Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Custom Electronic Design Services for You

The brand-new intelligent medical equipment, high-precision industrial robots, as well as every future-oriented electronic product and device, all require the support of custom electronic design services. This transforms concepts into reality while ensuring that products meet the highest standards of performance, reliability, and scalability. Precisely because of this, more and more enterprises are relying on electronic design services to optimize their designs and enhance product functions. This not only enhances the market competitiveness of the products but also provides users with a better experience.

In this article, we will delve deeply into the topic of custom electronic design services. We will explore the significance of tailored electronic design, custom electronic design services, and the electronic design process. After reading this article, you will surely have a deeper understanding of electronic design and be able to select the appropriate custom electronic design services.

Custom electronic design refers to the process of tailoring electronic systems to meet the unique requirements of customers. It is different from ready-made solutions. Ready-made solutions are usually general and mass-produced, while tailored electronic design services aim to provide personalized and high-performance designs. Custom electronic design involves various aspects from hardware to software, including circuit design, PCB layout, and embedded system development.

Applications of custom electronic design are also very extensive. For instance, in the consumer electronics sector, it has driven innovations and iterations in wearable devices, smart homes, and high-end audio systems; in the medical equipment sector, it ensures the accuracy, reliability, and compliance of products; in automotive and industrial automation, it enhances the safety, efficiency, and long-term stability of electronic systems. These applications demonstrate that tailored electronic design can meet the specific needs of different scenarios and help enterprises develop high-performance and differentiated products.

Custom electronic design services aim to transform innovative ideas into practical and scalable products. This service can be divided into three main categories.

|

Custom Electronic Design Service |

Core Description |

Key Scope of Work |

Value & Advantages |

|

Product Design and Development |

Covers the entire process from concept to mass production |

- Product concept planning and feasibility analysis - System architecture design and component selection - Hardware and software integration and optimization - Prototype development and pilot production support |

- Accelerates product time-to-market - Ensures high product reliability and stability - Enhances market competitiveness and adaptability |

|

Microcontroller Hardware and Software Design |

Core embedded system design and control logic implementation |

- Select the most suitable microcontroller based on application needs - Design efficient, low-power hardware circuits and I/O interfaces - Develop real-time firmware and system control logic |

- Provides stable, scalable embedded solutions - Reduces power consumption while improving performance - Ensures reliable hardware-software integration |

|

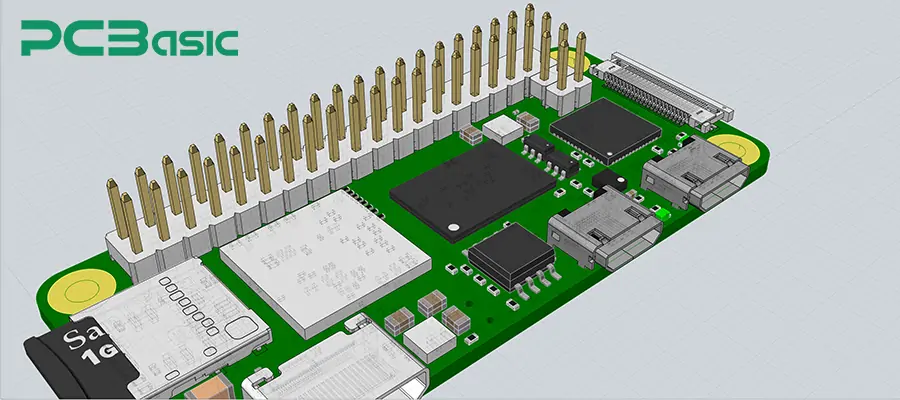

PCB Design and Layout |

The core foundation of product performance and reliability |

- Optimize schematic and multi-layer PCB stack-up design - High-speed signal routing and electromagnetic compatibility (EMC) optimization - Power distribution and thermal management design - Compliance with manufacturing processes and industry standards |

- Improves signal integrity and reduces interference - Ensures power and thermal stability - Lowers production costs and enhances long-term reliability - Supports future product upgrades and scalability |

Enterprises in various industries such as healthcare, automotive, and consumer electronics, have products that stand out in the market by relying on custom electronic design and manufacturing services. By collaborating with electronic design companies, enterprises can develop better solutions. In addition, there are many more benefits to choosing a tailored electronic design company:

1. The greatest advantage of custom electronic design lies in the ability to develop exclusive solutions based on specific application scenarios. That is to say, enterprises can obtain tailor-made functions and performance. Whether it is to achieve high energy efficiency, miniaturization design, or to meet the requirements of high speed, high frequency or complex interfaces, this custom service can better meet the needs.

2. Custom electronic design services can bring about greater competitive advantages. In a highly competitive market, differentiation is the key to success. By collaborating with experienced electronic designers and hardware design service teams, this differentiation can be achieved. As a result, not only will the product be ahead of competitors in terms of appearance, performance, and functionality, but it will also help to establish a strong corporate brand influence.

3. Custom electronic design inherently possesses the adaptability for future development. With the accelerated technological iteration, it becomes crucial for products to be able to be upgraded and expanded rapidly. And tailored electronic design services can meet the constantly changing market demands, thus enabling enterprises to achieve long-term competitiveness.

4. Custom solutions help simplify the manufacturing process, reduce resource waste, and thereby enhance production efficiency and cost-effectiveness. In the long run, these optimizations not only save costs but also increase the return on investment, creating higher business value for the enterprise.

The core of custom electronic design services lies in quickly converting concepts into high-performance, reliable, and mass-producible electronic products. Electronic product design usually involves several stages to produce products that meet performance and reliability standards. Now, we will introduce the complete process of electronic design to you.

Firstly, understand the customer's requirements clearly. Custom electronic design means designing based on the customer's requirements. Understanding the customer's requirements is crucial. At this stage, the electronic design team will communicate deeply with the customer to clarify product goals, usage scenarios, core functions, and budget requirements, etc. This step is the foundation for successful design. Confirming this information can ensure the consistency of the achieved goals.

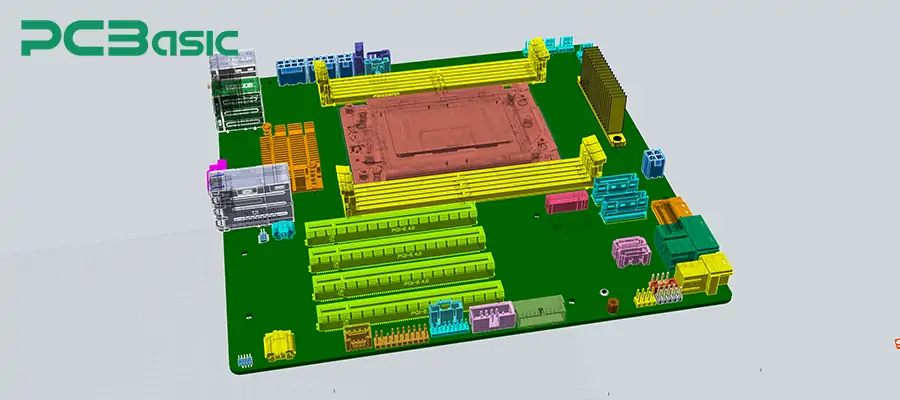

After clearly understanding the customer's requirements, the next step is system architecture design. The electronic design company will select the appropriate hardware and software architecture based on the requirements, including microcontroller models, power solutions, sensor interfaces, and communication protocols. This early architecture optimization can ensure that the design achieves the best balance between performance, energy efficiency, and cost. This step lays the foundation for subsequent PCB design, layout, and firmware development.

Then, the stage of circuit design and PCB design can be entered. This stage includes creating the schematic diagram, selecting components and designing the PCB layout. During the circuit schematic drawing stage, multi-layer PCB design and layout will be carried out. This process usually involves high-speed signal routing, power distribution optimization and manufacturability analysis. This step ensures complete functionality and stable, reliable mass production.

After the hardware design is completed, it will enter the stage of firmware development and function implementation for the microcontroller. The embedded development team will write the firmware for the microcontroller. The firmware is responsible for implementing the logic control, data acquisition, communication and security functions of the product. This stage requires close cooperation between the software and hardware teams and through repeated debugging and optimization, the entire system can meet the design requirements in actual operation.

After the hardware and firmware are ready, prototypes can be made and functions can be verified. Usually, this stage will produce small-batch PCB prototype boards and complete assembly (PCBA) first. Then, the assembled products will undergo strict functional, performance, power consumption, temperature and anti-interference tests. Through this round of strict verification, potential problems can be promptly identified and solved. This can reduce the risks in subsequent mass production.

Finally, it comes to design optimization and production preparation. Based on the prototype testing, the design team will further optimize the design. They will optimize the circuit, PCB layout and firmware logic, complete the BOM list, and conduct manufacturability (DFM) analysis. After completing the final design documents in accordance with the manufacturing process requirements, the product can enter the mass production stage.

This is the entire tailored electronic design process. This process not only enables efficient product development, but also ensures the long-term scalability and market competitiveness of the design. If you want to customize the electronic design yourself, below, we will recommend some practical tools for you.

A good custom electronic design cannot be achieved without advanced software tools and professional hardware equipment. By integrating digital design with actual verification, electronic design can move from concept to mass production more quickly and effectively reduce errors.

|

Tool Category |

Functions & Applications |

Common Tools/Equipment |

|

CAD & Simulation Tools |

- Create circuit schematics and PCB layouts - Analyze signal integrity and thermal behavior -Virtually test performance before manufacturing to detect potential issues |

Altium Designer, KiCad, OrCAD, SPICE simulators, Proteus, Mentor Graphics PADS/Xpedition |

|

Prototyping & Testing Equipment |

- Quickly build functional prototypes and validate designs - Test signal quality, thermal performance, power efficiency, and overall system stability - Optimize design and reduce mass production risks |

Rapid prototyping machines, 3D printers, PCB assembly lines, oscilloscopes, logic analyzers, spectrum analyzers, Automated Test Equipment (ATE) |

An experienced and well-versed partner not only can shorten the R&D cycle, but also can help reduce risks and enhance the competitiveness of the products. It can be said that the custom electronic design service provider is the key to the efficient implementation and smooth mass production of electronic products. When selecting a service provider, we can focus on the following aspects:

1. Evaluate the technical capabilities and industry experience of the service provider. A high-quality electronic design service provider should possess solid skills in hardware design, microcontroller development, PCB design, and embedded system development. Additionally, review their successful cases in target industries such as healthcare, automotive, industrial electronics, or consumer electronics. These cases can directly reflect the company's ability to handle the complexity of actual projects.

2. It is best to choose a one-stop service provider that can offer support from concept design, prototype development to mass production. This can significantly reduce communication costs and collaboration risks.

3. Check if the service provider has advanced tools and equipment. Because the tools and test equipment used will directly affect the accuracy and reliability of the design. Companies with advanced tools such as Altium Designer, SPICE simulator, high-speed oscilloscope and automated test equipment (ATE) can be prioritized.

4. Select electronic design companies that have passed authoritative certifications such as ISO and IPC. Because quality control and certification guarantees can ensure that the design results meet international standards and have long-term stability. Moreover, these companies often have greater reliability in product testing, BOM optimization and mass production delivery.

|

The above are the several selection criteria we have summarized. Of course, we have also listed some outstanding electronic design and manufacturing companies in the industry. Please read this article: Top 20 Electronic Design and Manufacturing Companies in the World. |

Custom electronic design services are the core element for creating innovative, reliable and quickly marketable electronic products. It has the advantage of having pre-existing solutions that cannot be replaced. It can provide enterprises with high-performance, scalable and innovative products. By collaborating with experienced electronic design companies, enterprises can quickly transform ideas into scalable products, shorten the product launch cycle, and ensure long-term stability and reliability. In this article, we introduce custom electronic design, custom electronic design services, and the relevant content on how to choose such services.

About PCBasic

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.