Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > > PWB: Definition, Manufacturing, and PWB vs PCB

In the electronics manufacturing industry, abbreviations of terms are often easily confused, especially between PCB and PWB. Although these two terms are often used interchangeably, they refer to different stages and contents in the manufacturing process. So, what exactly does PWB refer to? What's the difference between it and a PCB?

This article will systematically introduce the meaning of PWB and explain the key steps of PWB manufacturing. Meanwhile, we will explore its application value in contemporary electronic products and focus on analyzing the common term distinction problem in the industry – PCB vs PCB. In addition, several commonly used terms related to PCB, including PWA, PCBA, CCA, and PCA, will be explained to help readers fully understand the professional terminology system in the electronic assembly process.

PWB is the abbreviation of Printed Wiring Board, referring to a kind of foundational structure board used for electrical connections, whose conductive paths are formed by etching copper foil. These paths are used to connect electronic components. But at the PWB stage, these components have not yet been mounted. Therefore, PWB usually refers to a bare board without assembled electronic components, which is different from functional finished boards.

The term printed wiring board originated in the early stage of electronic manufacturing in the mid-20th century. At that time, the design and manufacture of circuit boards focused primarily on the wiring process, that is, creating conductive traces on insulating substrates. Therefore, it was more appropriate to call it a "wiring board." Component assembly was usually an independent subsequent step, handled separately from wiring fabrication.

With the development of electronics manufacturing technology, especially with the wide application of SMT (Surface Mount Technology) and THT (Through-Hole Technology), circuit boards have gradually evolved from simple wiring substrates to fully functional platforms for electronic assemblies. To reflect this change, the industry began to use a more comprehensive term - PCB (Printed Circuit Board), which can refer to either an unassembled bare board or a assembled functional board.

Nowadays, in Europe, North America and international common standards, the term PCB has become mainstream. However, in Japan and some certain specific industries, such as military, medical or photocopying and printing equipment fields, the term "PWB" is still in use, especially when describing the stages of circuit design, prototyping or board manufacturing.

About PCBasic

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

The PWB vs PCB debate is primarily about terminology and scope. Here’s how they differ:

|

Feature |

PWB (Printed Wiring Board) |

PCB (Printed Circuit Board) |

|

Components |

No components; bare board only |

May refer to either bare board or assembled board |

|

Usage |

Legacy term, still used in Japan and formal settings |

Modern, global term used in most industries |

|

Focus |

Wiring and layout |

Full circuit, including components |

|

Assembly status |

Pre-assembly |

Can be pre- or post-assembly |

Despite the differences, the terms are often used interchangeably in practice. However, in technical documentation, understanding PWB vs PCB ensures clarity, especially when distinguishing between a printed wiring board and a fully functioning circuit.

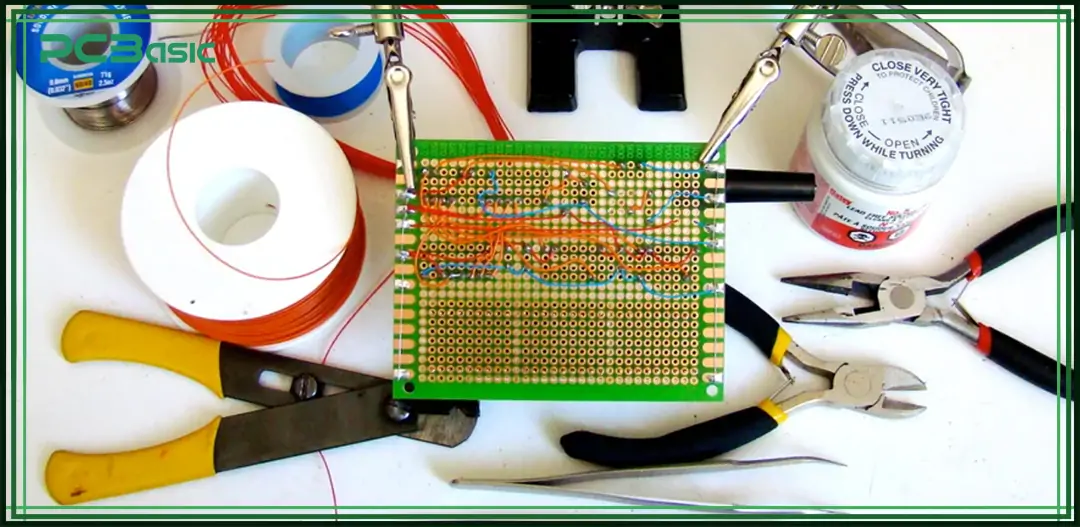

PWB manufacturing is a fundamental link in the production of electronic products. Its aim is to manufacture wiring boards with reasonable structure, reliable conduction, and easy soldering. The entire process consists of multiple precise techniques and mainly includes the following steps:

Appropriate substrates are selected, such as FR-4, polyimide or ceramic materials. These materials need to offer good insulation, heat resistance and mechanical strength.

The copper foil is laminated onto the surface of the substrate to lay the foundation for forming the circuit patterns on the printed wiring board.

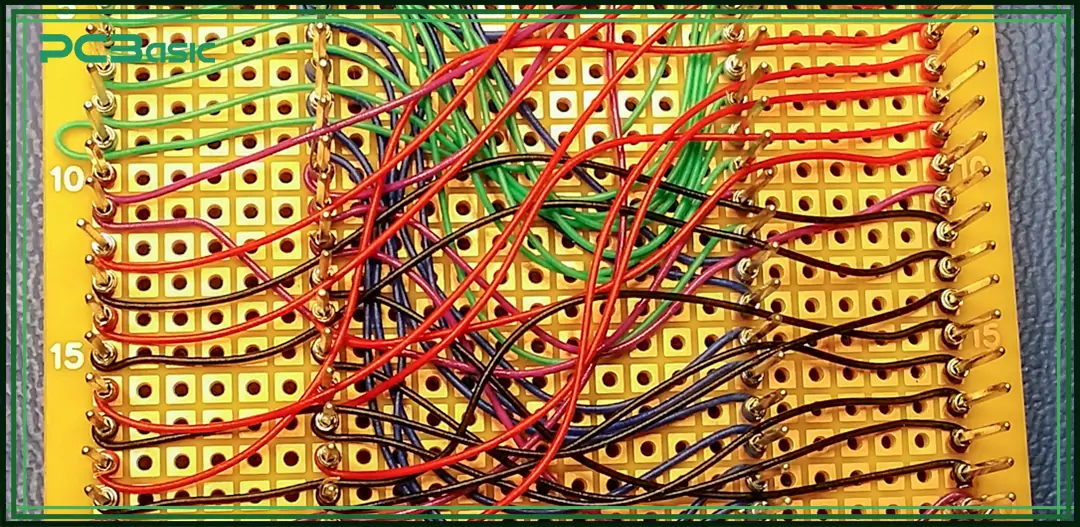

A photoresist layer is applied to the board surface, and the PWB design pattern is transferred to the copper through exposure and development.

Unprotected copper is chemically removed and the required traces are remained, completing the production of the printed wiring board circuit path.

Holes (including through holes and blind holes) are drilled at the required positions. The hole walls are then plated to enable electrical connections between multiple layers.

A solder mask is applied to prevent solder bridging during assembly, and silkscreen text is used to identify components.

Surface finishes such as HASL, ENIG, or OSP are applied to improve pad solderability and ensure long-term performance.

Each step of PWB design and manufacturing needs to strictly control the accuracy to ensure that the subsequent PWB assembly meets the requirements of product quality and reliability.

To understand the differences between PWB vs PCB more comprehensively, it is also necessary to know several closely related terms, which are used to describe the state of the circuit board at different manufacturing stages or in different application scenarios. Although they may seem similar, they have their own clear definitions and scopes of application in professional documents, industry standards and practical use.

PCBA refers to the complete circuit module formed after the soldering and assembly of all electronic components are completed on the printed circuit board. It is a finished board with electrical functions, which can usually be directly used for overall machine testing or system integration.

Circuit Card Assembly (CCA) is a term commonly used in high-reliability industries such as military, aerospace, and defense electronics. It usually refers to the PCB assembly that has completed the component assembly and can be used in the task system, that is, the modular circuit card that already has functions but still needs further integration.

In most technical documents, CCA and PCBA are basically the same thing, but the choice of terms is more inclined to meet the expression methods of specific industry or government procurement standards.

PCA is another name for PCBA and is often used in the internal systems of European or some multinational enterprises. Its actual meaning is the same as that of PCBA, which refers to the assembled circuit board, including all necessary electronic components and soldering processes.

However, the use of the term PCA is relatively less common than PCBA, because it is easily confused with "Personal Computer Architecture" or other abbreviations in non-electronic manufacturing fields.

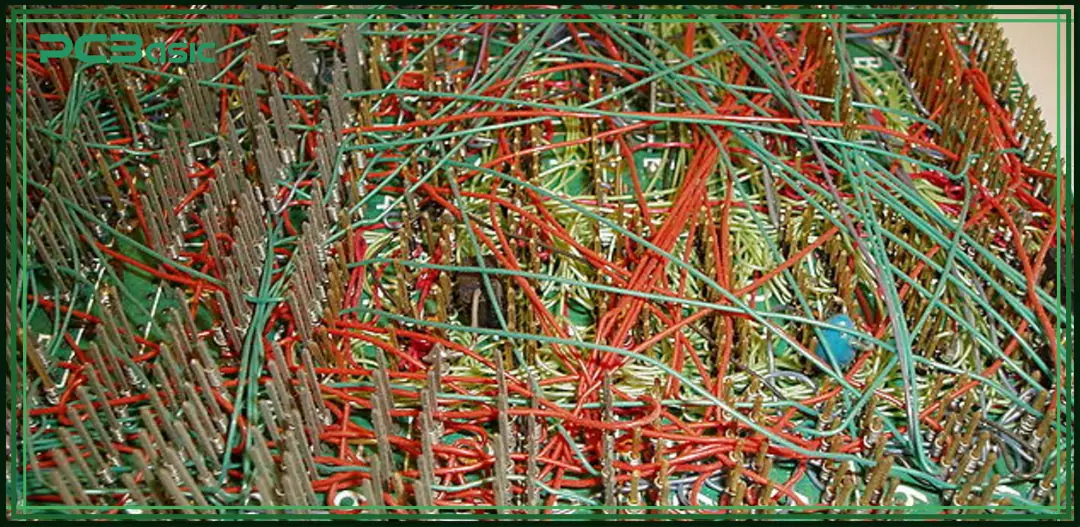

Printed Wiring Assembly (PWA) is an earlier used traditional term, specifically referring to the board on which electronic components have been soldered onto the printed wiring board, and its function is similar to that of PCBA.

Although its actual function is no different from that of PCBA, due to historical and industry practices, a large number of technical manuals, maintenance documents and BOM files still use the PWA expression method.

Understanding what a PWB is, grasping its differences from PCB, and the relationships among terms such as printed wiring assembly, PCBA, and CCA can help the purchasing, design, and manufacturing teams communicate efficiently in the development of electronic products.

• PWB: PWB stands for printed wiring board, usually referring to a bare board without assembled components.

• PWB manufacturing: PWB manufacturing focuses on wiring structures, materials and board layer processes.

• PWB vs PCB: PCB is more general, but PWB still has normativity and historical background.

• Related terms: Terms such as CCA, PCA and PWA are still widely used in specific industries.

As electronic technology continues to evolve, these terms may also change. But currently, understanding the meaning of PWB is a key foundation for building professional communication, precise delivery and engineering collaboration.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.