Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Ultimate Guide to PCB Conformal Coating

The operating environments of various electronic devices are complex and changeable. Moisture, dust, high temperatures, salt spray, chemical corrosion and even physical wear and tear during daily use can all cause circuit boards to fail or be scrapped prematurely.

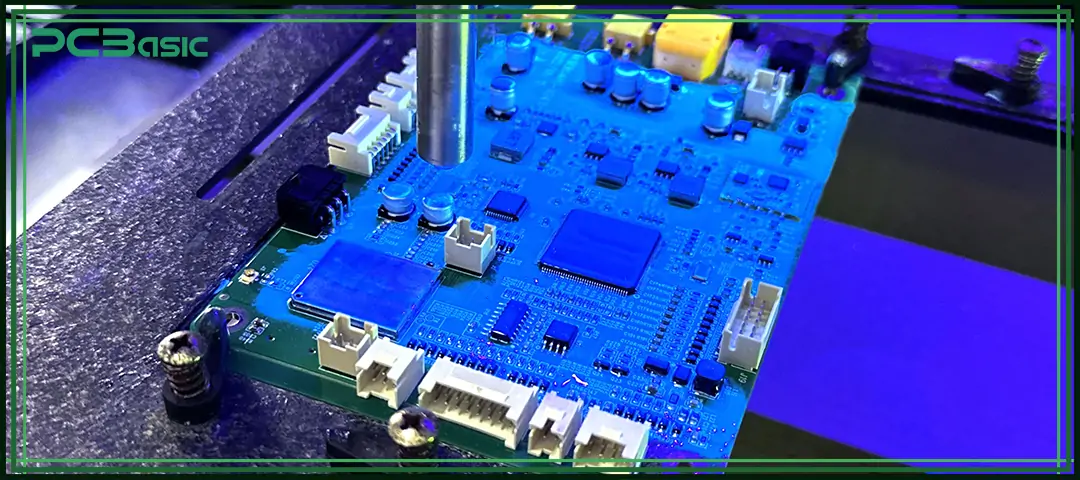

To avoid these problems, engineers apply a layer of conformal coating on the surface of the circuit board, which is like putting on an invisible protective coat for the PCB. It can prevent moisture, corrosion and dust, enhance insulation strength, and ensure that PCBS can still operate stably in damp, high-salt fog or polluted environments. Whether it is consumer electronics, automotive ECUs, industrial control boards, medical devices or aerospace systems, the use of PCB conformal coating can effectively reduce the failure rate and extend the product life.

This article will focus on introducing what conformal coating is, common types of conformal coating, the process of conformal coating, as well as its practical applications in various electronic products. After reading this article, you will be able to determine whether a certain type of PCB needs coating, which PCB coating material should be chosen, and how to correctly apply conformal coating to enhance product reliability.

Conformal coating is a thin protective layer applied to the surface of circuit boards, mainly used to prevent damage to PCBs caused by moisture, salt spray, dust, chemical contaminants, and electrical discharges. Unlike potting, it does not encapsulate the entire circuit board. Instead, it covers the surface of the PCB in a very thin way and closely adheres to the components and solder joints, just like putting on a transparent and lightweight protective coat for the PCB.

This kind of PCB protective coating can enhance electrical insulation, prevent short circuits, reduce metal oxidation and corrosion, and at the same time resist a certain level of mechanical stress and temperature changes. Therefore, whether in automotive electronics, aerospace, industrial equipment, medical devices, or outdoor LED lamps, conformal coating for electronics is an effective way to enhance the reliability of circuit boards and extend the lifespan of equipment.

Different types of conformal coatings have their own characteristics in terms of protective performance, flexibility, chemical resistance and ease of rework. Common PCB coating materials include the following types:

PCB Conformal Coating Types – Comparison Table

|

Coating Type |

Key Features |

Advantages |

Limitations |

Typical Applications |

|

Acrylic Conformal Coating |

Single-component, transparent, easy to apply |

Easy to spray or brush, fast drying, easy to remove and rework |

Poor solvent resistance, not suitable for high temperatures |

Consumer electronics, general PCB protection, boards that require repair or modification |

|

Silicone Conformal Coating |

Highly flexible, wide temperature range (-55°C to +200°C) |

Excellent moisture and salt spray resistance, ideal for outdoor and automotive use, and great thermal stability |

Low abrasion resistance and higher thermal resistance may affect heat dissipation |

Automotive ECUs, aerospace electronics, LED drivers, outdoor devices |

|

Polyurethane (Urethane) Coating |

Tough coating with strong chemical resistance |

Excellent resistance to moisture, oils, and chemicals |

Difficult to remove, not ideal for rework |

Industrial control systems, aerospace electronics, high-reliability manufacturing |

|

Epoxy Conformal Coating |

Very hard and durable circuit board coating |

Superior protection against solvents, abrasion and corrosion |

Extremely difficult to remove once cured, rigid and prone to stress cracking |

Power electronics, industrial equipment, harsh chemical environments |

|

Parylene Coating |

Applied by Chemical Vapor Deposition (CVD), ultra-thin and pinhole-free |

Uniform coverage on complex geometries, high dielectric strength, excellent insulation |

High cost, specialized equipment required, not suitable for on-site repair |

Medical devices, military electronics, aerospace systems, high-reliability sensors |

|

Application Method |

Description |

|

Manual Spraying / Brushing |

Used for small batches and repairs |

|

Dip Coating |

PCB is immersed in PCB coating material; requires masking |

|

Automated/Selective Coating |

Robotics apply the conformal coating for PCB precisely, minimizing masking |

|

Parylene Vapor Deposition |

Advanced conformal coating process for ultra-thin, uniform layers |

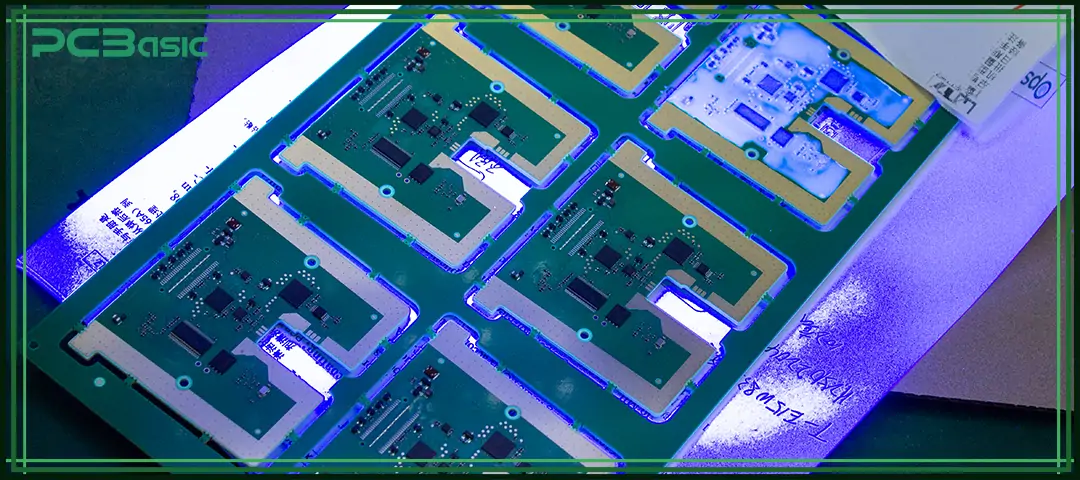

Before applying conformal coating for PCBs, it is necessary to ensure that the surface of the circuit board is clean and dry, and any areas that should not be coated must be properly protected.

First, the PCB needs to be cleaned using deionized water or ultrasonic methods to thoroughly remove flux residues, dust, oil and moisture. This prevents contaminants from affecting the adhesion of the coating or insulation performance.

Subsequently, for areas such as connectors, gold fingers, and test points that need to remain exposed or conductive, masking should be carried out in advance to prevent the conformal coating from covering these critical positions, thereby ensuring that subsequent soldering, testing, or connector mating are not affected.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

After the conformal coating is applied to the PCB, the coating thickness is usually controlled between 25 and 127 μm (1 - 5 mils). If the thickness is too thin, it will affect the protective effect; if it is too thick, it may crack or affect the heat dissipation of components. Therefore, thickness and quality inspections need to be carried out after the coating is completed.

Common measurement methods include immediate checks using a wet film thickness gauge or calculating the coating thickness by measuring the thickness difference of the plate with a micrometer before and after coating. For more precise applications, non-contact methods such as eddy current or ultrasonic testing are also adopted to confirm whether the coating is uniform and meets the standards.

After the conformal coating is applied, it does not immediately form a final protective film. Instead, it needs to go through a curing process to firmly adhere to the surface of the PCB. Different types of conformal coatings adopt different curing methods, which will affect the hardness, adhesion, production speed and reliability of the coating. The following are several common curing methods.

|

Curing Method |

Details |

|

Evaporative Drying |

Solvent-based conformal coating types like acrylic or urethane |

|

Moisture Curing |

Used mainly in silicone conformal coating |

|

Heat Curing |

Speeds up curing for epoxy and hybrid PCB coating materials |

|

UV Curing |

Ultra-fast curing for UV-sensitive coatings |

• IPC-CC-830B / MIL-I-46058C – Industry standard for conformal coating for electronics

• UL94 V-0 – Flammability classification

• UL746E – Electrical insulation performance

• RoHS / REACH – Environmental compliance

The working environments of different electronic devices vary greatly. Some are exposed to high temperatures and vibrations, while others are exposed to moisture, salt spray or chemical substances. Therefore, it is particularly important to apply PCB conformal coating to the circuit board.

|

Industry |

Why Use PCB Conformal Coating? |

|

Automotive ECU / ADAS |

Heat, vibration, humidity |

|

Aerospace & Defense |

Altitude, chemical exposure |

|

Medical Devices |

Sterile, biocompatible surfaces |

|

LED Lighting |

Outdoor moisture, UV exposure |

|

Industrial Power Systems |

Chemical vapors, dust, heat |

Conformal coating for electronics is no longer optional, but a necessary process to ensure the reliability of circuit boards. Whether it is ordinary consumer electronics or highly demanding aerospace equipment, as long as PCB conformal coating is used reasonably, the circuit board can be effectively protected from moisture, dust, corrosion, chemical pollution, vibration or extreme temperatures.

When using conformal coating, choosing the right conformal coating types, mastering the correct conformal coating process, and operating in accordance with industry standards can significantly enhance the stability of electronic products, reduce malfunctions, and extend their service life at the same time.

Whether it is acrylic conformal coating, silicone conformal coating, or parylene PCB protective coating, each type of PCB coating material has its own advantages and applicable environments. As long as this circuit board coating is considered and correctly applied during the product design and production stages, electronic devices can operate stably in harsher environments and be durable and reliable.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.