Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Full Turnkey Solutions in PCB Assembly

As products become increasingly complex and supply chains more globalized, the number of matters that companies have to deal with in the production process has also significantly increased. Each production stage of a product requires the connection of different resources and personnel. Once any stage fails to cooperate properly, it may lead to delayed delivery, unstable quality, and even invisible additional costs. Precisely because of this, the advantages of the full turnkey solution have begun to be valued by more and more companies.

In this article, we will focus on explaining what a turnkey business is and introduce in detail how turnkey manufacturing solutions operate. At the same time, we will explain why turnkey contract manufacturing is becoming a common cooperation model for startups, OEMs, and global brands. Finally, we will also combine practical experience to introduce how PCBasic's full turnkey solution supports high-reliability PCB assembly projects in different industries.

Before truly understanding the value of a full turnkey solution, we first need to clarify a basic question: What is a turnkey business?

In simple terms, a turnkey business means that the supplier completes the entire process of the product or project from start to finish. When it is delivered to the customer, it can be used directly. Customers no longer need to manage design, material sourcing, production scheduling, or logistics coordination by themselves. They only need to receive the finished products.

In the manufacturing industry, this model is usually referred to as turnkey manufacturing and is often described as a complete turnkey project.

Generally speaking, a complete PCBA full turnkey solution includes the following work contents:

• Engineering and design support

• PCB fabrication

• Electronic component sourcing

• SMT and THT assembly

• Testing and inspection

• Packaging and labeling

• Logistics and global shipping

• Post-production technical and quality support

Choosing a full turnkey solution is essentially for making the project easier to manage and reducing risks, rather than merely for convenience.

A complete project usually involves multiple stages such as design, sourcing, manufacturing, testing and logistics. After choosing the turnkey solutions, customers only need to connect with one turnkey manufacturer, which will uniformly coordinate the entire process, making the project advancement smoother.

A mature turnkey manufacturing solution can manage sourcing, production and inventory in a single planning framework. Through volume purchasing and process integration, the overall cost is easier to control.

In many projects, time itself is a cost. Turnkey manufacturing services reduce the handoffs and waiting time among suppliers, making the project execution rhythm more compact. For projects with high time requirements, a full turnkey solution can significantly shorten the overall delivery cycle.

One of the advantages of turnkey contract manufacturing is clear responsibility. No matter at which stage the problem occurs, it shall be uniformly responsible and solved by the turnkey manufacturer. This can reduce back-and-forth communication, and the project risk will also be lower.

In the full turnkey solution, engineering support is not an option but the foundation for keeping the entire project on track.

Professional turnkey manufacturing services usually start with design reviews. Engineers will examine Gerber, BOM and assembly files to confirm whether the design is suitable for real-world production.

The purpose of DFM is very simple: to identify problems before production, such as:

• Improper footprints

• Inadequate solder pad design

• Risky component placement

• Thermal and reliability concerns

In a turnkey project, testing is not something to be considered at the end. The engineering team will plan ICT, FCT or functional testing in advance, which can expose problems earlier, improve first-pass yield, and also be conducive to long-term stability.

It is common for design or material adjustments to occur during the production process. Experienced turnkey manufacturers will uniformly manage engineering changes (ECO) to ensure that every modification is recorded, verified, and does not affect the overall progress.

A true full turnkey solution does not merely stop until assembly is completed.

In the turnkey manufacturing solutions, logistics are usually arranged by a single party. The turnkey manufacturer will be responsible for export documentation, customs clearance, and the selection of transportation methods to ensure that the products are smoothly delivered from the factory to the designated location of the customer.

For customers who need to ship to multiple countries or regions, this unified management can significantly reduce the risks of communication and errors.

Mature turnkey manufacturing services can usually provide different packaging solutions according to customer requirements, including:

• ESD-safe packaging

• Moisture-sensitive device (MSD) handling

• Customer-specific labeling and barcodes

• Retail-ready or industrial packaging

Appropriate packaging not only protects the product but also makes subsequent transportation, storage and use smoother.

The complete full turnkey solution also includes continuous support after delivery, such as:

• Failure analysis

• Quality documentation

• Traceability reports

• Ongoing production scaling

This continuous cooperation is precisely what separates high-level turnkey manufacturers from suppliers that only engage in processing.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Understanding the differences among these manufacturing models can help enterprises make more appropriate choices in actual projects.

In the full turnkey solution, the turnkey manufacturer is responsible for all the work from beginning to end. Customers only need to connect with one window. The process is the simplest, responsibilities are the clearest, and overall efficiency is the highest.

A partial turnkey solution divides responsibilities. Manufacturers are usually responsible for PCB manufacturing and assembly, while customers provide some or all of the components themselves. This approach allows the client to retain a certain degree of control, but it also means more communication, coordination and potential risks.

In consignment manufacturing mode, the customer is responsible for all materials, and the manufacturer is only responsible for production and assembly. This places high demands on the client's supply chain management capabilities. Once there are issues with the materials, the project risks will also be concentrated on the client's side.

For most enterprises that hope for the stable progress of the project and have the ability to expand at the same time, a full turnkey manufacturing solution often strikes a better balance between control and execution efficiency.

|

Comparison Criteria |

Full Turnkey Solution |

Partial Turnkey Solution |

Consignment Manufacturing |

|

Primary Responsibility |

The turnkey manufacturer takes full responsibility |

Responsibility is shared between the customer and the manufacturer |

The customer assumes primary responsibility |

|

PCB Fabrication |

Handled by the manufacturer |

Handled by the manufacturer |

Typically handled by the manufacturer |

|

Component Sourcing |

Handled by the manufacturer |

Supplied partially or fully by the customer |

Supplied entirely by the customer |

|

Assembly & Testing |

Handled by the manufacturer |

Handled by the manufacturer |

Handled by the manufacturer |

|

Logistics & Delivery |

Fully managed by the manufacturer |

Depends on project scope |

Mostly coordinated by the customer |

|

Customer Involvement |

Low |

Medium |

High |

|

Communication & Coordination Cost |

Lowest |

Medium |

Highest |

|

Project Risk |

Lowest, with clear accountability |

Medium, requires close coordination |

Higher, risk concentrated on the customer |

|

Scalability & Ramp-Up |

Best suited |

Moderate |

Not ideal for fast scaling |

|

Best Suited For |

Companies seeking efficiency, stability, and minimal management |

Companies that want some level of control |

Companies with mature supply chain capabilities |

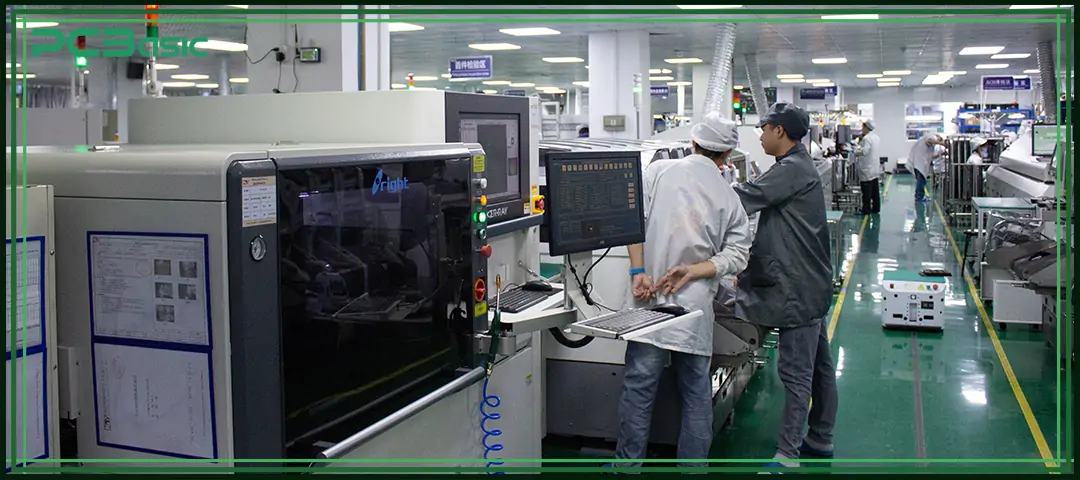

As an experienced turnkey manufacturer, PCBasic provides complete full turnkey solutions for PCB and PCBA projects in different industries.

The turnkey manufacturing services of PCBasic cover the entire life cycle of the product from the early stage to delivery, including:

• Engineering review and DFM analysis

• PCB fabrication from prototype to mass production

• Global component sourcing with verified suppliers

• SMT, THT, and mixed-technology assembly

• AOI, X-ray, ICT, and functional testing

• Final inspection, packaging, and shipping

This highly integrated turnkey manufacturing solution can ensure stable product quality and predictable delivery cycles.

The turnkey contract manufacturing model of PCBasic, relying on a complete MES system, realizes the full traceability of the entire process from incoming materials to finished products.

Every turnkey project is carried out based on standardized processes, real-time data monitoring, and a strict quality control system that complies with IPC standards.

The full turnkey solution of PCBasic is widely applied in:

• Industrial control systems

• Automotive electronics

• Medical devices

• Energy storage and power electronics

• IoT and smart devices

In response to the demands of different industries, PCBasic offers customized turnkey manufacturing solutions, with a focus on meeting the requirements of reliability, compliance and large-scale production.

In today's highly competitive and fast-paced manufacturing environment, it has become increasingly difficult to continue relying on multiple decentralized suppliers to advance production. Full turnkey solution provides a clearer and more efficient approach by centralizing engineering, sourcing, manufacturing, testing and logistics to the same responsible party.

Choosing mature turnkey solutions can help enterprises reduce project risks, control costs, shorten delivery cycles, and stabilize product quality at the same time. Truly understanding what a turnkey business is and how turnkey manufacturing operates can help enterprises build a more stable supply chain system.

Whether it is the launch of a new product or the scale-up of mass production, cooperating with a reliable turnkey manufacturer like PCBasic can make the turnkey project more controllable, transparent and of greater long-term value during the execution process.

A fully implemented turnkey solution is not only about providing services, but also a long-term, reliable, competitive advantage.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.