Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > PCB Overmolding: A Comprehensive Guide

How can we effectively protect delicate circuit boards from environmental stress, mechanical shocks and daily wear and tear? The answer lies in PCB overmolding. PCB overmolding is a powerful and efficient packaging solution. This solution can enhance the durability of products and create sealed casings that are suitable for harsh environments. This process is used in automotive modules, wearable devices, medical sensors, and industrial control systems.

This is the topic we will be discussing in this article. In this guide, we will comprehensively introduce what the advantages of PCB overmolding are, common materials, specific processes, and typical application scenarios. This article provides comprehensive and practical references. Let's first understand what PCB overmolding is!

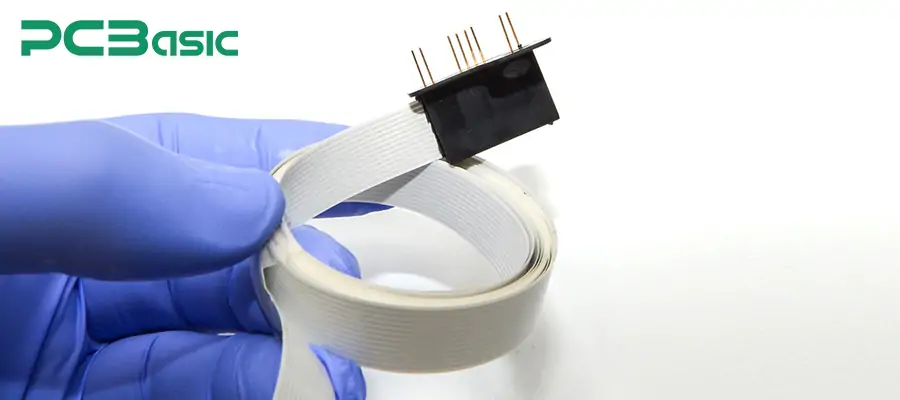

PCB overmolding is a specialized embedded injection molding technology. It directly injects a layer of protective plastic or elastic material onto the fully assembled PCB. This protective layer directly covers the assembled PCB, forming a sturdy and protective overall structure. This structure can protect the circuit board from environmental stress, mechanical shock, and electrical interference.

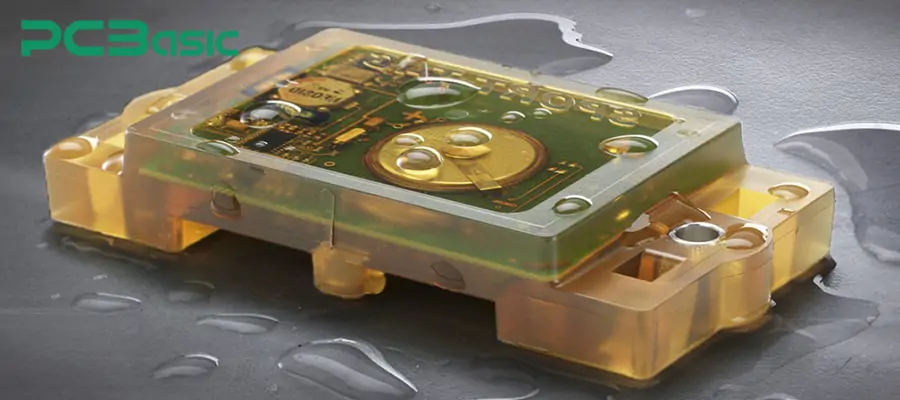

Compared with traditional enclosures or packaging methods, overmolded PCBs can achieve the effects of structural reinforcement, waterproofing, dustproofing, impact resistance, and aesthetic appearance simultaneously. This plastic overmolded PCB not only reduces the number of components but also simplifies the assembly process.

PCB overmolding is not merely about "covering with a layer of plastic". Its true purpose is to make the product more sturdy, more durable, and easier to assemble. Below, we list several benefits of overmolding for PCBs.

1. Overmolding can enhance the structure of the circuit board, making it more shock-resistant and impact-proof. This is because the overmold material tightly wraps around the PCB and components. As a result, the entire PCB becomes more stable and can effectively absorb shocks and prevent damage from vibrations. This process is highly practical for scenarios such as automobiles, industrial equipment, and outdoor controllers, which are prone to collisions or vibrations. Moreover, overmolded PCBs are much more stable and durable than traditional enclosures.

2. Overmolding PCB has a stronger environmental protection capability. Through the PCB overmolding process, the product can achieve a protection level of IP67 or even IP68. That is to say, it not only can prevent water and dust, but also can resist oil stains, ultraviolet rays, chemical corrosion, etc. For electronic products in harsh environments, overmolding is a more reliable choice. This is the reason why many engineers choose to overmold PCBs.

3. The overmolded PCB not only provides protection but also allows for the direct molding of colors, textures, logos, QR codes, etc. through the mold in a single process. This results in a more upscale and uniform appearance for the entire product, along with a better feel.

4. Traditional PCB packaging usually requires a casing, screws, sealing rings, adhesives, etc. However, overmolding PCB only requires one molding process, and all the structures can be completed in one step. Compared with traditional PCB packaging, this method uses fewer components and is simpler to assemble.

The material selection in the PCB overmolding process is extremely crucial. The materials used for overmolding not only need to effectively protect the circuit board, but also must have good adhesion and be able to adapt to the working environment of the final product. Below, we will introduce several of the most commonly used materials in overmolding PCBs:

1. TPU(Thermoplastic Polyurethane)

TPU is one of the most widely used materials for plastic overmolding of circuit boards. It is soft and elastic, and at the same time has excellent wear resistance, oil resistance and scratch resistance. It can be found in automobiles, medical equipment and consumer electronics. It not only provides a good feel but also enhances mechanical protection, making it highly suitable for outdoor wearable devices, handheld controllers, etc.

2. TPE (Thermoplastic Elastomer)

TPE is similar to TPU, but it has a softer texture and is closer to the feel of rubber. It is suitable for overmolded PCB (circuit board with encapsulation) that requires a good grip or ergonomic design. TPE is easy to process and can be directly molded using standard insert injection molding equipment. It is commonly used in smart remote controls, handles, and the housings of household appliances.

3. PA (Polyamide/Nylon)

PA, also known as nylon, is a material with high strength and rigidity. It has excellent mechanical strength and thermal stability, making it suitable for environments requiring high-quality PCB injection molding (such as Insert Molding for automotive modules, industrial equipment, sensor housings, etc.). However, it is important to note that PA is hygroscopic and may affect long-term performance. Therefore, it is necessary to assess it in advance during the overmold design process.

4. PC (Polycarbonate)

PC has excellent impact resistance and good transparency. It is suitable for applications that require visible windows (such as LED lights or indicator lights), allowing for clear visibility while ensuring circuit protection.

5. Silicone Overmolding

Silicone overmolding is the best choice for products that require high temperature resistance, high flexibility or biological compatibility. Although the processing of silicone is more complex compared to thermoplastic materials, it performs extremely well in terms of sealing and insulation.

The PCB overmolding process is a step-by-step and sequential molding technique. Now, let's introduce this process.

Firstly, make sure that all the circuits on the circuit board have been fully soldered and have been tested to confirm there are no issues. Why do we do this? Because once the encapsulation is complete, it is impossible to rework the internal parts. After confirming everything, the next step is to clean the circuit board. Sometimes, a primer layer needs to be applied on the surface to enhance the adhesion between the material and the circuit board and prevent detachment or water ingress in the future.

Then, the PCBA will be placed in a specially designed mold. The mold will precisely fix its position to ensure that the encapsulated material can accurately flow to every area without damaging the components. Then, the material that has been heated to a certain temperature will be injected into the mold cavity of the insert injection molding machine to uniformly surround the circuit board. After the injection molding is completed, the material needs to cool and set before being removed from the mold. At this point, the circuit board has been firmly encapsulated and can be directly used in the final product.

In practical applications, the method of coating also has two types: direct coating and pre-packaging followed by coating. Direct coating means that the material directly covers the circuit board. This method is suitable for situations where the structural strength is high and the components have good heat resistance. Pre-packaging involves first encapsulating or coating some sensitive components before coating. This can achieve a higher level of protection.

Furthermore, depending on the complexity of the product and the tolerance of the components, different types of molding equipment will be selected. There is low-pressure injection molding. This equipment is suitable for products with fragile electronic components, such as hot melt adhesives or thermoplastic materials. Its temperature and pressure are relatively mild, making it less likely to damage the board. There is also high-pressure injection molding. This equipment is more suitable for products with complex structures and high-strength requirements for the casing.

Overall, the entire PCB overmolding process must be extremely precise in order to ultimately deliver a stable and durable product.

In addition to the precise process of PCB overmolding, there are also many details that must be given attention during the design stage. Below, we have summarized several important design elements that must be considered in advance.

1. The circuit board layout should leave sufficient space. Do not place the components too close to the edges; there should be some gaps in the edge areas. This way, during the encapsulation process, the pressure or the closure of the mold will not squeeze the components. If there are areas with specific structural requirements, then a "keep-out zone" must be set. This is to prevent the material from flowing into unintended places, such as the USB interface area.

2. The molten material flows into the mold through the injection port. Therefore, the position of the injection port needs to be carefully selected. If the injection port is too close to the components, high temperatures and pressure may cause the components to deform or the solder joints to crack. Therefore, the position of the injection port should be designed properly so that the material can flow evenly.

3. During the design process, it is important to protect the exposed components. For components such as USB ports, LED lights, and sensors that need to be exposed, we must ensure that the encapsulation design will not be covered or damaged by the materials. Sometimes, additional covers or seals may be required to prevent situations where the interface is sealed or functions fail.

4. From the very beginning of the design process, consideration should be given to the compatibility of the process. Because if the design is reasonable, it not only avoids errors but also can be adapted to different processes, thereby increasing production efficiency and ensuring a more stable quality rate.

When conducting PCB overmolding, improper handling can easily cause damage to the circuit board. Therefore, to ensure that the overmolded PCB is both safe and reliable, special attention needs to be paid to the following aspects during production:

1. Temperature and pressure. Materials such as TPU or silicone overmolding have relatively high temperatures during injection, and the pressure is also significant. Fragile components on the circuit board, such as chips and LEDs, are prone to being damaged. Therefore, for such components, it is recommended to choose materials with a lower melting point and adjust the injection temperature and pressure according to the PCB's heat resistance.

2. During overmolding, use high-precision fixtures and positioning tools. Because if the position is off, the overmolding may not be uniform. Or the material may flow to the wrong place, resulting in functional failure. We recommend using positioning fixtures with mechanical guidance or vacuum suction functions to ensure that each overmolded PCB can be precisely aligned and evenly stressed.

3. Before formal overmolding, it is best to dry the PCB. Because if the circuit board or components absorb moisture, during the injection heating process, the moisture inside may turn into steam, causing bubbles, cracking or delamination. Therefore, it is necessary to control the moisture. This can greatly enhance the adhesion of the overmolding layer and the stability of the product.

4. Finally, pay attention to the mold ventilation and flow channel design. During injection, air must have a place to escape. Otherwise, it will cause the overmolding to be insufficient, excessive pressure or burn marks.

Overmolded PCBs are widely used in various industries that have requirements for waterproofing, dustproofing, shock resistance or anti-impact from external forces. For example:

|

Industry |

Typical Applications |

Benefits of Overmolding |

|

Automotive |

Sensors, ECUs, battery modules, under-hood electronics |

Resistant to heat, oil, vibration; ideal for harsh engine environments |

|

Medical Devices |

Wearables, handheld diagnostics, sensor modules |

Waterproof, hygienic, soft-touch; supports silicone overmolding |

|

Consumer Products |

Smartwatches, earbuds, remote controls, game controllers |

Sleek look, durable housing, ergonomic grip with plastic overmolding PCB |

|

Industrial Controls |

PLC units, sensor hubs, rugged handhelds, remote terminals |

Dustproof, waterproof, chemically resistant; supports low-pressure molding |

|

LED Lighting |

Outdoor LEDs, waterproof drivers, tunnel lighting, underwater lighting |

Excellent sealing and heat resistance for harsh-environment electronics |

|

IoT & Communication |

Smart sensors, weather stations, remote transmitters |

UV-resistant, supports antenna integration; boosts reliability outdoors |

PCB overmolding is a technology that integrates protection, design flexibility and production efficiency. PCB overmolding can significantly enhance the durability of products, reduce the number of components, and also make the appearance of electronic products cleaner and have a better feel. Whether it is automotive electronics, wearable devices, medical sensors or industrial controllers, the overmolding process can provide excellent structural protection and environmental sealing effects.

In this article, we systematically introduce what PCB overmolding is, its advantages, common materials, overmolding steps, and applications in various industries. After reading this article, you will surely gain something! As long as the initial design is reasonable, the materials are selected correctly, and the process control is in place, PCB overmolding can bring real competitive advantages to our products.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

About PCBasic

About PCBasic

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.