Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Fiberglass PCB: A Complete Guide

Fiberglass PCB is the core of our current electronic products and is widely used in PCB manufacturing. With the addition of some new resins and materials, this type of PCB can provide us with higher performance and more cost-effective solutions.

Compared with traditional materials, fiberglass circuit boards can withstand higher temperatures, have excellent moisture-proof performance, and will not easily deform under mechanical stress. They are favored by many people.

It is the foundation of modern electronic devices. Next, we will delve into the composition, characteristics and extensive application scenarios of this type of PCB. Let's get straight to the point!

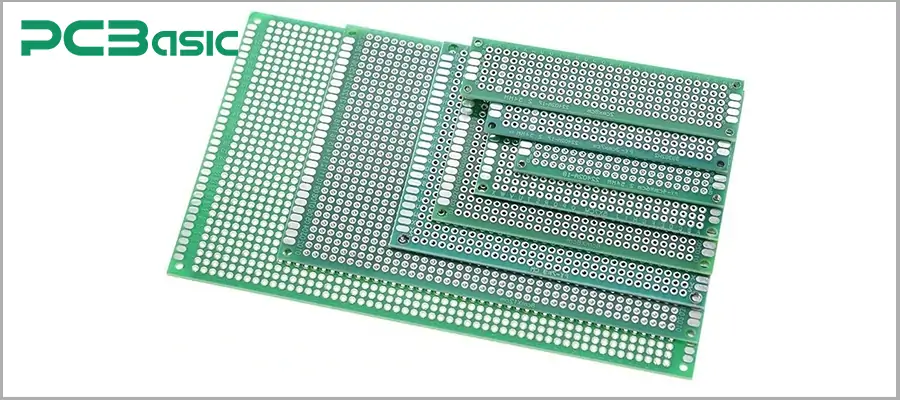

Fiberglass PCB is a type of printed circuit board that uses glass fiber and resin (usually epoxy resin) as the main base material. It is a composite material composed of woven glass fiber and epoxy resin adhesive, commonly referred to as FR4. The circuit board formed by combining these materials not only has electrical conductivity but also possesses excellent capabilities in withstanding high temperatures, resisting mechanical stress, and resisting environmental factors. Thanks to these capabilities, fiberglass PCBs are widely used in various electronic devices. As shown in the following picture, it is a picture of a fiberglass PCB.

Why is the FR4 substrate important?

FR4, which can also be written as FR-4, plays a crucial role in the overall performance of the fiberglass circuit board. The glass circuit board made of fiberglass has the following key advantages:

1. Excellent heat resistance, suitable for high-temperature environments.

2. The woven fiberglasses give the circuit board strength and durability, enabling it to withstand bending and mechanical stress.

3. Excellent insulation performance, which can effectively prevent short circuits and ensure that the current passing through the copper lines is not disturbed.

4. The strong resistance to moisture is of vital importance for preventing corrosion and ensuring the long-term service life of fiberglass PCBs in humid or harsh environments.

5. Compared with other materials (such as ceramics or metals), fiberglass PCBs achieve a good balance between performance and cost.

These advantages of glass fiber PCBs are all inseparable from the fiberglass (FR4) substrate.

As we mentioned earlier, a fiberglass PCB is mainly composed of FR4 fiberglass composite materials. Here, we will introduce several key components of the fiberglass PCB board from its construction.

Weaving fiberglass fabric: It is the core component of fiberglass PCB. The substrate of the circuit board is formed by it. The fiberglasses are tightly woven together to form a mesh structure. It endows the fiberglass circuit board with high tensile strength and durability, enabling the fiberglass circuit board to resist mechanical stresses such as bending, twisting, and warping.

Epoxy resin (flame retardant): It is the adhesive that binds the woven fiberglass cloth together. It provides the necessary insulation and flame-retardant properties for fiberglass PCB materials. Epoxy resin cures under heat and pressure, forming a strong and stable structure, enhancing the circuit board's ability to withstand high temperatures. FR4 is classified as a flame-retardant material because the epoxy resin helps prevent the spread of flames. Epoxy resin provides bonding strength, insulation, and dimensional stability — but FR4 is still a rigid material, not flexible.

Copper-clad FR4: The copper-clad FR4 forms the conductive part of the fiberglass PCB board. Thin copper sheets are adhered to one or both sides of the FR4 fiberglass substrate to create the conductive paths for the circuit. The copper layer is then etched to form the required circuit traces and pads, ensuring electrical connections between electronic components.

Solder mask layer and screen printing layer: These are important components of fiberglass PCB. The solder mask layer is usually green and covers the copper lines to prevent oxidation and soldering bridges during assembly. The screen printing layer is printed on the solder mask layer and is used to indicate component placement, labels, and other auxiliary references to assist in the PCB assembly process.

Routing and through-hole design: In fiberglass PCBs, copper foil on FR4 is etched to form traces, while through-holes are made by drilling and plating copper to create electrical connections. These designs directly affect the electrical performance and reliability of the circuit.

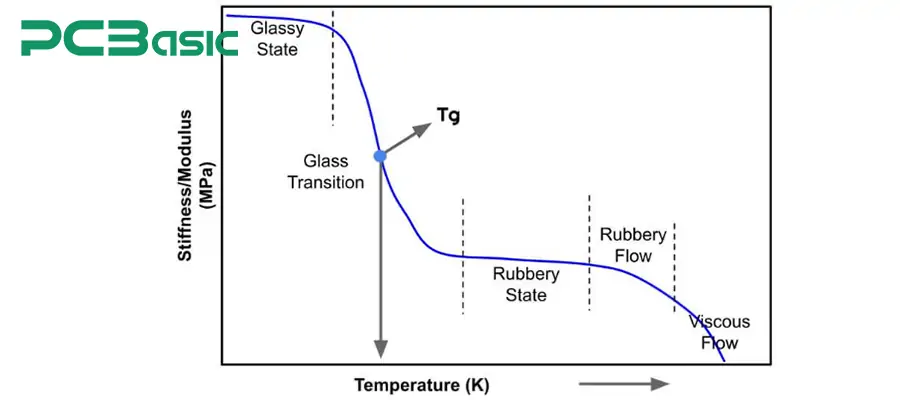

In fiberglass PCBs, there is a crucial performance indicator - the glass transition temperature (Tg).

The glass transition temperature (Tg) refers to the temperature at which fiberglass PCB materials change from a rigid state to a flexible state. This characteristic is of vital importance for the performance and durability of the circuit board.

During the soldering process, the PCB will be exposed to high temperatures. If the Tg is too low, the circuit board may deform, which will affect the assembly process and the quality of the final product.

A higher Tg can ensure that the fiberglass PCB maintains mechanical strength in high-temperature environments, better withstand temperature fluctuations, enhance its resistance to thermal stress, and extend its service life.

There are numerous types of fiberglass PCBs. The table below provides a detailed classification of fiberglass PCBs by number of layers, structure and technology.

|

Aspect |

Type |

Description |

Key Features |

Advantages |

|

By Layer Count |

Single-layer PCB |

Consists of only one copper layer laminated on one side of the fiberglass (FR4) substrate. |

Simple structure, easy to fabricate, low material cost. |

Low cost, quick prototyping, ideal for simple circuits. |

|

Double-layer PCB |

Has copper traces on both top and bottom layers, connected through plated vias. |

Moderate routing density, supports more components. |

Better performance and flexibility than single-layer boards. |

|

|

Multi-layer PCB |

Contains three or more conductive layers separated by dielectric material. |

High density interconnection, optimized signal and power routing. |

Compact size, enhanced EMI performance, supports complex designs. |

|

|

By Structure & Technology |

HDI PCB (High-Density Interconnect) |

Uses microvias, buried and blind vias for denser routing between layers. |

Fine trace width (<0.1 mm), laser-drilled microvias, stacked vias. |

Enables miniaturization, improves signal integrity and speed. |

|

Rigid-Flex PCB |

Combines rigid and flexible layers into a single structure. |

Mixed rigidity with flexible interconnects. |

Compact assembly, reduces connectors and cabling. |

|

|

High-Frequency PCB (RF / Microwave) |

Built with low-Dk materials like Rogers or PTFE. |

Stable dielectric constant, low signal loss. |

Suitable for high-speed signal transmission. |

The main characteristics of fiberglass PCBs are reflected in aspects such as electrical performance, mechanical strength, heat resistance, and long-term reliability. Below, these features will be introduced.

1. Electrical performance

Low signal loss and high stability. A fiberglass circuit board has excellent insulation properties and low dielectric loss. Copper-clad FR4 can better control impedance and reduce electromagnetic interference (EMI), and is very suitable for multi-layer wiring and precise signal control.

2. Mechanical and physical strength

Fiberglass PCBs exhibit excellent mechanical stability, which is mainly reflected in the following aspects:

High tensile/bending strength, with little risk of cracking or breaking;

Good resistance to vibration and impact;

High dimensional stability during processing and soldering, and less prone to deformation.

3. Heat resistance and chemical resistance

The glass transition temperature (Tg) of fiberglass PCBs is typically between 130–180 ℃. They are not prone to warping or delamination at high temperatures. Therefore, they can operate stably in SMT reflow soldering, wave soldering, or high-power equipment. Additionally, glass circuit boards have excellent moisture resistance and resistance to acids, alkalis, and solvents.

4. Flame retardant property

In FR-4, the "FR" also indicates flame retardancy, and the "4" is not a flame retardancy "grade", but rather NEMA's grade/identifier for the material system of "fiberglass reinforced epoxy resin copper clad laminate". PCB fiberglass can be formulated to achieve UL 94 V-0 flame retardancy grade (it can extinguish itself after being removed from the fire source).

5. High Tg level

Copper-clad FR4 can be selected with different Tg grades based on the application:

|

Type |

Tg Range |

Common Applications |

|

Standard FR4 |

130–140 °C |

Home appliances, toys, general control boards |

|

High-Tg FR4 |

150–170 °C |

Automotive electronics, industrial power supplies, communication boards |

|

Ultra High-Tg FR4 |

≥180 °C |

Aerospace, high-frequency or high-power electronic devices |

High Tg materials can reduce warping, delamination and reliability degradation in scenarios involving multiple reflows, long-term high temperatures or power heating.

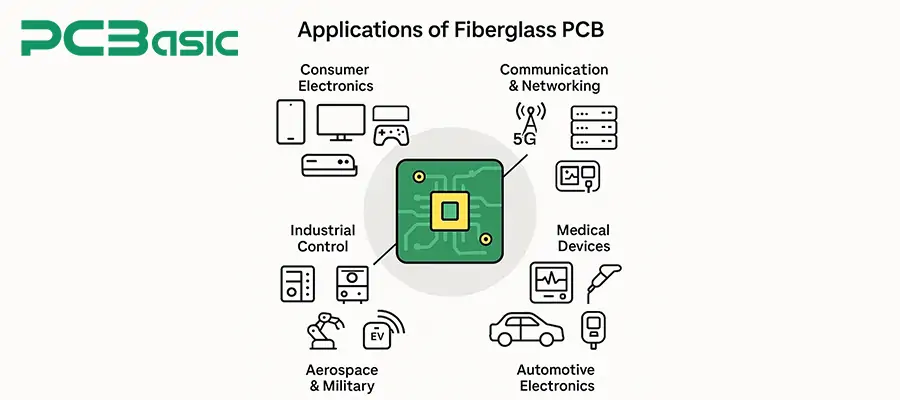

The various advantages and characteristics of fiberglass PCBs make them the most widely used type of circuit board at present. They are widely applied. Below, we will mainly introduce their applications in several fields.

1. Consumer Electronics

In various consumer electronics, fiberglass PCB boards are widely adopted due to their moderate cost, stable performance, and suitability for mass production.

Common products include:

Mobile phone mainboards, camera modules

Notebook mainboards, graphics cards, power boards

Smart TVs, audio systems, game consoles

Chargers, power adapters, toys, etc.

2. Communication and Network Equipment

FR4 fiberglass boards or structures made by pressing with high-frequency materials (such as FR4 + Rogers) are often used in communication devices with high requirements for signal integrity.

Application scenarios include:

Router, optical network terminal (ONT), optical network unit (ONU), switch mainboard

4G/5G base station control board, communication power supply module

Server mainboard, network processor board card

Small RF module

3. Industrial Control and Automation

Fiberglass circuit boards have excellent heat resistance, corrosion resistance and reliability, and are often used in industrial equipment with complex application environments.

Common applications:

PLC controllers, motor drivers, frequency converters

Robot boards, industrial sensors

Servo systems, smart meters, energy monitoring systems, etc.

4. Automotive Electronics

High-Tg fiberglass PCBs that can withstand high temperatures and mechanical shocks are standard equipment in modern automobiles, which contain numerous ECU control units.

Common applications include:

Engine control board, transmission control unit

Headlight control module, LED headlight driver board

Radar, ADAS system, parking assistance module

Electric vehicle charging system, battery management system (BMS), etc.

5. Medical Equipment

The medical field has strict requirements for reliability and insulation performance. Glass PCB is widely used due to its stability and low water absorption rate.

Common products:

Electrocardiogram (ECG/EKG) monitoring board

Blood glucose meters, portable testing equipment

Ultrasound probe electronic module

Infusion pumps, defibrillator control circuits, etc.

6. Aerospace and Military Equipment

Although radar or high-frequency systems often use ceramics or PTFE plates, reinforced fiberglass PCBs are still widely used in control systems and data processing units.

Common application fields:

UAV navigation board

Satellite communication power supply and control module

Military radio equipment, radar interface board

Flight recorder, onboard computing system

Fiberglass PCBs, especially those with FR4 as the base material, are the mainstream types of PCBs in electronic manufacturing. They not only ensure excellent insulation, mechanical strength and heat resistance, but also take into account cost and processing efficiency. It can be said that fiberglass PCB is the basic carrier of most electronic products and is also the most mature, most commonly used and most representative material system in the PCB industry.

Time is money in your projects – and PCBasic gets it. PCBasic is the pcb assembly company that delivers fast, flawless results every time. Our comprehensive PCB Assembly Services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB Assembly Manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB Prototype Factory for quick turnarounds and superior results you can trust.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.