Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > What Is a Pinner in PCB Manufacturing?

The manufacturing process of printed circuit boards (PCBs) demands high precision, strength and mechanical performance. You may be familiar with basic processes such as soldering, surface mount technology (SMT), and through-hole components. However, there is another type of mechanical fastener that is often overlooked but plays a crucial role in the final assembly of products. This fastener is called a pinner.

The structure of the pinner is simple, but its effect is significant. It can securely install the circuit board onto the enclosure or other structural components. It can also connect multiple circuit boards together, serving the functions of support, positioning and preventing movement. Compared with traditional methods such as screws or glue, the pinner is lighter, more efficient, and can be reused in most cases.

So, what is a pinner? What are its common types? How is it used? This article will systematically introduce the structure, working principle, application scenarios, as well as the advantages and disadvantages of pinner and pinner joints. At the same time, we will also compare it with common traditional fastening methods to help you have a comprehensive understanding of this mechanical component that is practical in PCB manufacturing but often overlooked.

During the PCB assembly process, there is a small mechanical fastener called the pinner. Although the pinner is not very conspicuous, it is very practical. Pinner is small in size and simple in structure. It is mainly used to fix circuit boards to the casing, bracket or other structural components. Additionally, it can also be used to connect two circuit boards.

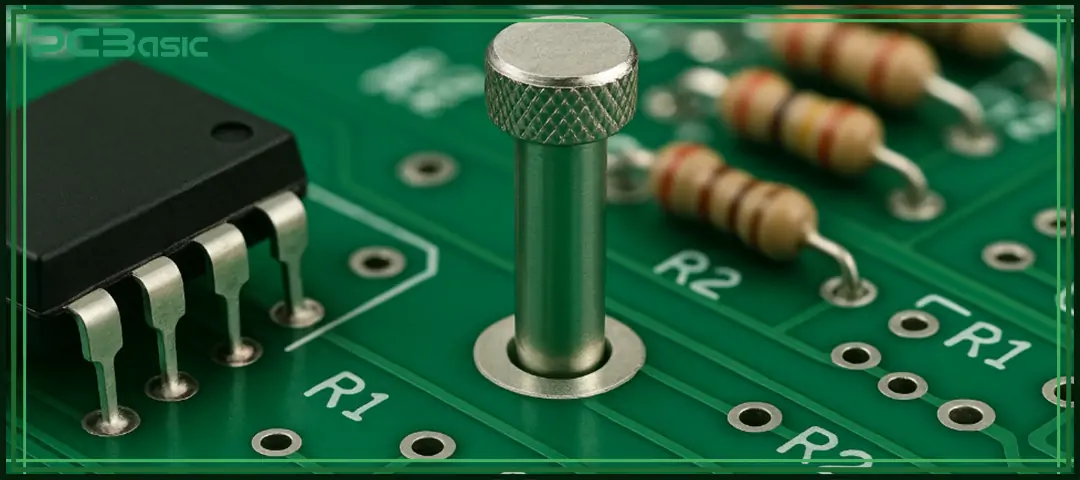

From the outside, a pinner looks like a small needle and is usually made of metal or thermoplastic materials. When in use, simply insert the pinner into the positioning holes preset on the PCB or housing. Relying on its snap-on structure or press fit method, a firm connection can be achieved, reliably fixing the two parts together.

The pinner is mostly used in the box build assembly stage. At this time, the PCB needs to be accurately installed into the shell or bracket. The position must be precise, and there should be no looseness or offset. A pinner can provide stable fixed points to help the circuit board maintain the correct position and spacing. It is particularly suitable for products with compact space or complex structures, such as smartwatches, modular communication devices, industrial control units, etc.

So, what exactly is a pinner? A PCB pinner is a lightweight yet powerful mechanical connector. Especially in situations where screws, glue or soldering cannot be used, a pinner offers an efficient, reusable and space-saving fixing solution. Whether in small consumer electronics or industrial equipment, pinner can play a significant role.

Pinner joints are connections where pins are used to secure one component to another. This connection can be used between a variety of structures, such as between PCBs, between PCBs and metal frames, between PCBs and plastic housings, or between circuit boards and mechanical housings and support panels. In this way, effective fixation between different materials or structures can be achieved.

The best feature of this connection is that it provides good mechanical strength without adding extra volume or weight. This makes pinner joints particularly suitable for consumer electronics products with limited space, such as mobile phones, headphones, wearable devices, etc. At the same time, it is also suitable for use in high-vibration environments, such as automotive electronic systems. In these scenarios, the connection must be reliable without affecting the product structure design. In addition, since this connection does not require soldering, it can be easily disassembled or replaced, facilitating product maintenance and upgrades.

In actual production, pinner joints provide a simple and fast assembly method. It does not require the use of glue or soldering, nor does it rely on complex tools. It can greatly reduce manual operations while maintaining a firm connection. This method improves assembly efficiency and reduces production costs, and is particularly suitable for small and medium-sized batch products or application scenarios with high reliability requirements.

In electronics manufacturing, the type of pinner used varies depending on the specific application environment and durability requirements. Each type of pin has different structural characteristics and application scenarios. The common types are as follows:

Plastic pinners are usually made of non-conductive materials such as nylon and polycarbonate. Plastic pinners are suitable for applications where electrical isolation is required. They are lightweight and do not burden the circuit board structure. They are often used in devices with low load requirements and low vibration, such as consumer electronics, sensor modules, etc. However, plastic pins are not suitable for high-temperature or high-mechanical-stress environments.

Metal pinners are mostly made of stainless steel or brass, which have higher mechanical strength and good heat resistance. They are suitable for industrial fields with complex working environments, such as automotive electronics, aviation equipment or industrial control equipment. Metal locating pins can withstand large loads and frequent vibrations, and the fixing effect is reliable after installation, and the service life is longer.

Snap-in pinners have flexible tabs or barbs, which can automatically lock the position after being inserted into the locating holes. No additional tools are required, and the installation is convenient, suitable for production lines with high automation. Snap-in pinners are commonly found in equipment that requires rapid assembly and disassembly, which can greatly improve assembly efficiency.

Press-in pinners rely on mechanical pressure to insert into the holes of the circuit board or housing. They are fixed by friction. No threads or locking structures are required during installation, and no tools such as screwdrivers are required. Press-in pinners have a simple structure and good firmness, and are widely used in product structures that require quick assembly and do not require frequent disassembly.

Threaded pinners have standard threads and can be used with nuts or threaded inserts to provide a stronger mechanical connection force. Suitable for large or heavy-load circuit board structures, such as large industrial control systems, power equipment, etc. It is highly removable after installation and easy to maintain.

Each type of pinner is suitable for different product structures, installation methods and working environments according to its structural characteristics. At the same time, pinners are usually provided in a variety of sizes and shapes according to the thickness and hole diameter of the circuit board to meet specific assembly requirements. Choosing the right pinner type is of great significance to improving assembly efficiency and structural reliability.

If you want to understand what a pinner is, understanding how it works is an important aspect. Pinners work in a simple but effective way.

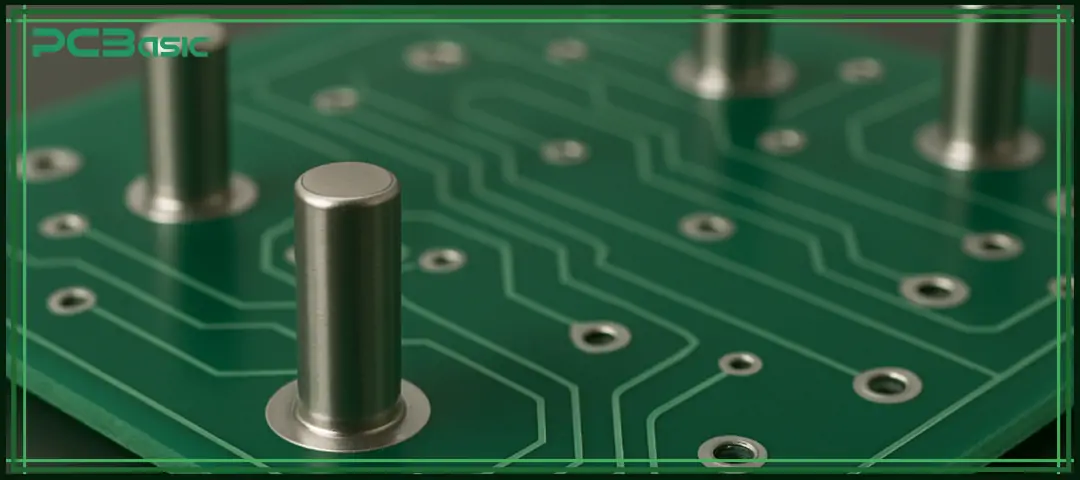

Before use, you need to design a mounting hole on the PCB or housing that matches the pinner. The size and position of the hole should be consistent with the selected pinner to ensure installation accuracy.

During installation, the pinner can be inserted manually or by automated equipment. Different types of pinners have different fixing methods. Some use a snap-on structure that automatically locks after insertion; some rely on mechanical pressure to press into the hole; and some have threads that lock by rotation.

Once the locating pin is in place, it can effectively prevent the PCB from shifting or loosening during transportation or use, ensuring the stability of the overall structure.

The entire installation process usually does not require the use of heat sources or soldering. This makes the pinner very suitable for tool-free or semi-automated assembly processes. Compared with traditional screws and glue, pinner joints are easier to disassemble, which is conducive to later repair, replacement or recycling. It is an efficient, clean and reusable connection method suitable for a variety of electronic assembly environments.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Pinners are widely used in various industries and are commonly found in electronics, automobiles, medical equipment, etc. Whether it is a small handheld device or a large industrial system, pinners can firmly fix the circuit board without taking up extra space to ensure structural reliability.

Applications of PCB Pinners

|

Application Area |

Example Devices |

Role and Advantages of Pinners |

|

Consumer Electronics |

Smartphones, tablets, wearables |

Securely mount internal PCBs without adding weight or size |

|

Automotive Electronics |

ECUs, vehicle sensors |

Provide vibration-resistant mounting and ensure mechanical stability under stress |

|

Medical Devices |

ECG monitors, portable diagnostic tools |

Offer clean, sterile, and secure fastening for life-critical electronic assemblies |

|

Industrial Automation |

Control panels, embedded boards |

Use metal pinners to resist mechanical stress in high-load environments |

|

LED Lighting Modules |

LED arrays, driver boards |

Simplify assembly and help maintain thermal management for efficient cooling |

In PCB assembly, the pinner is a very practical small fixing component. Whether in the prototype development stage or the mass production stage, it can play a stable and efficient structural support role.

First of all, the pinner is very small in size and takes up much less space than traditional screws, nuts or metal brackets. For products like smartphones, headphones and smartwatches that are extremely sensitive to space, every millimeter counts. Pinner precisely meets the demands of such compact designs.

Secondly, its installation method is also very flexible and simple. Whether it's a snap-on type, a press-in type or a threaded type, most pinners do not require special tools. They just need to be aligned with the hole position and inserted. The positioning is quick and secure. If parts need to be replaced or equipment is maintained later, the pinner joint can be easily disassembled without damaging the circuit board or structure, greatly simplifying the maintenance work.

In terms of cost control, a pinner typically uses plastic or metal materials, which are inexpensive and highly suitable for automated batch assembly. In standard process flows such as SMT or THT, the pinner can be installed synchronously with other components without additional procedures, thereby saving labor and improving the overall line efficiency.

For some application scenarios with high requirements for mechanical performance, such as automotive electronics or industrial control systems, metal material Pinners have more advantages. It can withstand vibration, shock and high temperature for a long time. After being installed in place, its structure is stable and not easy to loosen or shift, which can ensure the stable operation of the circuit board in complex environments.

In addition, the pinner also conforms to the concept of environmentally friendly manufacturing. Compared with the non-detachable adhesive method, the pinner joint can be easily disassembled and reused, which is conducive to the separation and recycling of materials and is more in line with the current trend of green production.

Overall, the PCB pinner is a compact, easy-to-install and maintenance-friendly fixed solution, suitable for the assembly of various types of electronic products. The rational use of locating pinners can not only enhance assembly efficiency but also reduce maintenance costs, better supporting the design goals of modern electronic products that are lightweight and maintainable.

Although there are many advantages to using pinners, some challenges should be noted in practical applications:

High hole tolerance requirements

The mounting holes on the PCB must be precisely processed to ensure the stability of the pinner joint. If the hole position deviation is large, it may cause loose fixation or looseness.

Limited electrical conductivity

Most pinners do not have the ability to conduct electricity and cannot achieve grounding or electromagnetic shielding. In this case, additional grounding shrapnel or shielding structure is required.

Low manual installation efficiency

In small batch production, positioning pins usually need to be inserted manually. Improper operation is prone to errors, and the efficiency is relatively low, which is not suitable for large-scale use.

Compatibility limitations

Not all housings or mounting structures are suitable for pinner joints. Some require customized holes or special tooling to work with them.

These problems can be effectively avoided or mitigated by optimizing the scheme and selecting the right tools during the structural design phase. Choosing the right type of pinner and assembling it properly is the key to ensuring the quality of the connection.

When comparing pinners to traditional fasteners such as screws or glue, there are clear differences:

|

Feature |

Pinner |

Screw |

Adhesive |

|

Reusability |

High |

Medium |

Low |

|

Assembly Speed |

Fast |

Moderate |

Slow |

|

Tool Requirement |

Low |

High |

None |

|

Vibration Resistance |

High (Metal) |

Medium |

Low |

|

Electrical Grounding |

No |

Yes |

No |

|

Space Saving |

Yes |

No |

Yes |

|

Cost |

Low |

Medium |

Low |

In general, pinners have the advantage when space utilization, assembly speed, and reusability are critical, but torque or conductivity is not.

So, what exactly is a pinner? Simply put, it is a small component used to fix the circuit board. Although it is not large in size and has a simple structure, it is very important in preventing the circuit board from shaking and ensuring a stable installation, especially after the equipment is put into use.

The pinner can be found in many products, such as smartwatches, mobile phones, and some industrial control devices. Among these space-constrained products, the pinner can firmly fix the circuit board without taking up too much space.

Nowadays, electronic devices are getting smaller and smaller, and traditional screws and glue are sometimes not very suitable. In contrast, pinner is more lightweight, easy to install, disassemble and maintain. Although it may seem unremarkable, it is a key small component that makes the entire assembly process more efficient and smoother.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.