Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Land Grid Array (LGA) Explained

In modern electronic technology, the performance and reliability of circuits largely depend on the packaging method of integrated circuits. Especially in high-speed and high-frequency applications, the packaging structure will directly affect the integrity of signal transmission and the efficiency of heat dissipation.

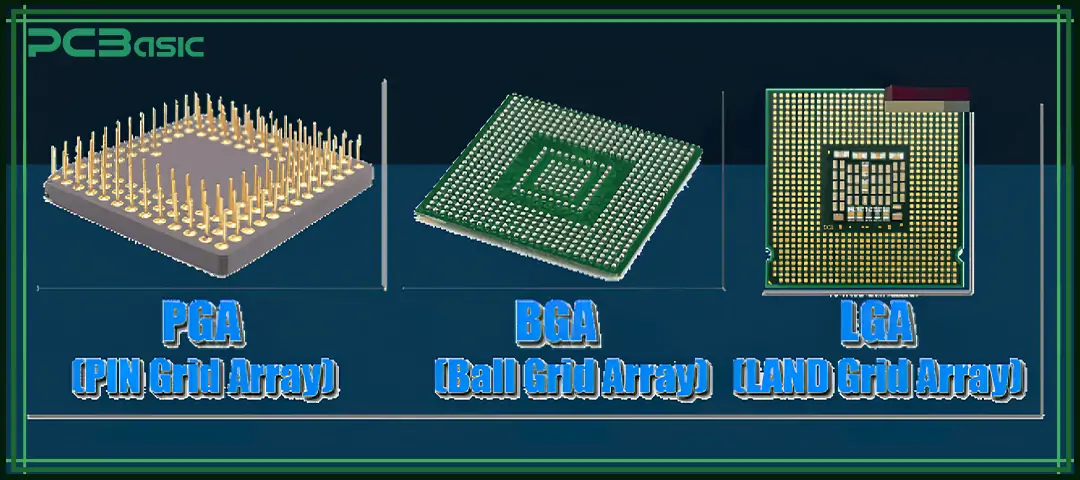

Land Grid Array is a widely adopted surface-mount packaging form and has become the mainstream choice for many modern electronic products. At present, LGA packages are widely used in CPUs, server motherboards and various network devices. Unlike the traditional PGA, LGA does not have easily damaged pins set on the chip. Compared with BGA, LGA adopts the flat grid at the bottom of the chip and achieves electrical connection through a socket or solder pad.

This article will introduce the structure, advantages and disadvantages of LGA packaging and make a comparison with PGA and BGA to help readers understand which type of LGA component is more suitable for the requirements of modern electronic systems.

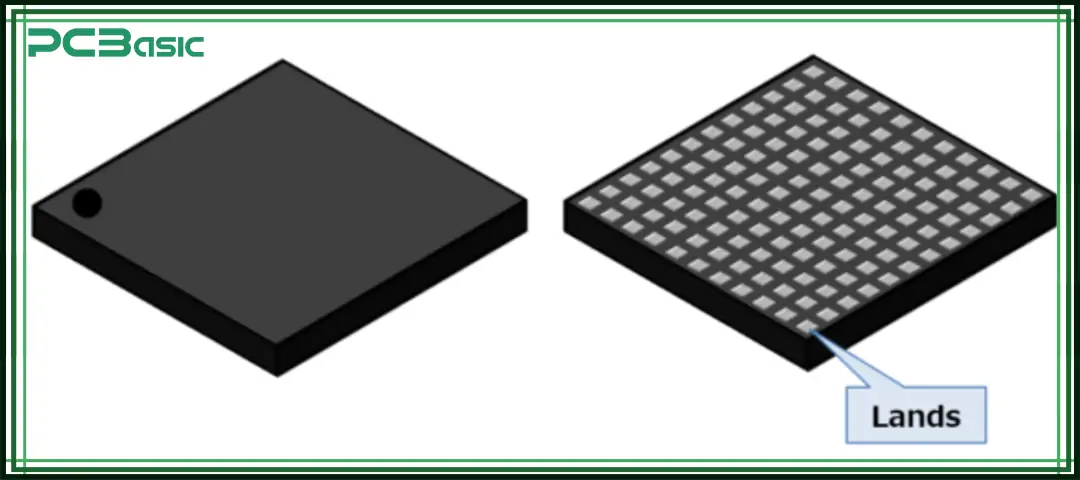

Land Grid Array (LGA) is a common surface-mount packaging form and is widely used in integrated circuits (IC). It is particularly suitable for devices with high requirements for performance and pin density, such as CPUs (central processing units), FPGAs, and network controllers.

The bottom of the LGA packaged chip is arranged with regular flat metal lands, which are distributed in a grid and used to achieve electrical connections with spring-loaded pins on a socket (for socketed installation) or with solder pads (for direct mounting) on the motherboard.

Since the LGA chip does not contain a protruding pin structure, it can effectively avoid physical damage during handling and assembly, improving the overall mechanical robustness. Furthermore, LGA supports higher pin density, which is crucial for complex and high-performance computing platforms. Therefore, the LGA package has become one of the preferred packaging solutions in modern desktop computing, server systems, and high-frequency and high-speed circuit design.

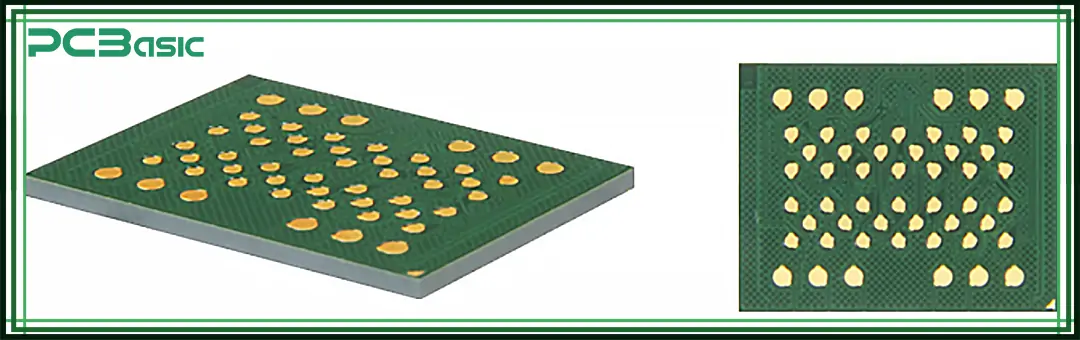

In a typical Land Grid Array package, the bottom of the chip is covered with a neatly arranged array of flat metal pads, which is called a land grid. These contact pads are distributed in a grid array and are used to achieve electrical connections with the corresponding contacts on the motherboard or circuit board.

There are two main installation methods for LGA packages:

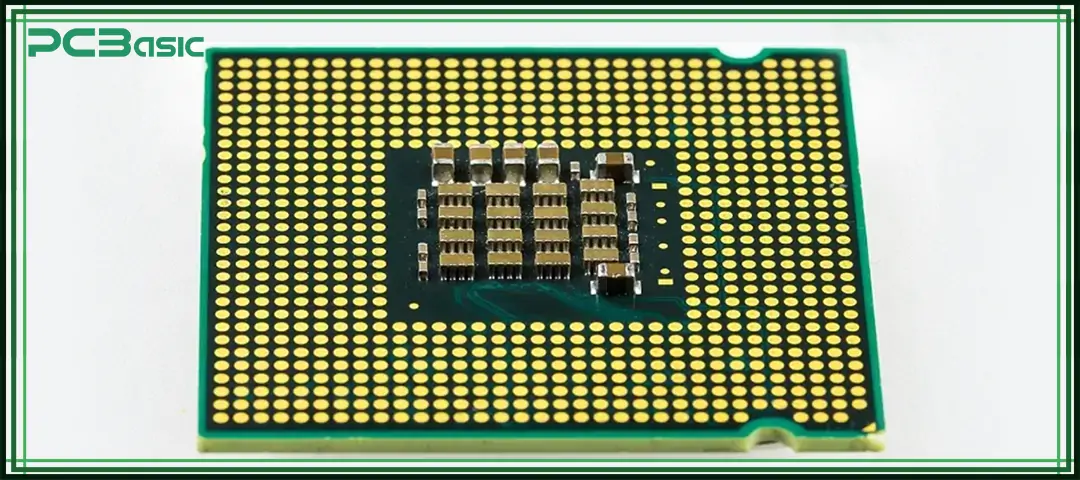

Replaceable/Upgradable installation: For devices like desktop-level LGA CPUs, the contact pads at the bottom of the chip will connect to the spring-loaded pins in the motherboard socket. The socket is usually equipped with a set of elastic metal contacts, and the chip is fixed in the slot through a lever mechanism to ensure stable contact and a firm connection.

Permanent installation: For scenarios such as server motherboards, embedded systems or industrial modules where chip replacement is not required, LGA chips can be directly soldered onto PCB boards. The contact pad at the bottom of the chip is aligned with the PCB pad and then soldered through the reflow soldering process. This process has very high requirements for temperature control and alignment accuracy.

In summary, LGA packaging has become a commonly used packaging form in high-performance processors and complex electronic systems by simplifying the structure, increasing pin density and enhancing connection stability.

High Pin Density: The bottom of the LGA chip can accommodate a large number of contact pads, supporting more pins than the traditional PGA packages. This enables the LGA CPUs to have stronger computing power and better signal integrity, making them suitable for high-performance computing tasks.

Lower Risk of Pin Damage: LGA uses flat contact pads instead of fragile pins on the chip, which makes it less prone to bending or breaking during insertion or handling than PGA, thereby enhancing the reliability of the chip.

Easy Inspection: Unlike BGA (Ball Grid Array), the contact pads of LGA are visible, making it easier to inspect using a microscope or AOI (Automatic Optical Inspection). Any soldering defects are also easier to detect and rework.

Socket Flexibility: LGA chips can be installed through sockets and are suitable for systems that need to be replaced or upgraded. It can also be directly soldered onto the PCB and is suitable for designs with limited space or fixed structures. This flexibility enables it to be applied to a variety of products.

Cost-Effective: Compared with BGA packaging, LGA does not require ball replacement or reflow processes for solder balls, making its production process simpler. In some cases, it can reduce manufacturing costs.

Alignment Sensitivity: During installation, if the chip and the socket are not precisely aligned, it is easy to cause poor electrical contact or bending the spring-loaded pins in the motherboard socket. The requirements for technological accuracy are relatively high.

Thermal Limitations: Compared with BGA, which offers direct thermal paths via solder ball, LGA CPUs may require additional cooling solutions such as heatsinks or fans due to longer thermal conduction paths — especially for high-power applications.

Socket Damage Risk: The pins in LGA sockets are relatively fine and delicate. Once they are bent or damaged due to proper handling, the sockets themselves are not easy to replace or repair, and the entire motherboard may need to be replaced.

In summary, the LGA package is suitable for systems with a high number of pins, high performance, and the need for flexible assembly or easy maintenance. However, during the usage process, attention should also be paid to alignment accuracy and heat dissipation design to avoid affecting system performance and lifespan due to socket damage or improper thermal management.

About PCBasic

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Land Grid Array (LGA) is widely used in electronic systems that require high performance, frequent upgrades, or strong reliability. The structure of the LGA package makes it easy to install and ensures stable connections. It is especially suitable for applications that demand high pin density, good electrical performance, and easy maintenance.

Typical use cases include:

• LGA CPUs: LGA is the standard package for modern desktop processors. It is used in desktop computers and high-performance workstations. For example, Intel Core i7 and i9 processors use LGA packaging, making it easy to replace or upgrade the CPU.

• Server CPUs: In data centers and enterprise servers, LGA is commonly used. Processors like Intel Xeon and AMD EPYC adopt LGA sockets that support high-power delivery and multi-core designs. This helps systems run under heavy loads for long periods.

• Networking Equipment: Devices like Ethernet controllers, routers, switches, and telecom modules often use LGA components. These applications require stable connections and easy replacement or repair.

• High-Reliability Embedded Systems: Industrial PCs, control units, and FPGAs (Field-Programmable Gate Arrays) also use LGA chips. These systems need strong electrical connections and must work in harsh environments. LGA provides both reliability and serviceability.

In summary, whether in desktop computing, server platforms, or embedded industrial systems, the LGA package offers a high pin count, reliable connection, and flexible mounting options. It is one of the most important packaging technologies in modern electronics.

For LGA chips that are not installed using a socket, soldering quality has a direct impact on connection reliability and system performance. Therefore, it is important to follow the correct soldering process for the LGA package.

1. Surface Preparation:

Before soldering, clean the metal contact pads (lands) on the bottom of the LGA chip and the PCB pads. Remove any oxidation, dust, or oil to improve soldering quality.

2. Flux Application:

Apply flux evenly on the contact pads and PCB pads. This improves metal wetting, helps the solder flow into the joint, and increases adhesion strength.

3. Precise Alignment:

LGA uses flat contact pads instead of solder balls. So, accurate alignment between the chip and the PCB is essential. Misalignment may cause open circuits or shorts.

4. Reflow Soldering:

After aligning the chip, place it into a reflow oven. Follow a controlled temperature profile with preheat, soak, and reflow stages. This ensures that the solder fully melts and forms reliable joints.

• Reflow Oven: Provides accurate temperature control for batch soldering. Ideal for mass production.

• Hot-Air Station: Suitable for small-batch soldering or rework. Allows manual heating of targeted areas.

• Alignment Jig: Helps align the LGA chip with the PCB accurately. Prevents shifting and improves assembly precision.

Compared to BGA, LGA has no hidden solder balls, making it easier to inspect solder joints using a microscope or AOI. This also makes rework simpler. For products that require reliable connections and easy maintenance, the LGA package is an excellent choice.

After assembly, LGA chips must be inspected to ensure reliable electrical connections. Compared to BGA packaging, LGA inspection is more straightforward and cost-effective, making it a better choice for R&D and small to medium production runs.

Common inspection methods include:

Thanks to its structural design, the Land Grid Array (LGA) package is easier to inspect and verify. This visibility and accessibility make it a preferred choice during prototyping and testing—one key reason many engineers choose LGA over BGA in the early development stages.

PGA (Pin Grid Array) is a traditional and commonly used packaging type. On the bottom of the chip, there are rows of metal pins that need to be inserted into holes in the motherboard socket to make a connection. Many early AMD processors and some embedded chips used this packaging.

The main advantage of PGA is its simple structure and ease of installation. It also makes it convenient for users to upgrade or replace the CPU. However, there are some downsides. The pins on the chip are thin and fragile, and they can easily bend or break during handling or installation, which can lead to poor connection. Also, because each pin needs space around it, PGA can’t support very high pin counts, which limits its use in high-performance chips.

BGA (Ball Grid Array) is a packaging method designed for high pin count devices. Instead of pins, small solder balls are arranged in a grid on the bottom of the chip. When installed, these solder balls melt during reflow soldering and connect directly to the PCB.

The main benefits of BGA are its ability to support many more connections and provide better electrical performance and heat dissipation. This makes it ideal for high-speed and high-frequency applications, such as mobile processors, memory chips, and communication devices. However, it also has some drawbacks. Since the solder joints are hidden under the chip, they can’t be inspected visually. If there are any soldering issues, repairs are difficult and expensive.

|

Feature |

LGA (Land Grid Array) |

PGA (Pin Grid Array) |

BGA (Ball Grid Array) |

|

Electrical Connection |

Flat metal pads connect with socket pins or PCB pads |

Chip pins are inserted into holes in the motherboard socket |

Solder balls are reflow soldered directly onto the PCB |

|

Chip Structure |

Flat contact pads on the bottom of the chip |

Exposed metal pins on the bottom of the chip |

Matrix of solder balls on the bottom of the chip |

|

Pin/Solder Joint Density |

Supports high density, ideal for high-performance CPUs |

Limited density, typically used for chips with moderate pin counts |

Very high density, ideal for compact, high-speed designs |

|

Installation & Maintenance |

Can be socketed or soldered; easy to replace and inspect |

Easy to install, but pins are fragile and not ideal for frequent swaps |

Stable installation, but difficult to inspect or repair |

|

Alignment & Soldering Difficulty |

Requires precise alignment; the reflow process needs tight thermal control |

Easy alignment; simple manual installation |

Very high precision required; difficult to rework |

|

Thermal Performance |

Relies on external heatsinks; longer heat path |

Average thermal performance |

Low thermal resistance; suitable for high heat loads |

|

Inspectability (Post-Assembly) |

Lands are visible; easy AOI inspection and rework |

Visual inspection possible |

Solder joints are hidden; requires X-ray for inspection, higher cost |

|

Typical Applications |

Desktop CPUs, servers, industrial controllers |

Some AMD CPUs, embedded processors |

Smartphone SoCs, memory chips, networking and communication modules |

The land grid array (LGA) is a reliable and versatile packaging option for modern high-performance electronics. Whether you're making a desktop computer, building servers, or developing embedded systems, LGA provides strong performance, easy repair and upgrade options, and good thermal and mechanical stability. Compared to PGA and BGA, the LGA chip offers a practical balance of performance, durability, and ease of use, making it a popular choice for CPUs, FPGAs, and other critical components.

Q1: Can LGA support multi-core CPUs?

Yes. The LGA package is commonly used for high-core-count processors such as Intel Xeon and AMD Ryzen.

Q2: Which is easier to inspect: LGA or BGA?

LGA is much easier to inspect due to its exposed land grid contacts, while BGA requires X-ray inspection.

Q3: Is LGA suitable for thermal-intensive applications?

Yes, but it depends on external cooling. While BGA provides better internal thermal flow, proper heatsink design makes LGA CPUs equally viable.

Q4: Can I reuse an LGA CPU?

Absolutely. The socketed design allows for simple upgrades or replacements of LGA chips.

Q5: Is FCLGA better than standard LGA?

FCLGA offers better electrical performance and heat dissipation, especially in compact systems like laptops or high-density servers.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.