Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Rogers PCB Material: A Complete Guide

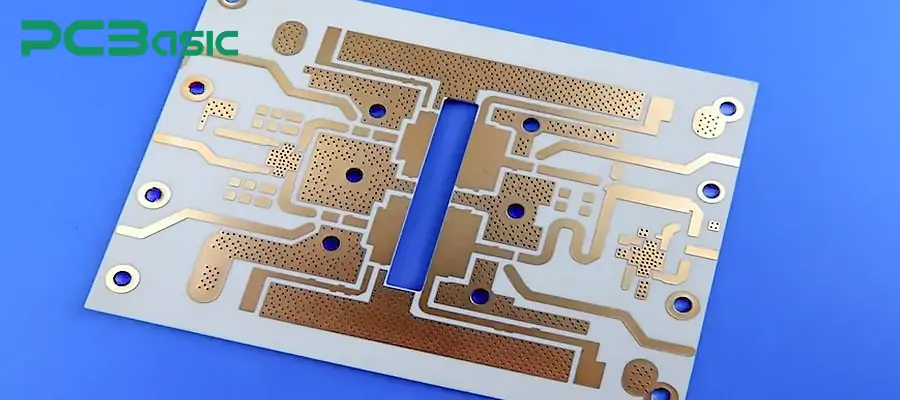

Nowadays, high-frequency PCB materials are increasingly being used in high-end electronic products. The demand for this material is huge. Today, we will introduce a type of high-frequency PCB material - that is Rogers PCB material. This material is different from the traditional FR-4 copper foil laminate. We will compare the differences between these two materials in more detail in the article. Without further ado, let's get straight to the point!

Before introducing the definition of Rogers PCB materials, we need to first understand what "Rogers" is. Rogers originated from a company called Rogers Corporation. It is an enterprise specializing in the production of high-frequency circuit board substrates. Due to the significant influence of this company's produced boards in the industry, people use "Rogers" as a general term for high-frequency boards or high-frequency materials. Over time, this name has become the synonym for high-frequency boards.

The so-called Rogers PCB materials are actually the copper-clad boards produced by Rogers Corporation. This material is much superior to the traditional FR-4 material in terms of electrical performance and mechanical properties. Next, we will introduce the core characteristics of this material.

1. Low dielectric constant (Dk)

One of the characteristics of Rogers PCB material is its adjustable dielectric constant. This constant ranges from 2.2 to 10. This flexibility allows engineers to precisely design impedance control at various RF and microwave frequencies. For example, Rogers 4003 and Rogers 4350 are widely used because they can provide stable Dk values while maintaining cost-effectiveness.

2. Low dielectric loss factor (Df)

The dielectric loss factor of Rogers copper clad laminate is extremely low, which is why it is well-known. A low dielectric loss factor means that signal loss can be minimized. This is crucial for maintaining signal integrity in high-frequency PCB material design.

3. Thermal stability

The thermal stability performance of Rogers PCB material is excellent. It can maintain consistent electrical performance and dielectric constant (Dk) in an environment ranging from -55°C to +280°C. This means that it can maintain the high reliability of the circuit even when operating in extremely cold high-altitude conditions or in hot environments.

In addition, the glass transition temperature (Tg) and decomposition temperature (Td) of Rogers PCB material are significantly higher than those of common FR-4 (if you have the data sheet of Rogers PCB material, you can take a look at it.) This indicates that Rogers material can avoid the medium damage caused by overheating in high-power RF circuits and high-density interconnection designs.

4. Reliable mechanical properties

The mechanical properties of Rogers material are also equally outstanding. Its thermal expansion coefficient (CTE) is close to that of copper. And with the consistency of CTE, Rogers PCB material can significantly reduce the risks of delamination, warping or solder joint cracking between the substrate and copper due to a mismatch in expansion.

This characteristic is very important for enhancing the long-term reliability of the circuit board. At the same time, Rogers PCB material has excellent dimensional stability. It can always maintain consistent thickness and structure during drilling, etching and lamination processes.

By comparing Rogers PCB material with the most common substrate in the industry - FR4, the outstanding characteristics of Rogers material can be more intuitively demonstrated. As shown in the table below,

|

Property / Parameter |

Rogers PCB Material |

FR-4 PCB Material |

|

Dielectric Constant (Dk) |

Adjustable 2.2 – 10 (wide range, precise impedance control). Different series like Rogers 4003 (Dk≈3.55) and Rogers 4350 (Dk≈3.66) support various RF and microwave designs. |

Fixed around 4.2 – 4.8, very limited options. |

|

Dissipation Factor (Df) |

Ultra-low (typically 0.001 – 0.004 at 10 GHz). Ensures minimal signal loss, ideal for high-frequency PCB materials. |

Higher (~0.02 at 10 GHz). Causes significant signal loss at high speed/frequency. |

|

Thermal Stability (Tg / Td) |

High Tg > 280 °C, Td up to 390–425 °C depending on series. Stable dielectric behavior from –55 °C to +280 °C, suitable for aerospace, radar, and 5G. |

Moderate Tg (~140–170 °C). Electrical properties degrade at high power/temperature. |

|

CTE (Coefficient of Thermal Expansion) |

Closely matches copper (~10–14 ppm/°C in-plane). Reduces delamination and stress in multilayer PCB assemblies. |

Mismatch with copper. Higher Z-axis CTE increases risk of warping, cracking, and delamination. |

|

Thermal Conductivity |

~0.69–0.71 W/m·K (better heat spreading than FR-4). |

~0.3–0.4 W/m·K (poorer thermal management). |

|

Moisture Absorption |

Very low (~0.02–0.06%). Stable RF performance in humid environments. |

Higher (~0.10%+). Properties shift under moisture, detuning RF circuits. |

|

Dimensional Stability |

Excellent. Maintains thickness/structure during drilling, etching, and lamination. |

Lower stability. Susceptible to process stress, harder to keep precision for high-frequency designs. |

|

Manufacturability |

RO4000 series (e.g., 4003, 4350) compatible with FR-4 processes → cost-effective. High-end series (RT/duroid, TMM) require specialized processing but give unmatched performance. |

Fully compatible with standard PCB processes, but only suitable for low- to mid-frequency consumer/industrial electronics. |

Rogers PCB materials are not a single product, but rather a broad range of Rogers copper-clad laminates. The multi-series of Rogers PCB materials provided by Rogers Corporation ensure that designers can select the most suitable one according to their requirements. Next, we will mainly introduce several of the most commonly used series:

RO3000 Series

The RO3000 series is specifically developed for high-frequency microwave circuits and antennas. This series features a stable dielectric constant (Dk ≈ 3.0 – 6.15), extremely low dielectric loss factor (Df ~ 0.0013 – 0.003), and outstanding thermal stability. Even at extremely high frequencies, this material can maintain consistent RF performance.

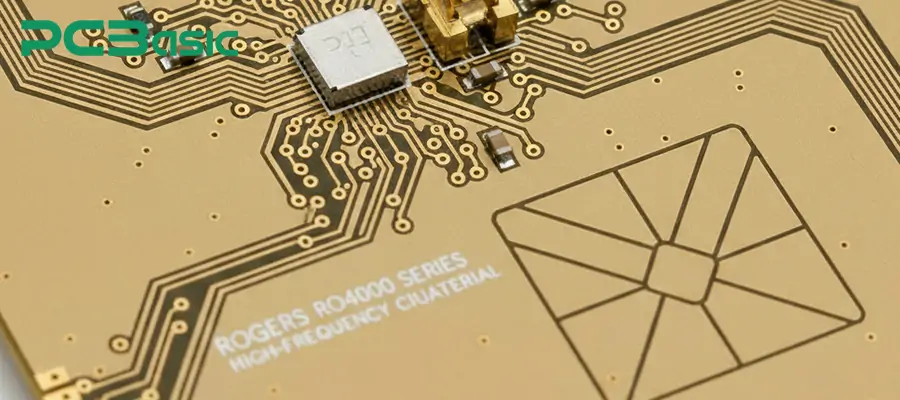

RO4000 Series

The RO4000 series is one of the most popular Rogers copper-clad laminate series, and it is the preferred solution for many Rogers PCB assemblies. It offers both high cost-effectiveness and FR-4 process compatibility. Among this series, the two most typical types are Rogers 4003 and Rogers 4350.

Rogers 4003 (RO4003C): Dk ~3.55, Df ~0.0027 (at 10 GHz), maintaining stable performance over a wide frequency range.

Rogers 4350 (RO4350B): Dk ~3.66, Df ~0.0031, a series specifically optimized for multilayer PCB assembly.

RT/duroid series

The RT/duroid series represents Rogers' high-end products and is specifically designed for the most demanding applications. This series is based on PTFE composite material and features an extremely low Df value (<0.001), excellent dimensional stability, and extremely low water absorption rate (~0.02%). The products made from this series possess world-class RF performance and are highly suitable for extremely high frequencies and aerospace environments.

TMM Series

The full name of TMM is thermoset microwave materials. This series bridges the gap between performance and processing convenience. Its Dk range is generally from 3.27 to 13.0, with a low Df and high mechanical strength. If its ceramic properties are combined with the thermosetting process, it not only provides high-end RF performance but is also easier to process than PTFE-based copper-clad laminates.

In addition to the four series mentioned above, Rogers PCB materials also have several other series. The following table summarizes the main Rogers PCB material series, including their dielectric constant (Dk), dissipation factor (Df), and key performance characteristics.

|

Rogers Series / Product |

Dielectric Constant (Dk) |

Dissipation Factor (Df) |

Key Features |

|

RO3000 Series |

3.0 – 6.15 |

0.0013 – 0.003 |

High stability, low loss, wide Dk options |

|

RO4000 Series (RO4003C, RO4350B) |

3.38 – 3.66 |

0.0027 – 0.0031 |

Cost-effective, FR-4 compatible processes |

|

RT/duroid Series |

2.2 – 10.2 |

<0.001 – 0.002 |

PTFE-based, extremely low loss, very low moisture absorption |

|

TMM Series |

3.27 – 13.0 |

0.002 – 0.0025 |

Thermoset ceramic-filled, easier processing, strong mechanical strength |

|

RO2000 Series |

~2.98 |

~0.0012 |

Very low loss, excellent thermal stability |

|

CLTE-XT Series |

2.94 – 3.0 |

0.001 – 0.002 |

Ultra-low CTE, copper-matched expansion |

|

AD/AD Series |

2.5 – 10.2 |

0.001 – 0.003 |

Low-loss PTFE/glass laminates, excellent consistency |

|

RO4700 Series |

~3.5 |

0.0026 |

Enhanced thermal performance, halogen-free |

|

CLTE-MW Series |

~2.94 |

0.0015 |

Microwave-optimized, stable over wide temperature ranges |

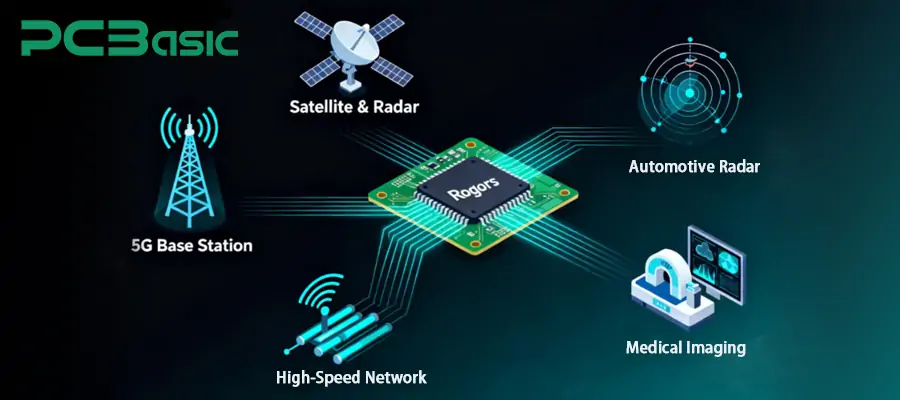

Thanks to its unique Rogers PCB material properties, Rogers copper-clad laminates have become an indispensable core in many advanced electronic systems.

In the field of 5G base station antennas and RF circuits, Rogers PCB materials are commonly used in antenna arrays, RF front-end modules and filtering circuits. The 5G network needs to achieve ultra-high-speed data transmission and low latency at high frequencies, and the control of signal loss is extremely strict. The dielectric loss factor of Rogers materials is low, which can ensure that signal attenuation is minimized. Moreover, engineers can design compact and efficient antenna structures based on precise dielectric constants.

In the fields of satellite communication and aerospace radar, Rogers PCB materials also play a very important role. Rogers copper-clad laminates (such as the RT/duroid series) have extremely low hygroscopicity and excellent thermal stability, which can ensure long-term stable operation in orbital or high-altitude environments. For example, using Rogers PCB materials in satellite and radar equipment enables reliable long-distance communication and high-precision signal detection at gigahertz and millimeter wave frequencies.

Modern vehicles utilize 24 GHz and 77 GHz radar modules in advanced driver assistance systems (ADAS) to achieve adaptive cruise control, collision warning, and autonomous driving functions. The high-frequency requirements of automotive radars necessitate substrates with low signal loss and high dimensional stability. By using Rogers PCB materials, automobile manufacturers can ensure that radar sensors remain accurate and reliable in high-temperature, vibration, and moisture environments.

Rogers materials are also widely used in PCB assembly for high-speed routers and network equipment. They can maintain signal integrity at multi-gigabit rates, significantly reducing data loss and latency.

Rogers' PCB materials also possess stability and low loss characteristics, which can ensure the accuracy of imaging. Advanced medical equipment such as magnetic resonance imaging (MRI), CT scanners, and high-frequency ultrasound systems all utilize Rogers PCBs. It can be said that Rogers products can provide unparalleled performance in environments that require signal integrity, thermal stability, and long-term reliability.

It is divided into five steps:

1. The first step in choosing Rogers PCB is to clearly determine the operating frequency of the circuit. For example, for microwave or millimeter-wave applications (above 10GHz), it is recommended to use materials with low dielectric loss (Df), such as RT/duroid® 5880 or RO3003.

2. When evaluating Rogers material, both electrical performance and manufacturing cost should be taken into consideration. For example, for Rogers PCB manufacturing projects that are cost-sensitive and still require high-frequency performance, the RO4000 series would be the best choice.

3. Before finalizing the Rogers laminate, we need to ensure that it is compatible with our PCB manufacturing process (such as drilling, lamination temperature, electroplating, etc.). We can choose to collaborate with experienced Rogers manufacturing partners, who can ensure precise lamination control and stable board quality.

4. When selecting materials, it is important to choose Rogers materials with appropriate thermal conductivity, coefficient of thermal expansion (CTE), and glass transition temperature (Tg). This can prevent warping and maintain stable performance.

5. Before finalizing the selection, it is essential to review the official Rogers PCB material datasheet. Compare parameters such as Dk, Df, CTE, thermal conductivity, and moisture absorption rate, and match them to the project requirements.

By following these steps, we can select the appropriate Rogers PCB material.

Rogers materials have extremely low dielectric loss, a stable Dk value, and high thermal stability. This material is an indispensable core component in our modern high-frequency circuit board manufacturing.

About PCBasic

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.