Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Watts-to-Amps Conversion Guide: How to Calculate Electrical Current Easily

If a beginner understands how to convert watts to amps, he can easily follow the basic principles of electric current flow in circuits. This conversion is important for safety, to select equipment, and power management. Therefore, you need voltage values to execute accurate calculations between power and current measurements.

A watt is the SI unit of power. It measures electrical power. For example, it shows how much energy a device uses per second. Light bulbs, motors, and heaters all consume watts. Higher wattage will lead to more power consumption. For example, a 100-watt lightbulb uses 100 watts of power every second.

An amp measures electrical current. It shows how much electrical charge flows through a conductor per second. Circuit breakers, fuses, and wire ratings use amperage specifications. You know, understanding amps prevents electrical hazards and equipment damage.

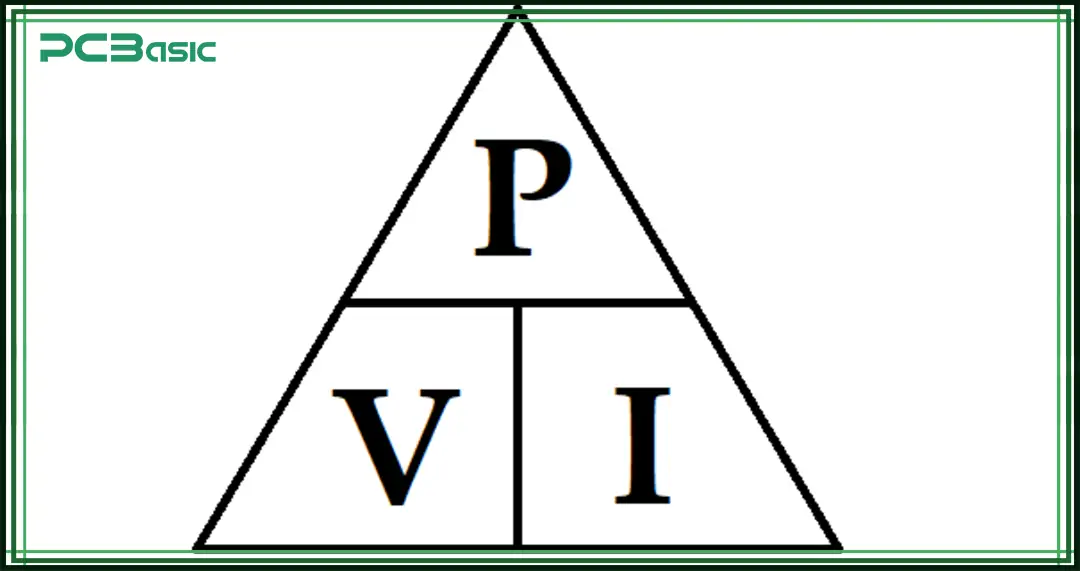

Watts and amps connect through Ohm's Law. Power equals voltage times current (P = V × I). Voltage is the main power that pushes current through circuits. So, without knowing the voltage, you cannot convert between watts and amps accurately.

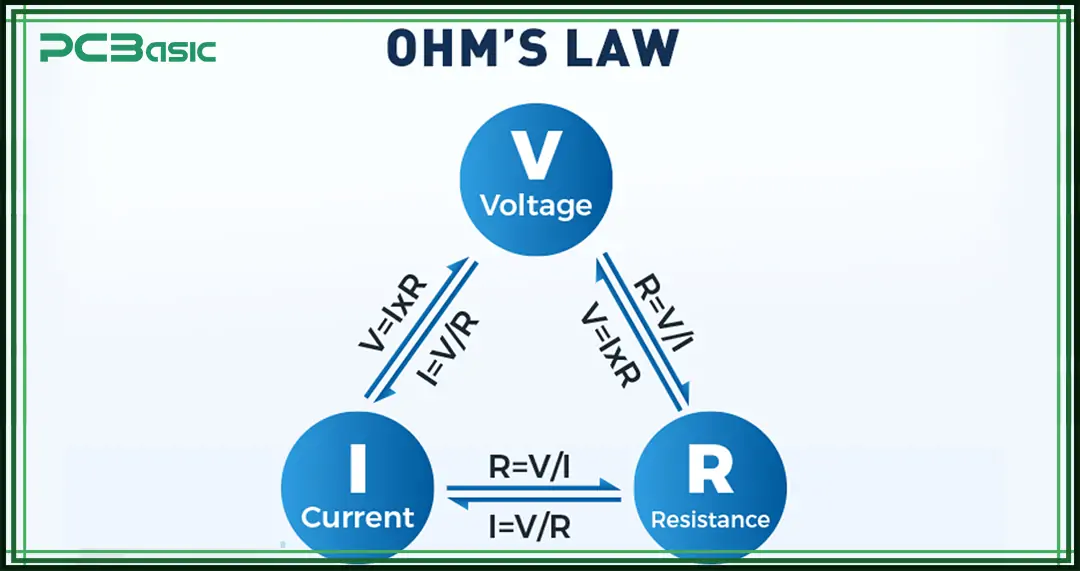

Ohm's Law forms the foundation of electrical calculations. It shows the relationship between:

1. Voltage

2. Current

3. Resistance.

Power equations are built on these basic points. The purpose is to help solve real-world electrical problems.

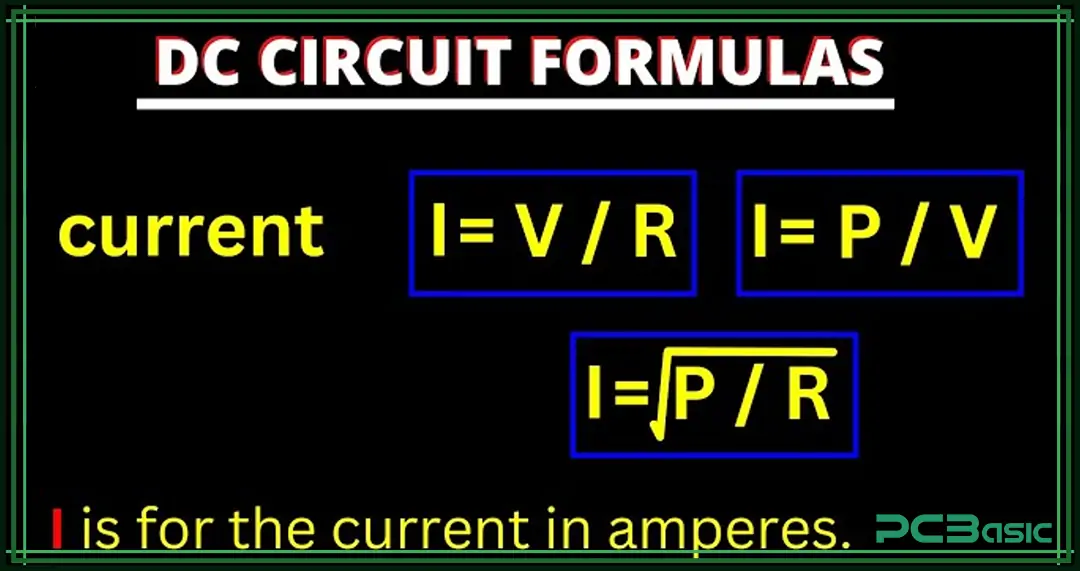

For DC circuits, use this simple formula: Amps = Watts ÷ Volts

DC circuits have constant voltage and current flow. Batteries, LED strips, and automotive systems use DC power. The calculation stays straightforward because the voltage remains steady.

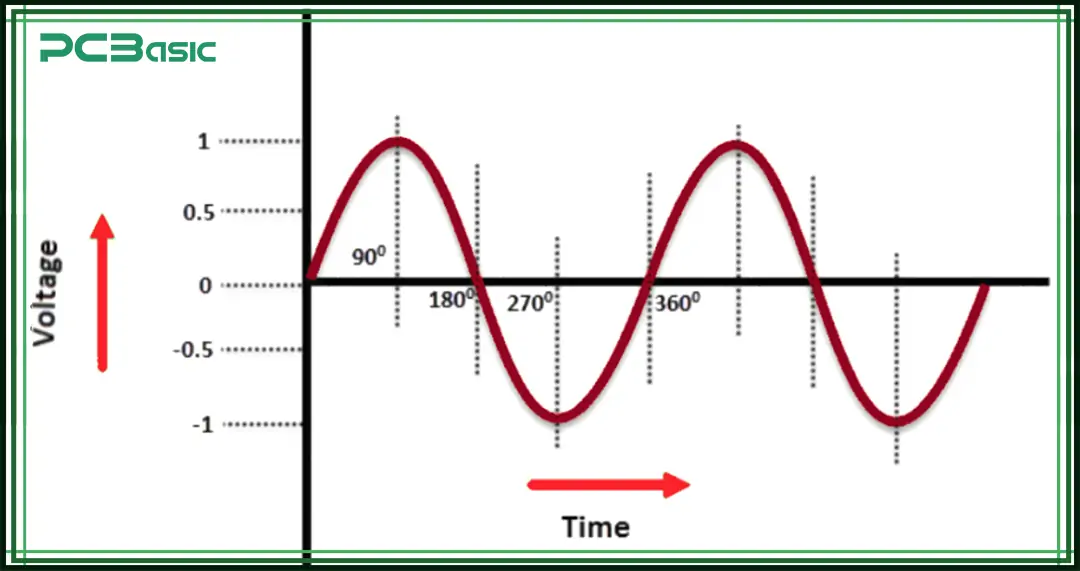

Single-phase AC circuits use this formula: Amps = Watts ÷ (Volts × Power Factor)

Most household appliances run on single-phase AC power. The power factor accounts for the phase difference between voltage and current. For resistive loads like heaters, the power factor equals 1.0.

Three-phase systems use this calculation: Amps = Watts ÷ (√3 × Volts × Power Factor)

Industrial equipment and large motors use three-phase power. The √3 factor accounts for the three-phase configuration. This system delivers power more efficiently than single-phase.

Online calculators simplify the conversion process. Here's how to use them effectively

1. Select your circuit type

2. Enter the power rating in watts

3. Input the voltage value

4. Add the power factor if needed

5. Click Calculate to get your current result

The calculator handles the math automatically. It prevents calculation errors and saves time. Most tools show step-by-step solutions to help you understand the process.

A 12V LED strip consumes 60 watts of power. Calculation: 60W ÷ 12V = 5 amps

This LED strip draws 5 amps of current. You need a 12V power supply rated for at least 5 amps to run this strip safely.

A 120V microwave uses 1200 watts (assuming power factor = 1). Calculation: 1200W ÷ 120V = 10 amps.

This microwave draws 10 amps from your household circuit. A 15-amp circuit breaker can handle this load with some margin for safety.

A 480V three-phase motor consumes 7500 watts with a 0.85 power factor.

Calculation 7500W ÷ (1.732 × 480V × 0.85) = 10.6 amps

This industrial motor draws 10.6 amps per phase. PCB engineers know this type of calculation helps size electrical components properly.

|

Watts |

12V DC (Amps) |

120V AC (Amps) |

240V AC (Amps) |

|

100 |

8.3 |

0.8 |

0.4 |

|

500 |

41.7 |

4.2 |

2.1 |

|

1000 |

83.3 |

8.3 |

4.2 |

|

1500 |

125.0 |

12.5 |

6.3 |

|

2000 |

166.7 |

16.7 |

8.3 |

Sometimes, you need to convert amps to watts. The process reverses the original formula:

For DC circuits: Watts = Amps × Volts

For AC single-phase: Watts = Amps × Volts × Power Factor

For AC three-phase: Watts = Amps × √3 × Volts × Power Factor

This point is noticeable when sizing electrical systems. You might know the current capacity but need to determine power consumption limits.

About PCBasic

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Electricians use these calculations to size circuit breakers and wire gauges. They ensure circuits can handle the expected current load without overheating or tripping.

Solar installers calculate current flow through DC wiring. The size of fuses, breakers, and conductors are based on panel wattage ratings and system voltage.

Printed circuit board companies need current calculations for trace width design. Higher current requires wider copper traces to prevent overheating and voltage drops.

Homeowners check if their electrical panels can support new appliances. They compare appliance wattage against available circuit capacity.

You cannot convert watts directly to amps without knowing the voltage. This creates the most frequent calculation error. Always identify system voltage first.

AC circuits often have power factors less than 1.0. Motors, transformers, and electronic devices introduce reactive power. Using 1.0 as the power factor gives inaccurate results.

DC and AC circuits use different formulas. Using the wrong formula leads to incorrect amperage calculations. Check your circuit type before starting calculations.

Electrical systems need safety margins above calculated values. Size breakers and wires 25% above calculated current for safety and code compliance.

Line-to-line and line-to-neutral voltages differ in three-phase systems. Using incorrect voltage values throws off your entire calculation.

RapidTables offers simple watts-to-amps conversion tools. The interface stays clean and provides instant results for basic calculations.

Omni Calculator includes multiple electrical conversion tools. It handles complex three-phase calculations and shows detailed working steps.

Electrical Safety First provides safety-focused calculators. These tools emphasize proper electrical practices and code compliance.

Bosstab offers comprehensive electrical calculators for professionals. The platform includes advanced features for complex industrial applications.

A1SolarStore specializes in solar system calculations. It helps size DC components for photovoltaic installations.

Several smartphone apps provide instant electrical conversions. Look for apps that include multiple circuit types and power factor adjustments. These tools help field technicians make quick calculations on job sites.

PCB manufacturers use specialized software for electrical design. These programs integrate current calculations with thermal analysis and component selection.

Wire resistance increases with temperature. This affects voltage drop calculations and actual current flow. Hot environments require larger wire sizes to maintain performance.

AC frequency affects reactive components like motors and transformers. 50Hz and 60Hz systems have different characteristics that impact power factor calculations.

Modern electronic devices create harmonic currents. These harmonics increase the effective current above simple calculation results. Consider harmonic effects in sensitive applications.

Electrical codes require specific safety factors for current calculations. The National Electrical Code (NEC) mandates minimum wire sizes and protection ratings. Local codes may have additional requirements.

Why does it matter? Safety protects people and property from electrical hazards. Proper calculations prevent fires, equipment damage, and personal injury.

Electric vehicles need accurate, current calculations for battery management systems. Engineers design charging infrastructure using watts to amps formulas. Battery packs require precise current monitoring to prevent overheating. Motor controllers convert DC power efficiently. Charging stations must handle high amperage safely. Vehicle wiring harnesses need proper sizing for different power levels.

Boat electrical systems run on 12V or 24V DC power exclusively. Marine electricians calculate current loads for battery bank sizing. Alternators must produce enough amperage for all onboard equipment. Navigation lights, pumps, and radios draw specific current amounts. Saltwater environments demand robust electrical connections. A proper wire gauge prevents voltage drops in long cable runs.

Factory equipment uses high-power three-phase motors for production lines. Maintenance teams monitor current draw to predict equipment failures. Variable frequency drives control motor amperage precisely. Power distribution panels require accurate load calculations. Electrical inspections check actual versus rated current consumption. Preventive maintenance schedules depend on current measurement data collected over time.

How to Convert Watts to Amperes? Converting watts to amps assumes that you know the voltage in the circuit in which the electrical appliances being mentioned are connected. Some online calculators speed up the process, but understanding what’s going on helps avoid mistakes. In general, electrical safety is related to correct current computations. Good customers care about the results when it comes to sizing electrical systems correctly. Learn these conversion methods, and you’ll be comfortable tackling any electrical project.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.