Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Types of Capacitors – A Complete Guide

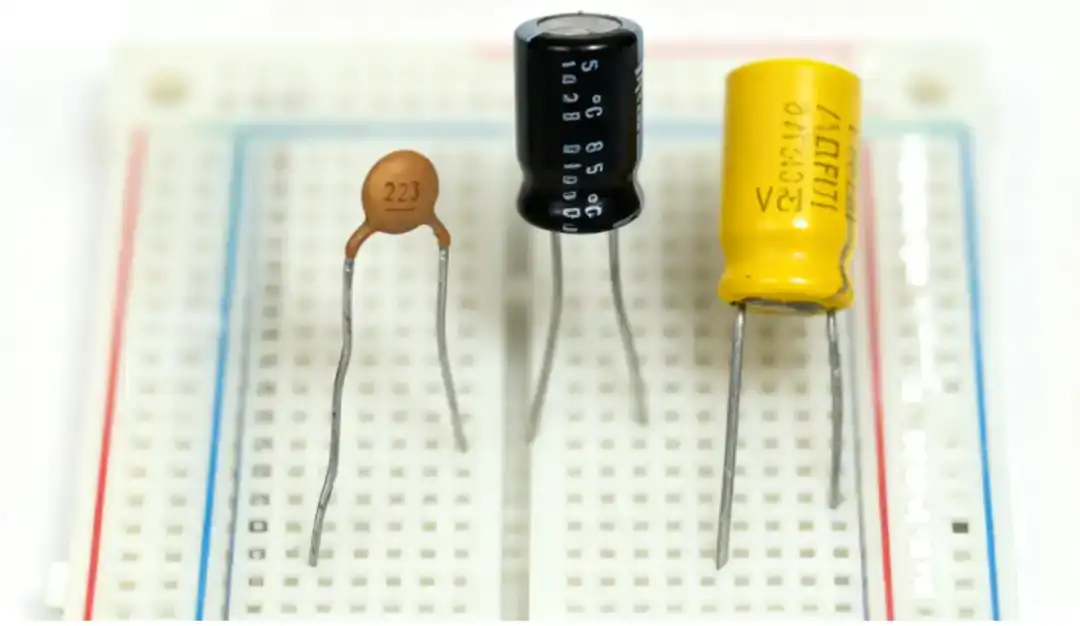

Capacitors are one of the most important basic components in modern electronics. From smartphones and laptops to industrial automation systems and renewable energy equipment, you can almost always find capacitors at the core of the design. To use electronic circuits efficiently, it is necessary to understand various types of capacitors and their roles in different applications.

Different types of capacitors make their applications very versatile. Common different types of capacitors can be classified based on dielectric material, polarity, structure and application. Each of these capacitor types has its own advantages and disadvantages, which determine in what circuits they are suitable for use.

This article will systematically introduce various types of capacitors - including their structures, characteristics, applications and manufacturing processes. After reading this, you will have a clearer understanding of the classification methods and selection approaches of different types of capacitors, and be able to better choose the appropriate capacitor types in electronic design.

The capacitor is one of the most important passive components in electronics. Essentially, a capacitor is an electronic device capable of storing and releasing energy in an electric field. It is made of two conductive plates, with an insulating material called the dielectric in between. When voltage is applied to the two plates, positive and negative charges accumulate respectively, enabling the capacitor to temporarily store energy. This fundamental principle is the same in all types of capacitors.

The definition formula of capacitance (C) is:

Where:

• Q = electric charge (in coulombs)

• V = applied voltage (in volts)

• C = capacitance (in farads)

The actual value of capacitance depends on the capacitor types - specifically related to the area of the plates, the distance between the plates, and the dielectric constant of the material. This is also why different types of capacitors exhibit different performance characteristics.

The standard symbol for a capacitor is represented as: two parallel lines represent non-polarized capacitors, while a straight line plus a curved line represents polarized capacitors. Being able to identify the symbol for capacitors and distinguish different types of capacitors is a basic skill for engineers, technicians and electronics enthusiasts.

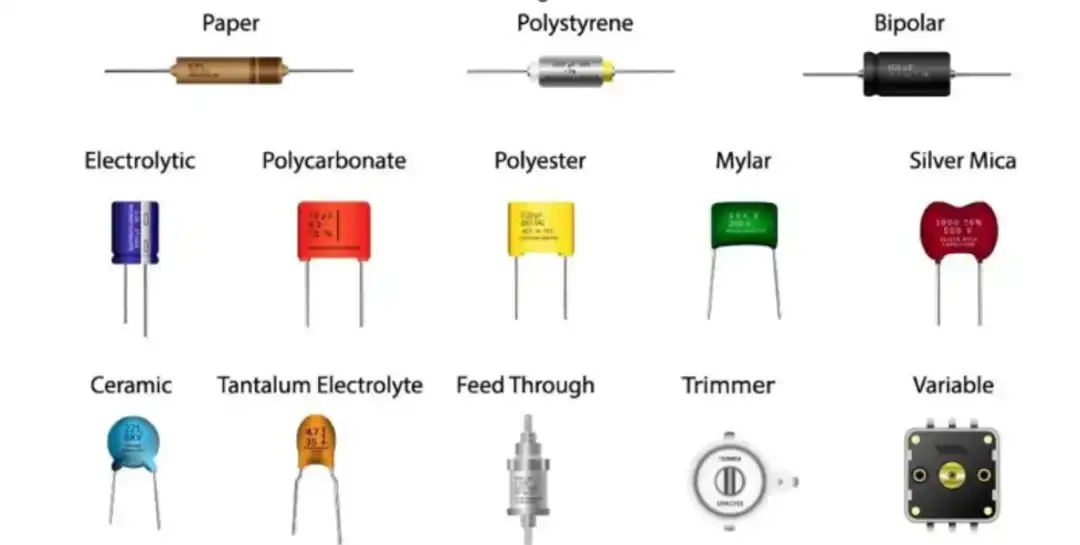

Capacitors may look similar on the surface, but in fact, they are not the same. To better understand the various types of capacitors, engineers and designers usually classify them based on several important criteria: polarity, adjustability and dielectric material. In this way, we can more conveniently compare different types of capacitors and select the appropriate capacitor types in the circuit.

Capacitor Classification Table

|

Classification |

Subcategory |

Description |

Common Examples / Applications |

|

By Polarity |

Polarized Capacitors |

Have positive and negative terminals, must be connected in the correct orientation, mainly for DC circuits |

Electrolytic capacitors, tantalum capacitors, polymer capacitors |

|

Non-polarized Capacitors |

No polarity restrictions, can be used in AC circuits, widely used for filtering, coupling, and decoupling |

Ceramic capacitors, film capacitors, mica capacitors, glass capacitors |

|

|

By Adjustability |

Fixed Capacitors |

Most common capacitor types, provide constant capacitance, reliable and easy to use |

All standard fixed capacitors in electronic circuits |

|

Variable Capacitors |

Allow manual or electronic adjustment of capacitance, used for precise tuning and calibration |

Tuning capacitors (radios, RF), trimmer capacitors (circuit calibration) |

|

|

By Dielectric Material |

Ceramic Capacitors |

Compact, low cost, excellent for high-frequency |

High-frequency circuits, filtering, decoupling |

|

Film Capacitors |

Stable, long lifespan, good temperature characteristics |

Audio circuits, timing, power factor correction |

|

|

Electrolytic Capacitors |

Very high capacitance, used in power supplies |

Power supply filtering, energy storage |

|

|

Tantalum Capacitors |

Small size, high capacitance density, highly reliable |

Medical devices, portable electronics |

|

|

Polymer Capacitors |

Low ESR, high ripple current capability |

Motherboards, telecom, computing |

|

|

Mica Capacitors |

Extremely stable, highly accurate |

RF circuits, precision tuning |

|

|

Paper Capacitors |

Older technology, moisture-sensitive |

Vintage equipment, old circuits |

|

|

Glass Capacitors |

High stability, heat resistant, durable |

Military, aerospace, harsh environments |

|

|

Air Capacitors |

Mostly variable, simple structure |

Radio tuning, antenna matching |

|

|

Supercapacitors (Ultracapacitors) |

Very high capacitance, bridge between capacitors and batteries |

Backup power, energy recovery, regenerative braking |

There are various types of capacitors, and different types of capacitors differ in structure, performance and application. To make a more intuitive comparison and understanding, the following table summarizes the key features and typical applications of the main capacitor types, facilitating engineers and electronics enthusiasts to quickly select the appropriate components.

|

Capacitor Type |

Polarity |

Capacitance Range |

Key Features |

Cost / Size |

Typical Applications |

|

Ceramic Capacitors |

Non-polarized |

1 pF ~ several µF |

Excellent high-frequency performance, low ESR; Class 1 (stable, low loss), Class 2 (higher density, less accurate) |

Very small, low cost |

PCB decoupling, RF circuits, motor noise suppression, power supply filtering |

|

Film Capacitors |

Non-polarized |

nF ~ hundreds of µF |

High stability and accuracy, long lifespan, self-healing |

Larger than ceramics, more expensive |

EMI suppression, hi-fi audio, power factor correction, high-voltage filtering |

|

Electrolytic Capacitors |

Polarized |

µF ~ thousands of µF |

Very high capacitance, higher ESR, limited lifespan (electrolyte evaporation) |

Medium size, low price |

Power supply smoothing, DC blocking/coupling, audio amplifiers, ripple filtering |

|

Tantalum Capacitors |

Polarized |

µF ~ hundreds of µF |

High capacitance density, stable and reliable, short-circuit risk |

Very small, expensive |

Mobile devices, laptops, medical electronics, timing circuits |

|

Polymer Capacitors |

Polarized |

µF ~ hundreds of µF |

Very low ESR, high ripple current capability, long lifespan |

Higher cost, limited voltage |

Motherboards, graphic cards, SSDs, telecom, high-performance DC/DC converters |

|

Supercapacitors (Ultracapacitors) |

Polarized |

mF ~ thousands of F |

Extremely high capacitance, rapid charge/discharge, high leakage current |

Large size, low voltage rating |

Backup power, regenerative braking, renewable energy storage, embedded systems |

|

Mica Capacitors |

Non-polarized |

pF ~ hundreds of pF |

Very precise, highly stable, very low dielectric loss |

Large size, expensive |

RF circuits, resonators, oscillators, precision timing |

|

Paper Capacitors |

Non-polarized |

nF ~ µF |

Outdated technology, moisture-sensitive |

Low cost, mostly obsolete |

Vintage audio, legacy high-voltage circuits |

|

Glass Capacitors |

Non-polarized |

pF ~ nF |

Extremely stable, heat resistant, very reliable |

Very large, very expensive |

Aerospace, RF amplifiers, microwave circuits |

|

Air Capacitors |

Non-polarized |

pF ~ hundreds of pF |

Simple structure, mostly variable |

Small capacitance, bulky |

Radio tuning, antenna matching, RF oscillators |

|

Variable Capacitors |

Non-polarized |

pF ~ hundreds of pF |

Adjustable capacitance (tuning and trimmer types) |

Generally larger |

Radio tuning, calibration, and precision adjustment |

The manufacturing method of capacitors has a direct impact on their performance, reliability and cost. Different types of capacitors adopt different production processes, so their characteristics and application scenarios can also vary greatly.

Usually, aluminum foil is etched first to increase its surface area, and then a thin oxide film is formed on the surface of the aluminum foil through anodic oxidation. This oxide layer is the dielectric of the capacitor.

Next, wind the aluminum foil together with separator paper and then inject the electrolyte.

Afterwards, the wound components are placed in a metal can for encapsulation and undergo aging treatment. This can repair minor defects and stabilize electrical performance.

During production, ceramic powder (such as barium titanate) is first mixed with a binder to form a ceramic slurry, and then a metal electrode layer is printed or superimposed on its surface.

Then, these layers are repeatedly stacked and pressed into sheets, cut into small pieces, and then subjected to high-temperature sintering (firing) and firing treatment to firmly bond the ceramic and metal.

Finally, plating is carried out at both ends of the capacitor to form the lead-out terminals, thereby obtaining the multilayer ceramic capacitor (MLCC) that we commonly see.

Using plastic films (such as polyester or polypropylene) as dielectric, metallization treatment is first carried out on the films or they are laminated with metal foils, and then they are wound into shape.

The wound components will be pressed, heated and set, and then encapsulated with resin on the outer layer. This not only isolates the influence of the external environment but also significantly enhances the lifespan and reliability of the capacitor.

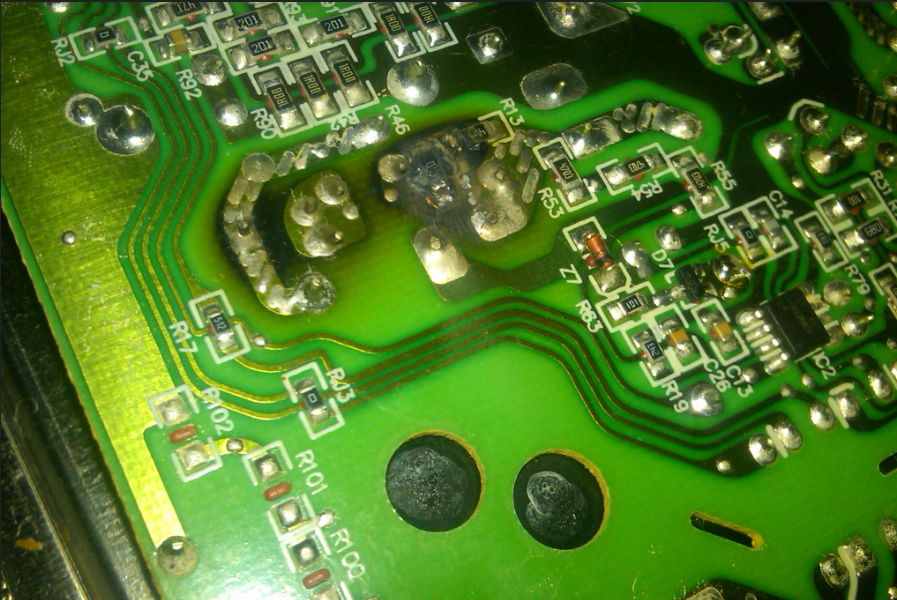

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

When choosing among the many types of capacitors, consider:

• Capacitance value (pF, nF, µF, F)

• Voltage rating (must exceed operating voltage)

• ESR and frequency response

• Tolerance (precision requirements)

• Size and cost

• Application (filtering, timing, decoupling, energy storage)

Capacitors are present in almost all electronic devices, whether it is the smallest ceramic capacitor chip or the large supercapacitor module; different types of capacitors all play a role in achieving energy storage, signal regulation and circuit stability.

By understanding the characteristics, manufacturing processes and applications of various types of capacitors, we can make more appropriate choices, thereby ensuring the performance and reliability of the circuit.

With the development of nanomaterials and improved dielectrics, future capacitor types will continue to expand, driving new innovations in fields such as electronics, automobiles, and energy.

Q1. Which type of capacitor has the highest capacitance?

Electrolytic capacitors and supercapacitors offer the highest capacitance values. Supercapacitors can reach thousands of farads but have low voltage ratings.

Q2. Which capacitors last the longest?

Film capacitors generally have the longest lifespan due to their stable dielectric and low leakage current. Ceramic capacitors (MLCCs) also offer long service life in most applications.

Q3. Can I replace an electrolytic capacitor with a ceramic capacitor?

Not always. Electrolytic capacitors are chosen for their high capacitance values, while ceramics are typically smaller in capacitance. Substitution depends on the circuit requirements.

Q4. What are supercapacitors used for?

Supercapacitors are used where rapid charge/discharge and backup energy storage are required, such as memory protection, regenerative braking, and renewable energy systems.

Q5. Why are capacitors polarized?

Polarized capacitors (like electrolytic and tantalum) are designed to handle DC voltages with a specific orientation. Incorrect polarity can destroy the dielectric layer and damage the capacitor.

Q6. What’s the main disadvantage of capacitors compared to batteries?

Capacitors store less energy than batteries and have higher self-discharge rates. However, they can deliver energy much faster and withstand millions of cycles.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.