Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > > Turnkey Manufacturing Services: End-to-End Production

In today's highly competitive manufacturing environment with a highly globalized supply chain, companies are commonly confronted with several practical challenges: rising costs, tighter delivery schedules, and increasingly stricter quality requirements. Meanwhile, the manufacturing process often involves multiple suppliers and production stages, and it is also necessary to coordinate complex logistics and follow up on production progress in different regions. This multi-party collaboration model is inherently complex in process and can easily lead to poor communication and even increase project risk. Therefore, more and more companies have begun to reassess their manufacturing methods and the overall path of their products from design to market.

It is precisely against this backdrop that turnkey manufacturing services have gradually become the preferred choice for many businesses. In this article, we will focus on clarifying what a turnkey is, the actual turnkey definition, and how turnkey manufacturing operates, as well as why more and more companies are beginning to choose turnkey manufacturing solutions instead of continuing to follow the traditional manufacturing model.

To understand turnkey manufacturing services, first of all, we need to clarify the turnkey definition. In the manufacturing context, "turnkey" refers to a delivery model where the supplier completes all production work. When the customer receives products, they no longer need to be involved in any manufacturing or implementation process, and the product can be put into use directly.

In manufacturing applications, what is turnkey?

Turnkey manufacturing is a production model in which a single turnkey manufacturer is responsible for the entire manufacturing process. This process typically covers engineering support, material sourcing, fabrication, assembly, testing, packaging, and the final delivery of a finished turnkey product.

Unlike the outsourcing model that only undertakes some production stages, turnkey contract manufacturing offers an integrated manufacturing approach. When cooperating with turnkey manufacturing companies, customers do not need to manage multiple suppliers by themselves or coordinate complex supply chain systems. Instead, a turnkey solution that meets their technical requirements and project goals is obtained through a single responsible party.

A mature turnkey manufacturing solution is usually executed in accordance with a clear and well-defined process. Although there may be differences in details among different products and industries, most turnkey manufacturing services basically follow the outline below.

At the beginning stage of the project, turnkey manufacturing companies usually review the design files, technical specifications and performance requirements first.

After the design is confirmed, the turnkey manufacturer usually makes prototypes or conducts low-volume pilot builds. The main purpose of this stage is to conduct functional testing, performance verifications, and make necessary adjustments to design details.

One of the major features of turnkey manufacturing services is that the same party is uniformly responsible for sourcing and supply chain management. The turnkey supplier is responsible for component selection, supplier evaluation and logistics arrangement, forming a centrally managed turnkey supply chain.

In the turnkey manufacturing process, production execution is the core part. According to the project requirements, this stage may include turnkey fabrication, turnkey assembly, and final system or product integration.

Quality control runs through the entire production process, rather than merely being inspected before shipment. Established turnkey manufacturing companies will conduct inspections during the incoming materials, production process and final testing stages to ensure the consistency and reliability of the products in all production stages.

The last stage of turnkey manufacturing services is the packaging, shipping and delivery of the products. The packaging method, labeling requirements and transportation plan are usually determined based on the actual needs of the customer and the target market.

When these activities are uniformly handled by the turnkey manufacturer, customers no longer need to coordinate logistics and transportation matters separately. They only need to receive the final delivered turnkey product solution as planned.

Different industries choose turnkey manufacturing services primarily because this model can simplify manufacturing management and provide greater control over cost, schedule, and quality.

The core advantage of turnkey contract manufacturing is the concentration of responsibility. Companies do not need to deal with multiple suppliers separately. Instead, they directly cooperate with a turnkey supplier, who is uniformly responsible for the entire manufacturing process, which is conducive to quickly identifying problems and clarifying responsibilities.

Since design, sourcing and production are coordinated and advanced by the same system, turnkey manufacturing solutions can shorten the overall development cycle.

Turnkey manufacturing focuses on the overall cost rather than just the price of individual pieces. By reducing rework, lowering inventory pressure and simplifying project management, companies can often achieve more stable and sustainable cost control in their long-term operation.

With unified processes and centralized responsibilities, turnkey manufacturing services can maintain the consistency of product quality. The turnkey manufacturer is responsible for uniformly implementing quality standards and testing procedures, thereby reducing variation between production batches.

By adopting a full turnkey solution for production outsourcing, enterprises can invest more resources in product research and development, marketing and customer-related work. This way of focusing on core businesses is one of the important factors driving the continuous development of turnkey manufacturing companies.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Understanding the differences between turnkey manufacturing services and other manufacturing models helps enterprises choose manufacturing methods that are more suitable for their own business needs.

Contract manufacturing is a common outsourcing manufacturing model. Under the contract manufacturing model, manufacturers are typically responsible only for production execution, such as fabrication, assembly or testing. The customer is required to provide complete design files, bill of materials (BOM) and production requirements, and be responsible for the sourcing of key materials and logistics coordination at the same time.

Toll manufacturing is a manufacturing model mainly based on processing services. In this model, the customer owns and provides raw materials or semi-finished products, while the manufacturer is only responsible for the designated processing or production steps.

|

Comparison Dimension |

Turnkey Manufacturing |

Contract Manufacturing |

Toll Manufacturing |

|

Scope of Responsibility |

The manufacturer is responsible for the complete process, from design support and sourcing to production and delivery |

Manufacturer is mainly responsible for production execution |

Manufacturer is responsible only for specified processing steps |

|

Product Design |

Manufacturer may participate in or support design optimization |

Led and provided by the customer |

Fully handled by the customer |

|

Material Sourcing |

Managed centrally by the manufacturer |

Customer is responsible for sourcing key materials |

Customer provides all raw materials or semi-finished goods |

|

Supply Chain Management |

Managed entirely by the manufacturer |

Coordinated by the customer across multiple parties |

Managed by the customer for materials and delivery |

|

Production Execution |

Fully executed by the manufacturer |

Manufacturer executes specified production tasks |

Manufacturer executes specified processing operations |

|

Quality Responsibility |

Manufacturer assumes overall quality responsibility |

Quality responsibility is relatively distributed |

Quality responsibility primarily lies with the customer |

|

Customer Involvement Level |

Low |

Medium |

High |

|

Communication Complexity |

Low (single point of contact) |

Medium (coordination across multiple parties) |

High (material and schedule depend heavily on the customer) |

|

Cost Control Focus |

Focus on total cost (Total Cost of Ownership) |

Focus mainly on production cost |

Focus mainly on processing fees |

|

Best Suited For |

Companies seeking simplified management and reduced risk |

Companies with engineering and supply chain capabilities |

Companies requiring strong control over materials and processes |

|

Key Advantages |

Simplified management, centralized responsibility, clear processes |

High control and flexibility |

Low upfront involvement, clear process scope |

|

Main Challenges |

High dependence on the manufacturer |

Higher management and coordination effort |

High requirements on the customer’s supply chain readiness |

Due to the complexity of the manufacturing process, strict regulatory requirements or the involvement of specialized techniques, many industries highly rely on turnkey manufacturing solutions, mainly including:

• Medical devices

• Aerospace and defense

• Life sciences

• Semiconductor and high-tech equipment

Among these industries, turnkey manufacturing companies can provide the necessary infrastructure, certification systems and professional capabilities to ensure the delivery of compliant, stable and reliable turnkey products.

Selecting the right turnkey manufacturer is critical. Companies should evaluate potential partners based on:

• Engineering and turnkey product development capabilities

• Supply chain robustness and transparency

• Ability to scale from prototype to volume turnkey production

• Quality systems and process control

• Communication and project management approach

A strong turnkey contract should clearly define responsibilities, quality expectations, and delivery milestones.

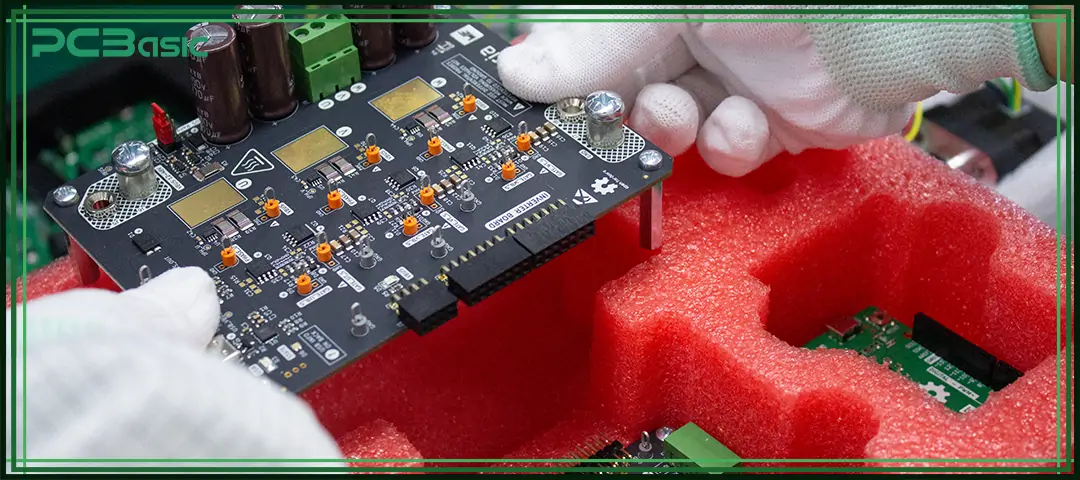

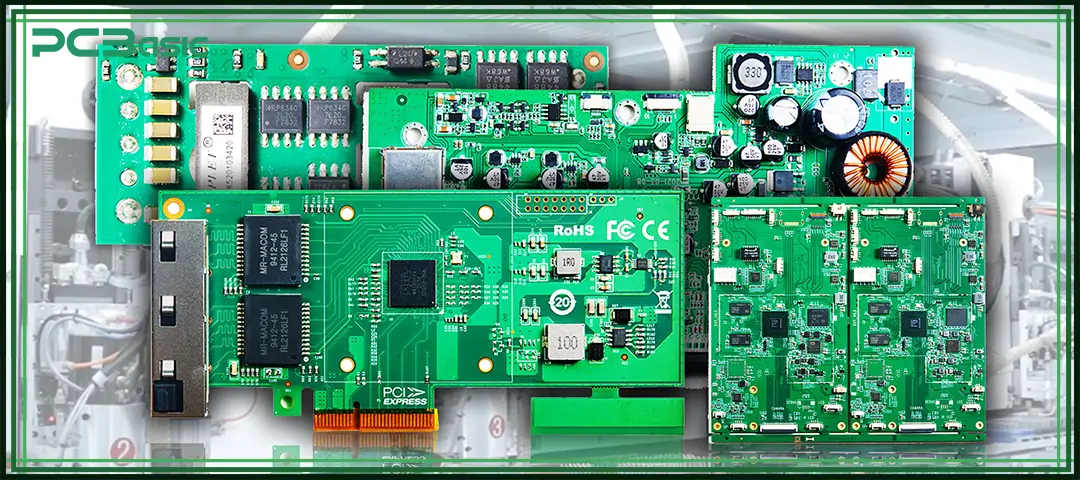

PCBasic offers professional turnkey manufacturing services, with a focus on electronic products and PCBA projects. As an experienced turnkey manufacturer, PCBasic provides turnkey manufacturing solutions covering the entire product life cycle, including design review, component sourcing, turnkey assembly, testing and global delivery.

Relying on the engineering-oriented execution system and the mature and stable turnkey supply chain, PCBasic can support customers to smoothly advance from early turnkey product development to scalable turnkey production. This end-to-end integrated model helps achieve stable product quality, reduce project risks and accelerate the time to market for complex electronic product projects.

With the manufacturing process becoming increasingly complex and market competition intensifying, turnkey manufacturing services offer companies a clear path to achieve high efficiency, clear responsibility and scalability. By integrating engineering support, sourcing, production and logistics into a turnkey solution, enterprises can effectively reduce operational burdens and invest more resources in business growth.

Whether compared with the traditional outsourcing model or with toll manufacturing, turnkey manufacturing demonstrates its advantages as a strategic manufacturing approach, which is capable of stably delivering high-quality turnkey products. After choosing the appropriate turnkey supplier, manufacturing will no longer be a limiting factor for business development, but will become an important driving force for enterprise success.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.