Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > PCBA Prototyping Guide – How to Choose a Reliable PCBA Prototyping Manufacturer?

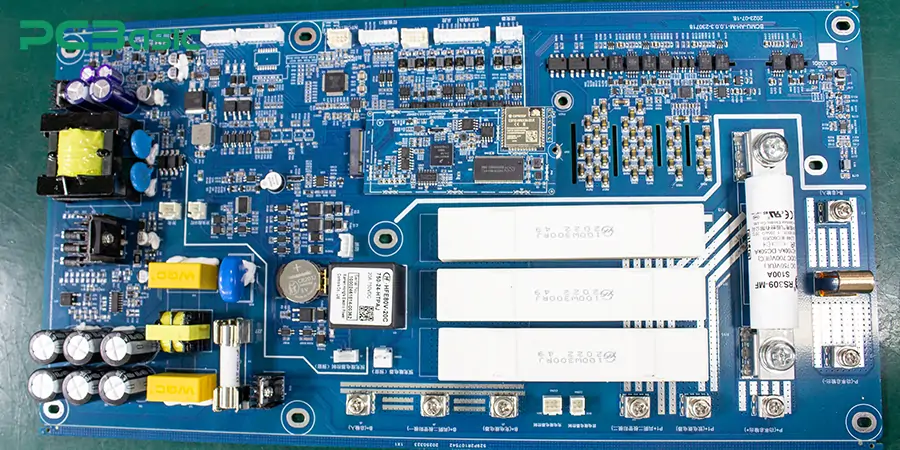

In today's fast-paced electronics manufacturing industry, turning an idea into a mass-produced product not only relies on excellent design, but also on an efficient, precise and reliable PCBA prototyping process. PCB assembly prototyping, as a crucial step connecting product concepts to physical verification, is becoming increasingly important. However, in the face of numerous PCBA prototyping manufacturers, how to find a truly reliable partner is a challenge faced by many R&D teams.

Next, this article will explore this issue. We will systematically introduce the core value and standard process of PCBA prototyping, and provide practical selection suggestions. At the same time, we will share with you a leading Chinese PCBA prototyping supplier that can provide a solid guarantee for your product development.

PCBA prototyping refers to the process of assembling electronic components onto a custom PCB, with the aim of creating functional prototypes for testing, verification and optimization before mass production. This process can be used to verify the design of custom PCBs, test electrical performance, evaluate circuit performance, assembly feasibility and manufacturing adaptability.

In the complete electronic product development process, PCBA prototyping usually includes PCB prototyping manufacturing, component procurement, PCB assembly prototype, testing and debugging. PCBA prototyping serves as a crucial bridge between circuit design and mass production, and it is an important step to ensure that each PCB assembly sample meets the expected functional and quality standards before the official mass production.

Efficient PCBA prototyping is of decisive significance for ensuring the successful mass production of products. Through the testing and verification of functional prototypes, the development team can identify and solve potential problems before mass production, thereby saving costs, shortening cycles, and enhancing product stability.

The following are the key advantages of the PCB assembly prototype:

1. Design Validation: Before mass production, testing through custom PCB and the actual assembly of components is the first step to ensure the reliability of the product.

2. Early detection of problems: Through PCBA prototyping, issues such as incorrect circuit layout, incomplete BOM, and mismatched component pad designs can be identified in a timely manner. This can eliminate potential risks for the subsequent PCB assembly manufacturing.

3. Accelerated testing and iteration: Sample making supports rapid testing and product optimization, which significantly shortens the R&D cycle.

4. PCB assembly prototype can serve as an intuitive display carrier. This can enhance communication efficiency and product recognition when dealing with customers, investors or internal reviewers.

5. During the sample-making stage, manufacturability design (DFM) analysis and pre-layout for functional testing can be conducted. This can ensure that the product has a higher yield and consistency when entering the formal PCB manufacturing and assembly process.

To sum up, PCBA prototype is crucial for engineers and product development teams who need to optimize product performance before mass production.

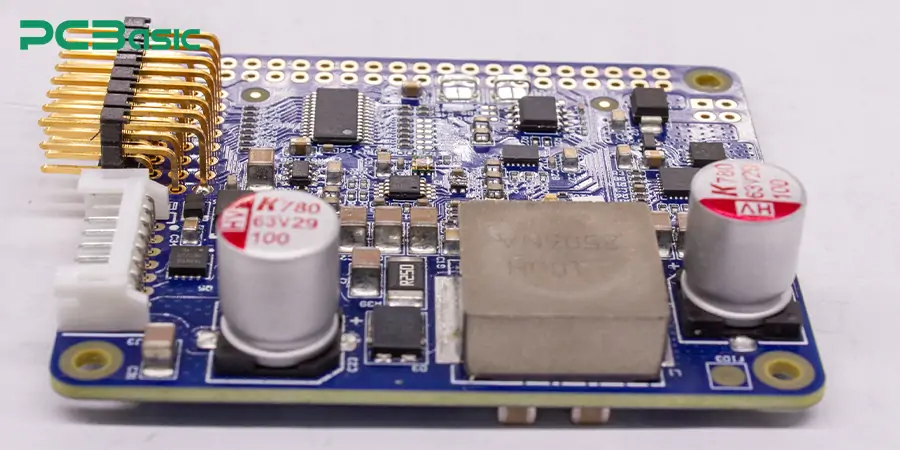

Whether it is a start-up enterprise or a mature R&D team, cooperating with PCBA prototyping factories that have complete production lines can significantly improve efficiency and delivery quality. The following is a typical PCB assembly prototype process:

1. Submitting complete design materials is the first step in PCBA prototyping. The complete design materials should include Gerber files (used for PCB Prototyping), BOM (Bill of Materials), and Centroid files, etc. These are all the necessary documents directly used in the SMT/THT assembly process.

2. After determining the required documents, PCBA prototyping manufacturers will carry out high-precision Printed Circuit Board Fabrication based on Gerber files.

3. Carry out the preparatory work before assembly. Confirm whether the components are provided by the customer or the "Turnkey" service (that is, uniformly purchased by the PCBA prototyping supplier). No matter which method is adopted, it is necessary to ensure that the devices are original and have a clear delivery date.

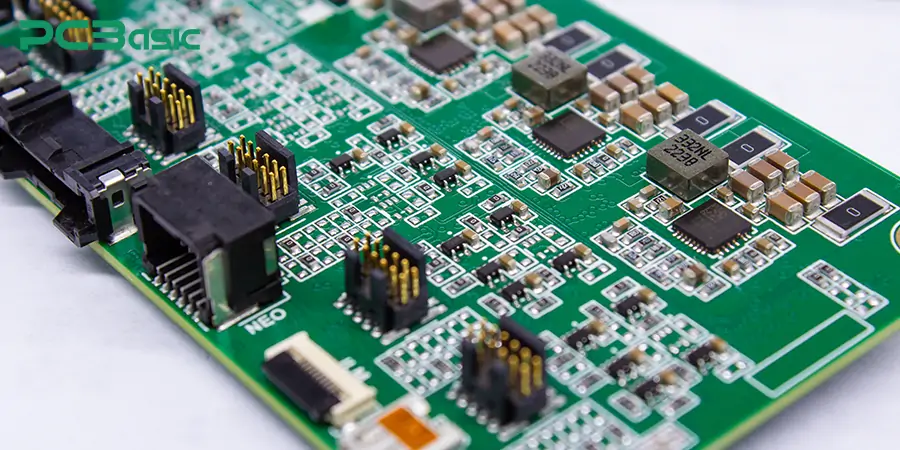

4. Depending on the type of component package, assembly is carried out using surface mount technology (SMT) or through-hole mounting technology (THT).

5. After the assembly is completed, conduct appearance inspection, AOI (Automatic Optical Inspection), X-ray solder joint inspection, and flying probe testing. Ensure the assembly quality and reliable welding.

6. After the sample is completed, it is delivered to the customer for functional verification. If there are any design or performance issues, a version iteration can be carried out quickly to proceed to the next round of sample making until the mass production standards are met.

Cooperating with experienced PCB assembly services that have internal process capabilities can significantly improve efficiency and quality.

When looking for a suitable PCBA prototyping manufacturer, many teams often only focus on the price or delivery time, while neglecting the service capability and quality guarantee. The result may lead to sample failure, waste of time, and even affect the entire product development plan. Understanding the common problems encountered when choosing a PCBA prototyping supplier is helpful for better selecting a reliable manufacturer. Common problems are:

1. Unstable quality or unclear production capacity. Many wholesale PCBA prototyping manufacturers do not have their own production lines, and the quality is affected by external factories, resulting in significant differences among different batches of products.

2. Lack of emergency sample response capability. If suppliers fail to respond promptly, it will seriously slow down the progress of the enterprise's development.

3. No DFM advice or technical support is provided. Manufacturers that only have processing capabilities but no engineering support cannot provide effective design for Manufacturability (DFM) feedback. This will lead to an increase in the failure rate of sample making and a rise in rework costs.

4. The quotation is not clear and there are hidden charges. Some suppliers offer initial quotations that do not include taxes, tests, packaging or freight charges. They add additional fees at the time of settlement, which undermines the trust in cooperation.

5. There is no standard document format for management and information feedback is lagging behind. Such manufacturers are highly prone to causing incorrect component substitution and misalignment of surface mount files, which seriously affects the quality of PCBA prototyping.

Of course, in addition to understanding the problem, one also needs to master the skills. When choosing a reliable PCBA prototyping manufacturer, the following points can be given particular attention:

1. Whether one-stop service is provided: covering PCB manufacturing, assembly and testing

2. Whether it has turnkey capabilities: supporting complete BOM procurement and file format parsing

3. How about the detection capabilities: Does it have AOI, X-ray, flying probe, and functional testing

4. Whether the delivery cycle is fast: Can the sample be completed within 2 to 5 days

5. Whether it has the ability to expand: Whether there is continuity from sample to mass production

When choosing a reliable PCBA Prototyping Manufacturer, a partner with rapid response, high-quality delivery and full-process support is the key to the successful implementation of the product. As a leading Chinese PCBA prototyping supplier, PCBasic can provide you with:

Fast delivery: The sample delivery time is 2 to 5 days

Integrated services: Complete the entire process of PCB manufacturing and assembly internally

Intelligent quotation system: Upload the BOM online to obtain the price immediately

Comprehensive testing support: complete AOI, flying probe, functional testing, etc.

Rich global customer experience: Widely applied in industrial PCBA prototyping scenarios

Whether you need 5 Prototype PCBs for functional verification or 50 for small-scale trial production, PCBasic can provide a flexible, fast and mass-production-compatible service model.

|

Item |

PCBA Prototyping |

Mass Production |

|

Quantity |

Small volume (1–100 pcs) |

High volume (thousands to hundreds of thousands) |

|

Objective |

Design validation, functional testing, DFM |

Commercial delivery, cost control, stable output |

|

Process Flexibility |

High – allows modifications and iterations |

Low – changes are costly after finalization |

|

Cost Structure |

Higher per unit, but total cost manageable |

Lower per unit, optimized for scale |

|

Testing Scope |

Emphasis on functional testing, flying probe |

Standardized testing focused on production flow |

|

Turnaround Time |

Expedited delivery (e.g., 2–5 days) |

Requires planning and longer setup lead time |

|

Service Orientation |

Customized support for development teams |

Standardized workflow for efficiency and volume |

PCBA Prototyping is not only a link in the circuit board manufacturing process, but also a crucial verification step for products to move from design to market. High-quality PCB assembly prototypes can help enterprises identify design issues early on, optimize production processes, and accelerate the time to market for products.

However, to achieve an efficient and reliable prototyping process, it is crucial to choose an experienced PCBA prototyping manufacturer. As a leading China PCBA prototyping supplier, PCBasic is committed to providing efficient and professional PCB assembly services for global hardware development teams. Whether it is functional verification, prototype display or industrial PCBA prototyping, PCBasic can provide you with stable support and rapid delivery. Welcome to consult!

About PCBasic

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.