Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > A Complete Guide to EMS Suppliers | PCBasic

In the fast-paced and highly competitive electronics market, most companies have found it difficult to complete all manufacturing processes entirely in-house. With the continuous complexity of product structures, the continuous shortening of product life cycles, and the increasing requirements for quality and consistency, outsourcing the production process to reliable EMS suppliers has become a long-term strategic choice for enterprises at the manufacturing level, rather than merely for cost reduction.

For OEMs that hope to steadily expand production capacity and market scale, accurately understanding EMS meaning is the basis for conducting electronic manufacturing cooperation. As a professional EMS company, PCBasic provides stable, flexible and scalable electronics manufacturing services to customers worldwide.

This article will systematically explain what does EMS stand for, the main reasons why OEMs choose the EMS cooperation model, and the core capabilities that professional EMS suppliers should possess. And the positioning and value of PCBasic in the current global EMS industry.

To understand the role of an EMS supplier, we first need to clarify what is EMS and what does EMS stand for.

EMS stands for Electronics Manufacturing Services. In simple terms, an EMS supplier is an electronics contract manufacturer that provides outsourced contract manufacturing services for electronic products. These services often go far beyond basic assembly.

Modern EMS manufacturing typically includes:

• Design for Manufacturing (DFM) support

• PCB fabrication and electronics assembly

• Component sourcing and supply-chain management

• Testing, inspection, and quality assurance

• System integration and box build

• Logistics, delivery, and after-sales support

Unlike traditional build-to-print factories, today’s electronics manufacturing services providers act as long-term manufacturing partners. A capable EMS company helps OEMs reduce risk, improve yield, and maintain consistent quality across production volumes.

The global shift toward outsourcing has reshaped the EMS industry. OEMs across consumer, industrial, medical, automotive, and telecom sectors increasingly rely on electronics contract manufacturing rather than internal production.

1. Cost efficiency

Using contract manufacturing services allows OEMs to avoid heavy capital investment in equipment, facilities, and labor. EMS manufacturing leverages shared infrastructure and economies of scale.

2. Faster time-to-market

Established electronics manufacturing companies already have qualified production lines, trained engineers, and optimized processes, significantly reducing ramp-up time.

3. Access to advanced technology

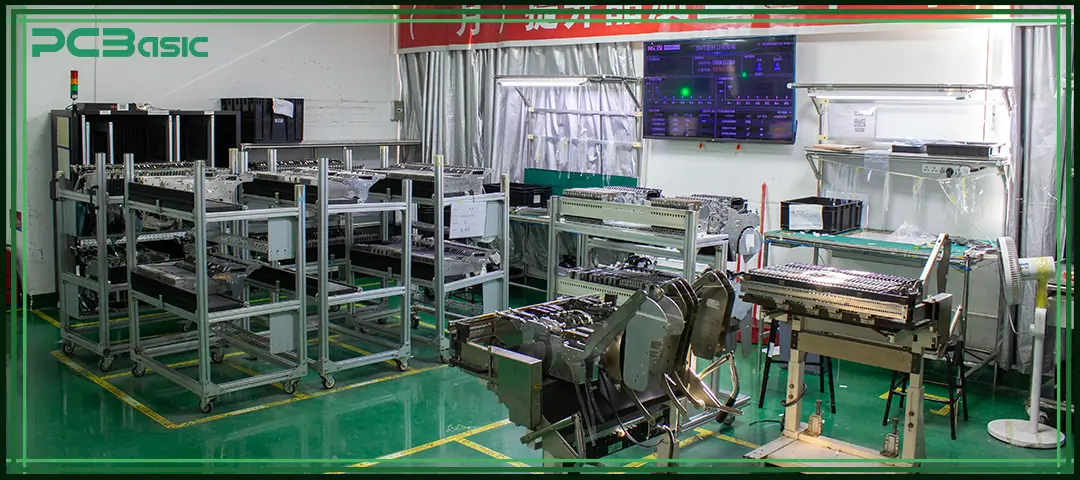

Professional electronics manufacturers invest continuously in SMT lines, inspection systems, and testing equipment that may be impractical for OEMs to maintain in-house.

4. Supply-chain resilience

An experienced EMS supplier offers component sourcing expertise, alternative part management, and traceability—critical advantages during shortages.

5. Focus on core competencies

By outsourcing electronics assembly services, OEMs can concentrate on R&D, product innovation, and customer engagement.

A reliable EMS supplier provides a complete set of manufacturing services covering the entire electronics lifecycle.

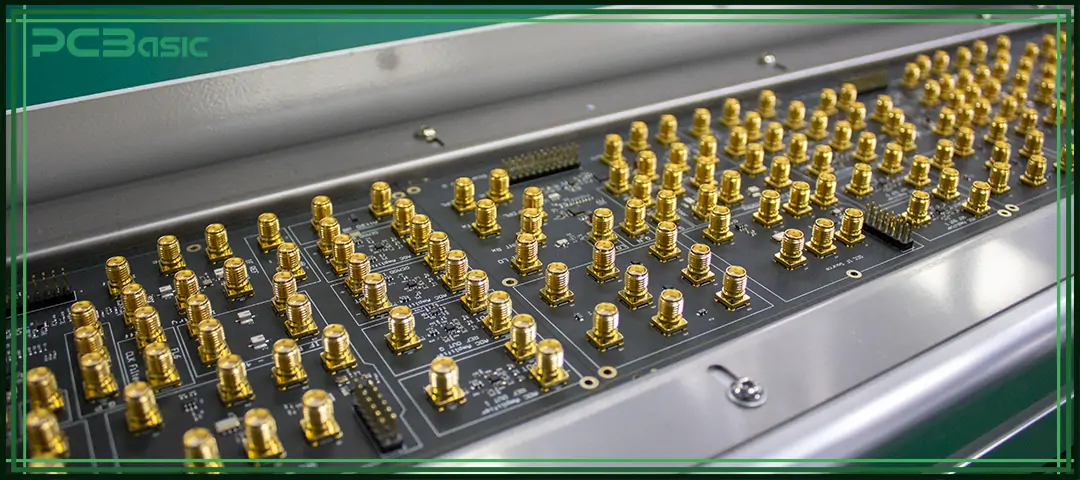

At the heart of all electronics manufacturing lies the printed circuit board. High-quality PCB production and electronics assembly are foundational to reliable products.

A professional electronics manufacturer supports:

EMS manufacturing includes advanced electronics assembly services such as:

A capable EMS company ensures repeatable quality across prototypes, low-volume builds, and mass production.

Quality is one of the main reasons OEMs choose an experienced EMS supplier.

Professional electronics manufacturing services integrate testing throughout the production process, including:

SPI (Solder Paste Inspection)

AOI (Automated Optical Inspection)

X-ray inspection for BGA and hidden joints

ICT (In-Circuit Testing)

FCT (Functional Circuit Testing)

Flying probe testing for prototypes and small batches

Robust testing ensures that electronics contract manufacturing delivers products that perform reliably in real-world conditions—not just boards that “look” correct.

Modern EMS solutions extend well beyond PCB-level manufacturing.

A full-service EMS supplier supports:

Mechanical and enclosure assembly

Cable and wire harness integration

Firmware and software loading

Final system-level testing and verification

With system integration and box build, electronics manufacturing services deliver fully functional, ready-to-ship products—reducing logistics complexity for OEMs.

The EMS industry has evolved to meet the growing demand for customization and rapid iteration. Many products today are produced in high-mix, low-volume (HMLV) environments.

Why HMLV matters

Shorter product lifecycles

Frequent design revisions

Customized variants for different markets

The role of an EMS supplier in HMLV

Effective EMS manufacturing for HMLV requires:

This is where professional electronics manufacturing companies differentiate themselves from low-end assembly providers.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Not all electronics manufacturers offer the same level of capability. Selecting the right EMS supplier is a strategic decision.

Technical Capability & Quality

Look for:

Proven electronics manufacturing services experience

Modern SMT equipment and inspection systems

Structured testing strategies

Process control and traceability

Certifications & Compliance

Depending on your industry, your electronics contract manufacturer should support relevant standards such as ISO 9001, ISO 13485, or automotive quality systems.

Supply Chain Strength

A strong EMS company offers:

Authorized component sourcing

Obsolescence and lifecycle management

Counterfeit prevention

Communication & Partnership Fit

An EMS supplier should provide:

Transparent communication

Clear project management

Digital tools for quoting, DFM, and order tracking

As a technology-driven EMS supplier, PCBasic delivers flexible and reliable electronics manufacturing services tailored to global customers.

What PCBasic Offers

PCB manufacturing and electronics assembly services

SMT, THT, and mixed-technology electronics assembly

Component sourcing and BOM optimization

Comprehensive testing and quality control

System integration and box build

Why Customers Choose PCBasic

Strong engineering support and DFM expertise

Advanced inspection and testing capabilities

MES-driven traceability for quality and compliance

Support for prototypes, HMLV projects, and volume production

By combining technical depth with responsive service, PCBasic positions itself as a trusted electronics contract manufacturer in the global EMS industry.

OEMs often ask about the difference between an EMS supplier and an ODM.

EMS supplier:

Focuses on electronics contract manufacturing, producing products based on the customer’s design while supporting industrialization, testing, and logistics.

ODM (Original Design Manufacturer):

Designs products that customers may rebrand, often limiting design ownership.

For OEMs with proprietary designs, EMS manufacturing provides greater control over IP while leveraging professional manufacturing services.

Understanding the EMS meaning, what is EMS, and what does EMS stand for is essential for any company involved in modern electronics manufacturing. An experienced EMS supplier is no longer just a factory—it is a strategic partner that enables scalability, quality, and speed.

From electronics assembly services and testing to full electronics contract manufacturing, EMS partners support OEMs in navigating complexity and global competition. As a reliable EMS company, PCBasic combines engineering expertise, advanced production, and flexible EMS solutions to help customers succeed.

Choosing the right EMS supplier is not just a purchasing decision—it is a long-term manufacturing strategy that directly impacts product quality, cost, and market success.

1. What does EMS stand for?

EMS stands for Electronics Manufacturing Services.

2. What is EMS in electronics manufacturing?

In electronics manufacturing, EMS refers to outsourced contract manufacturing services for building electronic products.

3. What is the EMS meaning?

The EMS meaning is providing end-to-end electronics manufacturing services, from PCB assembly to testing and delivery.

4. What does an EMS supplier do?

An EMS supplier handles electronics assembly, testing, system integration, and logistics for OEMs.

5. What services does an EMS company offer?

An EMS company offers PCB manufacturing, electronics assembly services, testing, and EMS manufacturing support.

6. What is EMS contract manufacturing?

EMS contract manufacturing means outsourcing production to an electronics contract manufacturer.

7. How is EMS different from ODM?

An EMS supplier manufactures to customer designs; an ODM owns the product design.

8. Why do OEMs use EMS suppliers?

OEMs use EMS suppliers to reduce costs, speed up production, and focus on R&D.

9. What industries use EMS manufacturing?

EMS manufacturing is common in medical, automotive, industrial, telecom, and consumer electronics.

10. What is HMLV in EMS?

HMLV means high-mix, low-volume electronics manufacturing with flexible production.

11. How does an EMS supplier ensure quality?

Through inspection, testing, and controlled electronics manufacturing services processes.

12. Is EMS suitable for small batches?

Yes, modern EMS solutions support prototypes and small-volume production.

13. What should I look for in an EMS supplier?

Strong quality systems, testing capability, and experience in electronics manufacturing.

14. What is the difference between EMS and electronics contract manufacturing?

There is no difference—both refer to outsourced electronics manufacturing services.

15. Is PCBasic an EMS supplier?

Yes, PCBasic is a professional EMS supplier providing electronics manufacturing services.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.