Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > LED Polarity Explained – How to Identify and Connect LEDs Correctly

The light-emitting diode (LED) is a very common component in modern electronic products. Whether it is in the small lights of household appliances or in large LED displays and automotive headlights, its presence can be seen everywhere.

Unlike ordinary electronic components such as resistors and capacitors, LEDs are polarized, which means they can only emit light normally when powered in one direction. If the LED is connected in reverse, not only will it not light up, but it may also burn out sometimes. Therefore, it is very important to figure out the LED polarity, the LED symbol and connect the LED correctly.

In this article, you will learn:

• What LED polarity is;

• The light-emitting diode symbol and the LED diagram in the circuit diagram;

• How to distinguish LED positive and negative;

• How to determine the LED polarity;

• Methods for correct LED connection.

In electronic components, LED polarity is a very important concept. It refers to the fact that LEDs must be connected in the specified direction in a circuit to function properly. The LED is a type of diode, and the working principle of all diodes is the same - they only allow current to flow in one direction. For an LED, the current must flow from the anode (positive) to the cathode (negative) in order to emit light.

In more straightforward terms:

• LED anode = LED positive side, which needs to be connected to the positive terminal (+) of the power supply.

• LED cathode = LED negative side, which needs to be connected to the ground (GND) of the circuit or the negative terminal of the power supply.

If the LED connection direction is incorrect, that is, the LED polarity is reversed, the current will be blocked. Under low voltage conditions, the LED will not light up and will not have any response. However, under high-voltage conditions, if the reverse voltage exceeds the withstand voltage value of the LED, it may cause the LED chip to be damaged permanently.

Therefore, in actual electronic design and assembly, we need to confirm the positions of the LED cathode and anode first, which is the first step to ensure the correct LED connection. If this step is ignored, it will not only cause the LED to not light up, but also may lead to device damage or circuit failure.

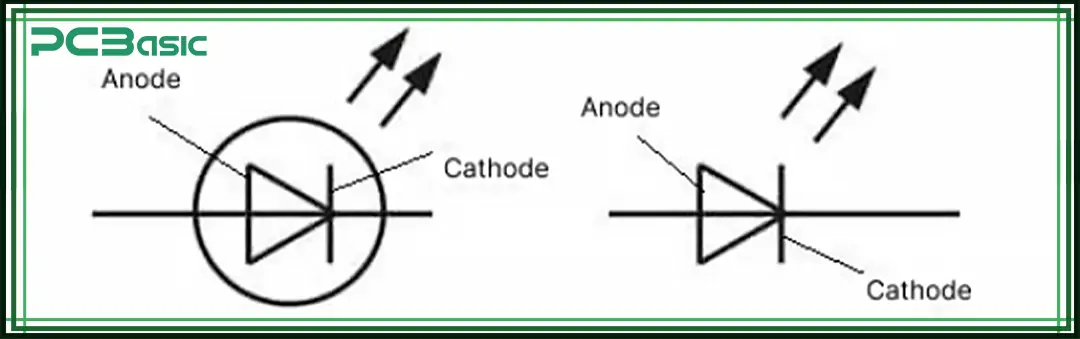

In electronic design, circuit schematics use standardized symbols to represent various components, so that engineers can quickly understand the circuit structure when reading and communicating. The LED symbol is based on the standard diode symbol, with an added feature to indicate light emission.

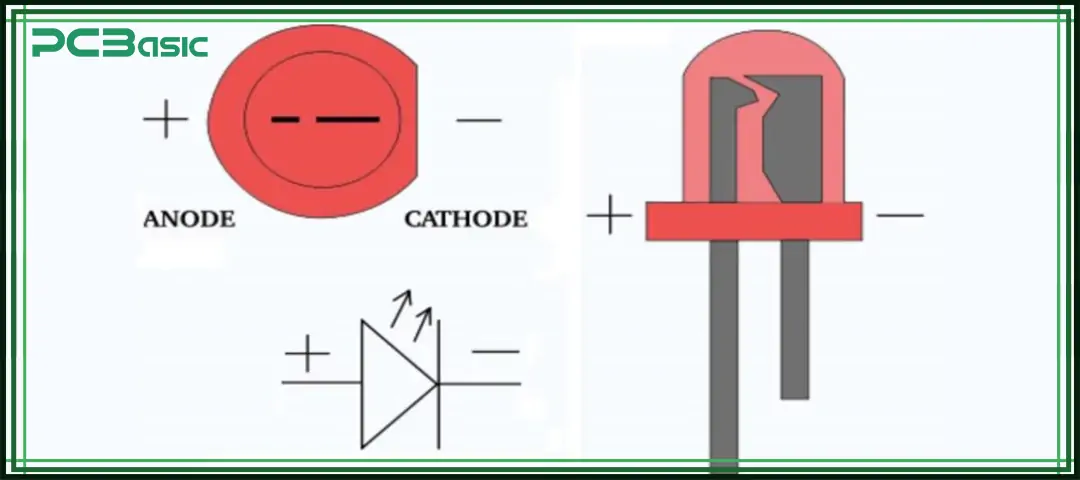

The main body of the light-emitting diode symbol is the same as that of a common diode, consisting of a triangle and a vertical line: the triangle represents the direction of current flow, with its tip pointing to the vertical line.

In addition, in the LED symbol, two outward arrows are added to the outside of the triangle to indicate light emission. This is the main visual mark to distinguish LEDs from ordinary diodes.

In terms of direction, the tip of the triangle indicates the current flowing from the LED anode to the LED cathode. The vertical line represents the LED cathode, that is, the negative side.

In the LED schematic or LED diagram, the combination of the triangle and vertical line not only indicates the type of device but also clearly marks the diode orientation. This means that in an actual circuit, the current can only make the LED light up in the direction indicated by the symbol, that is, from the positive terminal to the negative terminal.

Understanding and correctly identifying LED symbols is the foundation for avoiding LED connection errors. Incorrect understanding of symbols may cause the components to solder in reverse, resulting in the LED not lighting up or being damaged. Therefore, the polarity direction represented by the symbol must be carefully confirmed before drawing and assembly.

In actual electronic assembly and maintenance, even if there are polarity markings on the LED, it is still possible to find it difficult to identify. Especially in scenarios such as mass production, old board repair or component recycling, the accuracy of judging LED polarity is directly related to whether the product can work normally. The following content combines the identification methods of the polarity of ordinary through-hole LEDs and SMD LEDs to help you identify the LED polarity.

The most reliable way to confirm the polarity of an LED is to directly check the manufacturer's datasheet. In the datasheet, there are usually LED diagrams, LED schematic symbols, polarity identification descriptions, as well as the defined positions of the LED cathode and the LED anode.

For through-hole LEDs, the length of the leads is the most direct and simplest way to identify polarity. Normally, the long lead represents the LED anode (positive side), while the short lead represents the LED cathode (negative). This rule applies to the vast majority of newly manufactured LEDs, but in second-hand or repair scenarios, if the leads have been trimmed or modified, this method may no longer be reliable.

Many LED casings come with additional polarity markings to help quickly identify the LED polarity. For ordinary LEDs, it is common to make a flat edge on the side of the plastic package, which usually corresponds to the LED cathode. In the identification of SMD LED polarity, there may be a small notch, chamfered corner or dot on the casing, which usually also indicates that the LED cathode.

If the LED package is transparent or semi-transparent, the polarity can be determined by observing the internal metal electrodes. For a common LED, the two metal structures inside are usually of different sizes. The larger metal piece is generally connected to the LED cathode, while the smaller metal sheet is connected to the LED anode. For SMD LED polarity, a magnifying glass can be used to observe the size of the pads. Generally, the larger pads are cathodes, and the smaller ones are anodes.

The diode test mode of a multimeter is one of the most accurate methods for determining the LED polarity. Turn the multimeter knob to the diode test position, connect the red probe to the possible LED anode and the black probe to the LED cathode. If the connection is correct, the LED will emit a weak light. If it doesn't light up, reverse the test probes and test again. This method is applicable to all types of LEDs, including SMD LED polarity detection.

When there are LEDs of the same model with known polarity, the LED polarity can be determined by comparing its physical features.

For situations without a multimeter or where quick judgment is required, a simple test circuit can be set up using a low-voltage power supply (such as a 3V coin cell) and a current-limiting resistor. Connect the LED to be tested to the circuit. If it lights, the positive terminal of the power supply is connected to the LED anode. If it doesn't light, reconnect it in reverse and test again.

|

Method |

Applicable Range |

Advantages |

Disadvantages |

|

Datasheet |

All types |

Most accurate; suitable for verification before mass production |

Requires access to documentation |

|

Lead length |

Through-hole LEDs |

Quick and intuitive |

Not applicable to SMD LEDs |

|

Casing markings |

All types |

No tools needed; fast identification |

Some LEDs have no obvious markings |

|

Internal structure observation |

All types (transparent package) |

Useful as an auxiliary method |

Not applicable to opaque packages |

|

Multimeter test |

All types |

High accuracy; suitable for repair and inspection |

Requires tools |

|

Comparison with a known LED |

All types |

Simple and easy |

Requires a reference component |

|

Simple test circuit |

All types |

Low cost; highly versatile |

Requires building an additional circuit |

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Once the LED polarity is determined, it is very simple to judge its positive and negative. The LED positive is the LED anode, and the LED negative side is the LED cathode. Let’s summarize physical identification cues:

|

Indicator |

LED Anode (Positive) |

LED Cathode (Negative) |

|

Lead Length (Through-Hole) |

Longer lead |

Shorter lead |

|

Body Marking |

No flat edge |

Flat edge |

|

Internal Structure |

Smaller electrode |

Larger electrode |

|

SMD LED polarity marking |

Opposite of notch/dot |

Marked with notch/dot |

Knowing the LED cathode and anode is essential before making any LED connection.

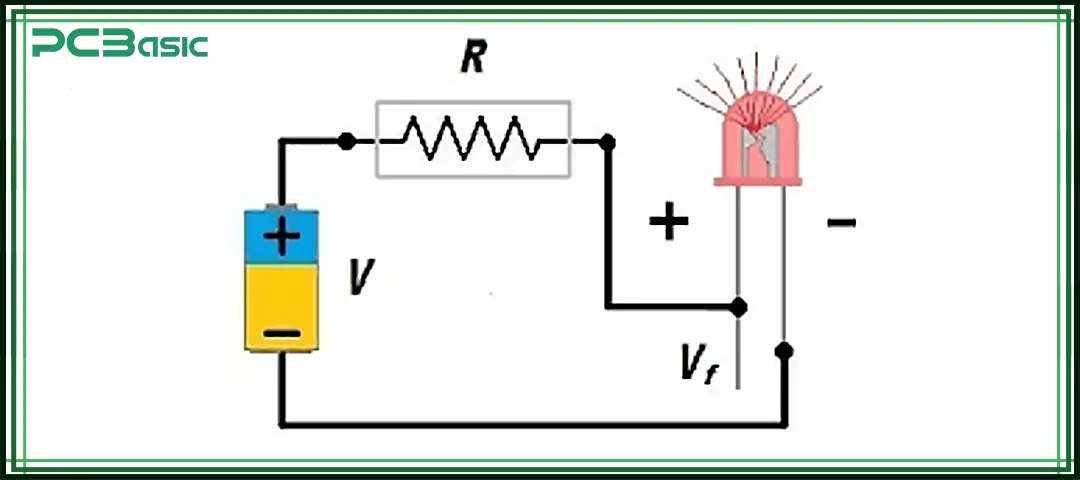

To ensure that the LED lights up normally, it is necessary to have the correct LED connection and avoid damage caused by incorrect wiring. The following is a simple and easy-to-understand step-by-step explanation:

Before starting the connection, confirm the positions of the LED anode and the LED cathode.

Connecting according to the LED diagram. In general, the LED anode needs to be connected to the positive terminal of the power supply through a current-limiting resistor, and the LED cathode needs to be connected to the negative terminal of the power supply or ground (GND). Current-limiting resistors are indispensable as they can prevent excessive current from burning out the LED.

LEDs of different colors have different forward conduction voltages. The forward voltage of a standard red LED is approximately 2V, while that of blue and white LEDs is approximately 3V. When choosing a power supply, make sure that the power supply voltage is higher than the forward voltage of the LED, but not too much, to avoid excessive current.

The current must flow from the LED anode to the LED cathode. If the direction is reversed, the LED will not light up and may even be damaged.

Before final installation or soldering, it is advisable to briefly power on the circuit for testing. Make sure the LED can light up normally and check if the brightness meets expectations. After confirming that there are no errors, proceed with the final fixation or welding operation.

LED polarity is a fundamental knowledge that everyone who works with electronics must understand. Whether it is looking at the LED symbol in the LED schematic, distinguishing the LED anode from the LED cathode on the component, or arranging the placement direction when installing SMD LEDs, only by connecting the wires correctly can the LED connection be ensured to be correct, allowing the equipment to work normally and prevent it from being burned out.

Learning to read diode markings and determine diode orientation, accurately distinguishing the positive and negative sides of an LED, you can wire it according to the LED diagram. Whether it is for simple wiring of LED light strips or installing LEDs in complex industrial systems, these methods can all be used.

Connecting the LED polarity correctly is not only for making the light on, but also for ensuring its long-term stable and reliable operation, reducing rework and avoiding losses caused by incorrect wiring.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.