Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > How Much Does PCB Assembly Cost?

Electronics construction always raises that fundamental question: how expensive is PCB assembly going to be? PCBA, is where you take raw boards and make functional units out of them by assembling things such as resistors, capacitors, ICs, connectors, and so forth, soldering them onto those boards. That's what gives your electronic design a purpose.

It's extremely necessary to have an understanding of PCB assembly costs for startups, engineers, and OEMs. The startups require accurate cost data to match funds and correctly value products. OEMs have to walk a tightrope, keeping costs in check and maintaining quality so that they can stay profitable and competitive. The engineers use the insight into cost to direct their design in keeping the whole project under control.

Of course, there are Internet tools such as a PCB assembly cost estimator available for fast quotes, but there are usually no accounts for hard realities. The actual expense in PCB assembly is derived from a myriad of sources: type of components, methods of assembly, labor, where it's assembled, level of testing, and how quickly you need it. This article elucidates those elements in progressive detail so that you have a reliable guide to determine expenses, identify any dubious charges, and make choices that reduce expenses without compromises in reliability.

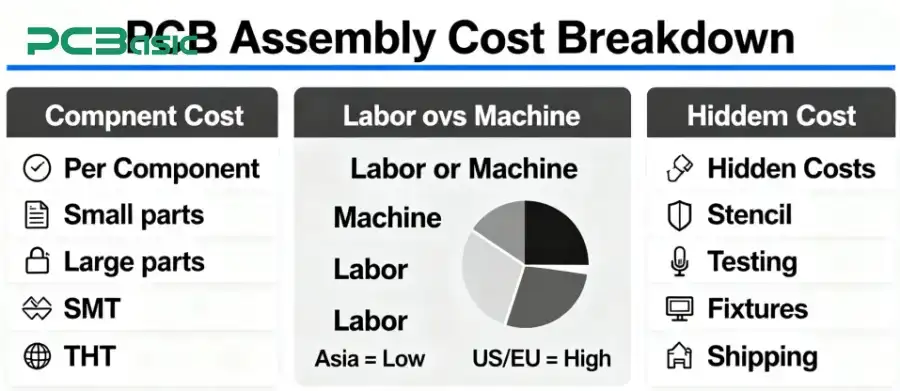

PCB Assembly Cost per Component

Another popular pricing method for a PCB assembly is an estimate of how much each component used in the circuit board will cost. This is a component-based PCB assembly, and it is estimated on parts as well as assembly type.

Simple passive components such as resistors or capacitors are inexpensive to install, usually a few cents when purchased in quantity. Connectors or integrated circuits, and parts that have a lot of pins are expensive as they require precise placement and verification.

It is remarkable that Surface Mount Technology (SMT) and Through-Hole Technology (THT) are different from one another. The parts in SMT are put in place automatically over the circuit board, which is faster and cheaper for large quantities. The parts in THT must be inserted by hand or with special soldering techniques, which is slower and pricier.

In principle, a circuit board consisting of 200 resistors and capacitors would only increase the PCB assembly cost by a few dollars. However, a circuit board composed of dozens of fine-pitch BGA components or special connectors would have a significantly different value and would be much higher, as a 200-piece circuit board.

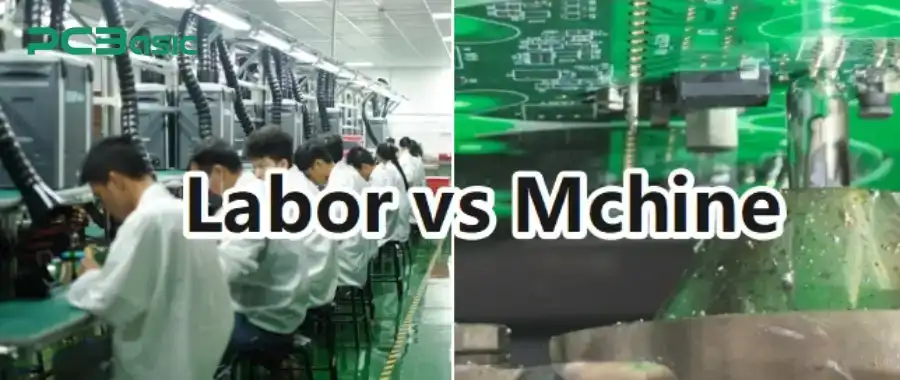

Next in the cost mix is the difference between machines and workers. Right now, PCB assembly services depend a lot on computer-based systems for quick, accurate, and ongoing production. When these systems are well-organized, they can make thousands of units in one hour, lowering costs for larger amounts. However, the initial setup has fixed costs in programming and stenciling, which impact smaller amounts or prototype orders more.

Some projects are still labor-intensive, e.g., building large connectors, handling exotic shapes, or solving soldering problems. Labor costs vary greatly by location. In Vietnam, India, or China, such costs are lower than in European countries or in America. That is why most electronics companies prefer to look for cheap PCB assembly factories located in other countries in hopes of lowering costs.

For tiny orders or reduced-volume PCB assemblage, however, being sticky local may work better for fast talk and fast turnover, though at greater rates.

Besides component and labor costs, there are a variety of other unseen costs adding up in the PCB assembly overall cost. Another factor added is stencil printing in solder paste, where laser-cut foils expand setup costs.

Testing piles on too: makers usually do Automated Optical Inspection (AOI) and X-ray scans, and stuff like In-Circuit Testing (ICT) or Functional Testing (FCT) can add more. Tools, jigs, and fixtures, and how you prepare goods to ship, will increase costs. And don't forget logistics; shipping across borders is uncertain in shipping goods from overseas suppliers. These are most costly in a small lot or a prototype PCB assembly, where there are fewer panels to spread these costs against.

What you choose and where it is coming from have a lot to do with custom PCB assembly costs. Ordinary, off-the-shelf parts like resistors, diodes, and general-purpose ICs stay cheap and easy to obtain. Special-purpose chips, custom connectors, or parts that require a wait time, though, will increase unit cost as well as handling fees.

Global shortages in recent times have demonstrated how a simple capacitor or microcontroller can spike in price and bring things to a crawl. Being consistent with popular parts is a leading method to keep PCB assembly expenses stable and in check.

How many boards you order has a big say in PCB assembly cost. For a single prototype, setup fees take over, making the cost per unit high. In low-volume PCB assembly—like 50 or 200 boards—the per-unit price drops some, but it's still way above mass production.

For large orders, smooth-running machines and setup expenses are divvied by thousands, providing the lowest PCB assembly cost per piece. Startup companies usually select inexpensive PCB assembly companies designed for small numbers in an effort to strike a decent balance between flexibility and prices.

Not all of your PCBs are going to cost the same to assemble. A basic 2-layer board with resistors and LEDs is affordable. But as boards get more complex—with more layers, tiny BGAs, and HDI (High Density Interconnect) configurations—the cost to assemble your PCB increases.

These will need to be handled gingerly, X-rayed to inspect them, and baked under controlled conditions, both of which drive up costs. That's why a cost estimator of a PCB assembly is diligent about factors like layers, types of parts, and pad sizes: greater sophistication, higher cost.

Turnaround time is also included in the costs. Making a standard prototype circuit board usually takes two to three weeks and follows basic rates.

But if you push for 3–5 day quick-turn, the extra can bump PCB assembly cost by 30–70 percent. This covers prioritizing gear, running off-hours, and overtime pay to hit tight deadlines.

It's a simple fact: going quickly costs money.

The location of your PCB assembler influences the cost. Asian assemblers typically will provide inexpensive assembly of PCBs due to low-cost labor and better production line capability in bulk. However, shipping times, linguistic issues, and fees can cause added expense. Locations in Germany, the USA, or elsewhere are more expensive, yet communication is better, local law is followed, and shipping is also quicker. Determining whether to select a cheaply assembled PCB manufacturer in a faraway country or a nearby one usually rests upon cost, speed, and legitimacy.

Engineers usually start by using a cost calculator of PCB assembly in order to check what is incurred. The web-based program needs specifications like the size of the board, the number of layers, the mix of SMT and THT, the quantities of components, and the test specifications. Then, in response, they will give an estimated cost.

It is clear that there is a speedy, easy, and efficient process involved in terms of reviewing suppliers or design changes. In terms of spending plan or comparing options, it can be used. However, there are also downsides identified. Most overlook changes in this year's current parts market, don't consider extra costs such as stencils or testing, and are unable to make adjustments in terms of labor changes to the location.

Finally, a PCB assembly cost estimator will give a preliminary figure of costs, but it is always a good idea to get a real price quote by contacting a PCB assembly house directly. They will consider your bill of materials, design, and test specifications, then make a price quote specific to this particular setup.

One of the simplest cost-cutting measures is in the design of a printed circuit board (PCB) that is readily manufactured. Through principles of Design for Manufacturability (DFM), errors as well as error-related costs can be reduced. The approach results in standard sizes, reduced custom parts, and beautifully laid out circuit boards. Again, such a clear-cut design means reduced development costs of the PCB.

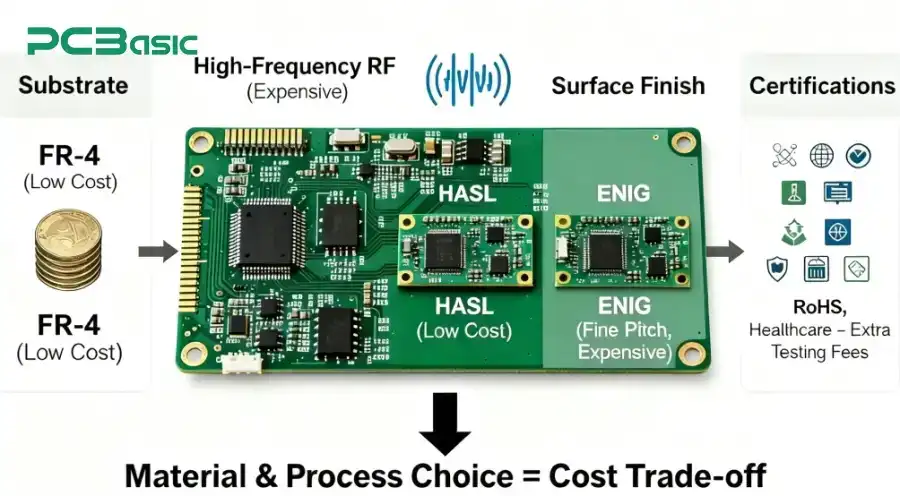

Material selection affects cost. Inexpensive substrates are common FR-4 substrates that cost a few cents, while high-frequency RF circuits become more expensive. Finishes also vary: HASL is inexpensive, while more expensive ENIG is used in fine-pitch assemblies.

Additives such as RoHS certifications or healthcare certifications also include test and inspection fees. When choosing PCB assembly prices, desired performance characteristics are sacrificed in price.

It is extremely important to compare across providers. There are providers selling this prototype of PCB assembly, and there are providers placing bulk orders. There are providers fulfilling low-cost PCB assembly requirements, there are providers focusing on reliability, certification, and sound test protocols.

It usually makes good economics to deal with a partner who manufactures and assembles finished PCBs, prototypes to production, to customers whose specifications continue to change. That saves overhead and shortens supply line, which usually costs money.

Further in life, PCB assembly as a prototype costs more than speed as a function of flexibility. Engineers aren't requiring boards as quickly, so the cost per unit can be more expensive as setup and tooling remain expensive while economies of scale are being achieved.

Many of them also have quick-turn services in such a manner that it could be worthwhile to inventors and entrepreneurs.

Some fields need custom PCB assembly to hit specific performance, safety, or regulatory needs. Automotive boards have to handle shocks and heat swings. Medical gear must meet ISO 13485 and FDA standards. IoT items might need tiny sizes and super-low power use.

These specifications increase costs of custom assembly of PCBs, such that products conforming to substantial industry specifications.

Low-volume PC assembly hits that sweet spot of inexpensive and versatile that tiny shops, niche products, or new companies cherish. That translates to hundreds, not thousands, of preproduction pieces, market test, and design modification with limited commitments.

It is due to the fact that a majority of low-cost providers of PCB assembly are specialists in this industry who help customers transform design into money in a limited time. Being early in marketplaces, they also stay ahead of small industry participants in competitive marketplaces.

Choosing the correct partner is more than about the lowest cost of PCB assembly. It's about reliability, straightforward transactions, and future potential. Our services encompass every facet of PCB manufacturing and assembly—from custom circuit board assembly of initial prototypes to one-of-a-kind PCB assembly for niche industries, to low-run PCB assembly as needed by inventors and entrepreneurs.

With leading SMT lines, selective solder, AOI, X-ray, ICT, and FCT test, we combine cost efficiency with quality. As a low-cost PCB assembly house, we provide competitive pricing without extra fees, while achieving global quality certifications.

Whether it's a startup in need of low-cost PCB assembly services or an OEM that needs certified custom PCB assembly, we've got efficient, scalable solutions that match what you need.

So, how costly is PCB assembly? No one-size-fits-all answer. Costs vary by part count, board complexity, labor rates, testing requirements, and shipping factors. While cost calculators and estimators of online PCB assembly can give a preliminary estimation, getting a full quotation from a recognized PCB assembler is still the safest approach.

By understanding what influences costs, implementing design alterations, and selecting a proper low-cost PCB assembly supplier, it is possible to save costs in PCB assembly while providing good-quality products. From prototype PCB assembly services to high-volume production, a good PCB assembly partner is what turns your designs into solid, ready-to-sell products.

About PCBasic

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.