Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Control Panel Assembly: A Complete Guide

The control panel is the cornerstone of modern automation, intelligent manufacturing, and the safe and reliable operation of industry. It is not merely an electrical box; it is the core of the operation of machines and production lines. From large industrial factories to small mechanical workshops, control panels are used everywhere. To successfully produce control panels, assembly is an indispensable step. Successful control panel manufacturing is not just about simple wiring; it also requires meticulous design and professional assembly.

Today, we would like to share with you some relevant content about control panel assembly. Without further ado, let's get straight to the point!

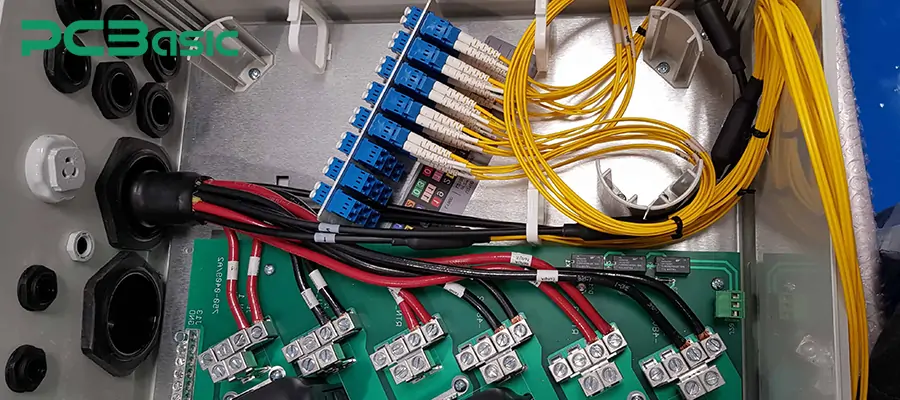

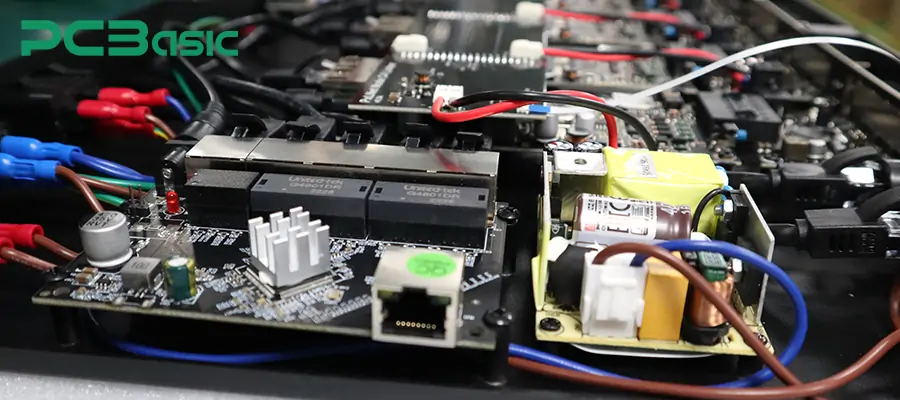

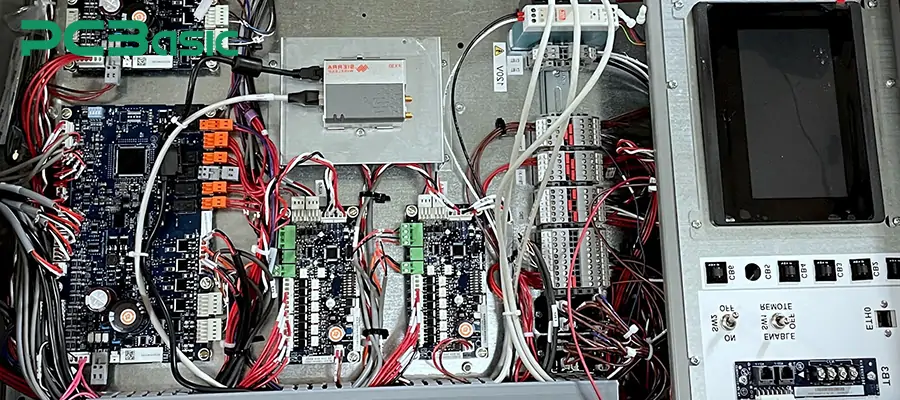

The control panel is a precisely designed enclosure. In the industrial field, it is often referred to as an "industrial control panel" or "electrical control cabinet". It serves as a container for various electrical devices such as circuit breakers, relays, PLCs, sensors, and metering equipment, as shown in the following figure.

Through professional electrical control panel assembly, various components are organized into a systematic and orderly system. Operators use it to efficiently monitor, control and troubleshoot complex industrial processes.

In industry, the significance of control panels is not merely about accommodating electrical components. A reliable electrical panel assembly is the foundation for dependable power distribution, process control, and system monitoring. Control panel assembly is an indispensable part of industrial systems. The quality of the assembly directly determines the performance, safety, and reliability of the control panel.

Of course, assembly is based on design and manufacturing. High-quality control panel assembly cannot be achieved without good control panel layout design and high-quality control panel manufacturing.

Next, we will use several examples to better illustrate the significance of control panel assembly in industry.

On the automotive production line, high-precision robots and automated assembly equipment rely on professionally assembled control panels to coordinate motors, sensors and PLC systems.

In wind power generation and photovoltaic power stations, an industrial control panel assembly is used to centrally manage the power generation equipment, inverters and monitoring systems.

In pharmaceutical factories and chemical production workshops, sophisticated process control systems rely on standardized electrical panel assemblies to ensure the accurate control of parameters such as temperature, pressure and flow rate.

In large machinery and industrial equipment, the electrical panels manufacturing and the high-level control panel installation are necessary to ensure the stable operation of the equipment over the long term.

The assembly of the control panel not only enhances the performance and reliability of the control panel itself, but also has a direct impact on the efficiency, safety and economic benefits of the industrial system.

Next, we will directly explain the process of assembling the control panel. The control panel assembly process is a multi-stage procedure. As we have mentioned earlier, assembly cannot be achieved without design and manufacturing. Therefore, here we will start by introducing the design layout of the control panel.

The first and most crucial step in the control panel assembly process is the control panel layout design. Why is it so crucial? Because at this stage, we need to determine the placement of all electrical components within the chassis. A reasonable plan is essential to ensure that all components function properly and are safe and reliable after assembly. This step forms the basis for the subsequent control panel manufacturing and assembly.

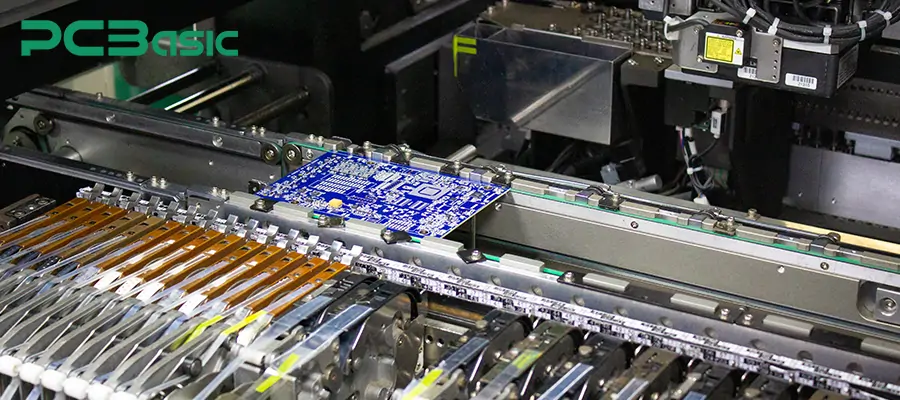

At this stage, engineers need to prepare detailed electrical schematic diagrams, wiring diagrams, and a complete bill of materials. The bill of materials should include all the components required for the project, such as DIN rails, wiring troughs, fuses, relays, and PLCs, etc. The layout of the control panel (control panel layout) should also be efficient. The physical layout design needs to be carefully considered to ensure reasonable component spacing, convenient maintenance operations, and compliance with safety standards. The design also needs to ensure compliance with international standards, such as UL, IEC, CE or NFPA 70/79. Once the planning and design are completed, production can begin. The best approach is to collaborate with a leading and reliable control panel manufacturer. Then, it's time for component assembly.

This stage involves installing the necessary components according to the planned layout diagram into the control panel chassis. Most control components, such as contactors, relays, fuses and automation controllers, are usually installed on sub-panels, and then the sub-panels are fixed to the main panel chassis. Note:

Standard-sized DIN rails are used for installing control components, which can simplify the installation process and ensure manufacturing consistency.

By neatly arranging and guiding the cables between devices in the wiring troughs, confusion can be reduced and maintenance efficiency can be improved.

It is necessary to follow the spacing requirements of the manufacturer to ensure adequate airflow around the components and prevent overheating, etc.

Correct assembly is the key to achieving reliable and efficient assembly of industrial control panels.

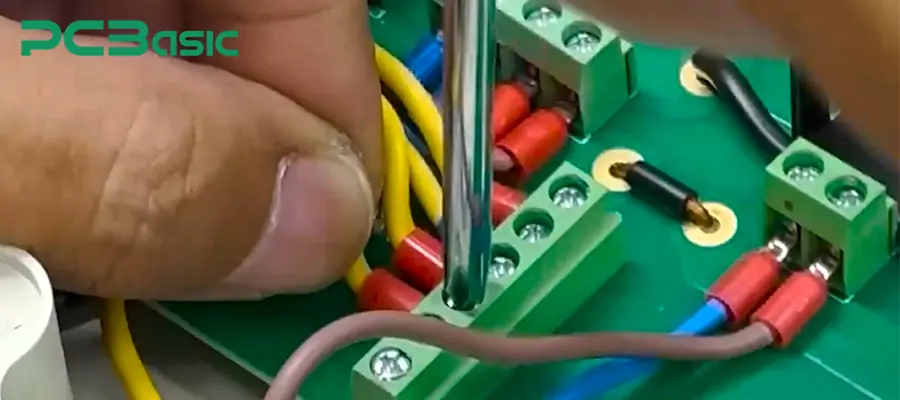

After all the components are firmly installed, it's time for wiring assembly (control panel wiring assembly). The wiring assembly of the control panel also needs to follow the electrical schematic to wire each component. This ensures that the wiring assembly is completed safely and efficiently.

Usually, the design schematic will clearly indicate the connection terminals of each component and the corresponding wire specifications. Paying attention to the color of the wires is also very important. Because it indicates the voltage or signal type that the wire can carry. In addition, each wire should have a unique identifier. This not only ensures correct wiring but also facilitates future troubleshooting and maintenance.

After the wiring is completed, the next step is to conduct testing and quality assurance. This stage is a crucial process for ensuring that the wiring of the electrical control panel assembly is correct, functioning properly, and complies with all safety and quality standards. Proper testing is essential to prevent failures, ensure the safety of operators, and guarantee the long-term reliability of the control panel. Usually, connectivity and wiring verification, as well as power-on and functional tests, are required.

The first step of the test is to conduct a point-to-point continuity check based on the electrical schematic design, also known as the "beep test". This check verifies whether each wire connection is correct and confirms the integrity of the wiring before powering on the equipment. After confirming the connectivity, the power can be safely connected to verify that all components are functioning properly. It is important to follow standard safety operating procedures and wear appropriate personal protective equipment at this stage.

The final checklist should confirm that the panel meets all design and specification requirements and complies with international safety and quality standards.

The final stage is the installation and commissioning of the control panel (control panel installation and commissioning). We need to ensure that it operates safely and efficiently, and complies with all applicable standards. Correct installation and commissioning are essential.

Before installation, we must first ensure that the control panel meets the local and national electrical regulations and standards. Then, we proceed with the physical installation. Securely install the manufactured and tested panel at the designated location in the factory. Next, technicians connect all on-site equipment, including sensors, actuators, and power supplies, according to the control panel layout design.

After installation, the panel is then commissioned. Verify the operation of all integrated devices, test the control sequence, and adjust parameters to ensure the smooth operation of the system.

Choosing to collaborate with a reliable control panel assembler or an experienced electrical panel manufacturer is a wise choice in the context of the growing demand for modern industrial automation. This enterprise usually focuses more on control panel manufacturing and provides a one-stop solution covering the entire control panel assembly process. Of course, collaborating with an electronic manufacturing assembler for control panel assembly is also a great option. Generally, their comprehensive services include:

The entire process of electrical control panel manufacturing

Professional control panel wiring assembly

Compliance with international standards and safety regulations

Reliable post-installation support and maintenance

Control panel assembly is the core link of the entire control panel manufacturing process. In fact, efficient and reliable assembly cannot be achieved without good design and manufacturing. Every stage of control panel fabrication plays a crucial role in ensuring performance, operational safety, and compliance with industry standards.

You can choose to work with an experienced control panel assembler or a reputable electrical panel manufacturer to achieve high-quality industrial control panel production. Or you can collaborate with a professional and reliable assembler. Both options are excellent choices.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

About PCBasic

About PCBasic

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.