Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Turnkey PCB Assembly: Process, Benefits, and the Right Partner

The update speed of modern electronic products is continuously accelerating. Product designs tend to be smaller in size and have higher functional integration. Meanwhile, the market's requirements for product delivery cycles are also constantly shortening. In this case, if PCB fabrication, component sourcing, assembly, testing and logistics are independently managed by different suppliers respectively, it often increases communication costs and brings about schedule uncertainty and quality risks. Therefore, turnkey assembly has gradually become the mainstream manufacturing choice for global startups, OEMs and product-focused companies.

This article will focus on the explanation of turnkey PCB assembly, systematically introducing its basic operation process, key benefits, and explaining how to select the appropriate turnkey manufacturing partner for real-world projects. Meanwhile, the article will also combine specific practices to explain how PCBasic can provide stable and reliable printed circuit board assembly services in the actual production process.

Turnkey PCB assembly is essentially a complete one-stop manufacturing service. The customer only needs to provide design materials, such as Gerber files, the BOM and assembly requirements, while the rest of the work will be completed by the manufacturer. These tasks include PCB fabrication and assembly, component sourcing, SMT and THT mounting, inspection, testing and final delivery.

Different from the traditional outsourcing method, turnkey assembly services are the responsibility of the manufacturer for the entire production process, avoiding the problems of complex communication and workflow fragmentation caused by PCB manufacturing, component procurement and assembly being completed by different suppliers. Under the turnkey manufacturing model, all production processes are carried out collaboratively within the same system, thereby effectively reducing the risk of errors and production delays.

For many companies, turnkey electronics manufacturing is not merely for convenience but a more efficient manufacturing option. By entrusting manufacturing and supply chain management to professional manufacturers, they can focus their energy on product design, engineering development and market execution, without having to invest too many resources in handling manufacturing details.

The term "turnkey" was originally used in construction and industrial projects, meaning that a project can be put into use directly after its completion. In PCB manufacturing, turnkey assembly follows the same idea: at the end of the project, what the customer receives is the finished product that has been assembled and passed the test, rather than the semi-finished product that requires further coordination of multiple stages.

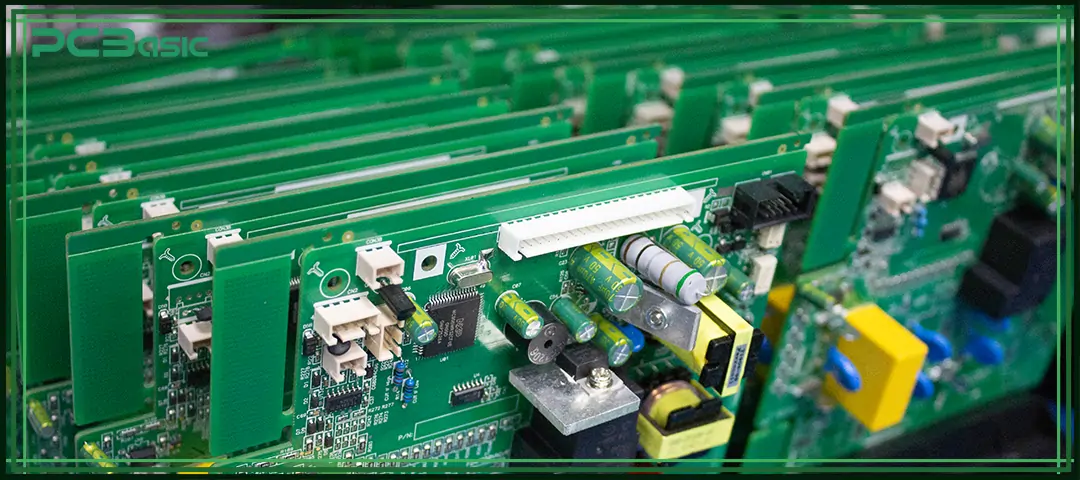

Integrating PCB fabrication and assembly within the same production system, turnkey assembly services can better control the process and ensure the traceability of production data, and respond quickly when the design is adjusted. Therefore, this mode has become a common choice for quick-turn PCB assembly and subsequent large-scale mass production projects.

Turnkey PCB assembly is usually carried out following a fixed and repeatable process, with the aim of identifying potential issues before production, reducing errors during the production process, and ensuring the stability of the final product quality.

Before starting production, engineers will check whether the design files are suitable for manufacturing and assembly to avoid rework in subsequent production. The review mainly focuses on package dimensions, pad design, component spacing, and the appropriateness of component selection.

Components are procured by the manufacturer from reliable suppliers. In the full turnkey assembly model, all components are purchased, inspected upon receipt, and managed by the factory to ensure reliable component sourcing, stable supply and consistent quality.

Bare PCBs are produced in accordance with the design requirements. When PCB fabrication and assembly are completed in the same factory or within the same system, handoff steps can be reduced, thereby shortening the delivery time and lowering the risk of quality fluctuations.

Surface mount technology (SMT) is completed using automated pick-and-place equipment, and through-hole components are installed either by equipment or manually.

According to the structure of the circuit board and the type of components, you can choose reflow soldering, wave soldering or selective soldering.

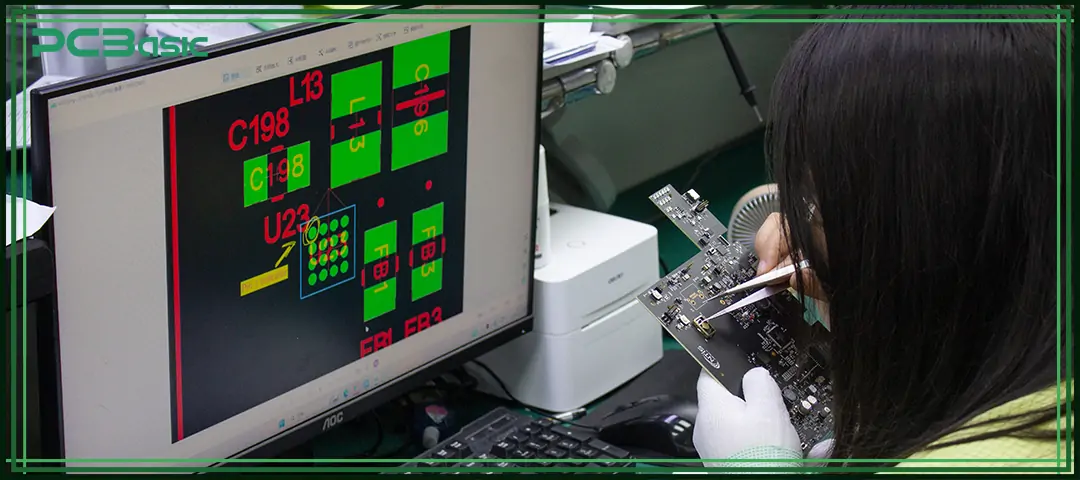

Through AOI, X-ray inspection and functional testing, the quality of solder joints, the installation of components and the circuit functions are confirmed to ensure that each circuit board meets the performance and reliability requirements of turnkey assembly services.

Finished products that pass tests are packaged as per the customer's requirements and directly sent to the designated location. At this point, the entire turnkey PCB assembly process is completed.

The growing adoption of turnkey assembly is driven by clear, measurable advantages.

By consolidating processes, turnkey manufacturing reduces logistics costs, minimizes rework, and leverages bulk purchasing. A turnkey electronic manufacturer can often secure better component pricing than individual buyers.

Integrated workflows enable quick-turn PCB assembly, allowing prototypes and production runs to move faster without sacrificing quality.

Single-vendor accountability eliminates miscommunication between suppliers. Engineering reviews and controlled processes improve first-pass success rates in printed circuit board assembly services.

With full turnkey, customers interact with one partner, one schedule, and one quality system. This is especially valuable for teams with limited manufacturing resources.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Modern products often require more than just PCB assembly. Box build assembly extends turnkey PCB assembly beyond the board level to include complete product integration.

Box build assembly may include:

• Enclosure installation

• Cable and harness assembly

• Connector integration

• Software loading and configuration

• Final system testing and packaging

For customers seeking complete turnkey electronics manufacturing, box build assembly eliminates the need for additional suppliers and ensures consistency from PCB to finished product.

Despite its advantages, turnkey assembly is not without challenges.

Global supply chain volatility can impact lead times. Experienced turnkey assembly services mitigate this risk through strong supplier networks and alternative sourcing strategies.

High-density and advanced designs require deep engineering expertise. A capable turnkey electronic manufacturer invests in advanced equipment and skilled engineers to handle complex assemblies.

While full turnkey simplifies management, clear documentation and communication remain essential. The best turnkey manufacturing partners act as extensions of the customer’s engineering team.

Understanding service models helps customers choose the right approach.

In a full turnkey assembly, the manufacturer handles everything—components, PCB fabrication and assembly, testing, and delivery. This model offers maximum simplicity and speed.

Component sourcing is shared between the customer and the manufacturer. This approach provides flexibility but requires more coordination.

The customer supplies all components, and the manufacturer performs only assembly labor. While offering control, this model lacks the efficiency of turnkey assembly services.

For most businesses, full turnkey delivers the best balance of cost, speed, and reliability.

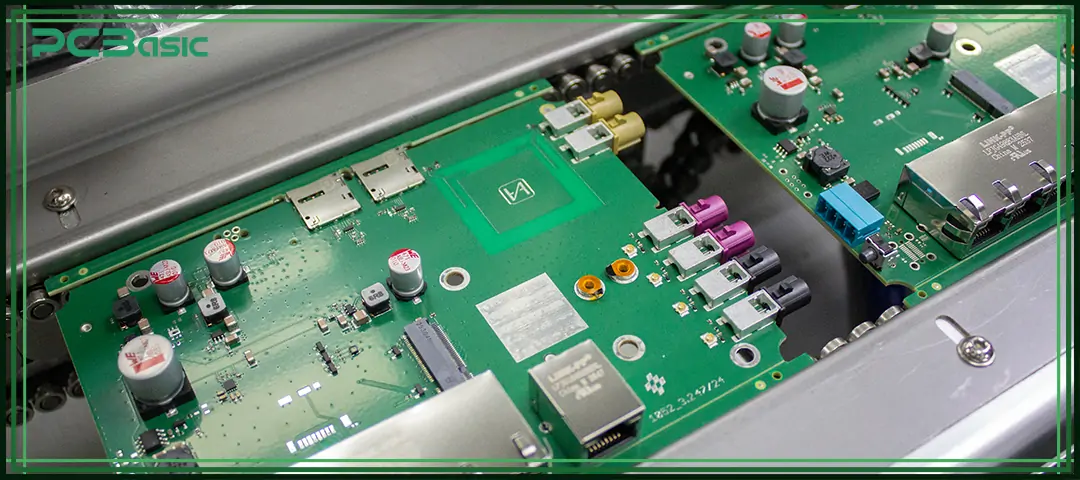

PCBasic provides comprehensive turnkey PCB assembly solutions designed for reliability, scalability, and transparency. As a specialized turnkey electronic manufacturer, PCBasic integrates PCB fabrication and assembly, component sourcing, testing, and logistics into a unified manufacturing system.

PCBasic’s turnkey assembly services include:

• Engineering-driven DFM/DFA review

• Verified component sourcing and BOM management

• Advanced SMT and mixed-technology assembly

• AOI, X-ray, and functional testing

• Quick turn PCB assembly for prototypes

• Scalable full turnkey assembly for production

• Optional box build assembly and system integration

By combining digital traceability with disciplined manufacturing processes, PCBasic supports customers across the entire product lifecycle—from early prototypes to volume turnkey electronics production.

In today’s fast-paced electronics industry, turnkey PCB assembly is no longer just an option—it is a competitive advantage. By consolidating PCB fabrication and assembly, sourcing, testing, and integration into a single workflow, turnkey manufacturing reduces complexity while improving quality and speed.

Whether you are developing a prototype, launching a new product, or scaling production, the right turnkey assembly partner makes the difference. With robust processes, advanced equipment, and end-to-end accountability, turnkey assembly services enable teams to focus on innovation instead of operations.

PCBasic’s approach to turnkey PCB assembly demonstrates how disciplined engineering, transparent sourcing, and scalable production can turn complex designs into reliable, market-ready products—efficiently, predictably, and with confidence.

1. What information is required to start a turnkey PCB assembly project?

Gerber files, a BOM, and basic assembly requirements are typically required. Pick-and-place files and testing requirements are recommended but not mandatory.

2. What is the difference between PCB fabrication and assembly, and turnkey PCB assembly?

PCB fabrication and assembly cover board manufacturing and component mounting, while turnkey PCB assembly also includes component sourcing, testing, and delivery under one responsibility.

3. When should I choose full turnkey assembly instead of partial or consigned assembly?

Full turnkey assembly is suitable when you want to reduce coordination effort, shorten lead time, and lower supply chain risk.

4. How do turnkey assembly services reduce manufacturing risk?

By assigning full responsibility to one manufacturer, communication errors are reduced, and quality control is more consistent.

5. Is quick-turn PCB assembly possible under a turnkey model?

Yes. Integrated sourcing, fabrication, and assembly enable faster turnaround times.

6. How is quality controlled in turnkey electronics manufacturing?

Through design review, incoming inspection, AOI, X-ray inspection, and functional testing.

7. Can box build assembly be included in a turnkey PCB assembly project?

Yes. Box build assembly can be added to deliver fully assembled and tested products.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.