Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Turnkey Manufacturer for PCBA: From Design to Reliable Production

High-density PCB designs, shorter product life cycles, unstable global component supply, and constantly rising quality standards have made PCBA projects more difficult to manage in real-world production. For many companies, if they need to separately connect with multiple suppliers such as PCB manufacturing, component sourcing, SMT assembly, testing and logistics, the project schedule is very likely to be affected, and the overall efficiency will also decline significantly.

In this case, the turnkey manufacturer has gradually become a more practical and reliable option. Compared with managing multiple suppliers and engineering interfaces simultaneously, companies introduce turnkey solutions, where a single manufacturer is responsible for the entire PCBA production cycle.

This article will focus on the application of PCBA, systematically explain what turnkey manufacturing is, and compare it with toll manufacturing and the traditional contract assembly model. Meanwhile, it will also introduce the complete turnkey process and explain why choosing the appropriate turnkey manufacturer is crucial for achieving.

In the PCBA field, a turnkey manufacturing solution refers to a manufacturing model in which a single turnkey manufacturer is responsible for all key stages in the PCB assembly process. The customer only needs to connect with one manufacturing company, and the rest of the work is coordinated and completed by the turnkey manufacturer as a whole, which usually includes:

• PCB fabrication

• Component sourcing and BOM management

• SMT, THT, and mixed-technology assembly

• Inspection, testing, and quality control

• Packaging, logistics, and final delivery

In simple terms, what is turnkey manufacturing?

That means that the customer ultimately receives a turnkey product that can be used directly or shipped, without the need to manage each production stage separately.

It should be noted that a turnkey supplier does not necessarily complete all processes in-house. The core of turnkey manufacturing services lies in the concentration of responsibility - a single manufacturer is fully responsible for engineering connection, material procurement, production arrangement and quality control.

To understand the value of the turnkey manufacturer, we first need to clearly see the differences in responsibility allocation and management methods among the three common PCBA manufacturing models.

Under the toll manufacturing model, customers need to supply most of the materials by themselves, including PCBs and all or most electronic components, and the factory is only responsible for processing tasks such as placement and assembly.

Toll manufacturing is usually more suitable for enterprises with well-established supply chain systems and in-house manufacturing management experience. However, its support capacity for projects with unstable supply chains is limited.

Traditional PCBA contract assembly usually involves the placement and assembly processes, while PCB manufacturing, component procurement, and even testing are still completed by the customer in contact with different suppliers, respectively.

Under this model, the manufacturing process is fragmented into multiple parties, and customers need to repeatedly communicate and coordinate among design, procurement and production. Once a project occurs, progress delays or quality issues occur, it is often difficult to quickly identify responsibility, and the overall management cost also increases accordingly.

Under the turnkey contract manufacturing model, a single turnkey manufacturer is responsible for the main stages of the PCBA project, including material procurement, PCB manufacturing, turnkey assembly, testing and final delivery.

All processes are coordinated as a whole by the same manufacturer, resulting in shorter communication paths, more direct information transfer, and clearer cost control and quality responsibilities.

|

Comparison Aspect |

Toll Manufacturing |

Traditional PCBA Contract Assembly |

Turnkey Contract Manufacturing |

|

Primary Responsibility |

Customer |

Customer + multiple suppliers |

Turnkey manufacturer |

|

PCB Fabrication |

Customer-managed |

Customer-managed |

Managed by a turnkey manufacturer |

|

Component Sourcing |

Customer-managed |

Customer-managed |

Centralized under a turnkey manufacturer |

|

BOM Management |

Customer |

Customer |

Turnkey manufacturer |

|

SMT / THT Assembly |

Factory execution only |

Factory execution |

Turnkey assembly |

|

Testing & Quality Control |

Factory or customer-defined |

Distributed across parties |

Unified under a turnkey manufacturer |

|

Logistics & Delivery |

Customer-coordinated |

Customer-coordinated |

Handled by a turnkey manufacturer |

|

Communication Complexity |

High |

High |

Low (single point of contact) |

|

Quality Ownership |

Unclear |

Often disputed |

Clear and centralized |

|

Supply Chain Risk |

Customer |

Customer |

Primarily borne by the turnkey manufacturer |

|

Best Suited For |

Companies with mature supply chains |

Companies with moderate manufacturing experience |

Companies seeking simplified management and lower risk |

|

Product Complexity |

Low to medium |

Medium |

Medium to high-complexity PCBA |

A mature turnkey process is essentially a set of engineering-driven workflows focused on execution and control.

Under the turnkey model, the turnkey supplier is responsible for the entire procurement process, including BOM optimization, supplier selection, and material traceability management. Relying on its own supply chain resources, turnkey manufacturing services can effectively reduce the impact brought by market fluctuations and improve the predictability of delivery.

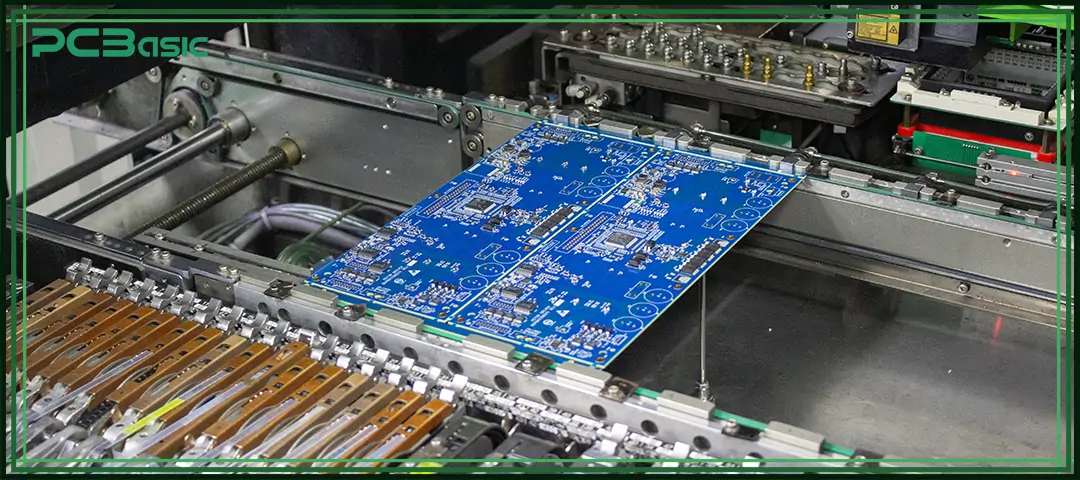

Turnkey assembly covers the main assembly processes of PCBA, including:

• High-density SMT assembly

• Fine-pitch components, BGA, QFN, and micro-sized packages

• Through-hole (THT) assembly

• Mixed-technology boards

A turnkey manufacturer with complete capabilities can support production at all stages, from prototypes and small-batch to large-scale mass production.

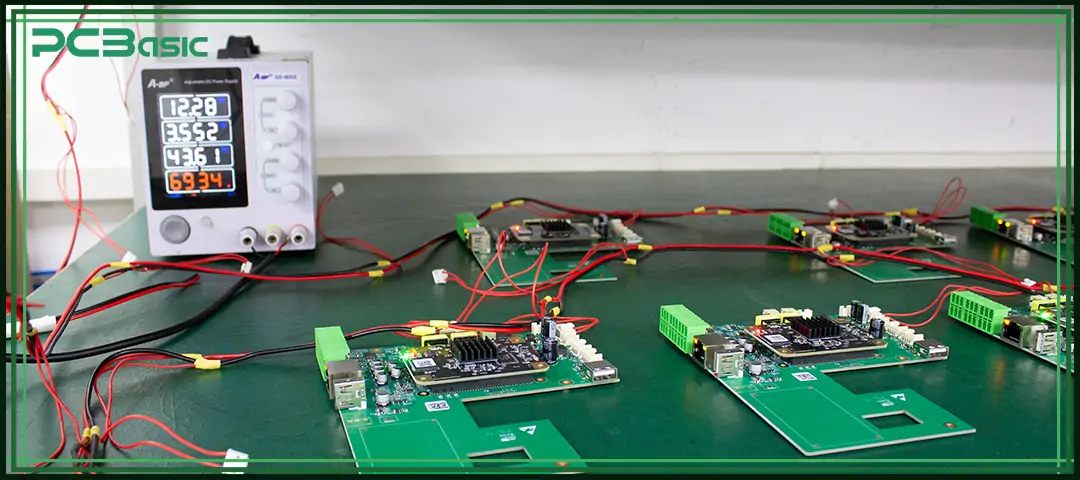

Quality control is not a single process but runs throughout the entire production process. In the turnkey manufacturing model, inspection and testing will be continuously carried out according to the defined process stages instead of only being inspected before shipment. Due to the centralized responsibility, the turnkey manufacturer has complete traceability and accountability for quality issues.

In the final stage of the turnkey process, the turnkey manufacturer is responsible for ESD-safe packaging, labeling, export documentation and transportation arrangements.

As there are no handoffs among multiple suppliers, the risks of transport damage, labeling errors and delivery delays are significantly reduced. What the customer eventually receives is a turnkey product that can be directly shipped or integrated for use.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Choosing a turnkey manufacturer for PCBA offers several strategic benefits:

• A single point of contact simplifies communication and project management

• Faster time-to-market through parallel engineering and production

• Lower total cost by reducing coordination overhead and rework

• Improved quality through centralized responsibility

• Better scalability from prototype to volume production

Rather than focusing on the lowest unit price, turnkey manufacturing solutions optimize overall project efficiency and reliability.

Turnkey manufacturing is particularly suitable when:

• Your company lacks in-house manufacturing infrastructure

• Your PCBA involves complex designs or dense component layouts

• Component sourcing is challenging or high-risk

• You want predictable costs and schedules

• Your core focus is product development, sales, or market expansion

In these situations, a trusted turnkey supplier becomes a long-term manufacturing partner rather than just a service provider.

PCBasic provides mature and reliable turnkey manufacturing services for PCBA projects of different scales and complexities. With over 15 years of experience in PCB and PCBA manufacturing, PCBasic has developed into an intelligent one-stop turnkey manufacturer, integrating engineering support, PCB manufacturing, assembly, testing and delivery into a unified manufacturing process.

PCBasic's turnkey PCBA services cover the entire life cycle of electronic product manufacturing, including:

• PCB fabrication ranging from single-prototype boards to high-volume production

• Component sourcing and BOM support through a stable global supply network

• SMT, THT, and mixed technology assembly across multiple lines

• Multi-stage inspection and testing to guarantee product reliability

• Final packaging, documentation, and global logistics to your factory or end customer

Quality is at the core of PCBasic's turnkey manufacturing services. We have obtained multiple international authoritative certifications, including:

• ISO 9001 Quality Management System

• IATF 16949 Automotive Quality Standard

• ISO 13485 Medical Device Quality Management

• ISO 14001 Environmental Management

• ISO 45001 Occupational Health & Safety

• RoHS, CE, FCC, and CCC product compliance certifications

Testing is a key stage in PCBasic's turnkey contract manufacturing. All PCBA undergo multi-level inspection and testing before shipment, including:

• Visual inspection after SMT

• Automated Optical Inspection (AOI)

• X-Ray inspection (optional or required based on design)

• In-Circuit Testing (ICT)

• Functional Testing (FCT)

• Final quality and shipment inspection

In the current highly competitive electronic manufacturing environment, turnkey manufacturing is no longer merely for convenience but has become a more efficient and reliable manufacturing model. By concentrating design support, component procurement, production and quality control in the hands of a turnkey manufacturer, enterprises can reduce management complexity, improve execution efficiency and lower production risks in PCBA projects.

Only by truly understanding what turnkey manufacturing is and choosing the right turnkey manufacturing company can enterprises steadily promote the implementation of their products. With the cooperation of the right partners, turnkey manufacturing solutions can transform the originally complex manufacturing work into a clear, repeatable execution path from design to reliable mass production.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.