Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > PCB Reliability Testing: Methods, Standards, and Failure Prevention

In modern electronics manufacturing, the printed circuit board is not only a carrier for component interconnections but also a key element that determines the stability and service life of the product. As electronic products develop towards miniaturization, higher integration and higher power, while operating long-term in more complex environments, the risks of temperature variation, mechanical stress, electrical loading, as well as humidity and corrosion that circuit boards face are constantly increasing. Relying solely on the result of functional testing at shipment is no longer sufficient to accurately assess the long-term reliability of circuit boards.

In practical use, many circuit boards that pass the basic PCB testing may still fail after being used for a period of time due to thermal stress, mechanical fatigue or environmental factors. Therefore, PCB reliability testing is a necessary measure to ensure the long-term stable operation of products.

Printed circuit board testing for reliability focuses on the performance changes and potential failure mechanisms of circuit boards under long-term operation and stress conditions, rather than whether the single function is normal. In high-reliability applications such as automotive electronics, aerospace, medical equipment, industrial control and energy systems, circuit board failure may bring safety risks and serious economic losses. Therefore, it is generally necessary to verify the reliability of design, materials and manufacturing processes through PCB reliability testing.

This article will introduce the basic methods and relevant standards of PCB reliability testing, as well as the role of printed circuit board failure analysis in reliability assessment.

PCB reliability testing refers to a series of systematic stress tests used to evaluate whether a printed circuit board can maintain stable performance continuously throughout its design service life. These tests mainly focus on the performance of PCBs under conditions such as thermal cycling, vibration, electrical stress, humidity, and chemical exposure.

Unlike functional PCB testing, which only verifies whether the circuit works normally at a certain point in time, PCB reliability testing pays more attention to the long-term behavior of the circuit board during extended use. The main purpose is to identify potential failure mechanisms, including copper layer fatigue, solder joint cracking, degradation of insulation performance, and the growth of conductive anodic filaments (CAF, Conductive Anodic Filament).

In short, printed circuit board testing for reliability focuses not on "whether it can work normally now", but on "whether it can still operate reliably after prolonged exposure to stress over time?"

Many PCB issues fall under latent failures, which are difficult to detect during early inspection. Even if a circuit board passes the functional PCB testing, it may still fail in actual use due to the long-term influence of thermal stress, mechanical fatigue or environmental factors. Therefore, PCB reliability has become an important indicator for evaluating product quality and brand credibility.

The importance of PCB reliability testing is mainly reflected in the following aspects:

• Preventing field failures:

Hidden problems can be detected in advance through stress testing to avoid sudden, unexpected failures during customer use.

• Improving safety in mission-critical applications:

In fields such as automotive electronics, aerospace, medical devices, and industrial control, PCB failures may affect system operation and even lead to safety risks.

• Reducing repair rates and recall risks:

Identifying potential defects in advance can lower after-sales maintenance costs and minimize product recall losses.

• Verifying the reliability of materials and manufacturing processes:

This includes evaluating copper plating quality, lamination structure stability, and solder mask curing performance for long-term use.

• Assessing long-term product performance:

It is not just relying on the results of a single-point functional test, but rather determining whether the circuit board can operate stably for a long time under the expected working conditions.

• Supporting printed circuit board failure analysis and design improvement:

Use the test results to identify the causes of failure and guide structural design and process optimization.

• Enhancing confidence in PCB testing solutions:

Shift quality control from identifying problems after they occur to preventing them in advance.

For manufacturers providing PCB testing services, PCB reliability testing is an important stage connecting production quality and actual performance in use. It is also a key means to ensure the long-term stable operation of high-reliability applications.

Most PCB reliability testing projects can be divided into four major categories:

• Thermal reliability testing

• Mechanical reliability testing

• Electrical reliability testing

• Environmental reliability testing

Each type of test targets different failure mechanisms and is used to identify and assess the key risk factors that affect PCB reliability.

Thermal stress is one of the main reasons for the failure of printed circuit boards, especially in multilayer boards and high-density designs. Due to the different coefficients of thermal expansion of copper, resin and reinforcing materials, internal stress will be generated in the circuit board during repeated heating and cooling, which will lead to structural damage and performance degradation.

Therefore, PCB reliability testing under thermal conditions is an important means to evaluate whether circuit boards are prone to fatigue failure.

Thermal cycling is one of the most commonly used methods for PCB reliability testing. By simulating the repeated heating and cooling process of the circuit board, it checks whether the vias show fatigue and micro-cracks.

Typical Conditions:

• −40°C to +125°C, or a wider temperature range

• Hundreds or even thousands of cycles

Common Failure Indicators:

• Intermittent opens

• Increased resistance

• Via barrel cracking

Among various testing methods, thermal cycling is usually regarded as the most effective PCB testing method for evaluating the long-term reliability of PCBs.

Thermal shock reliability testing involves rapidly switching the circuit board between two extreme temperatures.

Thermal shock reliability testing is particularly suitable for detecting the mismatch of the coefficient of thermal expansion (CTE) between materials. Rapid thermal expansion and contraction will accelerate the occurrence of failure, exposing faults that would otherwise take many years to occur in a short period of time.

Throughout the entire lifecycle of a PCB, from assembly and transportation to installation and operation, it will be affected by various mechanical stresses. This type of PCB reliability testing is mainly used to check whether external forces will cause damage to solder joints, vias or copper traces.

Vibration testing is designed to simulate the vibration conditions generated by the equipment during actual operation. It is mainly used to check whether the solder joints have become fatigued due to long-term vibration and to confirm whether the through-hole structure remains intact.

In applications with continuous motion or resonance, vibration-based PCB testing is an important means of evaluating reliability.

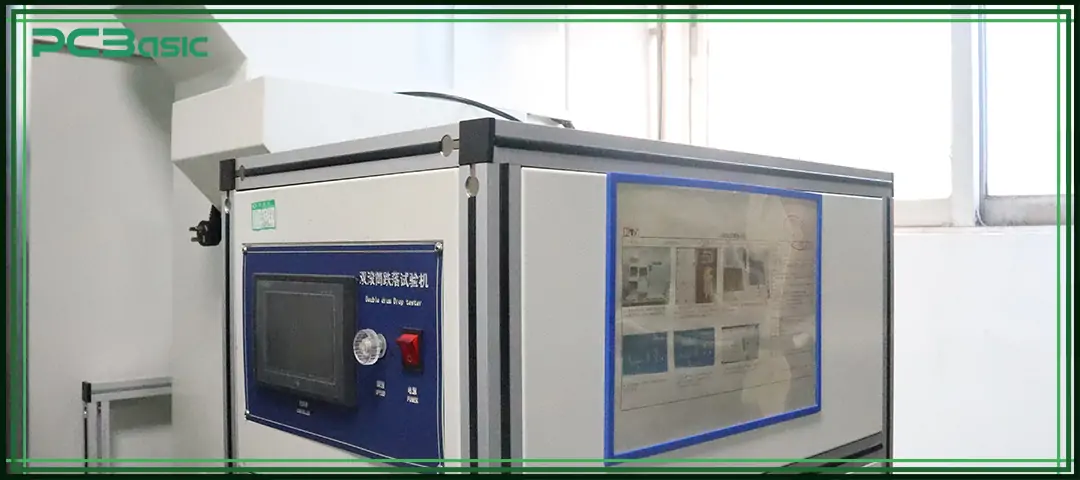

These tests are used to simulate the mechanical impact and structural stress that circuit boards may encounter in real-world use.

Shock and drop testing simulates collisions and drops that occur during handling or transportation.

Bending and flex testing examines the rigidity and interlayer bonding strength of the circuit board, and observes whether there are any copper layer cracking or delamination problems.

This type of PCB reliability testing is particularly crucial for thin boards, large panels and high-copper-weight designs.

Electrical reliability testing mainly checks whether the PCB can still maintain proper insulation performance and normal electrical functionality under higher voltage and current conditions.

The IR Test is mainly used to measure whether there is leakage current between conductors and to determine whether the performance of insulation materials is stable.

If the insulation resistance is low, it usually indicates that there is surface contamination, moisture absorption, or material aging on the PCB.

IR testing is a commonly used PCB testing solution and an important means of evaluating reliability.

Hipot testing involves applying voltage to a PCB under conditions higher than the normal operating voltage to check for breakdown and confirm whether the conductor spacing and insulation capacity are sufficient.

This kind of PCB testing is often used for power electronics products and high-voltage circuit boards.

CAF testing is used to evaluate whether there is a risk of conductive filament growth inside the PCB.

The reason why CAF testing is so important is that CAF failure usually occurs after the product has been in use for several months or even years, and it has a greater impact on fine-pitch and high-density circuit boards.

CAF testing belongs to a relatively professional type of PCB reliability testing, but it is becoming increasingly important in high-reliability products.

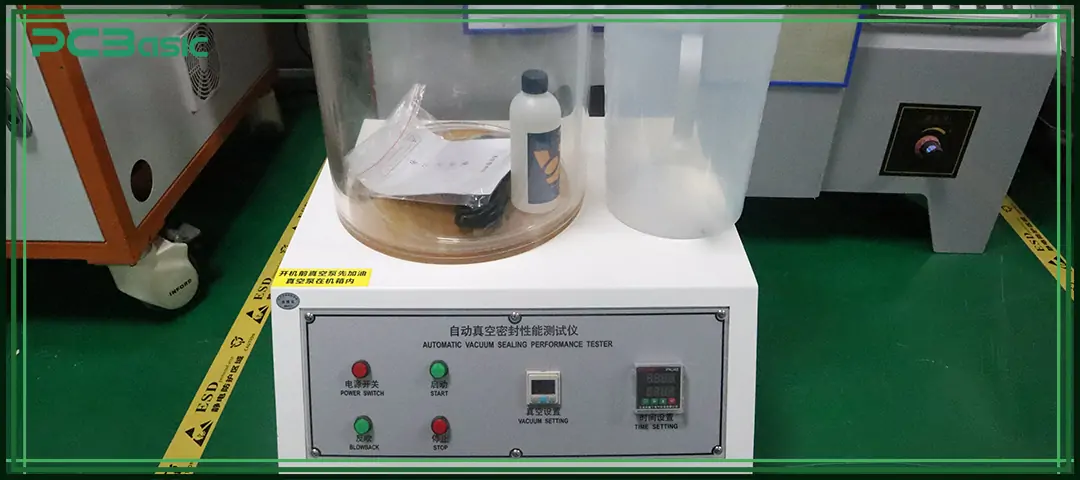

Environmental stress testing is used to simulate harsh working conditions to accelerate the aging and performance degradation of materials and structures.

Typical environmental tests in PCB reliability testing include:

• High-temperature storage

• High-humidity exposure

• Temperature-humidity bias testing

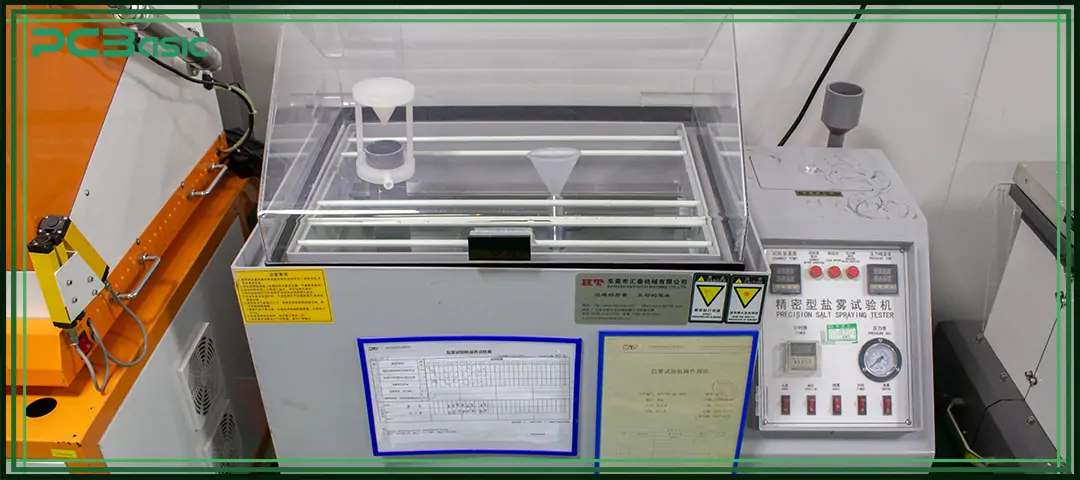

• Salt spray and corrosion testing

These tests can reveal delamination problems related to moisture, corrosion risks, and the long-term degradation of insulation performance, and provide a basis for more in-depth printed circuit board failure analysis.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

PCB reliability testing often refers to the following main industry standards:

• IPC-TM-650 – Test methods for PCBs and materials (thermal cycling, humidity, insulation resistance, etc.)

• IPC-6012 / IPC-6013 – Performance and reliability requirements for rigid and flexible printed circuit boards

• MIL-STD-202 / MIL-STD-810 – Environmental and reliability test standards for military and aerospace applications

• AEC-Q200 – Reliability testing standard for automotive electronics

• IEC 60068 – International environmental testing standard (temperature, humidity, vibration, shock, salt spray)

• JEDEC JESD22 series – Thermal cycling and thermal shock test standards

• UL 796 / UL 94 – Electrical safety and flammability rating standards

These standards stipulate test conditions and determination requirements, which help ensure the consistency of PCB testing. However, merely meeting the standards cannot fully guarantee PCB reliability. It is also necessary to combine reasonable design and stable process control.

PCB reliability testing is closely related to printed circuit board failure analysis. When failure occurs, it is necessary to determine the main cause through detection and analysis and provide a basis for corrective measures.

• Optical inspection: used to identify surface issues such as corrosion and solder joint defects

• Microsection analysis: evaluates via reliability and lamination quality

• X-ray inspection: detects internal solder joint defects and BGA-related failures

• SEM/EDX analysis: performs microstructural and chemical composition investigation

• Contamination testing: checks for flux residues and environmental contamination

These methods can transform the results of PCB testing into executable engineering conclusions, providing a basis for design improvement and process optimization.

PCB reliability testing is a key means to evaluate the actual performance of circuit boards beyond initial testing. By conducting multi-dimensional stress tests such as thermal, mechanical, electrical and environmental ones, manufacturers can identify potential defects, verify process capabilities and significantly enhance PCB reliability.

In an era when electronic products are constantly evolving towards smaller size, higher speed and greater durability, the printed circuit board testing used for reliability assessment is no longer an option but the foundation of high-quality design. True quality stems from systematic PCB reliability testing and is supported by effective printed circuit board failure analysis and continuous improvement mechanisms.

Is electrical testing enough to ensure PCB reliability?

No. Electrical PCB testing confirms functionality but does not predict long-term durability.

Which reliability test is most important?

Thermal cycling is the most widely used and revealing form of PCB reliability testing.

Are reliability tests required for all PCBs?

Not all, but they are critical for new designs and high-reliability applications.

Can reliability testing eliminate all failures?

No, but PCB reliability testing dramatically reduces failure risk.

How often should reliability testing be performed?

Typically, this occurs during new product introduction and after major design or process changes.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.