Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Sheet Metal Manufacturing: Processes, Design, Materials, and Applications

Sheet metal manufacturing is one of the most fundamental and widely used manufacturing methods in modern industry. Whether it is consumer electronics, automotive systems, medical equipment or aerospace structures, a large number of key components rely on sheet metal processing to be produced. As products evolve towards being lighter, stronger and more compact in structure, manufacturers are increasingly adopting mature sheet metal fabrication, CNC manufacturing and high-precision tooling equipment to ensure product performance and production stability.

With the widespread adoption of laser cutting machines, sheet metal bender systems and digital engineering processes, today's metal fabrication companies have been able to efficiently meet various manufacturing demands ranging from rapid prototyping services to mass production while ensuring quality consistency.

This article will focus on sheet metal manufacturing, systematically introducing common processing procedures, design for manufacturability (DFM), material and surface finish selection, key points of tolerance and quality control, as well as typical applications of sheet metal manufacturing in various industrial fields.

Sheet metal manufacturing is a widely used processing method in metal manufacturing, mainly used to process metal sheets with uniform thickness into various functional components for use. These sheets are usually made of steel or aluminum sheet metal. Through processes such as cutting, bending and assembly, they can be made into load-bearing structural components or used as cosmetic exterior parts.

Unlike subtractive manufacturing methods such as machining, sheet metal fabrication mainly changes the shape of materials through bending and forming rather than extensive cutting of materials. This processing method has a high material utilization rate and better processing efficiency. Meanwhile, since parts are usually processed from a single metal sheet, a uniform sheet thickness naturally becomes a basic requirement in sheet metal design.

In actual production, modern metal fabrication services usually rely on CNC manufacturing to complete processing, thereby ensuring dimensional consistency and stable processing accuracy. It can also flexibly support different demands from small-batch prototype trial production to large-scale production.

Every sheet metal manufacturing project begins with design and engineering evaluation. Engineers usually complete 2D drawings or 3D CAD models first, and then convert the design into a manufacturable flat pattern based on the bend allowances and K-factor calculations.

In the sheet metal manufacturing process, cutting is usually the first physical production step. Common cutting methods include high-precision contour cutting using laser cutting machines, mechanical shearing for straight cuts, as well as punching and blanking for holes and part outlines.

CNC metal cutting can stably and accurately process complex geometries. Therefore, it is suitable for both rapid prototyping services and mass production.

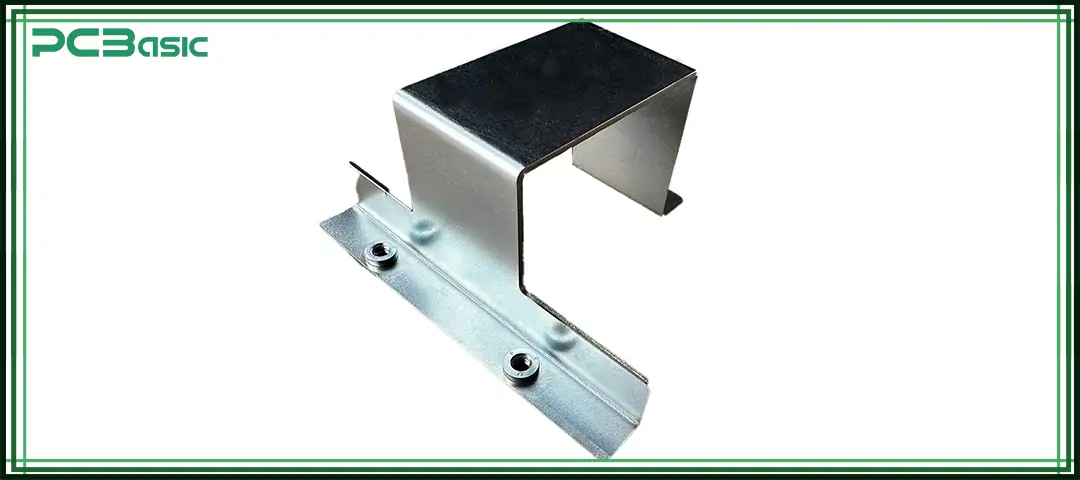

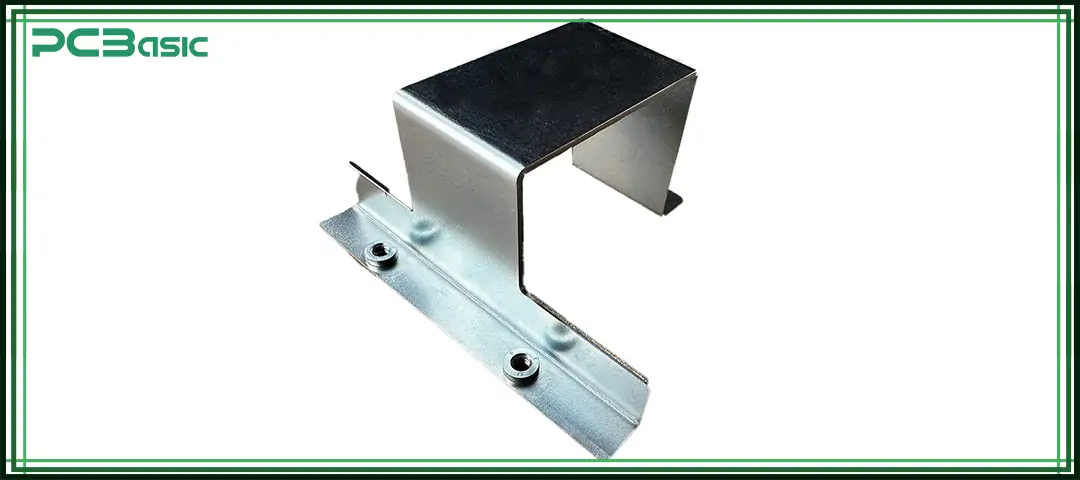

After the cutting is completed, the flat sheet blank will enter the forming and bending processes to be processed into the required structural shape. Bending is usually performed by a press brake or sheet metal bender, which forms angles and flanges by precisely controlling the pressure.

In practical applications, multiple sheet metal parts often need to be joined into a complete structure through connection processes. Common joining methods include welding (MIG, TIG, spot welding), mechanical fasteners (screws, rivets, PEM studs), and adhesive bonding tailored to specific application scenarios.

In stainless steel fabrication, welding remains the most commonly used and crucial joining method because it can simultaneously meet the requirements of structural strength and corrosion resistance.

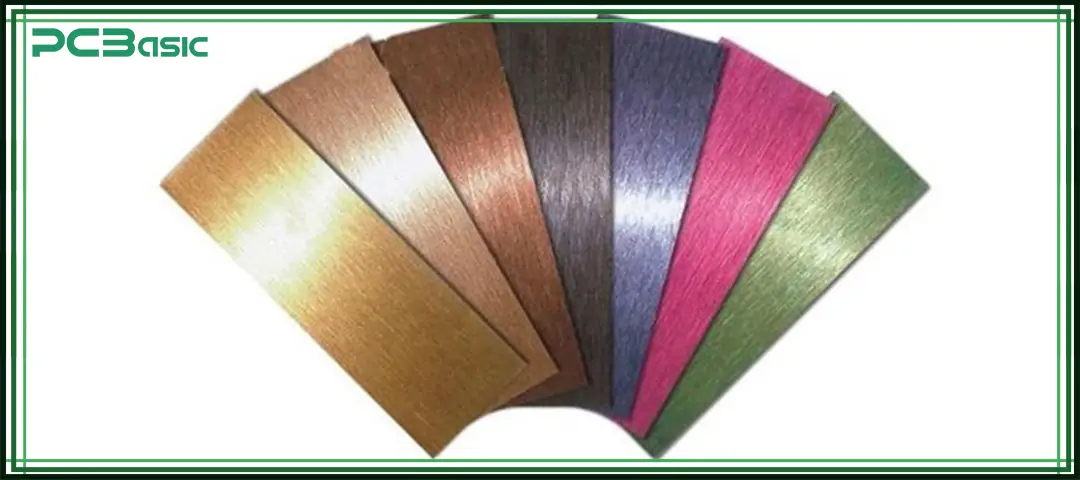

Surface finishing is mainly used to enhance the durability, appearance and environmental resistance of sheet metal parts. In sheet metal fabrication, surface finishing is usually the last process before delivery and has a direct impact on the service life and overall quality of parts.

• Laser cutting machine systems

• Plasma cutting

• Waterjet cutting

• Mechanical shearing

Among these methods, laser cutting has become the most widely used cutting process in modern sheet metal manufacturing due to its high precision, consistent cut quality, and good compatibility with the CNC metal cutting workflows.

Forming reshapes metal without removing material. Common techniques include:

• Press brake bending

• Roll forming

• Deep drawing

• Metal spinning

• Stamping

Through these processes, metal fabrication services can not only efficiently process simple structural bracket parts but also reliably produce more complex products such as enclosures and housings.

In sheet metal parts, holes are usually drilled through methods such as laser cutting, punching or drilling. According to product requirements, secondary processing operations such as tapping, countersinking and hole extrusion are often needed. This type of process is very common in custom metal fabrication projects and has a direct impact on assembly accuracy and functional performance.

Successful sheet metal manufacturing depends on:

• Uniform wall thickness

• Realistic tolerances

• Minimal forming complexity

Designs that respect these principles reduce rework and improve yield across sheet metal fabrication services.

Key bending parameters include:

• Bend radius (typically ≥ material thickness)

• Bend angle

• Bend height

• Bend relief

Ignoring these can cause cracking or deformation, particularly in stainless steel sheets and high-strength alloys.

The K-factor defines the neutral axis position during bending and directly affects flat pattern accuracy. Correct K-factor selection is essential in CNC manufacturing, especially for precision assemblies in metal manufacturing.

Holes, slots, and cutouts placed too close to bends may distort during forming. Following standard clearance rules ensures dimensional stability in sheet metal fabrication.

Compared with CNC machining, in sheet metal manufacturing, the material is stretched during the bending process, so a slightly larger tolerance is usually allowed in dimensional control. However, as long as the process parameters are properly controlled and combined with a stable CNC manufacturing, sheet metal parts can also achieve high processing accuracy.

Quality control measures include:

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

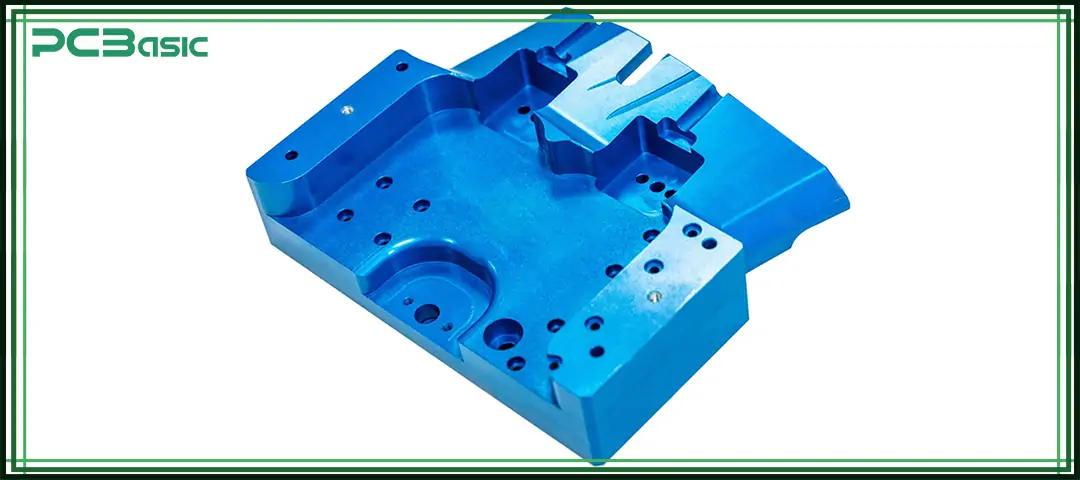

Lightweight, corrosion-resistant, and easy to form. Aluminum sheet metal is widely used in electronics, transportation, and enclosures.

Excellent corrosion resistance and strength. Stainless steel sheet is common in medical, food, and industrial applications.

Cost-effective and strong, often used in structural components and general metal manufacturing.

Zinc-coated for corrosion resistance, frequently used in construction and outdoor equipment.

High electrical and thermal conductivity, used where performance outweighs cost.

Used in safety-critical and load-bearing applications.

Exceptional strength-to-weight ratio and corrosion resistance, used in aerospace and medical sectors.

|

Surface Finish |

Description |

Primary Purpose |

Typical Applications |

|

Powder coating |

Durable, decorative coating applied as a powder |

Improves appearance and provides corrosion protection |

Enclosures, cabinets, industrial housings |

|

Anodizing |

Electrochemical process for aluminum |

Enhances corrosion resistance and surface hardness |

Aluminum sheets, electronic enclosures, structural parts |

|

Chromate conversion |

Chemical coating that preserves conductivity |

Provides corrosion protection while maintaining electrical conductivity |

Grounded sheet metal parts, electrical assemblies |

|

Bead blasting |

Abrasive blasting to create a uniform matte surface |

Removes tool marks and creates a consistent surface texture |

Cosmetic parts, surface preparation before coating |

|

Brushing & electropolishing |

Mechanical brushing followed by electrochemical polishing |

Improves aesthetics and creates smooth, hygienic surfaces |

Medical equipment, food processing equipment, stainless steel parts |

Used in electronics, industrial equipment, and control systems.

Brackets, panels, frames, and structural reinforcements rely heavily on sheet metal manufacturing.

Doors, railings, enclosures, and protective structures.

Visually appealing, durable display units created through metal fabrication services.

Hygienic stainless steel fabrication for regulated environments.

Lightweight, high-strength metal fabrication for demanding conditions.

• High strength-to-weight ratio

• Excellent scalability

• Wide material and finish options

• Cost-effective for rapid prototyping services and production

• Tooling and setup costs

• Design constraints tied to bending and thickness

• Requires experienced metal fabrication company support

PCBasic offers professional sheet metal manufacturing and sheet metal fabrication services with a focus on precision, flexibility, and fast turnaround. Their dedicated sheet metal facility handles a wide range of thicknesses (from 0.3 mm to 20 mm) and supports both prototypes and production parts such as enclosures, brackets, and assemblies.

The company’s processes cover key operations including cutting (laser, shearing, stamping), bending, welding (TIG, MIG/MAG), CNC punching, riveting, and stamping with dies, enabling complex shapes and reliable mass production.

Choosing PCBasic means access to end-to-end services—from design support and material selection to surface treatment and final assembly—streamlining supply chains and saving time. With advanced CNC equipment and experienced engineers, the company emphasizes strict quality control and adherence to international standards such as ISO9001:2015, ISO13485, ISO14001:2015, and IATF16949:2016.

PCBasic’s sheet metal services also stand out for fast delivery and flexible capacity, with options for small runs or larger batches and reliable inspection and logistics support to meet global delivery needs.

Sheet metal manufacturing remains an indispensable processing method in modern metal manufacturing, taking into account efficiency, precision and flexibility. Through reasonable structural design, combined with CNC manufacturing, advanced laser cutting machines and appropriate material selection, manufacturers can stably deliver reliable products for different industries.

Whether you need sheet metal fabrication services or custom metal fabrication, it is hoped that the scalable production will be accomplished by experienced metal fabrication companies. Understanding and applying these basic principles introduced in this article are all key to achieving product quality, cost control and long-term reliability.

What is the difference between sheet metal manufacturing and sheet metal fabrication?

They are closely related; sheet metal manufacturing is the broader process, while sheet metal fabrication often refers to the practical execution of cutting, bending, and assembly.

Why is laser cutting so common in sheet metal manufacturing?

A laser cutting machine offers precision, speed, and flexibility, making it ideal for both prototyping and production.

Which materials are best for sheet metal manufacturing?

Aluminum sheet, stainless steel sheet, and carbon steel are the most common due to their balance of formability, strength, and cost.

Is sheet metal suitable for rapid prototyping?

Yes. Modern CNC metal cutting and forming systems make rapid prototyping services highly efficient.

How do I choose the right metal fabrication company?

Look for experience, in-house CNC manufacturing, quality control systems, and comprehensive metal fabrication services.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.