Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > PCB Contract Manufacturing: A Practical Guide for Electronics Production

Electronic products are continuously evolving towards smaller sizes, more complex functions, and global delivery. The focus of enterprises has also changed. Now, enterprises are more concerned about achieving a reasonable balance among cost, quality, delivery time, and reliability. For many start-up teams and product-oriented enterprises, building or expanding production lines is costly, time-consuming, and comes with management and delivery risks. In such cases, these enterprises often choose PCB contract manufacturing.

Next, this article will focus on the topic of PCB contract manufacturing. We will introduce its basic concept and analyze its applicability. We will also compare PCB assembly contract manufacturing, EMS, and the self-production model, etc. First of all, let's take a closer look at what PCB contract manufacturing is.

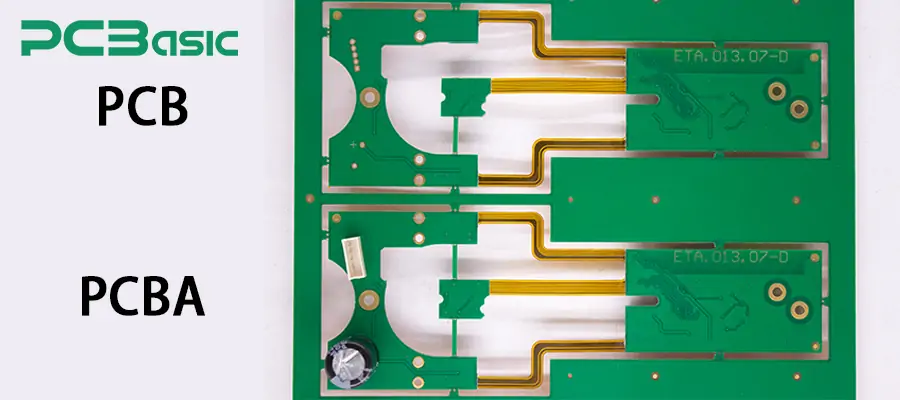

PCB contract manufacturing refers to the situation where, under a clear production agreement, the manufacturing of circuit boards is entrusted to a third-party factory. During this process, enterprises do not need to invest a large amount of equipment, manpower, and process management resources on their own. They only need to hand over the design files and technical requirements to a professional PCB contract manufacturer responsible for the actual production of circuit boards.

Typically, depending on the nature of the cooperation, contract PCB manufacturing may involve:

PCB bare board manufacturing

Component procurement and BOM management

SMT and THT assembly

Testing and inspection

Finished product packaging and logistics arrangement

The circuit board assembly services included in the cooperation scope are generally referred to as PCB assembly contract manufacturing, and are also commonly known as PCBA contract manufacturing. Unlike ordinary board factories that handle temporary orders, a professional electronic assembly contract manufacturer typically possesses a mature and stable production line, along with a complete quality management system and a comprehensive production traceability process. Such manufacturers can provide long-term and stable support for the batch production and large-scale delivery of products.

PCB contract manufacturing has many advantages, but not all projects are suitable for outsourcing production. Generally, in the following types of scenarios, it is a more reasonable and more efficient choice.

1. From small-scale production to large-scale production, in this case, outsourcing production is a suitable option. Many companies choose to assemble circuit boards themselves during the prototype or small-scale production stage. However, if they continue to produce the products in-house for mass production, many problems will arise, such as yield control, process stability, and supply chain coordination. If they choose a professional PCB contract manufacturer, these risks can be significantly reduced. They usually have a stable mass production process and supporting systems that can help the product smoothly transition from prototype to mass production.

2. If you have limited internal manufacturing resources, it is also recommended to choose outsourcing production. Because building a complete SMT production line requires significant upfront investment, and involves equipment maintenance, personnel training, and continuous process optimization. Such investments carry high risks and have long recovery periods. For start-up enterprises, it may be difficult for them to bear such costs.

3. For products that are more complex or require high-reliability, such as medical equipment, automotive electronics, industrial control, etc., there are higher requirements for the production process and product consistency. These products usually need strict process control and multiple levels of testing. In such cases, choosing an experienced electronic contract manufacturing service provider is often more appropriate.

4. The product is global-oriented. Products targeting the global market not only need to address production issues, but also involve cross-regional shipping, preparation of compliance documents, and customs clearance coordination. Partnering with contract manufacturers that have a mature logistics and delivery system can reduce communication costs and delivery risks. It is a better option.

In the following circumstances, outsourcing production is not the best option.

1. The first scenario is "Extremely Low or One-Off Quantities". If all you need is a single sample, we recommend against outsourcing production. Because outsourcing also involves additional communication, documentation establishment, and production scheduling time, etc. Moreover, it may incur minimum order or engineering support costs. In this case, the efficiency advantage brought by outsourcing is not obvious.

2. If the design is in a highly unstable stage, requiring frequent modifications or reversion of versions every day, then internal rapid assembly is often more flexible. If outsourcing production is chosen, repeatedly coordinating file updates and production adjustments with the external PCB assembly contract manufacturing partner will slow down the overall iteration rhythm.

3. For projects involving national defense, core algorithms, or highly proprietary technologies, outsourcing production cannot be chosen. In such cases, outsourcing production is likely to be restricted by legal, compliance, or security aspects.

Under such circumstances, we suggest that enterprises consider having limited in-house assembly capabilities, or adopt a hybrid model combining in-house production with contract manufacturing.

In actual production decisions, PCB contract manufacturing, EMS, and in-house assembly are often compared together. However, the focuses of these three are not the same. Below, we present a brief comparison of their differences using a table.

|

Comparison Dimension |

PCB Contract Manufacturing |

EMS Contract Manufacturer |

In-House Assembly |

|

Core Service Scope |

Bare PCB fabrication and PCBA assembly |

End-to-end electronic manufacturing from PCB to complete product |

PCB assembly performed internally |

|

System Integration Included |

No (typically board-level only) |

Yes (system assembly, enclosure, full integration) |

Depends on internal capabilities |

|

Design & Product Definition |

Managed by the customer |

Managed by the customer or jointly with EMS |

Fully managed internally |

|

Typical Use Cases |

Finished designs requiring stable board-level production |

Full product outsourcing from manufacturing to assembly |

R&D phase or very low-volume production |

|

Cost Structure |

Primarily variable costs, controlled investment |

Broader services with higher unit cost |

High fixed costs (equipment, staffing) |

|

Production Flexibility |

High, suitable from pilot runs to mass production |

Medium, more aligned with long-term projects |

High at a small scale |

|

Scalability & Ramp-Up Capability |

Strong, well-suited for volume scaling |

Strong, suitable for full product ramp-up |

Limited by internal line capacity |

|

Quality & Process Maturity |

Focused on board-level quality and consistency |

Covers full product quality systems |

Dependent on internal management |

|

Typical Decision Objective |

Balance between control, stability, and cost efficiency |

Minimize internal manufacturing involvement |

Maximum control and rapid iteration |

In summary, among these three options, PCB contract manufacturing offers a more balanced choice in terms of control, flexibility, and cost efficiency.

In actual production, professional PCB contract manufacturers have a relatively fixed and repeatable process that converts the design into producible products stably. The core purpose of this structured process is to reduce the risk of mass production and ensure consistency between different batches. Let's take a look at several key processes that contract manufacturers for electronics will follow.

1. Design Review & DFM

Before the official production commences, manufacturers will conduct a Design for Manufacturability (DFM) review. This is to assess from a manufacturing perspective whether the design provided by the customer is suitable for mass production. Generally, the following aspects will be given special attention:

The distance between the pad and the solder mask

Pad size and shape

Component spacing

Panel assembly method

The engineers will carefully review the documents. If problems are identified at an early stage, it will be possible to avoid rework, line stoppages or repeated revisions of the documents during the contract PCB manufacturing process. This stage is crucial for controlling costs and delivery times.

2. Material Sourcing & BOM Control

Materials are often the most prone to causing problems. At this stage, experienced manufacturers usually reduce risks through the following methods:

Use the vetted supplier channels

Conduct technical and reliability evaluations for alternative materials

Achieve batch-level traceability of materials

Examine the device lifecycle and the risk of discontinuation

Once these are completed, they can effectively prevent incorrect materials, mixed materials or mismatched components from entering the production line.

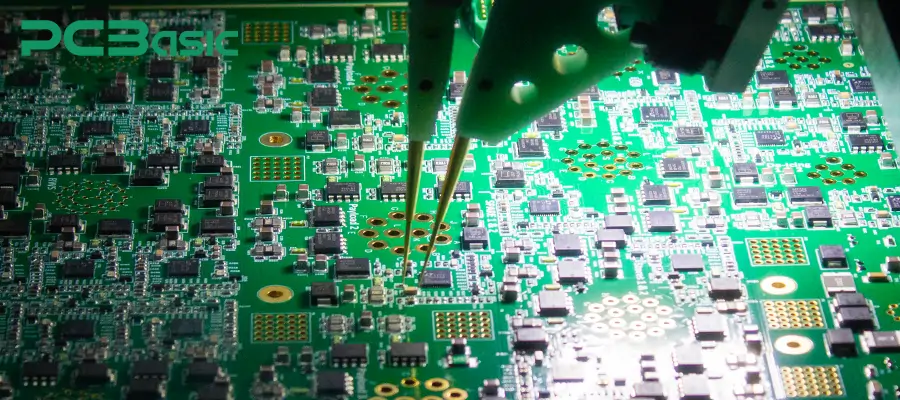

3. PCB Fabrication & PCBA Integration

Typically, PCB manufacturing and assembly require close coordination. The PCB contract manufacturer conducts unified coordination under the same production plan and process framework. The board layer structure, surface treatment methods, as well as the selection of solder paste and process parameters are usually confirmed together in the pre-production stage to ensure the reliability of subsequent assembly and welding.

4. Testing, Traceability, and Quality Control

In the process of contract PCB assembly, testing is a necessary step to ensure the quality of delivery. Depending on the product type and application requirements, common testing methods include:

AOI and SPI

X-ray inspection for BGA

Flying probe test or ICT

Function test

Aging or burn-in test

Apart from testing, a complete traceability system is also indispensable for products with high reliability requirements.

From a practical perspective, PCB contract manufacturing is not a simple outsourcing of a single process.

To determine whether a PCB contract manufacturer is reliable, one can look at whether its quality control is stable and sustainable.

First, let's look at the quality management at the system level. Generally, manufacturers that have obtained quality certifications such as ISO 9001, ISO 13485, and IATF 16949 can establish unified standards in document management, process norms, and responsibility allocation. These certifications are the foundation for ensuring that different batches, different personnel, and different production lines operate under the same rules.

Secondly, there is the consistency and standardization of the manufacturing process. Consistent and standardized processes can prevent batch differences when multiple SMT or hybrid process production lines are operating simultaneously.

The third aspect is real-time quality monitoring during the process. Real-time quality monitoring is highly necessary during the manufacturing process. By means of SPI, AOI and other methods, key data during the solder paste printing, placement and soldering processes can be monitored, enabling the early detection of trend issues. This process monitoring capability is particularly important for improving yield and reducing rework.

The last part is the closed-loop corrective and preventive mechanism. Quality control is more about analyzing the causes, taking measures and verifying the effects. Only through closed-loop management can problems be truly eliminated and thus not recur in subsequent batches.

The application of PCB contract manufacturing is very extensive, covering a wide range of demands from small-batch production to large-scale mass production. Common application fields include:

|

Application Area |

Typical Product Characteristics |

Key Focus in PCB Contract Manufacturing |

|

Consumer Electronics |

Fast product iteration, frequent model changes, mid- to low-volume production in multiple batches |

High changeover efficiency, fast NPI onboarding, stable yields in PCB assembly contract manufacturing |

|

Industrial Automation |

Long product lifecycles, steady demand, emphasis on consistency across batches |

Process stability, material control, and long-term supply reliability from the PCB contract manufacturer |

|

Medical Devices |

Strict regulatory requirements, high reliability, controlled production environments |

Full traceability, process control, and quality management within electronic contract manufacturing services |

|

Automotive Electronics |

Long production cycles, harsh operating environments, safety-critical applications |

High reliability, lifecycle management, and consistent quality in contract PCB manufacturing |

|

Energy Storage Systems |

Power-dense designs, thermal challenges, complex PCB structures |

Robust PCB design support, soldering reliability, and batch consistency in contract manufacturing |

|

Robotics and AI Hardware |

Rapid technology evolution, frequent design revisions, scaling uncertainty |

Flexibility for pilot runs combined with scalable PCB contract manufacturing capacity |

|

Communication Equipment |

High signal integrity requirements, long-term supply commitments |

Process control, impedance consistency, and sustained manufacturing stability |

Overall, the emphasis placed on PCB contract manufacturing varies depending on the specific application scenarios.

As a PCB manufacturing and assembly company specializing in board-level production, PCBasic's service system mainly focuses on engineering specifications, digital traceability, and scalable production capacity. PCBasic has rich experience in electronic assembly contract manufacturing. It integrates multiple key processes into a single manufacturing system, including:

The project introduction process centered on DFM

Involve design review at the pre-production stage, identify potential manufacturing risks in advance, and reduce the need for subsequent revisions.

Controlled component procurement and BOM management

Through standardized supply chain management and verification of substitute materials, ensure material consistency and continuous supply capability.

High-density SMT and THT assembly capabilities

Covering assembly requirements ranging from conventional mounting to complex structure boards, supporting projects of different complexity levels and batch sizes.

Automated inspection and testing methods

Combining AOI, SPI, X-ray and other inspection techniques, continuous monitoring is carried out for key manufacturing processes.

Production and quality traceability based on MES

Link materials, process parameters and test results to specific batches and individual boards, providing a data foundation for subsequent analysis and quality improvement.

Unlike full-system EMS providers that focus on complete product integration, PCBasic focuses more on PCB assembly contract manufacturing and PCBA contract manufacturing. It can serve both start-up teams, OEM manufacturers, and industrial customers simultaneously. Moreover, it supports different stages ranging from prototypes, small-batch trial production to large-scale mass production, and maintains consistent quality and delivery rhythm throughout the entire process.

PCB contract manufacturing is a practical and feasible manufacturing model. It achieves a balance among cost, quality, flexibility and scalability. Compared with full-scale EMS outsourcing or building an entire production line from scratch, PCB contract manufacturing focuses more on the manufacturing execution itself. It is a more controllable and cost-effective path for the product from pilot production to mass production.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.