Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > What is Contract PCB Assembly? Benefits, Process, and Key Considerations

The manufacturing difficulty of electronic products is increasing. Products are getting smaller and smaller, with more and more functions, and are required to be launched to the market at a very fast speed. At the same time, customers and the market are becoming more and more strict in terms of product stability, quality consistency and compliance requirements. Under such circumstances, more and more enterprises choose the contract PCB assembly, entrusting the production and assembly of circuit boards to professional manufacturers.

Today, we are going to talk about contract PCB assembly. In this article, we will introduce how contract PCB assembly operates, what its advantages are, and what issues need to be focused on when choosing a suitable PCB assembly manufacturer. First, we will explain what contract PCB assembly is.

Contract PCB assembly, also known as PCB contract assembly, is a manufacturing model in which the PCB assembly work is outsourced to a third-party manufacturer under a formal production agreement. Under this model, enterprises only need to provide the manufacturer with complete design and manufacturing data, including Gerber files, Bill of Materials (BOM), SMT placement data, and assembly drawings, etc. Then, the professional manufacturer will be responsible for carrying out all necessary assembly operations, such as SMT surface mount, THT through-hole, inspection, testing, and final delivery.

Contract PCB Assembly in Contract Electronics Manufacturing

Contract PCB assembly is a highly specialized subfield within contract electronic manufacturing, with its core focus on board-level production. Unlike some electronic manufacturing service (EMS) providers that emphasize complete machine assembly, contract PCB assembly is primarily dedicated to ensuring that PCBAs are reliable and have good manufacturability.

In PCB assembly contract manufacturing, it typically covers:

SMT and THT assembly for PCBs

Component procurement, BOM management and material traceability

AOI, X-ray inspection and electrical testing

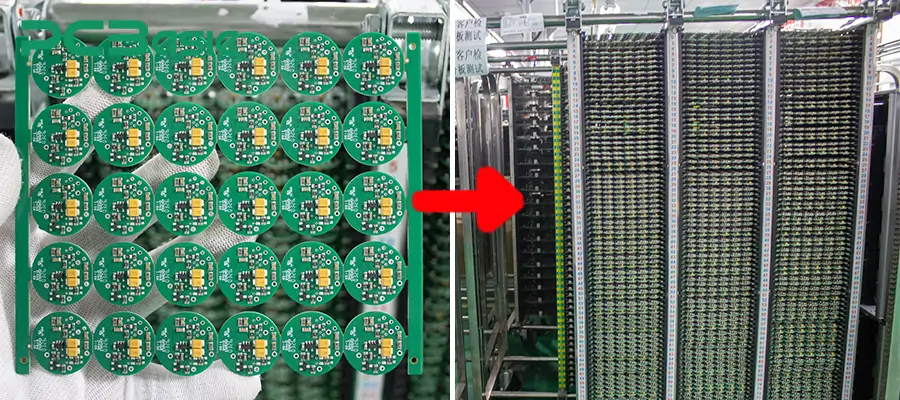

PCBA prototype, small batch and mass production

Sub-Contract PCB Assembly Description

Sub-contract PCB assembly refers to:

The main contractor responsible for the entire machine or system does not undertake the PCB assembly itself but delegates this step to a more specialized PCB assembly factory. The main contractor is only responsible for the subsequent assembly of the entire machine or system integration. This usually occurs in more complex production projects, such as those with a large number of product models, high quality requirements, or those subject to stricter industry regulations.

Separating the PCB assembly from the subsequent assembly stages enables enterprises to verify whether all circuit boards meet the requirements before proceeding to the next production step. This approach helps to reduce overall production risks and makes the manufacturing process more stable.

Collaborating with a suitable PCB assembly contract manufacturer not only helps to save costs, but also reduces uncertainties and enhances project execution efficiency. The improvement in efficiency is mainly reflected in the following aspects:

1. Faster product launch speed

Professional PCB assembly contract manufacturers have a mature engineering team, verified production processes, and equipment that can be put into operation directly. None of these needs to be built from scratch. This avoids the lengthy production line construction, debugging and trial operation cycle that enterprises would have to go through if they were to assemble it themselves. Therefore, the project can directly enter the production stage after the design is finalized.

2. Reduce capital investment and operational risks

Building an in-house PCB assembly line usually requires significant upfront investment in SMT equipment, inspection systems, factory space, and personnel. Continuous investment in manpower and management resources is also necessary to maintain good yield and production stability.

After adopting contract PCB assembly, these previously fixed and high-cost investments can be transformed into relatively predictable project costs. Meanwhile, operational risks such as equipment utilization rate, process stability, and production yield are borne by the contract PCB assembly factory. Companies can then focus more on product research and business development.

3. Scalable production capacity from samples to mass production

The same manufacturing partner can typically meet the demands of different production stages, including:

Engineering sample production

Trial production stage

Small batch, multiple variety production

Stable mass production

Throughout the entire process, maintaining cooperation with the same PCB assembly contract manufacturer can reduce quality risks during the process of mass production expansion, and also enable the smooth continuation of the experience accumulated in the early production to the subsequent batch manufacturing.

Professional contract PCB assembly usually follows a clear and traceable production process. Generally, mature PCB assembly contract manufacturers are largely consistent in their core steps.

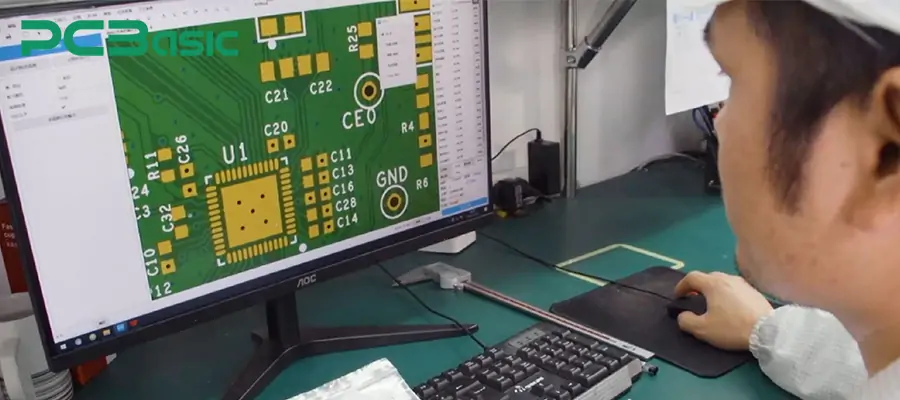

1. Design review and DFM analysis

Before the product is officially put into production, the manufacturer will conduct a DFM review of the design documents to ensure that the design can be assembled stably and efficiently.

The review content usually includes:

Component packaging and pad design

Resist layer windowing and stencil requirements

Panel assembly method and fiducial point setting

Assembly risk points, such as fine-pitch components, BGA, and mixed process design

Providing DFM feedback during the pre-production stage helps to identify potential issues in advance, avoiding subsequent rework, delivery delays and yield losses.

2. BOM Verification and Component Procurement

The bill of materials (BOM) will be carefully checked, including the material model, packaging consistency, lifecycle status, and the rationality of alternative materials. In a standardized contract PCB assembly factory, this step typically also includes:

Control of the Approved Supplier List (AVL)

Anti-counterfeiting and counterfeit material procurement mechanism

Traceability management of batch and date codes

Strict BOM control and material management are the key foundations for ensuring assembly quality and the long-term reliability of products.

3. PCB Manufacturing Coordination

Many PCB assembly contract manufacturers will also assist or directly coordinate the PCB manufacturing process to ensure that parameters such as board structure, surface treatment, tolerances, and panel assembly methods meet the requirements for subsequent assembly.

4. SMT and THT Assembly

During the assembly stage, it will be completed based on the circuit board design and the type of components, using both automated and manual processes. Typical procedures include:

Solder paste printing

SPI (Solder Paste Inspection)

High-speed and high-precision assembly

Reflow soldering

Selective wave soldering or manual soldering for THT components

The relevant process parameters will be adjusted according to the characteristics of the components and the complexity of the circuit board to ensure the quality of the solder joints and the stability of production.

5. Inspection and Testing

Inspection and testing are the core steps in the reliable contract assembly of PCBs. Common quality control methods include:

AOI

X-ray inspection for BGA, QFN and other components

Function Test (FCT)

ICT (applicable when necessary)

Flying Probe Test

Each inspection process will confirm the assembly quality before the product moves on to the next stage, thereby reducing the risk of potential defects flowing into the subsequent processes.

6. Traceability, Packaging and Delivery

In modern PCB assembly contract manufacturing, it usually relies on the MES system to record and manage the following information:

Material batch information

Key process parameters

Testing and test results

The assembled circuit boards will be packaged in accordance with ESD protection and customer requirements, and will be transported domestically or internationally for delivery.

|

Key Advantage |

Practical Impact |

|

Cost efficiency without quality trade-offs |

Shared manufacturing resources and mature processes help reduce per-unit cost while maintaining quality consistency |

|

Access to specialized expertise |

A professional PCB assembly contract manufacturer in USA or Asia brings experience across industries, board types, and assembly challenges |

|

Higher and more consistent quality |

Dedicated assembly factories invest continuously in AOI, X-ray, and testing systems to ensure stable results |

|

Scalable production capability |

The same partner can support prototypes, pilot runs, and volume production without process disruption |

|

Focus on core business activities |

Companies can prioritize design, software, and market growth instead of managing assembly operations |

When choosing a contract manufacturer for PCB assembly, we can focus on the following aspects:

1. Manufacturing capacity and process control

Manufacturing capability is the basis for evaluating whether a PCB contract assembly manufacturer is a viable option. In this regard, we can focus on the following:

SMT production line configuration and placement accuracy

Whether it supports fine-pitch devices, BGA packaging, and SMT/THT hybrid processes

Whether it has clear and executable process windows and control parameters

A mature PCB assembly factory should be able to clearly explain how quality control is carried out in each production stage, rather than relying on final inspection to identify problems.

2. Quality System and Certification

The prerequisite for stable manufacturing is a sound quality management system. Suppliers should establish a structured quality management process and hold industry certifications relevant to the application field of their products. Although certification itself does not represent everything, it at least indicates that the relevant processes have been standardized, audited, and have a foundation for continuous improvement.

3. Traceability and Data Transparency

Modern PCB assembly manufacturing increasingly relies on digital traceability systems. For products with long lifecycles or those subject to regulation, being able to trace the source of materials, process parameters, and test results is particularly crucial. Therefore, if you value this aspect, it is necessary to choose a supplier with good data transparency.

4. Regional Layout Strategy

Location is also a significant factor in choosing a PCB assembly contract manufacturer. Selecting a local assembly manufacturer facilitates communication, compliance, or supply chain coordination. Of course, considering factors such as cost, capacity, and delivery time, a mature overseas factory can also be a good choice.

The most suitable choice depends on the project's delivery requirements, production scale, and the actual needs in terms of regulations and supply chain.

5. Communication Skills and Engineering Support

Good engineering communication is often more important than the price itself in actual production. A reliable PCB assembly contract manufacturer can proactively provide feedback during the design and production stages, identify potential risks in advance, and work with customers to optimize the manufacturing plan. This engineering support capability can effectively reduce subsequent problems and make project progress smoother.

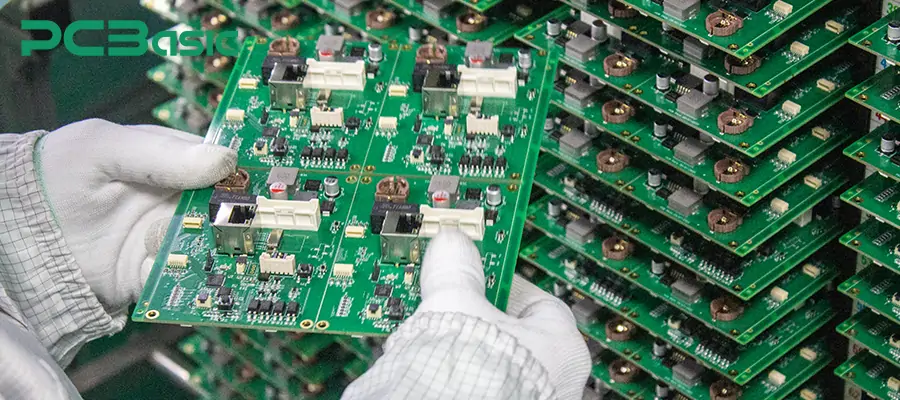

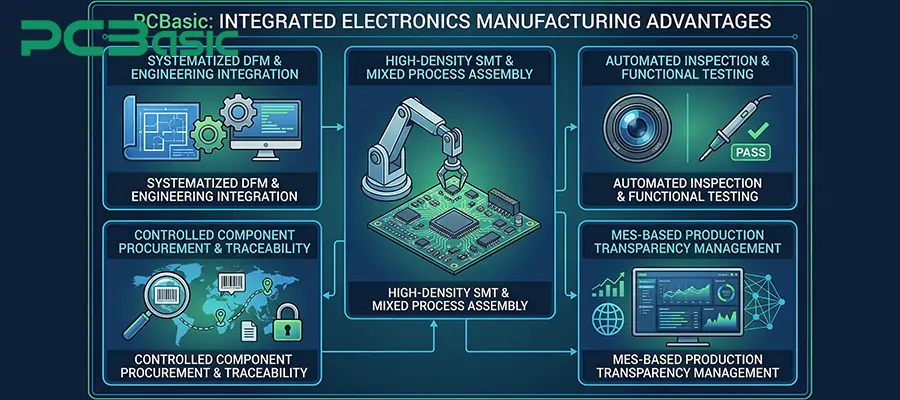

PCBasic is a professional factory specializing in PCB assembly, providing professional contract PCB assembly manufacturing services to global customers. From PCB prototyping to stable mass production, PCBasic has a manufacturing model centered on standardized processes, traceability, and scalability. This model ensures that products maintain stable and reproducible quality performance throughout multiple production stages.

The core capabilities of PCB contract assembly of PCBasic include:

Systematized DFM review and engineering integration

Controlled component procurement and complete traceability

High-density SMT and mixed process assembly capabilities

Automated inspection and functional testing systems

MES-based production transparency management

PCBasic is a reliable contract PCB assembly factory that can help customers achieve more stable board-level quality, more controllable delivery schedules, and lower overall project risks. You can learn more about PCBasic at www.PCBasic.com.

1. What kind of production volume is generally suitable for contract PCB assembly?

Contract PCB assembly is commonly used for prototyping, pilot production, and both medium- and large-scale production. Of course, with a stable partnership with the manufacturer, large-scale production can also be carried out.

2. If the product design is frequently modified, is contract PCB assembly still suitable?

Most contract PCB assembly factories can handle engineering changes, including BOM adjustments and design document updates, and the impact on the production schedule is relatively controllable.

3. How long is the delivery time for PCB assembly in the contract?

The delivery time depends on the complexity of the board, the availability of materials, and the testing requirements. In most cases, prototyping and small-scale assembly can be completed within a short period of time, while mass production will be scheduled based on the material preparation situation.

4. When using materials provided by the customer, how is the responsibility for quality divided?

Usually, the boundary of responsibilities will be clearly defined before the cooperation. The quality risks of the materials provided by the customer are generally borne by the customer.

5. Can the entire process from prototyping to mass production be carried out using the same contract PCB assembly factory?

Usually, it is possible. Using the same factory helps to retain the accumulated process experience from the early stage and is beneficial for maintaining product consistency.

In conclusion, entrusting the board-level assembly work to professional PCB assembly factories (i.e., PCB contract assembly) has become an important strategic choice for an increasing number of enterprises in the manufacturing process.

A reasonable contract PCB assembly model can help shorten the product launch cycle, reduce manufacturing risks, and maintain consistent product quality throughout the stages from prototyping to mass production. However, whether this model can truly bring value largely depends on the selection of partners. In this article, we have some suggestions on choosing PCB assembly contract manufacturers, and we also introduce a reliable PCB contract assembly manufacturer - PCBasic. It can help you better select the appropriate partner.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.