Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Steps to Verify Your PCBA Supplier’s Quality Control

PCBA quality control is a crucial aspect of electronics manufacturing. It determines the reliability and field performance of the products produced and is also related to the long-term reputation of the brand. In any industry, the manufacturing quality of PCB assembly suppliers directly affects the products. Therefore, the selection of PCBA suppliers is of great significance. When choosing PCBA manufacturers, many purchasers often only focus on price and delivery time. However, true quality issues often only surface after the products are delivered to the end users.

In this article, we will discuss from a practical perspective how to systematically evaluate the quality control and quality assurance capabilities of PCBA suppliers.

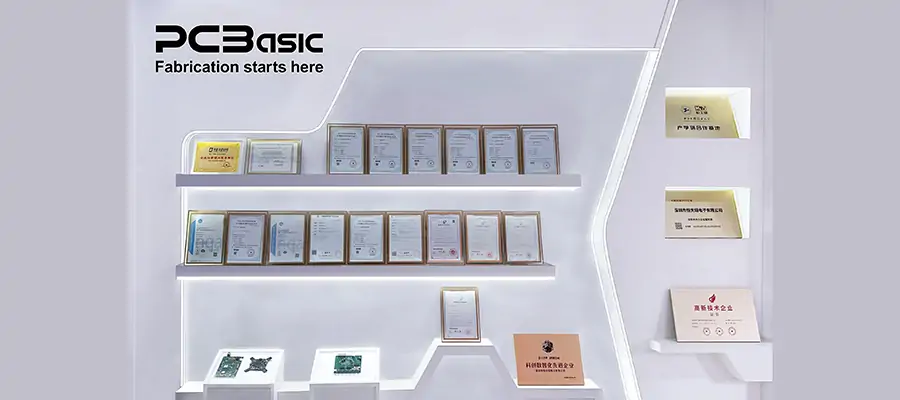

When evaluating a supplier's PCBA quality assurance capability, first of all, we can carefully check whether it has relevant certifications and whether it complies with mainstream international standards. However, please note that certification itself does not mean zero defects. But at least it can indicate that the PCB assembly manufacturer is operating under a standardized and auditable management system.

Generally, in the industries and application scenarios they serve, a reliable PCBA supplier will possess the corresponding qualification certifications. Common ones include:

ISO 9001

ISO 13485

IATF 16949

IPC standards

RoHS compliance

To obtain these certifications, factories must have systematic documentation management for the PCB assembly process, established risk control mechanisms, and undergo regular internal audits and third-party reviews. Therefore, compared to factories without certifications, certified manufacturers can maintain a more stable level of PCBA quality control during both the prototype and mass production stages.

In addition to the certificate itself, we also need to further confirm the IPC class standard implemented by the factory. IPC Class 2 is generally applicable to general industrial and consumer electronics, while IPC Class 3 is mainly targeted at high-reliability fields such as medical equipment and automotive electronics.

A higher IPC class indicates stricter requirements for appearance, solder joints and process acceptance, and also sets higher standards for process control and inspection. Verifying the certification and compliance of PCB assembly manufacturers helps quickly screen out suppliers lacking basic quality capabilities.

Incoming material quality control is the first crucial line of defense in preventing quality issues from entering the production process during PCBA production. In fact, many PCBA quality problems do not arise during the mounting or soldering stages, but stem from unqualified, incorrect or non-traceable components. Therefore, when evaluating PCBA suppliers, we should focus on understanding their incoming material inspection and material management capabilities. This is extremely necessary.

A qualified PCB assembly supplier should establish a complete and executable IQC process, which usually includes the following aspects:

Perform visual inspections on electronic components and packaging to ensure there are no damages, moisture, or contamination.

Verify that the material models, brands, specifications are consistent with the BOM list.

Check the batch number, production date, and packaging information.

Implement ESD protection and standardized storage management for electrostatic-sensitive components.

IQC should also be integrated with the material traceability system. A reliable PCBA manufacturer will establish batch records for incoming materials at the incoming stage, ensuring that each key component can be accurately traced throughout the subsequent production, testing, and after-sales stages. This is particularly important in some industries, such as healthcare, automotive, and industrial control, which have high reliability requirements.

If the incoming material control is weak, even if the subsequent SMT process and testing procedures are perfect, it is difficult to fundamentally eliminate quality risks. Therefore, having a complete PCBA incoming material quality control system is extremely important for evaluating the quality control of a PCB assembly supplier. It can be said that the IQC level is one of the important indicators for judging whether the PCB assembly quality management of a supplier is mature.

The SMT production line is the core part of the PCB assembly manufacturing process. Its stability and consistency directly determine the soldering quality and overall yield. When evaluating the process quality control capability of a PCBA supplier, it is not enough to only consider the equipment configuration. What is more important is to understand whether the SMT process has controllability and repeatability.

A mature SMT PCBA manufacturer usually implements systematic management of key process parameters, which mainly manifests in the following aspects:

Monitor the thickness, volume and alignment of solder paste printing through SPI.

Implement precise placement control for fine-pitch and BGA type high-density components.

Determine and optimize the reflow soldering temperature curve based on PCB structure, board thickness and component thermal capacity.

Record and manage the process of adjusting, changing and verifying process parameters.

It should be noted that factories that truly possess the capability for SMT process control do not adopt the approach of using a single set of parameters for all products.

Instead, they will adjust the stencil design, soldering parameters, and reflow soldering process based on the specific design characteristics of each product. This control method based on process understanding is the key to ensuring the stability of PCBA soldering quality.

Inspection and testing are the key steps in quality control of PCBA to identify and prevent defects. This stage is also an important indicator for evaluating the technical capabilities of a PCB assembly supplier. Even if the front-end process control is in place, if there are no effective inspection and testing methods, quality risks may still be magnified in the subsequent stages.

A reliable PCBA manufacturer usually adopts a multi-level inspection and testing approach to cover various types of defects. Common methods include:

AOI: Used to inspect issues such as component placement, polarity, and solder joint appearance.

X-ray inspection: For non-visible solder joints like BGA and QFN, to confirm the formation of solder balls and the quality of internal connections.

ICT: Used to verify electrical connectivity, component parameters, and soldering reliability.

FCT: To verify the normal operation of the entire board under conditions close to actual application.

The focus of different detection methods varies. For instance, AOI is more suitable for identifying visible defects; X-ray is an indispensable detection method for high-density packaging; while ICT and functional testing can verify from the electrical and functional aspects whether the PCBA is truly usable. This combination of multiple detection methods constitutes a complete PCBA defect interception mechanism.

At the same time, we also need to pay attention to whether the testing is closely integrated with the production process. Only a testing system with closed-loop management capabilities can truly enhance the assembly quality level of PCBs.

In a professional PCBA quality management system, traceability is not an additional feature but one of the core capabilities that ensure long-term stable quality. Especially in high-reliability fields such as healthcare, automotive, and industrial control, PCB assembly suppliers lacking a well-developed traceability system often struggle to support continuous production and problem resolution in a closed loop.

Therefore, when evaluating PCBA suppliers, we should also focus on verifying whether they have established a production and quality traceability mechanism covering the entire process. This usually includes the following contents:

Traceability of component batches, suppliers, and incoming material records

SMT production line, equipment number, workstation, and operation records

Association of inspection and testing data such as AOI, X-ray, ICT, and FCT

Management of product serial numbers, production times, and shipment batches

PCBA manufacturers with mature management capabilities usually rely on the MES system to centrally collect and manage the above data. This enables real-time monitoring of the production process and retention of quality data. When abnormalities occur or customer feedback issues arise, through the MES system, suppliers can quickly identify the problem location, significantly improving the efficiency of problem analysis and response.

The final inspection is the last quality checkpoint before the PCBA is shipped out, and it is also a crucial step to prevent defects from flowing into the customers and the market. Even if the process control and process inspection in the early stage are well executed, it is still very necessary to conduct a systematic final inspection to comprehensively confirm whether the PCB assembly quality meets the specification requirements.

When evaluating PCBA suppliers, it is essential to focus on understanding whether their final inspection covers the following aspects:

Conduct appearance and soldering quality inspections in accordance with IPC standards

Confirm the polarity, installation direction and assembly integrity of components

Check whether the markings, serial numbers, labels and packaging comply with requirements

Recheck the test results and test coverage

For products with high reliability or in harsh application environments, relying solely on routine final inspections is often insufficient. Corresponding reliability tests are also necessary. Common reliability tests include:

Aging test / Burn-in test (for exposing potential early failures)

High and low temperature cycling test, to verify the stability of solder joints and components under temperature variations

Vibration or environmental stress test, to simulate transportation or actual usage conditions

These reliability tests can effectively identify hidden defects and reduce the failure rate of the product during actual use. They are an important means to enhance the long-term reliability of PCBA.

How problems are recorded, analyzed and resolved is also an important aspect of quality control. When evaluating the quality control capabilities of a PCBA supplier, we also need to pay attention to whether their quality document management and communication mechanisms are standardized, transparent and efficient.

A mature PCB assembly manufacturer is usually capable of providing comprehensive and clear quality-related documents, including but not limited to:

Inspection and test reports for each stage

Non-conforming product records (NCR) and handling results

Corrective and preventive action (CAPA) reports

Critical quality data and statistical analysis records

These documents are not only used for quality traceability, but also serve as an important basis for determining whether the PCBA quality management system is operating effectively. Standardized document management can ensure that quality issues are recorded, analyzed, and concluded.

Equally important is the communication method of suppliers regarding quality issues. Reliable PCBA suppliers should possess the ability to actively provide feedback and collaborate in engineering. They can communicate with customers promptly when risks or abnormalities are identified, and provide engineering support during design reviews, DFM optimization, and problem rectification processes.

When evaluating the quality control capabilities of PCBA suppliers, multiple aspects need to be considered, including qualification certifications, IQC, SMT process control, testing and inspection, the traceability system for the entire process, final inspection before delivery, and quality document management, etc. Below is a table summarizing each evaluation dimension and its key judgment points.

|

Evaluation Area |

What to Check |

What Indicates Real Capability |

|

Certifications & Standards |

Relevant industry certifications |

Clear implementation of IPC Class 2 or Class 3, not just holding certificates |

|

Incoming Material Control (IQC) |

Component authenticity and consistency |

Batch records, supplier traceability, and controlled ESD storage |

|

SMT Process Control |

Process stability and repeatability |

Product-specific stencils and reflow profiles, not one-size-fits-all settings |

|

Inspection & Testing |

Defect detection coverage |

Combined use of AOI, X-ray, ICT, and FCT at appropriate stages |

|

Traceability System |

Ability to locate issues quickly |

MES linking materials, equipment, process data, and test results |

|

Final Inspection & Reliability |

Long-term performance validation |

Burn-in, thermal cycling, or environmental stress testing when required |

|

Quality Documentation & Communication |

Problem handling transparency |

Complete NCR, CAPA records and proactive engineering communication |

These aspects can truly reflect the manufacturer's standardization in production and risk control capabilities. A reliable manufacturer of printed circuit board components usually demonstrates consistent performance in these areas.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.