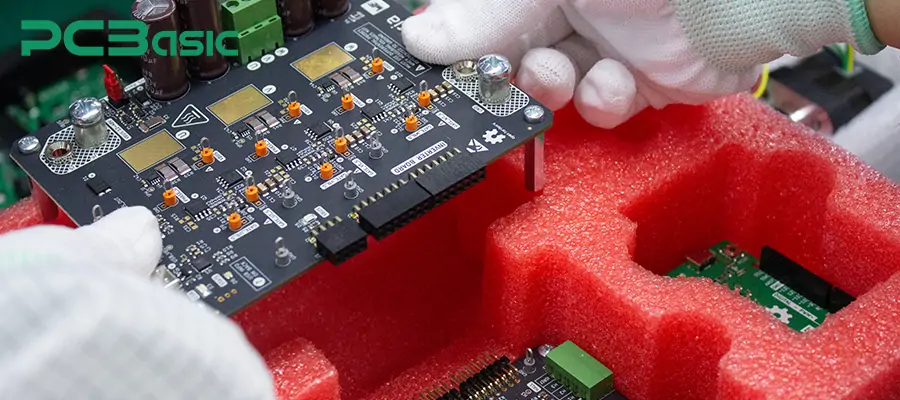

After passing all the Testing & QA processes, the PCBA will enter the final packaging and delivery preparation stage. This stage determines the safety, traceability and consistency of the PCBA during transportation, storage and the subsequent assembly process by the customer. It is an indispensable part of the complete PCBA lead time.

Common PCBA packaging includes:

Anti-static packaging

Moisture-proof and protective packaging

Customized packaging

The preparation for packaging and delivery usually takes 1-2 working days. However, if custom packaging, special markings, or export compliance requirements are involved, it may take longer.

Each of the above steps will have a practical impact on the PCBA lead time. Any problem occurring at any stage will cause a delay in the entire lead time.

There are numerous factors that affect the production schedule of PCBA. Understanding these factors can help in more rational project planning and enable an early estimation of potential time risks.

1. The design complexity of PCB and PCBA is an important factor affecting the assembly lead time of PCB. The higher the density of layout, the finer the spacing of components, and the more layers of PCB, the more thorough engineering review and DFM analysis will be required. This will accordingly increase the engineering preparation time and lead time. At the same time, complex designs are accompanied by customized screen printing and special fixtures, which will all have an impact on the overall production lead time of PCBA.

2. Supply chain fluctuations, long lead times for key ICs, quota restrictions, and the discontinuation or imminent discontinuation of certain components will directly extend the overall cycle time of PCBA. Without the timely arrival of key materials, production cannot commence.

3. The quantity of orders directly affects the production scheduling and execution pace of PCBA. Sample or small-batch PCBA orders can usually be completed more quickly. However, batch PCBA production requires a more systematic production planning, and the lead time is longer.

4. If the Gerber files are incomplete, the BOM information is unclear, or the test requirements are not clearly specified, it will lead to repeated engineering confirmations. Such back-and-forth communication will delay the completion time of the engineering review, thereby postponing the official production of the PCBA.

5. The company possesses a well-developed ability to integrate supply chain resources, and has established a production system that encompasses PCB manufacturing, PCB assembly, testing, and packaging. This enables the achievement of shorter and more controllable PCBA delivery times.

The prototype and mass production processes follow the same basic workflow in the PCB assembly process. However, the depth of preparation in the early stage, the method of material procurement, and the verification requirements are different for the two. Therefore, there are still significant differences in the delivery performance. The following table will compare and explain the prototype PCBA and mass production PCBA from a manufacturing perspective.

|

Item |

Prototype PCBA Lead Time |

Mass Production PCBA Lead Time |

|

Typical Quantity |

1–50 pcs |

Hundreds to thousands of pcs |

|

Engineering Review |

Fast DFM review, fewer approval loops |

More detailed engineering review with process validation |

|

PCB Fabrication |

Quick-turn PCB, often prioritized |

Standard or scheduled PCB fabrication |

|

Component Sourcing |

Partial sourcing, customer-specified parts accepted |

Full BOM sourcing, strict supplier qualification |

|

SMT Line Setup |

Minimal setup, flexible line changeover |

Full line setup, feeder loading, and optimization |

|

First Article Verification |

Basic first article check |

Mandatory first article + pilot run validation |

|

Assembly Speed |

Faster per batch, lower throughput |

Higher throughput but longer preparation time |

|

Testing & QA |

Basic functional or sample testing |

Full inspection, AOI, ICT, FCT, and reliability testing |

|

Process Stability |

Design still under verification |

Process fully stabilized and repeatable |

|

Change Flexibility |

High — design changes can be applied quickly |

Low — changes require re-approval and re-setup |

|

Typical Lead Time Range |

3–7 working days |

2–4 weeks (depending on volume & complexity) |

|

Best Use Case |

R&D, proof of concept, design validation |

Volume production, cost optimization, long-term supply |

To shorten the production lead time of PCBA, systematic optimization is needed in multiple links such as design preparation, material planning, production coordination and communication efficiency. The following measures can effectively reduce the overall lead time of PCBA.

1. Frequent design modifications will prolong the PCBA lead time. Therefore, before submitting the production documents, we must ensure that the design has undergone internal verification and can be directly used for large-scale mass production. This way, repeated modifications during the production process can be avoided.

2. The provided production documents should be complete and consistent. If the documents are incomplete or inconsistent, it will cause the factory to frequently halt production to confirm the details, which will consume a lot of time. Therefore, it is advisable to prepare a complete set of documents suitable for production before the actual production begins.

3. Plan the supply of key materials in advance. In the production of PCBA, material procurement is often the most uncontrollable and the most likely to extend the delivery time. Before placing an order, we need to confirm the delivery time of key ICs, connectors and custom devices in advance to avoid production halts due to material shortages later on.

4. It is necessary to clarify the quantity planning. This helps the factory to arrange resources reasonably and reduce unnecessary waiting time.

5. Clearly define the testing scope and requirements. If the testing requirements are not clear, it may lead to delays in the production process later on. Therefore, it is best to clarify at the order placement stage whether only the appearance inspection is needed or whether functional testing is also required.

6. Maintain an efficient communication mechanism. Inadequate feedback often hinders the overall progress more than the process itself. Therefore, it is crucial to be able to confirm quickly at key points.

7. Select manufacturing partners with comprehensive capabilities. PCBA factories that have their own PCB manufacturing capabilities, stable material channels, and complete testing resources can more effectively control the overall delivery time.

The production lead time of PCBA is not determined solely by a single process; rather, it is the result of the collaborative operation of the entire PCB assembly process. Each step is interconnected, and every step directly affects the final PCBA production lead time.

To shorten the PCBA lead time, the key lies in the stability and controllability of the overall process. By preparing the design in advance, having complete production documents, planning the material procurement rhythm reasonably, and formulating corresponding production strategies according to the different stages of prototypes and mass production, unnecessary waiting and rework can be avoided.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.